Professional Documents

Culture Documents

JSA FOR Concerate Placement

Uploaded by

wahyu nugroho0 ratings0% found this document useful (0 votes)

250 views1 pageJSA FOR concerate Placement

Original Title

JSA FOR concerate Placement

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentJSA FOR concerate Placement

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

250 views1 pageJSA FOR Concerate Placement

Uploaded by

wahyu nugrohoJSA FOR concerate Placement

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 1

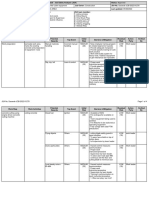

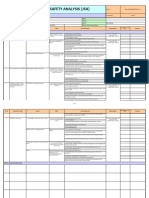

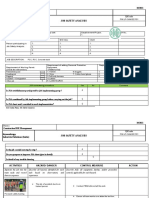

JSA FOR Concrete Work

PROJECT -- NISSAN (2ASDU)

DATE OF PREPARATION -- 28/01/2014

NAME OF THE JSA PREPARATION – R.RAMESH BABU

S.No Scope of Activity Hazard Control measures Request

by

1) Cut and Set 1) Excessive Noise 1) Hearing and eye protection will be worn while operating saws.

Lumber secure 2) Cuts/Lacerations 2) Inspect and test equipment and cords prior to use.

stacks 3) Electrical Shock 3) All guards must in place and operational, prior to use.

4) Flying Debris 4) Tools that are not in use will be unplugged from their power source.

5) Worker using sledge hammer will ensure that his work area is clear of other

workers prior to swinging the hammer

2) Rebar Installation 1) Mill scale 1) Workers cutting rebar will wear face shields, gloves, hearing protection, and

2) Sharp/Sheared Tire hard hats.

Wire ends 2) Grinder guards must be in place and fully operational prior to use.

3) Trips/Falls 3) Lathers will wear safety glasses, gloves, and hard hats.

4) Impalement Hazard 4) Construction debris will be removed on a daily basis.

5) Overhead Power 5) All rebar ends shall be capped to protect workers from Impalement and

Lines laceration hazards.

6) If possible, stack rebar in a location that is free from overhead power lines.

7) If this is not possible, rebar will be moved forward and away from the power

lines before being lifted.

3) Placing Concrete 1) Redi Mix Truck 1) Use qualified flagmen to ensure a clear path to the work zone.

Placement 2) The red mix truck will have an operational back-up alarm.

2) Struck By/Caught 3) Only the truck's operator will place the chute and run the mixer.

Between 4) Wear safety glasses when working with wet concrete.

3) Hand Injuries 5) Wear impervious gloves when working with wet concrete.

4) Eye Injuries 6) Wash off any excess concrete from your skin as soon as possible.

5) Concrete Burns

You might also like

- Bricks Messonary Work Job Hazard AnalysisDocument2 pagesBricks Messonary Work Job Hazard AnalysisMc Evans Magallanes100% (1)

- Jsa For Dismantel of StructureDocument2 pagesJsa For Dismantel of StructureBaiju SinghNo ratings yet

- JSA for Grinding WorkDocument5 pagesJSA for Grinding WorkM M PRADHANNo ratings yet

- Risk Assessment What Work Excavation Work With Help of JCB Location PM Warehouse Area Contractor Company-Aalanna Project PVT LTDDocument2 pagesRisk Assessment What Work Excavation Work With Help of JCB Location PM Warehouse Area Contractor Company-Aalanna Project PVT LTDhemant yadav0% (1)

- JSA For Bobcat OperationDocument2 pagesJSA For Bobcat Operationwahyu nugrohoNo ratings yet

- cONSTRUCTION WORK JSADocument21 pagescONSTRUCTION WORK JSAMohammed AlshehhiNo ratings yet

- Jsa PaintDocument2 pagesJsa PaintKhalid NaseemNo ratings yet

- JSA-RHI-ARZ-0-021 ASU - Rockwool Installation Rev02 - ArzewDocument8 pagesJSA-RHI-ARZ-0-021 ASU - Rockwool Installation Rev02 - ArzewHSE RHINo ratings yet

- Jsa For Operating A BobcatDocument2 pagesJsa For Operating A Bobcatsoubhagya100% (2)

- Sarawak JSA for Concrete CuttingDocument4 pagesSarawak JSA for Concrete CuttingMohammad Irfan Kiki IsmailNo ratings yet

- Maintaining Structural Beams SafelyDocument1 pageMaintaining Structural Beams SafelySajith C PauloseNo ratings yet

- JSA for Drain Line ReplacementDocument5 pagesJSA for Drain Line ReplacementMadhan KannanNo ratings yet

- 0 JsaDocument54 pages0 JsaRavi AmarlapudiNo ratings yet

- Job Safety Analysis (JSA) - Rebar Installation/steel Fixing DateDocument1 pageJob Safety Analysis (JSA) - Rebar Installation/steel Fixing DatenabeelNo ratings yet

- Jsa PCC & RCCDocument2 pagesJsa PCC & RCCNilesh koliNo ratings yet

- 02concreting & Block Bricks Work JSADocument3 pages02concreting & Block Bricks Work JSAJayendra Patel100% (1)

- JSA Earthpit Construction GeneralDocument4 pagesJSA Earthpit Construction Generalmukka88No ratings yet

- Job Safety Analysis (JSA) - CONCRETE WORKS - DateDocument2 pagesJob Safety Analysis (JSA) - CONCRETE WORKS - DatenabeelNo ratings yet

- JSA Confined Sapce EntryDocument1 pageJSA Confined Sapce EntryprasongNo ratings yet

- One Direct Method Statement: Preventative MeasuresDocument4 pagesOne Direct Method Statement: Preventative MeasuresAyu Wanda SaraswatiNo ratings yet

- Swms For Glass Partition FixingDocument6 pagesSwms For Glass Partition FixingSiddharth PNo ratings yet

- 4-Safety Violation Report Hemendra Kumar SinghDocument2 pages4-Safety Violation Report Hemendra Kumar Singhjithin shankar100% (1)

- JHA Formation Preparation or Leveling.Document2 pagesJHA Formation Preparation or Leveling.Mark Buendia100% (1)

- DOCUMENT Piping Insulation Installation and Dismantle Work JHADocument12 pagesDOCUMENT Piping Insulation Installation and Dismantle Work JHAAmirHakimRusli100% (1)

- Job Safety Analysis for Brick Work, Tile and Glass RemovalDocument4 pagesJob Safety Analysis for Brick Work, Tile and Glass RemovalSushil Kumar YadavNo ratings yet

- JHA PlumberDocument3 pagesJHA PlumberEko Susanto100% (1)

- Civil Works Construction Confined Space JSADocument5 pagesCivil Works Construction Confined Space JSAkosoko100% (1)

- JSA For Foundation Concrete RepairDocument6 pagesJSA For Foundation Concrete RepairOvais FarooqNo ratings yet

- Glass Installation - JOB SAFETY ANALYSIS (JSA) WORKSHEETDocument3 pagesGlass Installation - JOB SAFETY ANALYSIS (JSA) WORKSHEETusman rasheed100% (1)

- Jsa For Manual Backfiling Usin Hand Roller CompactorDocument5 pagesJsa For Manual Backfiling Usin Hand Roller CompactorAbdus SamadNo ratings yet

- PTW JHA Electrical Wiring Installation Work at Air Dryer RoomDocument4 pagesPTW JHA Electrical Wiring Installation Work at Air Dryer RoomPHH9834No ratings yet

- JSA For Concrete PouringDocument1 pageJSA For Concrete PouringHSE fahadNo ratings yet

- Job Hazard Analysis - Granite Surface PlateDocument2 pagesJob Hazard Analysis - Granite Surface PlateRaziellia Nor SaafriNo ratings yet

- File - 20200905 - 105458 - Jsa Wind PowerDocument10 pagesFile - 20200905 - 105458 - Jsa Wind PowerMon Trang NguyễnNo ratings yet

- Job Hazard Analysis DemolitionDocument2 pagesJob Hazard Analysis DemolitionvinothNo ratings yet

- JSA For Lifting of RebarsDocument5 pagesJSA For Lifting of RebarsNiraNo ratings yet

- Job Steps Potential Hazards Recommended Safe Job ProceduresDocument3 pagesJob Steps Potential Hazards Recommended Safe Job ProceduresDJadee Anuppur AmlaiNo ratings yet

- JSA For Installation of Out Door UnitsDocument4 pagesJSA For Installation of Out Door UnitsMohammed MinhajNo ratings yet

- JSA - Installation of U G PipingDocument11 pagesJSA - Installation of U G PipingOws Anish100% (1)

- Jsa006-Construction of Retaining WallDocument5 pagesJsa006-Construction of Retaining WallWan Muhammad Faiz100% (1)

- Job Safetyanalysis: Traffic Control & FlaggingDocument2 pagesJob Safetyanalysis: Traffic Control & Flaggingnasrul draco100% (2)

- Job Hazard Analysis: Rohan Builders (I) PVT LTDDocument4 pagesJob Hazard Analysis: Rohan Builders (I) PVT LTDsoubhagyaNo ratings yet

- Rohan Builders (i) Pvt.Ltd. - Job Safety Analysis for Compound Wall PaintingDocument2 pagesRohan Builders (i) Pvt.Ltd. - Job Safety Analysis for Compound Wall PaintingEka100% (1)

- 3.JOB SAFETY ANALYSIS Hot Work Project Title Installation of Wet Sprinkler System at Main WarehouseDocument5 pages3.JOB SAFETY ANALYSIS Hot Work Project Title Installation of Wet Sprinkler System at Main WarehouseMuhammad Umar Gondal100% (1)

- JOB SAFETY ANALYSIS FOR CARPENTRY AND WOOD WORKDocument3 pagesJOB SAFETY ANALYSIS FOR CARPENTRY AND WOOD WORKba ratnaparkheNo ratings yet

- Risk Assessment for Shuttering/FormworkDocument1 pageRisk Assessment for Shuttering/FormworkHSE fahadNo ratings yet

- Job Safety Analysis: Page 1 of 4Document4 pagesJob Safety Analysis: Page 1 of 4RakeshkasarlaNo ratings yet

- JSA Ladders Working at Heights 001Document2 pagesJSA Ladders Working at Heights 001Raman SawNo ratings yet

- Job Safety Analysis WorksheetDocument7 pagesJob Safety Analysis WorksheetMohamedSaidNo ratings yet

- Removing Staircase with Crane Lifts SteelDocument3 pagesRemoving Staircase with Crane Lifts Steelmarvin100% (1)

- Job Hazard Analysis for SurveyingDocument1 pageJob Hazard Analysis for SurveyingYogesh Gowda100% (1)

- JSA-010 Excavation Sampling PDFDocument5 pagesJSA-010 Excavation Sampling PDFArgaYurIstiawanNo ratings yet

- Jsa For Gypsum Fixing & DismentlingDocument5 pagesJsa For Gypsum Fixing & DismentlingSushil Kumar YadavNo ratings yet

- Jsa Civil Work (00000002)Document6 pagesJsa Civil Work (00000002)Ali AlahmaNo ratings yet

- JSA For Pipe Installation TS 3Document8 pagesJSA For Pipe Installation TS 3Shilpiengg SafetyNo ratings yet

- Plumbing Work JSA HSE ProfessionalsDocument1 pagePlumbing Work JSA HSE ProfessionalsStansilous Tatenda NyagomoNo ratings yet

- Thyssenkrupp Industrial Solutions (India) Job Safety AnalysisDocument5 pagesThyssenkrupp Industrial Solutions (India) Job Safety AnalysisNitesh KumarNo ratings yet

- Job Safety Analysis (Jsa) : Title of Activity / Work: Hot Work ActivityDocument2 pagesJob Safety Analysis (Jsa) : Title of Activity / Work: Hot Work ActivityJayendra PatelNo ratings yet

- Jsa For Painting Operation: S.N o Scope of Activity Hazard Control Measures Requested byDocument3 pagesJsa For Painting Operation: S.N o Scope of Activity Hazard Control Measures Requested bywahyu nugroho100% (2)

- Safe Work in Confined SpacesDocument61 pagesSafe Work in Confined SpacesTree TaweeNo ratings yet

- Responding To A Known Contact HazardDocument3 pagesResponding To A Known Contact Hazardwahyu nugrohoNo ratings yet

- Operating A Drill PressDocument2 pagesOperating A Drill Presswahyu nugrohoNo ratings yet

- HM - Policy and Procedure For BookingDocument4 pagesHM - Policy and Procedure For Bookingwahyu nugrohoNo ratings yet

- Blue Jasmine Event Package 2021Document20 pagesBlue Jasmine Event Package 2021wahyu nugrohoNo ratings yet

- Response To A Release of An Inhalation HazardDocument3 pagesResponse To A Release of An Inhalation Hazardwahyu nugrohoNo ratings yet

- Responding To Release of Flammable MaterialDocument5 pagesResponding To Release of Flammable Materialwahyu nugrohoNo ratings yet

- Operating A Pedestal GrinderDocument2 pagesOperating A Pedestal Grinderwahyu nugrohoNo ratings yet

- Operating and Maintaining Mat CutterDocument1 pageOperating and Maintaining Mat Cutterwahyu nugrohoNo ratings yet

- Operating An Air BlowerDocument2 pagesOperating An Air Blowerwahyu nugrohoNo ratings yet

- Operating Motorized Vehicle (Petroleum Powered)Document1 pageOperating Motorized Vehicle (Petroleum Powered)wahyu nugrohoNo ratings yet

- Operating An Electric Spot WelderDocument2 pagesOperating An Electric Spot Welderwahyu nugrohoNo ratings yet

- Rigging WindsurferDocument1 pageRigging Windsurferwahyu nugrohoNo ratings yet

- Ehs 2 HM 10Document1 pageEhs 2 HM 10Ruslan ThompsonNo ratings yet

- Vehicle Driving Safety TipsDocument4 pagesVehicle Driving Safety Tipswahyu nugrohoNo ratings yet

- Operating The Floor Cleaning MachineDocument4 pagesOperating The Floor Cleaning Machinewahyu nugrohoNo ratings yet

- Operating A Wood ChipperDocument2 pagesOperating A Wood Chipperwahyu nugrohoNo ratings yet

- Risk Assessment for Wall & Floor Tiling CompetitionDocument2 pagesRisk Assessment for Wall & Floor Tiling Competitionwahyu nugrohoNo ratings yet

- Using Polar Guillotine CuttersDocument1 pageUsing Polar Guillotine Cutterswahyu nugroho100% (1)

- Operating the generator in the emergency response truck safely in 4 stepsDocument3 pagesOperating the generator in the emergency response truck safely in 4 stepssyafiq ishakNo ratings yet

- Sheet Metal Brake SafetyDocument2 pagesSheet Metal Brake Safetywahyu nugrohoNo ratings yet

- Using LaddersDocument2 pagesUsing Ladderswahyu nugrohoNo ratings yet

- Using Hand-Operated Power ToolsDocument2 pagesUsing Hand-Operated Power Toolswahyu nugrohoNo ratings yet

- Fsarcweld 02Document2 pagesFsarcweld 02Marcelo Gil SimõesNo ratings yet

- JSA. Grinder, AngleDocument2 pagesJSA. Grinder, AngleSajid Hussain0% (1)

- Using An Oxy-Acetylene WelderDocument2 pagesUsing An Oxy-Acetylene Welderwahyu nugrohoNo ratings yet

- Using LSC CocktailDocument1 pageUsing LSC Cocktailwahyu nugrohoNo ratings yet

- Archiving FilesDocument2 pagesArchiving Fileswahyu nugrohoNo ratings yet

- High Risk Job Safety Analysis: Contractor ArgonneDocument11 pagesHigh Risk Job Safety Analysis: Contractor Argonnehalfy safitriNo ratings yet

- Arc Welding 10.1.2014 - 3Document3 pagesArc Welding 10.1.2014 - 3soubhagyaNo ratings yet

- BOOK - Prestressed Concrete Charles W. Dolan PDFDocument467 pagesBOOK - Prestressed Concrete Charles W. Dolan PDFpaula83% (6)

- Design of post-installed reinforcing bars as end anchorage or bonded anchorDocument11 pagesDesign of post-installed reinforcing bars as end anchorage or bonded anchorTugce CeranNo ratings yet

- EstimationDocument29 pagesEstimationLorraine TalattadNo ratings yet

- IRS 1997-Concrete-Bridge Code PDFDocument137 pagesIRS 1997-Concrete-Bridge Code PDFJoe Ps100% (3)

- Steel Reinforcement Area TableDocument2 pagesSteel Reinforcement Area Tableruby100% (2)

- Sample Structural Analysis For Building Permit Application - 2 Storey DwellingDocument52 pagesSample Structural Analysis For Building Permit Application - 2 Storey DwellingRichee Genesis TuasonNo ratings yet

- Precast Concrete and Its ConnectionsDocument27 pagesPrecast Concrete and Its ConnectionsAndrew Thomas100% (4)

- Seismic Strengthening of Reinforced Concrete Bridge Pier With FRP CompositesDocument8 pagesSeismic Strengthening of Reinforced Concrete Bridge Pier With FRP CompositesVipin Kumar ParasharNo ratings yet

- MSC Topic 3B - C21Document40 pagesMSC Topic 3B - C21myint phyoNo ratings yet

- Answer Key Structural Quiz 4Document5 pagesAnswer Key Structural Quiz 4Anonymous L4VPBZNo ratings yet

- Tek 5-5B Integrating Concrete Masonry Walls With Metal Building SystemsDocument4 pagesTek 5-5B Integrating Concrete Masonry Walls With Metal Building Systemsclam2014No ratings yet

- Foundation 3 DDocument4 pagesFoundation 3 Djakeer7No ratings yet

- รายการคำนวณวิศวกรรมโครงส้ราง แบบที่ 4Document21 pagesรายการคำนวณวิศวกรรมโครงส้ราง แบบที่ 4jackcoolsNo ratings yet

- Photoshop SheetsDocument7 pagesPhotoshop SheetsUmaira SarifNo ratings yet

- Kaong PS, Silang, Boq 11jun2021Document11 pagesKaong PS, Silang, Boq 11jun2021Fred PascuaNo ratings yet

- Technical Specification Volume II-Part IDocument244 pagesTechnical Specification Volume II-Part Inawajha0% (1)

- Understanding Shear WallsDocument70 pagesUnderstanding Shear WallsAboalmaaliNo ratings yet

- SAP2000 Analysis Report: License #Document35 pagesSAP2000 Analysis Report: License #bayuNo ratings yet

- Astm C 76 - 99Document11 pagesAstm C 76 - 99LNo ratings yet

- Shotcrete model validationDocument22 pagesShotcrete model validationtpgggkNo ratings yet

- Staad - Foundation Isolated Footing DesignDocument44 pagesStaad - Foundation Isolated Footing DesignboyzesNo ratings yet

- Department of Civil Engineering: Presented byDocument13 pagesDepartment of Civil Engineering: Presented byavi boseNo ratings yet

- Arcelor Mittal SlimFloor Steel Composite Floor StructureDocument36 pagesArcelor Mittal SlimFloor Steel Composite Floor Structurekatzan jammerNo ratings yet

- Basic Fence Specifications GuideDocument22 pagesBasic Fence Specifications GuidetajlandNo ratings yet

- Pds Leap Bridge Concrete LTR en LRDocument4 pagesPds Leap Bridge Concrete LTR en LRDen BagusNo ratings yet

- Field Inspection Plan for Concrete & Gabion WorksDocument4 pagesField Inspection Plan for Concrete & Gabion WorksSofda ImelaNo ratings yet

- Chapter 5: Shear in Beams: Figure 5.1: Shear in Beams: (A) Loaded Beam (B) Internal Forces at Section A-ADocument20 pagesChapter 5: Shear in Beams: Figure 5.1: Shear in Beams: (A) Loaded Beam (B) Internal Forces at Section A-Aravi1214No ratings yet

- Masonry Section 13Document40 pagesMasonry Section 13Basker BaluNo ratings yet

- (O) - 1 Bored PileDocument16 pages(O) - 1 Bored Pileautienhai100% (4)

- TR8138 G001 CostEstimation - V14Document55 pagesTR8138 G001 CostEstimation - V14Sreenivasula Reddy KandulaNo ratings yet