Professional Documents

Culture Documents

Jsa of Boiler Drum Lifting

Uploaded by

Gyanendra Narayan NayakOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Jsa of Boiler Drum Lifting

Uploaded by

Gyanendra Narayan NayakCopyright:

Available Formats

POWER MAX (I) Pvt Ltd.

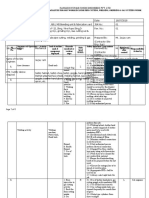

Job Safety Analysis(JSA) Job No: Client: JINDAL Date:

Department: Mechanical Job Location: Near Boiler Area Prepared By: Gyanendra Narayan Nayak

SEQUENCE OF BASIS JOB POTENTIAL HAZARD RECOMMENDED SAFE PROCEDURE

1.Only Authorized workmen Should Be Allowed While

Material Handling.

2.PPE's Shall Be Provied to All Worker. 3.

Hit Injury/Fall Of Material TBT Shall Be Conduct Before Material Handling.

Material Handling Cause To Trap Of 4.Experience Worker Shall Be Engaged While Material

Finger,Hand,Leg. Handling. 5.Make

Sure The Path Way is Clear & Free From Wet & Slick .

6.Work

Permit System To be Implimented.

1.Pre-Inspection Of Approach Soil & Position Area Of

Crane

2.Approach Area Development By Compacting

Pre-Arrangement Of

& Leveling.

Crane Operation For Crane Tilt/Toppling &

3.The Safe Bearing Capacity Of The Soil Is

Loading Of Boiler Drum Fallingdown

Considered

On Trailer Bed

4.Crane With Load at Slope Is Strictly Prohibited.

5.Trained OPerator is Deployed.

1.Trained OPerator is Deployed.

2.Only Authorized OPerator Allowed for

Operating Crane.

3.Before Engage the Crane Equipment

Fitness Should Be Checked.

4.Pre-Inspection Of Crane

& All Lifting Accessories. 5.All Lifting

Accessories & Crane Should Have a Valid TPI.

Lifting Operation By Crane Hitinury/Fall Of material

6.Rigging Permit Should Be Implimented. 7.Rigging

plan Should Be Attached With Permit. 8. Over

Load Is Strictly Restricted.

9.Tandem Lifting to be Avoided in Hydra

10.TBT Conduct for Riggers,Operators & Signalman.

11.Over Load,Over Hoist Limit Switch & Boom Limit

Switch are Provied & Checked For its Function.Proper

SLI system Should Be Provied.

1.Trained & Experianced Operator shall Deployed.

2.Trained & Experianced

Rigger/Signal man Deployed.

3.Rigging Plan Should Be

Attached. 4.Atlist 2-Signal man

Deploy at Both Side Of Crane For Good Coordination

Between Operator & Signalman.

5.Tag Line Should Be Used During

Lifting Of Boiler Drum

Tendum Lifting Occur For 6.TBT Should Be Conduct Before

Crane Tilt/Toppling &

Loading of Boiler Drum On Tendum Lifting Occure For Rigger,Signalman,Operator

Fallingdown

Trailer Bed. & Helper. 7.DURING Tendum Lifting,Check The

Position/Angel In-Between Two Crane By Competend

Rigger/ Engineer.

8.Emergency Plan Should,If any Incident

1.Trained & Experianced Operator shall Deployed.

2.Trained & Experianced

Rigger/Signal man Deployed.

3.Rigging Plan Should Be

Attached. 4.Atlist 2-Signal man

Deploy at Both Side Of Crane For Good Coordination

Between Operator & Signalman.

5.Tag Line Should Be Used During

Lifting Of Boiler Drum

Tendum Lifting Occur For 6.TBT Should Be Conduct Before

Crane Tilt/Toppling &

Loading of Boiler Drum On Tendum Lifting Occure For Rigger,Signalman,Operator

Fallingdown

Trailer Bed. & Helper. 7.DURING Tendum Lifting,Check The

Position/Angel In-Between Two Crane By Competend

Rigger/ Engineer.

8.Emergency Plan Should,If any Incident

Occure. 9.Lifting Of Boiler Drum By Two Crane Up

To 1ft From From Ground Level & Holding For 5mints

For Re-Checking of Tools & Load Distrubution to Equal

Of Two Crane.

10.Re-Check All The Lifting Tools Again During Holding

Position.

1.The Drum Must Be Tied With The Trailer By Using

Either Chain Or Any Other Proper Arrangement.

2.Load To Be Placed On The Welded Braceing/Iron

Frame Support.

Loading/Positioning Of Hapazard & Un- 3.Experianced Rigger/Signalman /Forman/Engineer

Boiler Drum On Trailer Secured/Projected Boiler Drum, Should Be Deployed.

Bed Cause To Fall Of Boiler Drum 4.Arrange TBT For Rigger/Signalman /Forman/

Operator Before Loading Of Boiler Drum.

5.Vehicle Should Be Provied With All Safety Devices As

Per Vehicle Fitness Report.

6.Fitness Stricker To Be Pasted On Vehicle.

1.Lifting Arrangement Should Be Done By Compitent

Rigger/Worker

2.Arrange Darik For Lifting Of Boiler Drum,On Top Of

Guarder.

Pre-Arrangement Of

Demolish Of Material 3.Welding Should Be Done Proper Of Darik.

Boiler Drum Lifting

4.Welding Inspection Should Be done By Quality.

Department Before Fixing On Top Of Girder.

5. Check Stability Of

Darik By Compitent Engineer.

1. Life Line (12mm wire rope) Should Be Provied On

Top Of Girder

2.Platform Should Be Provied On Top Of Girder For

Safe Movement.

3. Fixing Of Darik On Top Of Girder,Joint Welding

Should Be Done Properly.

Fixing Of Darik On Top Of

Fall Of Person/Fall of Material 4. proper Outsite Support Braceing Provied To Darik

Girder For Stability.

5.All Arrangement Shhould Be By Experianced

Engineer,Supervisor,Rigger,Forman, 6.Before

LIfting Of Boiler Drum,Proper Inspection Should Be

Done BY Compitent-Engineer,Supper visor, Quality.

Should Be Done Properly.

Fixing Of Darik On Top Of

Fall Of Person/Fall of Material 4. proper Outsite Support Braceing Provied To Darik

Girder

For Stability.

5.All Arrangement Shhould Be By Experianced

Engineer,Supervisor,Rigger,Forman, 6.Before

LIfting Of Boiler Drum,Proper Inspection Should Be

Done BY Compitent-Engineer,Supper visor, Quality.

Tilt & Falling Down

1.Only Authorized Operator Allowed To operate The

Winch Machine.

2.Before Engage The Winch Machine Or Lifting

Accessories,Valid TPI Should Be Available.

3.Pre-inspection Should Be Done All Tools & Machine.

Lifting Operation By Hit Injury/Fall of Material 4.Rigging Plan Should Be Attached with Permit Before

Winch Machine /unsafe operating condition lifting Boiler Drum.

5.Trained & Experiance Rigger/Forman/Fitter At

Various Elevation As Per Rigging Plan For Good

Coordination/ Good chaining Among Them.

6.Training/TBT Should Be Arrange For

Operator/Rigger/Signalman/Fitter Before Lifting

Activity.

1.Lifting Of Drum By Two Winch Machine up To 2''

From Ground Level & Holding for 10min.

2.Re-Inspection conduct Again All Tools & Tackle At

Holding Position.

Lifting Operation By 2- 3.After Inspection,The Drum Has To Raised

Hit/Struck against object

Winch Machine Gradually/Slowly Slowly.

4.During Lifting Operation Of Boiler Drum,Winch Rope

Should Be Checked Of Heating/Tension. 5.Winch

Operation Should Be Maintaining Running Gap For

Release Of Tension,During Lifting Of boiler drum.

Drum At Position Hit injury/fall of Load The Drum Must Be Keep Slowly At Position

1.Adiquite Platform/Approch Should Be Provied on

Top Of Giredr For Fitting Of U-Bolt.

2.Lifeline/Fallarrester Should Be provied For Height

Fitting & Tighting Of U- Fall Of Person work.

Bolt

3.Experiance/compitent Fitter Engaged For Fitting Of

U-sling Guard.

4.Emergency Plan Should Be/in Case Of any Incident.

Top Of Giredr For Fitting Of U-Bolt.

Fitting & Tighting Of U- 2.Lifeline/Fallarrester Should Be provied For Height

Fall Of Person work.

Bolt

3.Experiance/compitent Fitter Engaged For Fitting Of

U-sling Guard.

4.Emergency Plan Should Be/in Case Of any Incident.

HOD OF JUWM MECHANICAL CONTRACTER SITE INCHARGE/PMIPL EHSO OF JUWM

12. Trained /Experianced Operator & Rigger Deploy. 13.

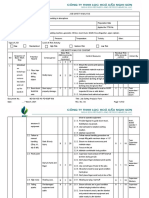

POWER MAX (I) Pvt Ltd.

Job Safety Job Task:Erection of

Client: JINDAL Date:

Analysis(JSA) Boiler Drum

Department: Job Location: Near Boiler

Prepared By: Gyanendra Narayan Nayak

Mechanical Area

SEQUENCE OF BASIS

POTENTIAL HAZARD RECOMMENDED SAFE PROCEDURE

JOB

1.Only Authorized workmen Should Be Allowed

While Material Handling.

2.PPE's Shall Be Provied to All Worker.

3. TBT Shall Be Conduct Before Material

Hit Injury/Fall Of Material Handling. 4.Experience Worker Shall Be

Material Handling Cause To Trap Of

Engaged While Material Handling.

Finger,Hand,Leg.

5.Make Sure The Path Way is

Clear & Free From Wet & Slick .

6.Work Permit

System To be Implimented.

1.Pre-Inspection Of Approach Soil & Position Area

Of Crane

2.Approach Area Development By

Pre-Arrangement Of

Compacting & Leveling.

Crane Operation For Crane Tilt/Toppling & 3.The Safe Bearing Capacity

Loading Of Boiler Fallingdown

Of The Soil Is Considered

Drum On Trailer Bed

4.Crane With Load at Slope Is

Strictly Prohibited. 5.Trained OPerator is

Deployed.

1.Trained OPerator is Deployed.

2.Only Authorized OPerator Allowed

for Operating Crane.

3.Before Engage the Crane

Equipment Fitness Should Be Checked.

4.Pre-

Inspection Of Crane & All Lifting Accessories.

5.All Lifting Accessories & Crane Should Have

Lifting Operation By a Valid TPI.

Hitinury/Fall Of material

Crane 6.Rigging Permit Should Be

Implimented. 7.Rigging plan Should Be Attached

With Permit. 8. Over Load Is Strictly

Restricted. 9.Tandem Lifting

to be Avoided in Hydra 10.TBT Conduct

for Riggers,Operators & Signalman. 11.Over

Load,Over Hoist Limit Switch & Boom Limit Switch

are Provied & Checked For its Function.Proper SLI

system Should Be Provied.

1.Trained & Experianced Operator shall Deployed.

2.Trained &

Experianced Rigger/Signal man Deployed.

3.Rigging

Plan Should Be Attached.

4.Atlist 2-Signal man Deploy at Both Side Of Crane

For Good Coordination Between Operator &

Signalman.

5.Tag Line Should Be Used During Lifting Of

Boiler Drum

6.TBT Should Be Conduct Before

Tendum Lifting Occur

Crane Tilt/Toppling & Tendum Lifting Occure For

For Loading of Boiler

Fallingdown Rigger,Signalman,Operator & Helper. 7.DURING

Drum On Trailer Bed.

Tendum Lifting,Check The Position/Angel In-

Between Two Crane By Competend Rigger/

Engineer.

8.Emergency Plan Should,If any Incident

Occure. 9.Lifting Of Boiler Drum By Two Crane

Up To 1ft From From Ground Level & Holding For

5mints For Re-Checking of Tools & Load

Distrubution to Equal Of Two Crane.

10.Re-Check All The Lifting

Tools Again During Holding Position.

1.The Drum Must Be Tied With The Trailer By

Using Either Chain Or Any Other Proper

Arrangement. 2.Load To Be Placed On The

Welded Braceing/Iron Frame Support.

3.Experianced

Hapazard & Un-

Loading/Positioning Of Rigger/Signalman /Forman/Engineer Should Be

Secured/Projected Boiler

Boiler Drum On Trailer Deployed.

Drum, Cause To Fall Of

Bed 4.Arrange TBT For Rigger/Signalman /Forman/

Boiler Drum

Operator Before Loading Of Boiler Drum.

5.Vehicle Should Be Provied With All Safety

Devices As Per Vehicle Fitness Report.

6.Fitness Stricker To Be Pasted On

Vehicle.

1.Lifting Arrangement Should Be Done By

Compitent Rigger/Worker

2.Arrange Darik For Lifting Of

Boiler Drum,On Top Of Guarder.

Pre-Arrangement Of Demolish Of Material 3.Welding Should Be

Boiler Drum Lifting Done Proper Of Darik. 4.Welding

Inspection Should Be done By Quality.

Department Before Fixing On Top Of Girder.

5. Check

Stability Of Darik By Compitent Engineer.

1. Life Line (12mm wire rope) Should Be Provied

On Top Of Girder

2.Platform Should Be Provied On Top Of

Girder For Safe Movement.

3. Fixing Of Darik On Top Of

Girder,Joint Welding Should Be Done Properly.

4. proper Outsite

Fixing Of Darik On Top Fall Of Person/Fall of

Support Braceing Provied To Darik For Stability.

Of Girder Material

5.All

Arrangement Shhould Be By Experianced

Engineer,Supervisor,Rigger,Forman,

6.Before LIfting Of Boiler Drum,Proper Inspection

Should Be Done BY Compitent-Engineer,Supper

visor, Quality.

1.Pre-Inspection Of Approach Soil & Position Area

Of Winch

2.Approach Area Development By

Compacting & Leveling.

3.Trained Operator Is

Pre-Arrangement Of

Deployed. Only Authorized Operator Allowed to

Winch Operation For

Tilt & Falling Down Operate Winch. 4.At list Two Winch

Erection Of Boiler

Provied For Lifting OF Boiler As Per Load

Drum

5. Winch

Should Be Locked By Heavy Steel Beam With

Attached Any Stable Structure,As Per Load Of

Lifting Or Any Other Arrangement Should Be

Provied.

1.Only Authorized Operator Allowed To operate

The Winch Machine.

2.Before Engage The Winch Machine Or

Lifting Accessories,Valid TPI Should Be Available.

3.Pre-inspection Should Be Done All Tools

& Machine.

Hit Injury/Fall of 4.Rigging Plan Should Be Attached with

Lifting Operation By

Material /unsafe Permit Before lifting Boiler Drum.

Winch Machine

operating condition 5.Trained & Experiance

Rigger/Forman/Fitter At Various Elevation As Per

Rigging Plan For Good Coordination/ Good

chaining Among Them. 6.Training/TBT

Should Be Arrange For

Operator/Rigger/Signalman/Fitter Before Lifting

Activity.

1.Lifting Of Drum By Two Winch Machine up To 2''

From Ground Level & Holding for 10min.

2.Re-Inspection conduct Again All Tools &

Tackle At Holding Position.

3.After Inspection,The Drum Has

Lifting Operation By 2-

Hit/Struck against object To Raised Gradually/Slowly Slowly.

Winch Machine

4.During Lifting Operation Of Boiler

Drum,Winch Rope Should Be Checked Of

Heating/Tension. 5.Winch Operation Should

Be Maintaining Running Gap For Release Of

Tension,During Lifting Of boiler drum.

Drum At Position Hit injury/fall of Load The Drum Must Be Keep Slowly At Position

1.Adiquite Platform/Approch Should Be Provied

on Top Of Giredr For Fitting Of U-Bolt.

2.Lifeline/Fallarrester Should Be provied For

Fitting & Tighting Of U- Height work.

Fall Of Person

Bolt 3.Experiance/compitent Fitter

Engaged For Fitting Of U-sling Guard.

4.Emergency Plan

Should Be/in Case Of any Incident.

CONTRACTER SITE

HOD OF JUWM MECHANICAL EHSO OF JUWM

INCHARGE/PMIPL

You might also like

- Column Erection JSA AnalysisDocument6 pagesColumn Erection JSA AnalysisRaghava Richhu100% (2)

- JSA-017 Lifting With ForkliftDocument3 pagesJSA-017 Lifting With ForkliftMoaatazz Nouisri67% (6)

- 00 Winch Inspection Check ListDocument1 page00 Winch Inspection Check ListGyanendra Narayan Nayak90% (10)

- JSA - CABLE TERMINATION TITLEDocument4 pagesJSA - CABLE TERMINATION TITLESyed Yousuf Ali100% (1)

- Risk Assess JSA Bolt Tightening 012Document7 pagesRisk Assess JSA Bolt Tightening 012Abdeldjalil Ferhati100% (2)

- JSA Mechanical Activity Risk AssessmentDocument1 pageJSA Mechanical Activity Risk Assessmentjithin shankarNo ratings yet

- JSA Hot WorkDocument2 pagesJSA Hot Workchhotelal kumar100% (1)

- JSA FOR STEEL ERECTIONDocument7 pagesJSA FOR STEEL ERECTIONRajuNo ratings yet

- JSA Confined Sapce EntryDocument1 pageJSA Confined Sapce EntryprasongNo ratings yet

- Hot Works: Risk Assesment Form For Rolling ShutterDocument1 pageHot Works: Risk Assesment Form For Rolling Shutterchandanprakash30No ratings yet

- Job Safety Analysis Foundation WorkDocument3 pagesJob Safety Analysis Foundation WorkMihirdutta75% (4)

- Astm - C1579Document7 pagesAstm - C1579Diego Bonadiman100% (1)

- Fire Fighting Isometric Layout PlanDocument1 pageFire Fighting Isometric Layout Planامان للأستشارات الهندسيةNo ratings yet

- HAZARD IDENTIFICATION AND RISK ASSESSMENT FOR SUSPENDED CEILING WORKSDocument4 pagesHAZARD IDENTIFICATION AND RISK ASSESSMENT FOR SUSPENDED CEILING WORKSfaizan khanNo ratings yet

- JOB SAFETY ANALYSIS FOR CHIMNEY REPAIRDocument2 pagesJOB SAFETY ANALYSIS FOR CHIMNEY REPAIRBrenden PalanithangamNo ratings yet

- JSA for Scaffolding Erection, Dismantling and Other Construction WorksDocument9 pagesJSA for Scaffolding Erection, Dismantling and Other Construction Worksuttam mishra100% (1)

- Jsa forOperatingAForkliftDocument2 pagesJsa forOperatingAForkliftsupahing supahingNo ratings yet

- JSA-Hydraulic Press Testing For PilesDocument6 pagesJSA-Hydraulic Press Testing For PilesUMUTNo ratings yet

- Shifting of Material & Equipment.: Job Safety Analysis JobDocument6 pagesShifting of Material & Equipment.: Job Safety Analysis JobPrabir PujariNo ratings yet

- Tower Crane Installation SOP SummaryDocument3 pagesTower Crane Installation SOP SummaryRashidi RahmanNo ratings yet

- 11 - JSA (Tower Crane) 12-9-06Document11 pages11 - JSA (Tower Crane) 12-9-06sattiNo ratings yet

- PTA-JSA-005-Material Handling by Farhana F-15 CraneDocument6 pagesPTA-JSA-005-Material Handling by Farhana F-15 CraneSaiyad RiyazaliNo ratings yet

- JSA Formet New Hot WorkDocument6 pagesJSA Formet New Hot Worksakthi venkat100% (1)

- HIRA For Steam Drum ErectionDocument18 pagesHIRA For Steam Drum ErectionNagendra Kumar SinghNo ratings yet

- Jsa For The Installation of I EamDocument5 pagesJsa For The Installation of I EamMohammed MinhajNo ratings yet

- JSA Format NEW Equipment ErectionDocument5 pagesJSA Format NEW Equipment Erectionsakthi venkatNo ratings yet

- Jsa PCC & RCCDocument2 pagesJsa PCC & RCCNilesh koliNo ratings yet

- Breaker Machine Safety ChecklistDocument1 pageBreaker Machine Safety ChecklistNair R RakeshNo ratings yet

- Exavation Works PipercksDocument4 pagesExavation Works PipercksHRTYR100% (1)

- JSA - CivilDocument5 pagesJSA - CivilRajuNo ratings yet

- Operating A Telescoping Aerial Boom LiftDocument1 pageOperating A Telescoping Aerial Boom LiftTFattahNo ratings yet

- Job Safety Analysis - Cone ErectionDocument7 pagesJob Safety Analysis - Cone ErectionMohammed MinhajNo ratings yet

- Slip Form Construction Safety AnalysisDocument5 pagesSlip Form Construction Safety Analysisputrasejahtra50% (2)

- Jsa Pipe Cutting at Fire PumpDocument5 pagesJsa Pipe Cutting at Fire PumpHow Chin Engineering Sdn BhdNo ratings yet

- 0 JsaDocument54 pages0 JsaRavi AmarlapudiNo ratings yet

- Ast Jsa - Piping FabricationDocument3 pagesAst Jsa - Piping Fabricationmd_rehan_2No ratings yet

- JSA - Structural Steel Fabrication and Installation WorksDocument3 pagesJSA - Structural Steel Fabrication and Installation Workssakthi venkatNo ratings yet

- Pipe Fabrication and Erection JSADocument8 pagesPipe Fabrication and Erection JSAjithin shankarNo ratings yet

- Lifting OperationDocument8 pagesLifting OperationFILE 1131No ratings yet

- Pre Commissioning Electrical EquipmentDocument4 pagesPre Commissioning Electrical Equipmentmohammed a hseNo ratings yet

- Form JSA Lifting CraneDocument6 pagesForm JSA Lifting CraneYeti Srinurhayati100% (1)

- JSA For Bobcat OperationDocument2 pagesJSA For Bobcat Operationwahyu nugrohoNo ratings yet

- 2.1 Precautions For Tower Crane Dismantle: Chapter II DismantlingDocument6 pages2.1 Precautions For Tower Crane Dismantle: Chapter II DismantlingYoutube SaleemNo ratings yet

- Job Safety Analysis Sheet: Activity Potential Hazard Likely Causes Control MeasureDocument2 pagesJob Safety Analysis Sheet: Activity Potential Hazard Likely Causes Control MeasureM Waqas HabibNo ratings yet

- Jsa For Fuel Pump Operation - Spill Clean-UpDocument1 pageJsa For Fuel Pump Operation - Spill Clean-Upwahyu nugrohoNo ratings yet

- Up Dated Job Safety Analysis-Gypsum Plastering WorksDocument12 pagesUp Dated Job Safety Analysis-Gypsum Plastering WorksAkhtar Ali100% (1)

- Thyssenkrupp Industrial Solutions (India) Job Safety AnalysisDocument5 pagesThyssenkrupp Industrial Solutions (India) Job Safety AnalysisNitesh KumarNo ratings yet

- Winch MachineDocument1 pageWinch MachineJomar Rudolph Cabesas100% (6)

- JSA For Flue Gas Duct Height WorkDocument4 pagesJSA For Flue Gas Duct Height Worksubhadipmanna8No ratings yet

- Area Hard Barrication JsaDocument7 pagesArea Hard Barrication JsaJanakiramanNo ratings yet

- Tower Crane Dismantling JSA HSE ProfessionalsDocument2 pagesTower Crane Dismantling JSA HSE ProfessionalsnabeelNo ratings yet

- JSA For DuctDocument13 pagesJSA For DuctRakeshkasarlaNo ratings yet

- JSA - LOAD TEST PILE No. 1Document6 pagesJSA - LOAD TEST PILE No. 1Sanjeet SinghNo ratings yet

- Cutting, Grinding and Welding Safety ProceduresDocument3 pagesCutting, Grinding and Welding Safety ProceduresOgunwa Emmanuel100% (1)

- JOB SAFETY ANALYSISDocument21 pagesJOB SAFETY ANALYSISThái Đạo Phạm Lê100% (1)

- Job Safety Analysis Erection SiloDocument3 pagesJob Safety Analysis Erection SiloDanangNo ratings yet

- Thyssenkrupp Industrial Solutions (India) Job Safety Analysis 1 7Document4 pagesThyssenkrupp Industrial Solutions (India) Job Safety Analysis 1 7abhijit janaNo ratings yet

- Confine Space at Water TankDocument7 pagesConfine Space at Water TanknaraNo ratings yet

- Job Safety Analysis: Page 1 of 4Document4 pagesJob Safety Analysis: Page 1 of 4RakeshkasarlaNo ratings yet

- JHA Scrap Handling HazardsDocument2 pagesJHA Scrap Handling HazardsDwitikrushna Rout100% (1)

- Risk Assessment Reinforcement Work: What Work Location PM Warehouse Area Contractor Company-Aalanna Project PVT LTDDocument3 pagesRisk Assessment Reinforcement Work: What Work Location PM Warehouse Area Contractor Company-Aalanna Project PVT LTDhemant yadavNo ratings yet

- Risk Assessment Shuttering Work: What Work Location PM Warehouse Area Contractor Company-Aalanna Project PVT LTDDocument3 pagesRisk Assessment Shuttering Work: What Work Location PM Warehouse Area Contractor Company-Aalanna Project PVT LTDhemant yadavNo ratings yet

- Hazard Identification Plan SummaryDocument6 pagesHazard Identification Plan SummaryDarius DsouzaNo ratings yet

- COVID-19 Daily Health Screening FormDocument1 pageCOVID-19 Daily Health Screening FormGyanendra Narayan NayakNo ratings yet

- Coronavirus (Covid-19) : Insert Your Logo HereDocument4 pagesCoronavirus (Covid-19) : Insert Your Logo HereAjay SharmaNo ratings yet

- Dial Phase 3A Project Risk Index For Hira: ActivityDocument2 pagesDial Phase 3A Project Risk Index For Hira: ActivityGyanendra Narayan NayakNo ratings yet

- HIRA - COVID 19 Prevention and ControlsDocument17 pagesHIRA - COVID 19 Prevention and ControlsGyanendra Narayan NayakNo ratings yet

- Covid 19Document14 pagesCovid 19Mustapha BouregaaNo ratings yet

- Weld Manual 4 PowerDocument77 pagesWeld Manual 4 PowerGyanendra Narayan NayakNo ratings yet

- THEORIES OF INCIDENTS AND ACCIDENTSDocument39 pagesTHEORIES OF INCIDENTS AND ACCIDENTSGyanendra Narayan NayakNo ratings yet

- 437-001-0760 Rules For All Workplaces: General AdministrationDocument4 pages437-001-0760 Rules For All Workplaces: General AdministrationOws AnishNo ratings yet

- Heat Treatment Manual for Boiler and AuxiliariesDocument30 pagesHeat Treatment Manual for Boiler and AuxiliariesParthiban KarunaNo ratings yet

- BHEL Welding Machine Check ListDocument1 pageBHEL Welding Machine Check ListGyanendra Narayan NayakNo ratings yet

- Osha 2226Document28 pagesOsha 2226Touil HoussemNo ratings yet

- Small Business PDFDocument56 pagesSmall Business PDFMayre Rachel RodriguezNo ratings yet

- BHEL Fire Extinguishers Inspection ChecklistDocument1 pageBHEL Fire Extinguishers Inspection ChecklistGyanendra Narayan NayakNo ratings yet

- Caution Compressed Gas PDFDocument1 pageCaution Compressed Gas PDFGyanendra Narayan NayakNo ratings yet

- Electrical Safety Inspection Checklist-FDocument2 pagesElectrical Safety Inspection Checklist-FGyanendra Narayan Nayak88% (8)

- Elcb Checking Format-TDocument1 pageElcb Checking Format-TGyanendra Narayan NayakNo ratings yet

- Purpose: Safety Management SystemDocument5 pagesPurpose: Safety Management SystemParth PatelNo ratings yet

- BHEL Crane & Hydra Check ListDocument1 pageBHEL Crane & Hydra Check ListGyanendra Narayan NayakNo ratings yet

- Full body Harness Checking Report for 3X600MW NKSTPP PROJECTDocument3 pagesFull body Harness Checking Report for 3X600MW NKSTPP PROJECTGyanendra Narayan NayakNo ratings yet

- BHEL Earth Pit Test ReportDocument2 pagesBHEL Earth Pit Test ReportGyanendra Narayan NayakNo ratings yet

- BHEL Safety Inspection For Drinking Water Facility - MonthlyDocument1 pageBHEL Safety Inspection For Drinking Water Facility - MonthlyGyanendra Narayan NayakNo ratings yet

- Fire ProtectionDocument10 pagesFire Protectionhector15013No ratings yet

- BHEL Gas Cutting Set Inspection Formate - Daily.Document1 pageBHEL Gas Cutting Set Inspection Formate - Daily.Gyanendra Narayan NayakNo ratings yet

- Fire Safety 0Document34 pagesFire Safety 0Anonymous iI88LtNo ratings yet

- CFR (Code of Federal Regulation) Code LinkDocument162 pagesCFR (Code of Federal Regulation) Code LinkGyanendra Narayan NayakNo ratings yet

- Ecat Fire Extinguisher AFFF Foam Data SheetDocument1 pageEcat Fire Extinguisher AFFF Foam Data SheetGyanendra Narayan NayakNo ratings yet

- Material Safety Data SheetDocument8 pagesMaterial Safety Data SheetNic RicNo ratings yet

- The ABCs of Fire ExtinguishersDocument11 pagesThe ABCs of Fire ExtinguishersSyed AdnanNo ratings yet

- Weld Manual 4 PowerDocument77 pagesWeld Manual 4 PowerGyanendra Narayan NayakNo ratings yet

- 7 steps to get construction clearanceDocument4 pages7 steps to get construction clearancerajs27No ratings yet

- HPC 1000 Single Row, 10.0mDocument2 pagesHPC 1000 Single Row, 10.0mgagajainNo ratings yet

- Cracks in ConcreteDocument2 pagesCracks in ConcretecristobaltagaburaNo ratings yet

- MOH STP Sludge Tank Concrete Pouring Method StatementDocument6 pagesMOH STP Sludge Tank Concrete Pouring Method StatementudithaNo ratings yet

- High Speed, High RiseDocument4 pagesHigh Speed, High RiseThanh VânNo ratings yet

- A A A A: Saudi Arabian Oil CompanyDocument1 pageA A A A: Saudi Arabian Oil CompanyAbu Anas M.SalaheldinNo ratings yet

- Covered Flume Design NotesDocument4 pagesCovered Flume Design NotesnidhisasidharanNo ratings yet

- NCRPO Infrastructure Projects SummaryDocument24 pagesNCRPO Infrastructure Projects SummaryOcasion KrischerNo ratings yet

- SAND WASHER MACHINE LAYOUT PLANDocument15 pagesSAND WASHER MACHINE LAYOUT PLANTito Talban Jr.No ratings yet

- Accepted Fsa Qualifications - August 2021Document36 pagesAccepted Fsa Qualifications - August 2021Neil KapoorNo ratings yet

- SOP QC-101 ASME B31.9 Shop and Field Inspection - Supervisor Intro RFS - Rev. 1Document36 pagesSOP QC-101 ASME B31.9 Shop and Field Inspection - Supervisor Intro RFS - Rev. 1iplaruffNo ratings yet

- Precast Concrete Structures For BuildingsDocument10 pagesPrecast Concrete Structures For BuildingsspqdragadosirelandNo ratings yet

- Chapter 4 Flexural Design - (Part 1) - 1Document21 pagesChapter 4 Flexural Design - (Part 1) - 1Huzaifa ZafarNo ratings yet

- General Building Construction 1Document183 pagesGeneral Building Construction 1lordfrank4080No ratings yet

- Stevens Animal Hospital Architectural Drawings 12-18-19Document34 pagesStevens Animal Hospital Architectural Drawings 12-18-19Alyssa Joy Finca100% (1)

- PG 1 3 AES2.1 QuarterlyAnnualWetPipe2013 FSCDocument3 pagesPG 1 3 AES2.1 QuarterlyAnnualWetPipe2013 FSCesgarNo ratings yet

- Report On Pre-Engineered BuildingsDocument22 pagesReport On Pre-Engineered BuildingsCAMPO, Andrea Patrice A.No ratings yet

- Abhishek Dixit - Cad ExpertDocument11 pagesAbhishek Dixit - Cad ExpertanilNo ratings yet

- Doneal Golbal Estate II Semi DetachedDocument5 pagesDoneal Golbal Estate II Semi DetachedJessi ObiorahNo ratings yet

- Reference Title Technical DomainDocument50 pagesReference Title Technical DomainMathias OnosemuodeNo ratings yet

- Chennai Metro Rail Limited: Part - 2 Secti On ViDocument56 pagesChennai Metro Rail Limited: Part - 2 Secti On ViArvind PandeyNo ratings yet

- Principles & Techniques of Bioengineering For Civil Engineers - VIVEK DHAKALDocument4 pagesPrinciples & Techniques of Bioengineering For Civil Engineers - VIVEK DHAKALpawan bhattaraiNo ratings yet

- Ender-3 Linear Rails - X Axis - 8.5x11 - Installation InstructionsDocument1 pageEnder-3 Linear Rails - X Axis - 8.5x11 - Installation InstructionsMustafaNo ratings yet

- Auditorium Theatre of Llinars Del Valles - Álvaro Siza Vieira + Aresta + G.O.P. - ArchDailyDocument17 pagesAuditorium Theatre of Llinars Del Valles - Álvaro Siza Vieira + Aresta + G.O.P. - ArchDailyTMOTNo ratings yet

- Cold Test & Live Test - LEVEL HT LEVEL 9 NEDocument1 pageCold Test & Live Test - LEVEL HT LEVEL 9 NENathan Emru Dela PeñaNo ratings yet

- Popular Aluminium Windows and DoorsDocument24 pagesPopular Aluminium Windows and DoorsmaheshNo ratings yet

- Laporan Absensi Over Time Agustus 2022 1Document3 pagesLaporan Absensi Over Time Agustus 2022 1adi wibowoNo ratings yet

- Antiquarian Resea 00 EvanDocument386 pagesAntiquarian Resea 00 EvanPaola LucchesiNo ratings yet