Professional Documents

Culture Documents

JSA - Civil

Uploaded by

RajuOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

JSA - Civil

Uploaded by

RajuCopyright:

Available Formats

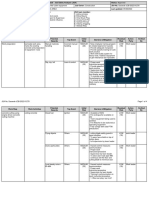

Document No & Rev: JOB SAFETY ANALYSIS

Effective Date: Job Duration: Agency: INDUS PROJECTS LIMITED JSA No.

1 Job Title: EXCAVATION ,REINFORCEMENT, DEMOLISHING, SHUTTERING, DESHUTTERING

2 Project: UP GRADATION OF FIRE FIGHTING NETWORK

3 Defination: To identify the hazard before starting the work to avoid incident & accident.

4 Scope: As per safety rules and standards.

To provide safe working environment & promote a safety awarness for staff / Workers. To Protect public from injury and to damage properties . To ensure Safe works without

5 Objectives:

disruption & to complete them within target in terms of safety and time.

6 Procedure: To identify probable hazards & risk, then the Risks are ranked. Find out counter measures & Safety key points to minimize probability of hazards.

7 Used abriviations: LTI-Lost Time Injuries,MTC-Medical Treatment Cases, FAC-First Aid Cases.

P1 Potential Death, Permanent Disability or Major Structural Damage, P2 Potential Temporary Disability or Minor Structural Damage, P3 Reportable Injuries /Environmental

8 RISK CLASS : Hazards,P4 First Aid Cases.

Sl. Activity Example Picture Probable Risk Risk By

Counter Measures Safety key Points Revised Job Responsibility

No. Hazard rank risk

1) Appropriate PPEs should be used 1) All workers / operators should be 1) Site

2) Access should be free from all obstacles inducted before start of work. Engineer

3) Work Permit should be taken with the 2) All drawing should be approved.

approval 3) All markings should be done as per 2) Site

1) Personal 4) Surveying the area as per drawing. drawings & surveyor instructions. Supervisor

1) LTI

Marking the Injuries 5) Ensure that all staff & workers should

1 P2 wearing all PPEs P4 3) Site safety

excavation area 2)MTC

2) Trip Officer

Hazards

3)FAC

1) Appropriate work permit will be 1) Operators & Drivers should be 1) Site

obtained with approval. experienced & trained with safety Engineer

2)Underground utility will be checked. induction.

3) The Machine should be inspected & 2) Tool box talk done by concerned 2) Site

approved before start the work. supervisor. Supervisor

4) Operator & Drivers should have valid 3) Vehicles Speed should be

license. controlled .4) After parking wheel 3) Site safety

5) Proper access should be provided for stopper should be applied. Officer

vehicle movement. 5) Ensure the safe parking area for

6) Ensure that electrical cables should not vehicles.

1) Vehicle obstruct the way for excavator.

1)LTI

JCB and tractor may hit 7) Each equipment/vehicle will have

2 comes to the P2 helper with flag for guidance to operator. P4

2)MTC

marked area. 2) Vehicle 8)All basic PPEs should be provided.

may topple 3) FAC 9) All vehicles pre- checklist will be

displayed.

10) SWMS will be followed

1) Unauthorized entries should be 1) Machine movement area will be 1) Site

prevented cleared from all unwanted materials Engineer

2) Signal to be given by one person to and traffic.

operator. 2) Vehicle should be checked along with 2) Site

3) Operator should be trained & the checklist and pre-entry check list Supervisor

experienced with valid license. will be displayed on the vehicle.

4) Continuous supervision should be done. 3) Proper leveled area should be used 3) Site safety

5)Proper access should be provided. for machine movement and banks man Officer

1)Fatal 6) Hand breaks & access should be safe on should guide properly

Hit Hazard the machine. 4) Tool box talk to be done before

Starting the 2)LTI 7)Signage should be displayed starting the work.

3 excavation with Traffic P1 8) Ensure that no electrical cable or any 5)Work will be carried out under the P4

slope cutting hazard, 3)MTC kind pipeline should be laid in under strict supervision

ground.

4) FAC 9)Reverse horn will be used.

10)SWMS will be followed,

1) Appropriate work permit will be 1) Operators & Drivers should be 1) Site

obtained with approval experienced & trained with safety Engineer

2) The Machine should be inspected & induction.

approved before start the work. 2) Tool box talk done by concerned 2) Site

3) Drivers should have valid license. supervisor. Supervisor

4) Proper access should be provided for 3) Vehicles Speed should be controlled .

vehicle movement. 4) After parking wheel stopper should 3) Site safety

1)Fatal 5) Ensure that electrical cables should not be applied. Officer

Tractor to carry 1) Hit Hazard obstruct the way for tractor. 5) Ensure the safe parking area for

2)L T I 6) The tractor must have helper for vehicles.

the excavated

4 2)Toppling P1 guidance to driver. P4

soil for dumping

away from pit Hazard 3)MTC 7)All basic PPEs should be provided.

8) All vehicles pre- checklist will be

4)FAC displayed.

9) SWMS will be followed

1.) Work Permit should be obtained with 1) Ensure that all workers got the safety 1) Site

approval. induction before deploying the work. Engineer

2) Sufficient manpower should be 2) Tool Box Meeting should be

deployed for handling the barricading conducted on daily basis. 2) Site

works. 3) Vehicle movements should be Supervisor

3) Workers must be used appropriate controlled if any;

1) Personal PPEs which should be ensured by 4)Do not start any machinery work near 3) Site safety

Providing the Injuries 1)LTI concerned safety officer/supervisor. where the manpower deployed. Officer

5 hard barricading P2 4) Do not use any defective tools. 5) Ensure that P4

for the excavated 2)Trip 2)MTC 6) Maintain the good housekeeping. there is no electrical wires passing

pit hazard through work location on the ground

3)FAC level.

1.) Work Permit should be obtained with 1) Work permit will be closed on daily 1) Site

approval. basis after the completion of particular Engineer

2) Access should be free from all task.

Vehicle will be 1) Personal obstacles. 2)Worked area and machines should be 2) Site

parked in the Injuries 3)Checking will be done regarding any inspected for its safe condition Supervisor

designated area hydraulic/oil leakages.

6 1)FAC P3 4)After parking, wheel stopper should be P4 3) Site safety

after the 2)Trip

completion of hazard applied. Officer

work 5)SWMS should be followed

Job Safety Analysis Page 1 of 5

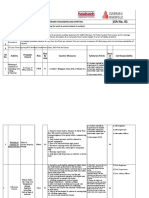

Sl. Probable Risk By Revised Job Responsibility

No. Activity Example Picture Hazard Risk rank Counter Measures Safety key Points risk

1) Appropriate work permit will be 1) Drivers should be experienced & 1) Site

obtained with approval trained with safety induction. Engineer

2) The Machine should be inspected & 2) Tool box talk done by concerned

approved before start the work. supervisor. 2) Site

3)Driver should be trained enough to do 3) Ensure the safe parking area for Supervisor

1) Hit Hazard the job. roller.

Use of roller / 1)LTI

earth ramer for 4) Proper access should be provided for 3) Site safety

7 P2 vehicle movement. P4 Officer

compacting and 2) Personal 2)MTC

leveling of soil. 5) Ensure that electrical cables should not

Injury 3)FAC obstruct the way for roller.

7)All basic PPEs should be provided.

1) Hard barricading should be provided 1) All workers / operators should be 1) Site

around the excavated pit inducted before start of work. Engineer

2)Appropriate caution board should be

2) Appropriate PPEs should be used. displayed according to the nature of 2) Site

work Supervisor

3) Access should be free from all obstacles 3) All markings should be done as per

1) Fall drawings & surveyor instructions. 3) Site safety

1) LTI 4) Work Permit should be taken with the 4) Access/egress arrangement should Officer

Excavated pit is Hazards

8 made ready for P2 approval be provided for excavated pits. P4

2)MTC 5) Concerned engineer/supervisor must 5) All drawing should be approved.

PCC 2) Trip

Hazards be presented and monitored the activities 6) Vehicle's legal documents will be

3)FAC for ensuring the safe working checked before they entering to site

environment. premises

1) Appropriate work permit will be 1) Site

obtained with approval. Engineer

2) The vehicle should be inspected &

approved before start the work. 2) Site

3) Drivers should have valid license. 1) Operators & Drivers should be Supervisor

1)Fatal 4) Proper access should be provided for experienced & trained with safety

vehicle movement. induction. 3) Site safety

1)Hit Hazard 2)L T I 5) Ensure that electrical cables should not 2) Tool box talk done by concerned Officer

Transit Mixer is obstruct the way for vehicle.

9 approaching near P1 supervisor. P4

2) Topple 3)MTC 6) The vehicle must have reverse horn 3) Vehicles Speed should be

to the pit and helper for guidance to operator.

Hazard controlled .4) After parking wheel

4) FAC 7)All basic PPEs should be provided. stopper should be applied.

8) SWMS will be followed 5) Ensure the safe parking area for

vehicles.

1) Reverse horn must be ensured for the 1) Drivers should be experienced & 1) Site

vehicle. trained with safety induction. Engineer

2) Appropriate PPEs must be used. 2) Tool box talk done by concerned

2) Unauthorized entry should be supervisor. 2) Site

prevented around the vehicle and work 3) Vehicles Speed should be controlled Supervisor

1)Fatal spot. 4) After parking wheel stopper should

1) Hit Hazard 3) Electrical cables should not obstruct the be applied. 3) Site safety

Plain cement way for vehicle. 5) Ensure the safe parking area for Officer

2)L T I

concrete will be 4) Access should be free from all obstacles vehicles.

10 2)Toppling P1 P4

poured in the for vehicles.

Hazard 3)MTC

excavated area. 4) FAC 5) Sufficient illumination should be

provided during the night work.

1.) Work Permit should be obtained with

approval.

2)

Sufficient manpower should be deployed

1) Fall of for unloading the shuttering material.

objects 3) Workers 1) Site

must be used appropriate PPEs. which 1) Ensure that all crew got the safety Engineer

1) LTI

Transportation 2) Hit Hazard should be ensured by concerned induction before deploying the work. 2)

11 reinforcement & 2) MTC P2 engineer. 4) Tool Box Meeting should be conducted P4 2) Site

steel shutter 3)Trip Short cut is not allowed. on daily basis.3) Vehicle movements Supervisor

materials to site hazard 5)Safety gloves should be should be controlled if any;5) Ensure

3) FAC

worn by personal unloading the material. that all the personal wear safety gloves 3) Site safety

4)Personal Officer

injuries. 6) Safe handling of materials should be

ensured. 7).Before entering the vehicle

into site, make sure that per-entry

checklist filled and submitted to the FABS

EHS dept.

1) Approved work permit will be obtained

from FABS.

1)Property

damage. 2) Wood and steel material will be 1) Site

stacked properly. 1)Ensure that all stacked material

1) MTC Engineer

Unloading of 2) Don't stack the material above 6ft should be well barricaded

2)Personal

reinforcement & Injuries. 2) Fatal 3) Barricades should be made to all 2) Place signage 2) Site

12 steel shutter P1 stacked material and tag line to be 3) Control of vehicle speed limit will be P4

Supervisor

Board at Site ensured while unloading the lifted load. maintanied

Yard As per JSA 3)Hit Hazard 3) LTI 4) Movement of vehicles and personal 4) Appropiate PPEs will be provided and

3) Site safety

shall be restricted to avoid damage to ensured by concerned supervisor.

4) Vehicle 3) FAC Officer

toppling man and materials.

5) Avoid standing/ working under the

lifted load.

1) Fall

1.) Work Permit should be obtained with

hazard

Making of approval. 1) Ensure that all crew got the safety

2)Trip 1) Site

channel in steel 1) Fatal 2)Workers must be used appropriate induction before deploying the work.

hazard Engineer

yard and cutting 3)Electrical PPEs which should be ensured by 2)Tool box talk done by concerned

of reinforcement 2) LTI concerned engineer. supervisor or safety officer .

13 as per drawing shock P1 3)Allow only trained crew to use power 3) Strict Monitoring by supervisor or P3 2) Site

with the use of (electrocutio 3) MTC tools with precautions. concerned engineer. Supervisor

n)

portable 4)All cables should be overhead. 4) All electrical connection through

4)Fire hazard 3) Site safety

electrical 4) FAC 5.All elctrical connection must be through ELCB.

tools/hand tools. ELCB. Officer

5) Personal

bruises 5)Use only Inspected and approved tools.

Job Safety Analysis Page 2 of 5

Sl. Probable Risk By Revised Job Responsibility

Activity Example Picture Risk Counter Measures Safety key Points

No. Hazard rank risk

1) Walk way should be free from all 1) Safety Induction should be given 1) Site

obstacles. before engaging to site activities. Engineer

2) Appropriate PPEs should be worn I.e 2)Medical check-up should have done

1)Hit Hazard hand gloves, shoulder pad etc. for all members before engaging to site 2) Site

Shifting of 3) Site vehicle's speed should be activities Supervisor

1) LTI controlled. 3)All workers should be undergone in

reinforcement 2)Trip

14 and shuttering Hazard P2 4)All electrical cables should be daily Tool Box Meeting. P4 3) Site safety

2)MTC overdrawn. 4)Work can be carried out under the Officer

boards from yard

to work spot. 3) Personal 5)Un authorized entries should be strict supervision

Injury 3) FAC prevented

6) Continuous supervision should be done.

1)Fall hazard 1) Work permit should be obtained with

approval,prior commence of work.

1) All crew should be experienced & 1) Site

Shifting of 2)Material 2) Manual material handling training to be

trained with safety induction. Engineer

reinforcement , damage provided. 2) Tool box talk done by concerned

channel and 1)MTC 3) Workers must use appropriate PPEs

15 Flooring material 3)Personal P2 like (hand gloves ,shoulder pad )which supervisor. P4 2) Site

3)Ensure that all the crew wear the PPE. Supervisor

from yard to injury 2)FAC should be ensured by concerned

4)Work must be carried out under the

work spot engineer.

strict supervision 3) Site safety

(Manually) 4)Muscle 4)Access should be clear from

Officer

skeletal obstructions.

disorders

1) Appropriate work permit will be 1) Safety Induction should be given 1) Site

obtained with approval before engaging to site activities. Engineer

2) Access/egress arrangement should be 2)Medical check-up should have done

1) Trip provided for the excavated pit. for all members before engaging to site 2) Site

Laying and tying Hazard 1) L T I 3) Appropriate PPEs should be used. activities Supervisor

of 4) All materials should stack properly. 3)All workers should be undergone in

vertical ,horizont 2) Fall 2)MTC 5)Unwanted materials should be removed daily Tool Box Meeting. 3) Site safety

16 P2 from the work location. 4)All equipments and tools should be in P4 Officer

al and circular Hazard

reinforcement on 3)FAC 6) SWMS will be followed good condition.

the marked area. 3) Personal 5)All electrical cables should be

Injury overdrawn.

1.) Work Permit should be obtained with

1) Fall approval. 1) Site

Ready made Hazard 1)LTI 2) Experienced and Sufficient crew should 1) Ensure that all workers got the safety Engineer

channel will be 2)Fall of be deployed for fixing of channel . induction before deploying to the work.

channel 3) Workers must 2) Tool Box Meeting should be 2) Site

17 fixed on the 2) Hit Hazard 2)MTC P2 be used appropriate PPEs which should be conducted on daily basis. P3 Supervisor

edges of floor 3)Trip ensured by concerned engineer. 3) Work must be carried out under strict

reinforcement. 3)FAC

hazard supervision. 3) Site safety

4) Officer

Maintain the good housekeeping

1) Appropriate work permit will be 1) Safety Induction should be given 1) Site

obtained with approval before engaging to site activities. Engineer

2) Access/egress arrangement should be 2)Medical check-up should have done

provided for the excavated pit. for all members before engaging to site 2) Site

1) Trip 1) L T I 3) Appropriate PPEs should be used. activities Supervisor

Shuttering will be Hazard 4) All materials should stack properly. 3)All workers should be undergone in

done around the 5)Unwanted materials should be removed daily Tool Box Meeting. 3) Site safety

2)MTC

18 laid P2 from the work location. 4)All equipments and tools should be in P4 Officer

reinforcement at 2) Fall

Hazard 3) 6) SWMS will be followed good condition.

required height. 5)All electrical cables should be

FAC

overdrawn.

1) Appropriate work permit will be 1) Safety Induction should be given 1) Site

obtained with approval before engaging to site activities. Engineer

2) Access/egress arrangement should be 2)Medical check-up should have done

provided for the excavated pit. for all members before engaging to site 2) Site

1) Trip 3) Appropriate PPEs should be used. activities Supervisor

Readymade Steel 4) All materials should stack properly. 3)All workers should be undergone in

Hazard 1) L T I

Shutter Boards 5)Unwanted materials should be removed daily Tool Box Meeting. 3) Site safety

19 Will be Fixed in 2)MTC P2 P4

2) Fall 3)FAC from the work location. 4)All equipments and tools should be in Officer

Around the Hazard 6) SWMS will be followed good condition.

Reinforcement 5)All electrical cables should be

overdrawn.

1) Appropriate work permit will be

obtained with approval.

2) The vehicle should be inspected &

approved before start the work. 1) Operators & Drivers should be

1) Fatal 3) Operator & Drivers should have valid experienced & trained with safety 1) Site

license. induction. Engineer

1)Hit Hazard 2) L T I 4) Proper access should be provided for 2) Tool box talk done by concerned

Entering Transit

20 Mixure vehicle to P1 vehicle movement. supervisor. P4 2) Site

2) Topple 3) MTC 5) Ensure that electrical cables should not 3) Vehicles Speed should be controlled . Supervisor

site.

Hazard obstruct the way for vehicle. 4) After parking wheel stopper should

4) FAC 6) Each vehicle should have reverse horn be applied. 3) Site safety

and helper for guidance to operator. 5) Ensure the safe parking area for Officer

7)All basic PPEs should be provided. vehicles.

8) All vehicles pre- checklist will be

displayed.

9) SWMS will be followed.

1)Personal 1) Work permit should be obtained with

injury approval,prior commence of work. 1) All crew should be experienced & 1) Site

Engineer

2) Manual handling training to be trained with safety induction.

Fixing of

2)Muscle 1) MTC provided. 3) Workers must use 2) Tool box talk done by concerned

21 concrete pump skeletal P2 appropriate PPEs like hand gloves which supervisor. P4 2) Site

pipe to the disorders 2) FAC should be ensured by concerned 3)Ensure that all the crew wear the PPE. Supervisor

flooring area.

engineer. 4)Work must be carried out under the 3) Site safety

3) Hit Hazard 4)Access should be clear from strict supervision

Officer

obstructions.

4)Trip

hazard

Job Safety Analysis Page 3 of 5

Sl. Probable Risk By Revised Job Responsibility

Activity Example Picture Risk Counter Measures Safety key Points

No. Hazard rank risk

1) Reverse horn must be ensured for the

vehicle.

1) Fatal 2) Helper must be there to guide the

1) Operators & Drivers should be

operator. experienced & trained with safety

Pouring 1) Hit Hazard 2) L T I 3) Only trained person should operate the induction.

concrete into the transit mixute vehicle.

22 concrete pump 2)Personal 3)MTC P1 3) Electrical cables should not obstruct the 2) Tool box talk must be done by P4

concerned supervisor.

by Transit Mixer Injury way for vehicle.

3) Vehicles Speed should be controlled .

4) FAC 4) Access should be free from all obstacles

for vehicles.

5) Pre- Check list will be displayed for all

vehicles.

1) Personal

1.) Work Permit should be obtained with 1) Site

Injuries. 1) Ensure that all workers got the safety

approval. Engineer

Pouring 2) Hit 1) LTI 2) Separate Crew should be deployed for induction before deploying the work.

concrete on the Hazard. concrete. 2) Tool Box Meeting should be 2) Site

23 3)Trip P2 conducted on daily basis. P4

floor with hazard. 2) MTC 3) Workers must be used appropriate 3) Proper Gloves and nose masks shall Supervisor

concrete pump. PPEs which should be ensured by

4)Skin and be provided.

3) FAC concerned engineer. 3) Site safety

eye irritation

Officer

1) Work Permit should be obtained with 1) Ensure that all crew got the safety 1) Site

approval. induction before deploying the work. Engineer

2) Workers must be used appropriate 1) Tool box

PPEs which should be ensured by talk done by concerned supervisor or 2) Site

concerned engineer. safety personal. Supervisor

3) Unauthorised enty should be prevented 3) Vehicles Speed should be controlled.

around the vehicle and work spot. 4) After 3) Site safety

4) Manual handling training parking wheel stopper should be Officer

1) Personal 1)Fatal to be provided. applied.

Injuries by 5) Electrical cables should not obstruct the 5) Strict Monitoring by supervisor or

Concrete will be Hit/trip 2)L T I way for vehicle. concerned engineer. 6)All

poured inside the 6) Access should be free from all obstacles equipments and tools should be in good

24 shuttered board Hazard P1 P4

3)MTC for vehicles. condition.

by transit 7) Sufficient illumination should be

2)Toppling

mixture. provided during the night work. 8)

Hazard 4) FAC

Continuous supervision should be done

1.) Work Permit should be obtained with

1) Personal

approval.

Injuries 1) Ensure that all crew got the safety

Electrical 2)Workers must be used appropriate induction before deploying the work. 1) Site

Vibrator will be 2)Electrocuti PPEs which should be ensured by 2)Tool box talk done by concerned Engineer

1) LTI concerned engineer.

applied on the on 3)Allow only trained crew to use vibrator supervisor or safety officer . 2) Site

25 poured concrete 2) MTC P2 m/c with precautions. 3) Strict Monitoring by supervisor or P4 Supervisor

for its 3) Hit Hazard concerned engineer.

4)All cables should be overhead.

compaction / 4) All electrical connection through

3)FAC 5)All electrical connection must be 3) Site safety

settlement. 4)Trip through ELCB. ELCB. Officer

hazard

6)Vibrator m/c must be Inspected and

approved.

1. Proper access/egress arrangement will 1) Safety Induction should be given 1) Site

be provided for the workmen to work before engaging to site activities. Engineer

inside the pit. 2)Medical check-up should have done

2) Appropriate PPEs must be used. for all members before engaging to site 2) Site

1) Trip 1)L T I 3)Sufficient illumination should be activities Supervisor

Concrete will be Hazard provided during the night work. 3)All workers should be undergone in

26 leveled in proper 2)MTC P3 4)Unwanted materials should be removed daily Tool Box Meeting. P4 3) Site safety

manner 2) Fall from the work location. 4)Work can be carried out under the Officer

manually. Hazard 3) FAC 5)Access should be free from all obstacles strict suprevision

1) Worker must be inducted and Tool Box

1)Skin Talk must be done before deploying to

work.

Irritation

2)Workers must be used appropriate PPEs 1) Site

1) Ensure that all crew got the safety

like rubber handloves ,gum boot etc. Engineer

2)Personal induction before deploying the work.

Mannual Injury 1)FAC which should be ensured by concerned 2)Tool box talk done by concerned

Levelling of engineer. 2) Site

27 concrete by P2 3)Allow only trained crew to do the supervisor or safety officer . P4 Supervisor

3)Trip 2)MTC 3) Strict Monitoring by supervisor or

screed vibrator. levelling of concrete.

Hazard concerned engineer.

4)All cables should be overhead. 3) Site safety

5)All elctrical connection must be through 4) All electrical connection through ELCB Office

4)2)Electroc

ELCB.

ution

6)Screed Vibrator m/c must beInspected

and approved.

1) Personal

1) Work Permit should be obtained with

Injuries 1) Ensure that all crew got the safety

approval.

1) LTI induction before deploying the work.

2) Workers must be used appropriate

Application of 2) Skin 2)Tool box talk done by concerned

28 hardner irritation 2) MTC P2 PPEs I.e hand gloves ,nose mask and supervisor or safety officer .

safety googles which should be ensured

by concerned engineer. 3) Strict Monitoring by supervisor or

3) Eye 3) FAC concerned engineer.

3) Strict supervison of the usage of PPEs.

Irritation

Job Safety Analysis Page 4 of 5

Sl. Probable Risk By Revised Job Responsibility

Activity Example Picture Risk Counter Measures Safety key Points

No. Hazard rank risk

1.) Work Permit should be obtained with

1) Personal approval.

Injuries 2.) Workers must be used appropriate 1) Ensure that all crew got the safety 1) Site

1) LTI PPEs which should be ensured by induction before deploying the work. Engineer

2)Electrocuti concerned engineer. 2)Tool box talk done by concerned

Application of on 3.) Allow only trained worker should use supervisor or safety officer . 2) Site

29 power flotter. 2) MTC P2 Power Flotter m/c with precautions. 3) Strict Monitoring by supervisor or P4 Supervisor

3) Hit Hazard 4.)All cables should be overhead. concerned engineer.

3)FAC

5.)All elctrical connection must be through 4) All electrical connection through 3) Site safety

4)Trip ELCB. ELCB. Office

hazard 6.)Power Flotter m/c must be Inspected

before use.

1) work permit should be obtained with

1)Fall hazard approval. 1) Site

2) Manual handling training to be Engineer

All side channel 2)Personal 1) LTI provided. 3) Workers must be 1) Ensure that all workers got the safety

will be removed injury used appropriate PPEs which should be induction before deploying the work. 2) Site

30 and stacked after 2) MTC P2 P4

ensured by concerned engineer. 2) Tool Box Meeting should be Supervisor

24 hrs of

3)Muscle 4)Access should be clear from conducted on daily basis.

concreting. skeletal 3) FAC obstructions. 5)channels should be 3) Site safety

disorders stacked properly. Officer

5) Housekeeping to be maintained.

1) Work Permit should be obtained with

1) Personal approval.

Injuries 2) Workers must be used appropriate 1) Ensure that all crew got the safety 1) Site

PPEs which should be ensured by induction before deploying the work. Engineer

2)Electrocuti 1) LTI concerned engineer. 2)Tool box talk done by concerned

Floor grove on 3) Allow only trained worker should use supervisor or safety officer . 2) Site

31 cutting with 2) MTC P2 P4

Power Flotter m/c with precautions. 3) Strict Monitoring by supervisor or Supervisor

machine

3) Hit Hazard 3)FAC 4)All cables should be overhead. concerned engineer.

5)All elctrical connection must be through 4) All electrical connection through 3) Site safety

4)Trip ELCB. ELCB. Office

hazard 6)Power Flotter m/c must be Inspected

before use.

1) Work permit should be obtained with

Deshuttering will

1)Fall hazard approval. 1) Site

be done and

2) Material 2) Manual handling training to be 1) Ensure that all workers got the safety Engineer

materials will be

damage 1) LTI provided. 3) Workers must be induction before deploying the work.

stacked 3) Personal used appropriate PPEs which should be 2) Tool Box Meeting should be 2) Site

32 properly.Material injury 2) MTC P2 ensured by concerned engineer. conducted on daily basis. P4 Supervisor

s will be shifted

to yard for 4)Muscle 4)Access should be clear from

skeletal 3) FAC obstructions. 5)Boards should be 3) Site safety

cleaning and

disorders stacked properly. Officer

reuse

5) Housekeeping to be maintained.

1) Work permit should be obtained with

approval.

2) Manual handling training to be

1) Hit Hazard 1)Site

provided. 3) Workers must be 1) Ensure that all workers got the safety

Housekeeping 1) LTI Engineer

used appropriate PPEs which should be induction before deploying the work.

33 and Material 2)Trip P3 ensured by concerned engineer. 2) Tool Box Meeting should be P4 2)Site

stacking will be hazard 2) MTC 4)Access should be clear from conducted on daily basis. Supervisor

ensured. 3)Site safety

3) Dust 3) FAC obstructions. 5) Material should 3) Good supervision Officer

hazard be stacked properly and in its designated

places

JSA Prepared by - EHS Officer JSA Reviewed by EHS - JSA Approved by EHS - TPI

Job Safety Analysis Page 5 of 5

You might also like

- JSA For Cutting, Grinding and Welding in AtmosphereDocument21 pagesJSA For Cutting, Grinding and Welding in AtmosphereThái Đạo Phạm Lê100% (1)

- 10.26.2020 20-029 Drilling Activity Using Drill MachineDocument4 pages10.26.2020 20-029 Drilling Activity Using Drill MachinePangky AbasoloNo ratings yet

- JSA For Fire Water LineDocument4 pagesJSA For Fire Water Linemyo lwinNo ratings yet

- JSA For Painting Works-Hazards ControlDocument4 pagesJSA For Painting Works-Hazards Controlkaleem0% (2)

- Jsa For Steel ErectionDocument7 pagesJsa For Steel ErectionRajuNo ratings yet

- cONSTRUCTION WORK JSADocument21 pagescONSTRUCTION WORK JSAMohammed AlshehhiNo ratings yet

- Jsa Cable TerminationDocument4 pagesJsa Cable TerminationSyed Yousuf Ali100% (1)

- JSA For Lifting of RebarsDocument5 pagesJSA For Lifting of RebarsNiraNo ratings yet

- JSA For Foundation Concrete RepairDocument6 pagesJSA For Foundation Concrete RepairOvais FarooqNo ratings yet

- 0 JsaDocument54 pages0 JsaRavi AmarlapudiNo ratings yet

- JSA For Concrete PouringDocument8 pagesJSA For Concrete Pouringfayaz fayazhotmail.com100% (1)

- JSA No - 08 - Grounding System Installation and Testing - Biju - (Revised - 17 July 2016)Document6 pagesJSA No - 08 - Grounding System Installation and Testing - Biju - (Revised - 17 July 2016)babjihanumanthuNo ratings yet

- JSA Format NEW Equipment ErectionDocument5 pagesJSA Format NEW Equipment Erectionsakthi venkatNo ratings yet

- Quantity Survey Estimation and Valuation NumericalsDocument122 pagesQuantity Survey Estimation and Valuation NumericalsAditya Mane33% (3)

- JSA - Non-Destructive Testing (NDT) - Magnetic Particle TestDocument7 pagesJSA - Non-Destructive Testing (NDT) - Magnetic Particle TestRajuNo ratings yet

- JSA For DuctDocument13 pagesJSA For DuctRakeshkasarlaNo ratings yet

- S/N Sequence of Basic Steps Potential Hazards Hazards Control Action byDocument7 pagesS/N Sequence of Basic Steps Potential Hazards Hazards Control Action byjavithNo ratings yet

- 4.assembly & Erection of StructureDocument3 pages4.assembly & Erection of StructureFrancis Vinoj100% (2)

- Erection of DPC Clinker Silo Extraction-2Document7 pagesErection of DPC Clinker Silo Extraction-2RajuNo ratings yet

- The Lost Chapters of Overdeliver PDFDocument174 pagesThe Lost Chapters of Overdeliver PDFDouglas MarquesNo ratings yet

- Thyssenkrupp Industrial Solutions (India) Job Safety Analysis 1 7Document4 pagesThyssenkrupp Industrial Solutions (India) Job Safety Analysis 1 7abhijit janaNo ratings yet

- Pre Commissioning Electrical EquipmentDocument4 pagesPre Commissioning Electrical Equipmentmohammed a hseNo ratings yet

- ADB - Organizational ChartDocument1 pageADB - Organizational Chartsern soon0% (1)

- Risk Assessment Foundation WorkDocument2 pagesRisk Assessment Foundation WorkMihirduttaNo ratings yet

- 11 - JSA (Tower Crane) 12-9-06Document11 pages11 - JSA (Tower Crane) 12-9-06sattiNo ratings yet

- Exavation Works PipercksDocument4 pagesExavation Works PipercksHRTYR100% (1)

- JSA For Chimney Works 17.09.2021Document2 pagesJSA For Chimney Works 17.09.2021Brenden PalanithangamNo ratings yet

- Risk Assessment - Pipe Fit Up - Hot WorkDocument7 pagesRisk Assessment - Pipe Fit Up - Hot WorkHanu JemberNo ratings yet

- JSA For Bobcat OperationDocument2 pagesJSA For Bobcat Operationwahyu nugrohoNo ratings yet

- Risk Assess JSA Bolt Tightening 012Document7 pagesRisk Assess JSA Bolt Tightening 012Abdeldjalil Ferhati100% (2)

- Content Overview and OnboardingDocument29 pagesContent Overview and OnboardingMaria AngelNo ratings yet

- AST JSA Excavations.Document3 pagesAST JSA Excavations.md_rehan_2No ratings yet

- Ast Jsa - Piping FabricationDocument3 pagesAst Jsa - Piping Fabricationmd_rehan_2No ratings yet

- Concrete Cutting JsaDocument4 pagesConcrete Cutting JsaMohammad Irfan Kiki IsmailNo ratings yet

- JSA For TIE in of Utility Water With Fire Water Line Near Train 1 AreaDocument4 pagesJSA For TIE in of Utility Water With Fire Water Line Near Train 1 AreaMohammed Minhaj100% (1)

- 2020 06 17 JSA For Installation of The AC Unit in The Server RoomDocument11 pages2020 06 17 JSA For Installation of The AC Unit in The Server RoomDarren OscarNo ratings yet

- JSA - Blasting & PaintingDocument11 pagesJSA - Blasting & PaintingRajuNo ratings yet

- JSA - Blasting & PaintingDocument11 pagesJSA - Blasting & PaintingRajuNo ratings yet

- JSA For Installation of Out Door UnitsDocument4 pagesJSA For Installation of Out Door UnitsMohammed MinhajNo ratings yet

- Jsa No-01 Container UnloadingDocument4 pagesJsa No-01 Container Unloadingsumith s100% (1)

- Jsa For Dismantel of StructureDocument2 pagesJsa For Dismantel of StructureBaiju SinghNo ratings yet

- JSA For HILTIDocument3 pagesJSA For HILTIMohammed Minhaj100% (1)

- JSA - De-ShutteringDocument10 pagesJSA - De-ShutteringRaju0% (1)

- Jsa For Blowing of Air in Underground PipesDocument4 pagesJsa For Blowing of Air in Underground PipesMohammed MinhajNo ratings yet

- Hot Works: Risk Assesment Form For Rolling ShutterDocument1 pageHot Works: Risk Assesment Form For Rolling Shutterchandanprakash30No ratings yet

- JSA - Hydro-Testing of Pipe & EquipmentDocument1 pageJSA - Hydro-Testing of Pipe & EquipmentRajuNo ratings yet

- JSA Manual Excavation and Cable LayingDocument3 pagesJSA Manual Excavation and Cable Layingimran100% (1)

- JSA Erection StructureDocument11 pagesJSA Erection StructureJAYESH JOSHINo ratings yet

- JSA For Coating and Raping Activity in TankDocument7 pagesJSA For Coating and Raping Activity in TankEslam lotfy- Eslam elsadatNo ratings yet

- JSA - Baby Rollar and CompectorDocument5 pagesJSA - Baby Rollar and CompectorRaju100% (1)

- JSA Pipe Installation 2012Document2 pagesJSA Pipe Installation 2012Deshbandhu Aman Pandey100% (2)

- JS A Excavation Work For Electrical CableDocument3 pagesJS A Excavation Work For Electrical CableMohammed MinhajNo ratings yet

- Jsa For Manual Backfiling Usin Hand Roller CompactorDocument5 pagesJsa For Manual Backfiling Usin Hand Roller CompactorAbdus SamadNo ratings yet

- 15.tube Bundle Puller.Document3 pages15.tube Bundle Puller.Mohammad Fazal Khan100% (1)

- RISK ASESSMENT For Hot Dip GalvanizingDocument15 pagesRISK ASESSMENT For Hot Dip Galvanizingadeoye Adeyemi100% (1)

- Healthcare Technology Innovation Adoption - Electronic Health Records and Other Emerging Health Information Technology Innovations PDFDocument257 pagesHealthcare Technology Innovation Adoption - Electronic Health Records and Other Emerging Health Information Technology Innovations PDFOL Yra DiomandeNo ratings yet

- Jsa Pipe Cutting at Fire PumpDocument5 pagesJsa Pipe Cutting at Fire PumpHow Chin Engineering Sdn BhdNo ratings yet

- Third Party Ownership and Multi-Club OwnershipDocument36 pagesThird Party Ownership and Multi-Club OwnershipBruno ToniniNo ratings yet

- Tanks Confined Space JSADocument5 pagesTanks Confined Space JSAkosoko100% (1)

- DTC95B GTSGMBH 12 23Document19 pagesDTC95B GTSGMBH 12 23Esteban Enrique Posan BalcazarNo ratings yet

- jsa-for-electrical-conduit-installationdocx - compress-đã chuyển đổiDocument6 pagesjsa-for-electrical-conduit-installationdocx - compress-đã chuyển đổiMon Trang NguyễnNo ratings yet

- 0019 JSA Crane LiftingDocument4 pages0019 JSA Crane LiftingViron Baxhia100% (1)

- 4-JSA - Unloading Under Inert - F9030 B NewDocument6 pages4-JSA - Unloading Under Inert - F9030 B NewAde RahmadiNo ratings yet

- JSA - LOAD TEST PILE No. 1Document6 pagesJSA - LOAD TEST PILE No. 1Sanjeet SinghNo ratings yet

- Hadeed JSA Shearing Machine InstallationDocument11 pagesHadeed JSA Shearing Machine InstallationDhanu NikkuNo ratings yet

- Brahmaputra Cracker and Polymer Limited Lepetkata, Assam: Job Safety AnalysisDocument2 pagesBrahmaputra Cracker and Polymer Limited Lepetkata, Assam: Job Safety AnalysiszebmechNo ratings yet

- PVCMS-BMV-HSE-JSA-001 InsulationDocument6 pagesPVCMS-BMV-HSE-JSA-001 InsulationBkdn DungNo ratings yet

- Jsa PCC & RCCDocument2 pagesJsa PCC & RCCNilesh koliNo ratings yet

- HIRA 008 Height Work.Document4 pagesHIRA 008 Height Work.srinibas mohapatraNo ratings yet

- Jsa Bearing Replacement-OverhaulingDocument2 pagesJsa Bearing Replacement-Overhaulingashish engineeringNo ratings yet

- JSA - Installation of U G PipingDocument11 pagesJSA - Installation of U G PipingOws Anish100% (1)

- Risk Assessment-Bridge ConstructionDocument1 pageRisk Assessment-Bridge ConstructionMirzojon MirzoevNo ratings yet

- 4 JHA On Erection of Auxilary Transformers and Main TransformersDocument4 pages4 JHA On Erection of Auxilary Transformers and Main TransformersPiyush SinghNo ratings yet

- JSA - Opening A High Pressure Steam ValveDocument1 pageJSA - Opening A High Pressure Steam ValveRajuNo ratings yet

- JSA - Bar BendingDocument6 pagesJSA - Bar BendingRajuNo ratings yet

- JSA - Civil Compaction WorkDocument4 pagesJSA - Civil Compaction WorkRajuNo ratings yet

- JSA - Chop Off Machine For Cutting.Document6 pagesJSA - Chop Off Machine For Cutting.RajuNo ratings yet

- JHA - LiftingDocument14 pagesJHA - LiftingRajuNo ratings yet

- Confined Space Hazard Assessment QuestionnairDocument3 pagesConfined Space Hazard Assessment QuestionnairRajuNo ratings yet

- Hopper Building: Tikaria Expansion Project-ACC Pre-Commissioning ChecklistDocument2 pagesHopper Building: Tikaria Expansion Project-ACC Pre-Commissioning ChecklistRajuNo ratings yet

- Equipment PermitDocument8 pagesEquipment PermitRajuNo ratings yet

- LNV Technology (P) LTD ACC LTD, Tikaria Expansion Project: Daily Crane Inspection Checklist - Format / CraneDocument1 pageLNV Technology (P) LTD ACC LTD, Tikaria Expansion Project: Daily Crane Inspection Checklist - Format / CraneRajuNo ratings yet

- 2.4 Million Man Hours - SindriDocument1 page2.4 Million Man Hours - SindriRajuNo ratings yet

- 270T Load ChartDocument1 page270T Load ChartRajuNo ratings yet

- 270T Load ChartDocument1 page270T Load ChartRajuNo ratings yet

- DS - 09 To 17Document9 pagesDS - 09 To 17RajuNo ratings yet

- DS - 09 To 17Document9 pagesDS - 09 To 17RajuNo ratings yet

- ANTICHRESISDocument4 pagesANTICHRESISmichellouise17No ratings yet

- Lean, Sustainability and The Triple Bottom Line Performance - A Systems Perspective-Based Empirical ExaminationDocument21 pagesLean, Sustainability and The Triple Bottom Line Performance - A Systems Perspective-Based Empirical ExaminationAhmed HassanNo ratings yet

- Consumer Reactions To Sustainable PackagingDocument10 pagesConsumer Reactions To Sustainable Packagingxi si xingNo ratings yet

- Break-Even Level of Output BUSINESS STUDIES IGCSEDocument3 pagesBreak-Even Level of Output BUSINESS STUDIES IGCSEHriday KotechaNo ratings yet

- Mohibur Rahman Bank Savings New 4pageDocument4 pagesMohibur Rahman Bank Savings New 4pageUmasankarNo ratings yet

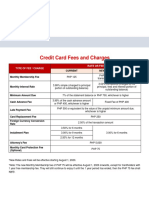

- Credit Card Fees and Charges: Type of Fee / Charge Rate or FeeDocument1 pageCredit Card Fees and Charges: Type of Fee / Charge Rate or FeeKram Yer EtentepmocNo ratings yet

- LESSON 1 (Week 1)Document6 pagesLESSON 1 (Week 1)Wilmark PalmaNo ratings yet

- Student NameDocument44 pagesStudent Name201930037No ratings yet

- Welfare ProvisionsDocument28 pagesWelfare ProvisionsMalik Khuram ShazadNo ratings yet

- Pet MatchmakerDocument15 pagesPet MatchmakerShria TripathyNo ratings yet

- LamboSkyDocument54 pagesLamboSkyphuoclee733No ratings yet

- Welsoft Technologies PVT Limted: Edit Thisvideobest DealDocument11 pagesWelsoft Technologies PVT Limted: Edit Thisvideobest DealsanthoshinouNo ratings yet

- All About Customers: Presented By: Prakshi Chaturvedi Ritesh KhandelwalDocument33 pagesAll About Customers: Presented By: Prakshi Chaturvedi Ritesh KhandelwalPrakshi ChaturvediNo ratings yet

- Csc-Roii-Acic and Lddap of Payment For Online TrainingDocument4 pagesCsc-Roii-Acic and Lddap of Payment For Online TrainingJale Ann A. EspañolNo ratings yet

- Chapter 13 Intermediate AccountingDocument18 pagesChapter 13 Intermediate AccountingDanica Mae GenaviaNo ratings yet

- Entrep 1Document9 pagesEntrep 1Danielle T. JustinianoNo ratings yet

- Castillon, Annette Charmaine. CommrevdigestsDocument195 pagesCastillon, Annette Charmaine. CommrevdigestsJea CoNo ratings yet

- Employment Agencies in BangladeshDocument23 pagesEmployment Agencies in BangladeshMd Abdur Rahman Bhuiyan0% (1)

- DOC-20240502-WA0002. (1)Document4 pagesDOC-20240502-WA0002. (1)sirsamarvind866No ratings yet

- Internship ProgrammingDocument3 pagesInternship ProgrammingJahangir ashrafNo ratings yet

- Customer Information Sheet (CRL-FM-ADMN-049) - r1Document1 pageCustomer Information Sheet (CRL-FM-ADMN-049) - r1alvin salmingoNo ratings yet

- Aerostructures Supplier Quality Requirements Control of Nonconforming ProductDocument20 pagesAerostructures Supplier Quality Requirements Control of Nonconforming ProductGấu Du CônNo ratings yet

- Impact of Liberalization, Privatization & Globalization On Indian EconomyDocument13 pagesImpact of Liberalization, Privatization & Globalization On Indian EconomyYogesh GuptaNo ratings yet