Professional Documents

Culture Documents

Termofusion Con SDR Diferente

Uploaded by

jose mezaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Termofusion Con SDR Diferente

Uploaded by

jose mezaCopyright:

Available Formats

Butt Fusion of Pipes and Components With

Different Wall Thicknesses

According to ASTM F2620, section X1.4 of Appendix X1 addresses, “butt

fusion joining of pipes and fittings that have the same outside diameter but

unlike wall thickness (different by one standard DR or more) is possible.”

ISCO recommends following accepted industry practice that the wall

thickness difference should not exceed 26% in order to maintain the

pressure rating of the lowest rated component (the thinner of the two wall

thickness) involved in the butt fusion. Wall thickness differences in excess

of this recommendation may induce a stress riser that could affect the

quality of fusion joint to withstand events like pressure surges and external

loading that may not affect welds with the same wall thickness.

Example: Pipe or fittings that have a wall thickness of 1” would be

welded to a pipe or fitting with a wall thickness of .74” or 1.35” to

maintain full pressure rating.

CONSIDER:

• The pipe line is only as strong as its weakest link or lowest rated

component

• Beveling or counter-boring the thicker wall can help reduce or

eliminate the difference in wall thickness

• The fusion pressure used to join two different wall thicknesses is

always that of the thinner wall pipe/component.

* See chart on page 37 for more information.

Install Clamping Inserts

Select and install appropriate clamping

inserts for the pipe that is being fused.

No. 1LC & Mini-Mc® Machines

(1/2” CTS - 1” IPS Pipe)

1” CTS and smaller inserts are fitted to jaw

castings using flat head fasteners.

No. 2LC & No. 2CU Machines (1/2” CTS - 2” IPS Pipe)

1-1/2” and smaller inserts are fitted to jaw castings using flat head fasteners.

No. 14 Pitbull Machines (1” IPS - 4” DIPS Pipe)

2” Master, 3”, and 4” inserts are held in place by spring pins located

on upper and lower jaws. 1-1/2” and smaller inserts are fitted to 2” IPS

Master inserts using flat head fasteners.

No. 26 Pitbull Machines (2” IPS - 6” DIPS Pipe)

2”, 3”, and 4” inserts are held in place by spring pins located on upper

and lower jaws.

Fusion Hotline 1-800-345-4726 ext. 4790

© Copyright 2018 ISCO Industries, Inc. All rights reserved. 21

Butt Fusion of Pipes and Components With

Different Wall Thicknesses

According to ASTM F2620, section X1.4 of Appendix X1 addresses, “butt

fusion joining of pipes and fittings that have the same outside diameter but

unlike wall thickness (different by one standard DR or more) is possible.”

ISCO recommends following accepted industry practice that the wall

thickness difference should not exceed 26% in order to maintain the

pressure rating of the lowest rated component (the thinner of the two wall

thickness) involved in the butt fusion. Wall thickness differences in excess

of this recommendation may induce a stress riser that could affect the

quality of fusion joint to withstand events like pressure surges and external

loading that may not affect welds with the same wall thickness.

Example: Pipe or fittings that have a wall thickness of 1” would be

welded to a pipe or fitting with a wall thickness of .74” or 1.35” to

maintain full pressure rating.

CONSIDER:

• The pipe line is only as strong as its weakest link or lowest rated

component

• Beveling or counter-boring the thicker wall can help reduce or

eliminate the difference in wall thickness

• The fusion pressure used to join two different wall thicknesses is

always that of the thinner wall pipe/component.

Range of PE Wall Thickness Fusion Compatibility

Can be fused to a pipe or fitting with a

Pipe or Fitting DR

Min DR of or Max DR of

7 5.5 9

9 7 11

11 9 13.5

13.5 11 17

17 13.5 21

21 17 26

26 21 32.5

32.5 26 41

Fusion Hotline 1-800-345-4726 ext. 4790

© Copyright 2018 ISCO Industries, Inc. All rights reserved. 37

You might also like

- PP819-TN Field Bending of PE Pipe J 2010Document4 pagesPP819-TN Field Bending of PE Pipe J 2010Edinson NavarroNo ratings yet

- Wiik & Hoeglund Pipe FittingsDocument60 pagesWiik & Hoeglund Pipe Fittingsliang jasonNo ratings yet

- Profi FOOD - CTP Bucharest ParkDocument26 pagesProfi FOOD - CTP Bucharest ParkGaftoi TicaNo ratings yet

- Composite PC Slabs and SCI P287 Release Note PDFDocument3 pagesComposite PC Slabs and SCI P287 Release Note PDFRobert GilbertNo ratings yet

- Flange Closure Design Spreadsheet-11 AmerivenDocument27 pagesFlange Closure Design Spreadsheet-11 AmerivenWilmer FigueraNo ratings yet

- S Speed Loc ClampsDocument3 pagesS Speed Loc Clampsibrh42No ratings yet

- S Speed Loc ClampsDocument3 pagesS Speed Loc ClampsAdrian PetrascuNo ratings yet

- TDS 09 18Document7 pagesTDS 09 18Mahmoud AglanNo ratings yet

- Designing Diaphragms Over Existing Board Floors or Roofs: Technical TopicsDocument4 pagesDesigning Diaphragms Over Existing Board Floors or Roofs: Technical Topicsyoshdog@gmail.comNo ratings yet

- Process Pipeline Repair ClampsDocument4 pagesProcess Pipeline Repair ClampsHeru SuryoNo ratings yet

- ASME B31.4 Design Minimum Wall ThicknessDocument6 pagesASME B31.4 Design Minimum Wall ThicknessAlfredo BravoNo ratings yet

- 11 Wall TiesDocument28 pages11 Wall TiesDuncan Lillistone100% (1)

- Understanding Finished Slot Size Tolerances When Manufacturing PCBDocument16 pagesUnderstanding Finished Slot Size Tolerances When Manufacturing PCBjackNo ratings yet

- Attachment of Brick Veneer in High-Wind Regions: Purpose: Key IssuesDocument3 pagesAttachment of Brick Veneer in High-Wind Regions: Purpose: Key IssuesSugarPOP666100% (1)

- IPC 2223 Design Standard For Flex and Rigid Flex CircuitsDocument19 pagesIPC 2223 Design Standard For Flex and Rigid Flex CircuitsMariano DiazNo ratings yet

- 615499fb78247e6a4579d993 6202 Cosasco Disc Coupon HolderDocument3 pages615499fb78247e6a4579d993 6202 Cosasco Disc Coupon HolderPatricia RomeroNo ratings yet

- Flooring Design GuideDocument81 pagesFlooring Design GuideArmin KovacevicNo ratings yet

- CSR Roofing ArchManual S1-S8Document127 pagesCSR Roofing ArchManual S1-S8k2v1n5100% (1)

- Raised Heel TrussesDocument8 pagesRaised Heel TrussesPatrice AudetNo ratings yet

- ST Wa BraDocument20 pagesST Wa BrakjdaraNo ratings yet

- Design Concepts For AnchorageDocument6 pagesDesign Concepts For AnchorageChristopher Aaron SiregarNo ratings yet

- HVAC Specs - ComplianceDocument32 pagesHVAC Specs - ComplianceArchanaShenoyNo ratings yet

- Rociador EC 11Document8 pagesRociador EC 11Alejandro Chumpitaz MarchanNo ratings yet

- Wall Theo PDFDocument23 pagesWall Theo PDFFranklin UkaohaNo ratings yet

- Conbextra EP10TG PDFDocument2 pagesConbextra EP10TG PDFAcho SupraholicNo ratings yet

- Shear Transfer at Engineered Wood FloorsDocument12 pagesShear Transfer at Engineered Wood FloorsIonFlorentaNo ratings yet

- 38mm Flooring: Physical PropertiesDocument2 pages38mm Flooring: Physical PropertiesalpogaltreeNo ratings yet

- Engineering Standards Manual: Code of Practice For City Infrastructure & Land DevelopmentDocument13 pagesEngineering Standards Manual: Code of Practice For City Infrastructure & Land DevelopmentAther Hussain MoverNo ratings yet

- Design Limitations PCBDocument18 pagesDesign Limitations PCBRalf Conrado ScodelerNo ratings yet

- Grayloc Connector: The Ultimate ConnectionDocument8 pagesGrayloc Connector: The Ultimate ConnectionMohamadIbnuHassanNo ratings yet

- Ipb TB 2011 014Document3 pagesIpb TB 2011 014texas_peteNo ratings yet

- Welded Wire MeshDocument23 pagesWelded Wire MeshSushmit Sharma100% (1)

- IR 25-3 GypsumCeilingDocument3 pagesIR 25-3 GypsumCeilingmark.taylor2962No ratings yet

- Structural Design: Information SheetDocument4 pagesStructural Design: Information SheetVRKVRK10No ratings yet

- Acs102v3 Floating FloorDocument24 pagesAcs102v3 Floating FloorDaris SkaNo ratings yet

- Catalouge For Lenton CouplersDocument18 pagesCatalouge For Lenton Couplerss.skumar1No ratings yet

- Section 19: FabricationDocument23 pagesSection 19: FabricationAndres Hernandez CorreoNo ratings yet

- How To Control Flex PCB ImpedanceDocument10 pagesHow To Control Flex PCB ImpedancejackNo ratings yet

- 4323Mt Metrotile Metal Roofing Tiles: 1. GeneralDocument12 pages4323Mt Metrotile Metal Roofing Tiles: 1. GeneralRoland BroadbentNo ratings yet

- ADSSDocument19 pagesADSSMichalNo ratings yet

- Roof Sheathing FasteningDocument4 pagesRoof Sheathing Fasteningnumber_25No ratings yet

- Architectural Precast JointsDocument28 pagesArchitectural Precast JointsFalgun HindochaNo ratings yet

- Future Pipe InfoDocument29 pagesFuture Pipe Infomekag94No ratings yet

- solidworks ขั้นพื้นฐานDocument74 pagessolidworks ขั้นพื้นฐานChonTicha'No ratings yet

- Rebar TolerancesDocument4 pagesRebar Tolerancesjade5704No ratings yet

- Storm and Sewerage Pipe Installation Guide, VinidexDocument16 pagesStorm and Sewerage Pipe Installation Guide, VinidexMiroslav AleksicNo ratings yet

- Appendix 2 Concrete OverlaysDocument29 pagesAppendix 2 Concrete Overlaysproteor_srlNo ratings yet

- Ovp PDFDocument14 pagesOvp PDFNam Song Hau CTONo ratings yet

- HD - SPS-9 Foam MakerDocument4 pagesHD - SPS-9 Foam MakerJavier Hinojosa Garrido LeccaNo ratings yet

- 5313ub Usg Boral Sheet Ceiling SystemsDocument5 pages5313ub Usg Boral Sheet Ceiling SystemsJessie Jr CuisonNo ratings yet

- QFN LAnd PatternsDocument9 pagesQFN LAnd PatternsTyler WilsonNo ratings yet

- Conexion BlueDocument32 pagesConexion Bluecesardario90No ratings yet

- AM Breeze Block DesignDocument92 pagesAM Breeze Block DesignMattNo ratings yet

- Western India Wire IndustriesDocument7 pagesWestern India Wire Industriesyns_krisNo ratings yet

- Pavement Joint DetailsDocument7 pagesPavement Joint DetailsMahmood MuftiNo ratings yet

- Viscous DampersDocument1 pageViscous DampersMuhammad AbdulQawii Abd El-LatifNo ratings yet

- Residential Asphalt Roofing Manual Design and Application Methods 2014 EditionFrom EverandResidential Asphalt Roofing Manual Design and Application Methods 2014 EditionNo ratings yet

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- Tr-33 Generic Butt Fusion Joining Gas PipeDocument32 pagesTr-33 Generic Butt Fusion Joining Gas PipeLuis QuinoNo ratings yet

- F1411-200-ASS, Rev.4Document1 pageF1411-200-ASS, Rev.4jose mezaNo ratings yet

- UL Listed Basket Strainer - Fire Protection - Model F1411Document2 pagesUL Listed Basket Strainer - Fire Protection - Model F1411jose mezaNo ratings yet

- F1411-200-ASS, Rev.4Document1 pageF1411-200-ASS, Rev.4jose mezaNo ratings yet

- Spun Pipe RCC Pipe Hume PipeDocument1 pageSpun Pipe RCC Pipe Hume PipeAbhiishek SinghNo ratings yet

- List of Boiler Manufacturer 2021Document64 pagesList of Boiler Manufacturer 2021siddhant kohli71% (7)

- Discrete Mathematics - Propositional LogicDocument8 pagesDiscrete Mathematics - Propositional LogicAldrich PanioNo ratings yet

- Meridium Enterprise APM ModulesAndFeaturesDeploymentDocument517 pagesMeridium Enterprise APM ModulesAndFeaturesDeploymenthellypurwantoNo ratings yet

- Entrepreneurial Skills-II: in This Chapter..Document34 pagesEntrepreneurial Skills-II: in This Chapter..TECH-A -TRONICSNo ratings yet

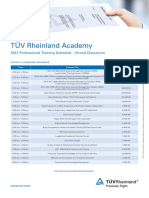

- TÜV Rheinland Academy: 2021 Professional Training Schedule - Virtual ClassroomDocument3 pagesTÜV Rheinland Academy: 2021 Professional Training Schedule - Virtual ClassroomAaron ValdezNo ratings yet

- The Power of Social MediaDocument3 pagesThe Power of Social MediaTIGER CHEETANo ratings yet

- TRENDS AND CRITICAL THINKINGExamDocument4 pagesTRENDS AND CRITICAL THINKINGExamRyan TamelinNo ratings yet

- Simple Quiz App Using PythonDocument47 pagesSimple Quiz App Using Pythonatozdhiyanes100% (1)

- OM Appendix 3D Diamond DA40NG Flight Operations ManualDocument123 pagesOM Appendix 3D Diamond DA40NG Flight Operations ManualBekhzod ArtygaliyevNo ratings yet

- Huawei FusionServer RH8100 V3 Data SheetDocument4 pagesHuawei FusionServer RH8100 V3 Data Sheetpramod BhattNo ratings yet

- OpenTaps in RetailDocument13 pagesOpenTaps in RetailtarunsainaniNo ratings yet

- DC BASIC GAS at Ravi Ranjan KumarDocument1 pageDC BASIC GAS at Ravi Ranjan KumarRAVI RANJAN KUMARNo ratings yet

- Advantages and Disadvantages of Distance LearningDocument2 pagesAdvantages and Disadvantages of Distance LearningШвидка Вікторія ТарасівнаNo ratings yet

- Lesson 7 - Digital SelfDocument38 pagesLesson 7 - Digital SelfM'Edna AguilarNo ratings yet

- HTML Project On Shopping WebsiteDocument2 pagesHTML Project On Shopping WebsiteSunitha ManamNo ratings yet

- Philly To AML Migration: PrerequisitesDocument3 pagesPhilly To AML Migration: PrerequisitesElNo ratings yet

- Java DL 2023Document16 pagesJava DL 2023Sktr BhanuNo ratings yet

- Flashattention: Fast and Memory-Efficient Exact Attention With Io-AwarenessDocument34 pagesFlashattention: Fast and Memory-Efficient Exact Attention With Io-AwarenessMarcos CostaNo ratings yet

- Lesson 12&13Document4 pagesLesson 12&13Jhynes RenomeronNo ratings yet

- Coursera XQVQSBQSPQA5 - 2 PDFDocument1 pageCoursera XQVQSBQSPQA5 - 2 PDFAlexar89No ratings yet

- Lubuklinggau Price 2017Document59 pagesLubuklinggau Price 2017akhmad hidayatNo ratings yet

- Hidden Beam DesignDocument8 pagesHidden Beam DesignAnil kumar R100% (1)

- Maintenance Instructions For Voltage Detecting SystemDocument1 pageMaintenance Instructions For Voltage Detecting Systemيوسف خضر النسورNo ratings yet

- Progress Test 2 (Units 4-6) : Name - ClassDocument6 pagesProgress Test 2 (Units 4-6) : Name - ClassРусланNo ratings yet

- 4MATION SAM Module IO-IDocument54 pages4MATION SAM Module IO-IIkhuosho AbodeNo ratings yet

- Albright DADM 6e - PPT - Ch04Document27 pagesAlbright DADM 6e - PPT - Ch04Zoel-Fazlee OmarNo ratings yet

- Outreach in FIRST LEGO LeagueDocument10 pagesOutreach in FIRST LEGO LeagueΑνδρέας ΜήταλαςNo ratings yet

- Tuguegarao Certificate of Non-Availability of Stocks: Product Code Product Description UOM PriceDocument7 pagesTuguegarao Certificate of Non-Availability of Stocks: Product Code Product Description UOM PriceNenbon NatividadNo ratings yet

- Reliability and Its Application in TQMDocument15 pagesReliability and Its Application in TQMVijay Anand50% (2)