Professional Documents

Culture Documents

WP1 - A2-2 Capwap

Uploaded by

Megah Adhi KaryaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

WP1 - A2-2 Capwap

Uploaded by

Megah Adhi KaryaCopyright:

Available Formats

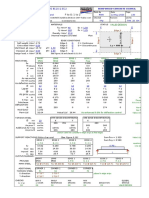

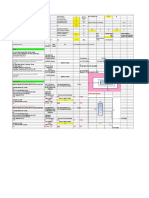

LOTTE LINE PROJECT WIKA BETON; Pile: WP1 - A2-2; SPUN PILE D 60 DD 65; Blow: 11 (Test: 09-Apr-2022 09:18:)

25-Apr-2022

Megah Adhi Karya CAPWAP(R) 2014-3

400 400

Force Msd Force Msd

tons tons

Force Cpt Velocity Msd

200 200

5 195 ms 5 195 ms

0 0

17 2L/c 17 2L/c

-200 -200

20

Shaft Resistance Length b. Sensors 16.5 m

Load (tons) Distribution Embedment 15.0 m

Pile Top

Top Area 1570.8 cm2

0 100 200 300 400 500 600 Bottom 15

0.0 End Bearing Area 2827.4 cm2

Top Perimeter 1.88 m

tons/m

Top E-Modulus 352 tons/cm2

10 Top Spec. Weight 2.4 tons/m3

RU = 441 tons Top Wave Spd. 3788 m/s

5.0

SF = 132 tons Overall W.S. 3788 m/s

EB = 309 tons 5

Displacement (mm)

Dy = 18.727 mm Match Quality 2.50

Dx = 18.818 mm Top Compr. Stress 0.2 tons/cm2

10.0 0 Max Compr. Stress 0.3 tons/cm2

SET/Bl = 0.100 mm

0 Max Tension Stress -0.06 tons/cm2

110 Avg. Shaft Quake 1.104 mm

15.0 EB Toe Quake 5.045 mm

220 Avg. Shaft Smith Dpg. 0.40 s/m

tons

Toe Smith Damping 0.32 s/m

330

20.0

SF

440

Pile Force

25.0 at Ru

550

CAPWAP(R) 2014-3 Licensed to Megah Adhi Karya

LOTTE LINE PROJECT WIKA BETON; Pile: WP1 - A2-2 Test: 09-Apr-2022 09:18

SPUN PILE D 60 DD 65; Blow: 11 CAPWAP(R) 2014-3

Megah Adhi Karya OP: Marcho

About the CAPWAP Results

The CAPWAP program performs a signal matching or reverse analysis based on

measurements taken on a deep foundation under an impact load. The program is based

on a one-dimensional mathematical model. Under certain conditions, the model only

crudely approximates the often complex dynamic situations.

The CAPWAP analysis relies on the input of accurately measured dynamic data plus

additional parameters describing pile and soil behavior. If the field measurements

of force and velocity are incorrect or were taken under inappropriate conditions

(e.g., at an inappropriate time or with too much or too little energy) or if the

input pile model is incorrect, then the solution cannot represent the actual

soil behavior.

Generally the CAPWAP analysis is used to estimate the axial compressive pile

capacity and the soil resistance distribution. The long-term capacity is best

evaluated with restrike tests since they incorporate soil strength changes

(set-up gains or relaxation losses) that occur after installation. The calculated

load settlement graph does not consider creep or long term consolidation settlements.

When uplift is a controlling factor in the design, use of the CAPWAP results to assess

uplift capacity should be made only after very careful analysis of only good

measurement quality, and further used only with longer pile lengths and with nominally

higher safety factors.

CAPWAP is also used to evaluate driving stresses along the length of the pile.

However, it should be understood that the analysis is one dimensional and does not

take into account bending effects or local contact stresses at the pile toe.

Furthermore, if the user of this software was not able to produce a solution with

satisfactory signal “match quality” (MQ), then the associated CAPWAP results may be

unreliable. There is no absolute scale for solution acceptability but solutions with

MQ above 5 are generally considered less reliable than those with lower MQ values and

every effort should be made to improve the analysis, for example, by getting help

from other independent experts.

Considering the CAPWAP model limitations, the nature of the input parameters,

the complexity of the analysis procedure, and the need for a responsible application

of the results to actual construction projects, it is recommended that at least one

static load test be performed on sites where little experience exists with dynamic

behavior of the soil resistance or when the experience of the analyzing engineer with

both program use and result application is limited.

Finally, the CAPWAP capacities are ultimate values. They MUST be reduced by means

of an appropriate factor of safety to yield a design or working load. The selection

of a factor of safety should consider the quality of the construction control,

the variability of the site conditions, uncertainties in the loads, the importance

of structure and other factors. The CAPWAP results should be reviewed by the Engineer

of Record with consideration of applicable geotechnical conditions including, but not

limited to, group effects, potential settlement from underlying compressible layers,

soil resistances provided from any layers unsuitable for long term support,

as well as effective stress changes due to soil surcharges, excavation or change

in water table elevation.

The CAPWAP analysis software is one of many means by which the capacity of a deep

foundation can be assessed. The engineer performing the analysis is responsible for

proper software application and the analysis results. Pile Dynamics accepts

no liability whatsoever of any kind for the analysis solution and/or the application

of the analysis result.

Analysis: 25-Apr-2022

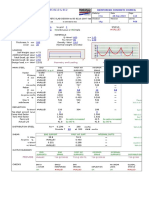

LOTTE LINE PROJECT WIKA BETON; Pile: WP1 - A2-2 Test: 09-Apr-2022 09:18

SPUN PILE D 60 DD 65; Blow: 11 CAPWAP(R) 2014-3

Megah Adhi Karya OP: Marcho

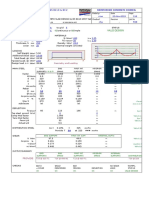

CAPWAP SUMMARY RESULTS

Total CAPWAP Capacity: 440.57; along Shaft 131.93; at Toe 308.64 tons

Soil Dist. Depth Ru Force Sum Unit Unit

Sgmnt Below Below in Pile of Resist. Resist.

No. Gages Grade Ru (Depth) (Area)

m m tons tons tons tons/m tons/m2

440.6

1 4.1 2.6 5.06 435.5 5.06 1.93 1.02

2 6.2 4.7 8.65 426.9 13.71 4.19 2.22

3 8.3 6.8 14.01 412.8 27.72 6.79 3.60

4 10.3 8.8 19.66 393.2 47.38 9.53 5.06

5 12.4 10.9 24.86 368.3 72.24 12.05 6.39

6 14.4 12.9 28.82 339.5 101.06 13.97 7.41

7 16.5 15.0 30.87 308.6 131.93 14.97 7.94

Avg. Shaft 18.85 8.80 4.67

Toe 308.64 1091.59

Soil Model Parameters/Extensions Shaft Toe

Smith Damping Factor 0.40 0.32

Quake (mm) 1.104 5.045

Case Damping Factor 0.36 0.68

Damping Type Viscous Sm+Visc

Unloading Quake (% of loading quake) 96 107

Reloading Level (% of Ru) 100 100

Unloading Level (% of Ru) 55

Resistance Gap (included in Toe Quake) (mm) 0.390

Soil Plug Weight (tons) 0.362

CAPWAP match quality = 2.50 (Wave Up Match) ; RSA = 0

Observed: Final Set = 0.100 mm; Blow Count = 10000 b/m

Computed: Final Set = 0.100 mm; Blow Count = 9999 b/m

Transducer F3 (U586) CAL: 144.3; RF: 1.00; F4 (B588) CAL: 146.5; RF: 1.00

A1 (K5926) CAL: 382; RF: 1.00; A2 (K5927) CAL: 368; RF: 1.00

max. Top Comp. Stress = 0.2 tons/cm2 (T= 51.2 ms, max= 1.116 x Top)

max. Comp. Stress = 0.3 tons/cm2 (Z= 8.3 m, T= 52.0 ms)

max. Tens. Stress = -0.06 tons/cm2 (Z= 8.3 m, T= 74.9 ms)

max. Energy (EMX) = 4.29 tons-m; max. Measured Top Displ. (DMX)=16.925 mm

Page 2 Analysis: 25-Apr-2022

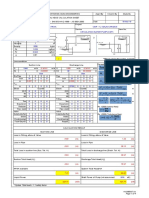

LOTTE LINE PROJECT WIKA BETON; Pile: WP1 - A2-2 Test: 09-Apr-2022 09:18

SPUN PILE D 60 DD 65; Blow: 11 CAPWAP(R) 2014-3

Megah Adhi Karya OP: Marcho

EXTREMA TABLE

Pile Dist. max. min. max. max. max. max. max.

Sgmnt Below Force Force Comp. Tens. Trnsfd. Veloc. Displ.

No. Gages Stress Stress Energy

m tons tons tons/cm2 tons/cm2 tons-m m/s mm

1 1.0 370.9 -73.8 0.2 -0.05 4.29 1.2 16.519

2 2.1 379.7 -77.8 0.2 -0.05 4.16 1.1 15.809

3 3.1 388.4 -82.1 0.2 -0.05 4.02 1.1 15.082

4 4.1 397.1 -86.7 0.3 -0.06 3.87 1.1 14.340

5 5.2 399.8 -88.6 0.3 -0.06 3.64 1.1 13.592

6 6.2 407.8 -94.1 0.3 -0.06 3.48 1.0 12.828

7 7.2 406.3 -94.1 0.3 -0.06 3.20 1.0 12.066

8 8.3 413.7 -98.7 0.3 -0.06 3.04 0.9 11.292

9 9.3 405.9 -93.5 0.3 -0.06 2.70 0.9 10.532

10 10.3 412.9 -97.1 0.3 -0.06 2.55 0.8 9.761

11 11.3 398.6 -87.3 0.3 -0.06 2.19 0.8 9.027

12 12.4 404.6 -89.6 0.3 -0.06 2.05 0.7 8.294

13 13.4 384.0 -74.1 0.2 -0.05 1.70 0.7 7.607

14 14.4 388.2 -75.0 0.2 -0.05 1.57 0.6 6.920

15 15.5 361.5 -56.0 0.2 -0.04 1.26 0.5 6.282

16 16.5 363.9 -55.5 0.2 -0.04 1.00 0.5 5.644

Absolute 8.3 0.3 (T = 52.0 ms)

8.3 -0.06 (T = 74.9 ms)

CASE METHOD

J = 0.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9

RP 454 448 441 435 429 423 417 411 405 399

RX 471 466 462 457 452 448 443 439 434 430

RU 460 455 449 444 438 433 427 422 417 411

RAU = 259 (tons); RA2 = 454 (tons)

Current CAPWAP Ru = 441 (tons); Corresponding J(RP)= 0.21; J(RX) = 0.66

VMX TVP VT1*Z FT1 FMX DMX DFN SET EMX QUS KEB

m/s ms tons tons tons mm mm mm tons-m tons tons/mm

1.2 44.92 174 341 369 16.925 0.098 0.100 4.38 515 66

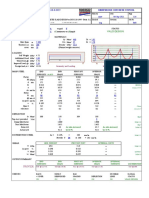

PILE PROFILE AND PILE MODEL

Depth Area E-Modulus Spec. Weight Perim.

m cm2 tons/cm2 tons/m3 m

0.0 1570.8 351.5 2.403 1.88

16.5 1570.8 351.5 2.403 1.88

Toe Area 2827.4 cm2

Top Segment Length 1.03 m, Top Impedance 146 tons/m/s

Wave Speed: Pile Top 3787.8, Elastic 3787.8, Overall 3787.8 m/s

Page 3 Analysis: 25-Apr-2022

LOTTE LINE PROJECT WIKA BETON; Pile: WP1 - A2-2 Test: 09-Apr-2022 09:18

SPUN PILE D 60 DD 65; Blow: 11 CAPWAP(R) 2014-3

Megah Adhi Karya OP: Marcho

Pile Damping 2.00 %, Time Incr 0.272 ms, 2L/c 8.7 ms

Total volume: 2.592 m3; Volume ratio considering added impedance: 1.000

Page 4 Analysis: 25-Apr-2022

You might also like

- F To G: 1 To 2: Spreadsheets To BS 8110 & EC2Document4 pagesF To G: 1 To 2: Spreadsheets To BS 8110 & EC2Mohammed ElemamNo ratings yet

- Ralco R302 Collimator Service ManualDocument173 pagesRalco R302 Collimator Service ManualMadhavesh KulkarniNo ratings yet

- Retaining Wall DesignDocument21 pagesRetaining Wall DesignkaushikNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Design of Isolated Footing With Vertical Load Only - According To ACI 318M-99Document1 pageDesign of Isolated Footing With Vertical Load Only - According To ACI 318M-99mahmoud IbrahemNo ratings yet

- Handbook of Heating, Ventilating and Air ConditioningFrom EverandHandbook of Heating, Ventilating and Air ConditioningRating: 4 out of 5 stars4/5 (6)

- Thierry Bardini - BootstrappingDocument324 pagesThierry Bardini - Bootstrappingh0ry0% (1)

- BridgeDocument8 pagesBridgeTuklal Chaudhary100% (1)

- Software Architecture Document TemplateDocument13 pagesSoftware Architecture Document TemplateJaruhi ウェイ100% (2)

- Roland Vs 640 Mechanical DrawingDocument40 pagesRoland Vs 640 Mechanical DrawingEdwardo RamirezNo ratings yet

- 1-Way Solid Concrete Slab Design To Bs 81101997 Table 3.12Document7 pages1-Way Solid Concrete Slab Design To Bs 81101997 Table 3.12bunheng lonNo ratings yet

- 13.375 Inch Geoconn 64-QDocument1 page13.375 Inch Geoconn 64-QBalkis FatihaNo ratings yet

- 5 Turbine ProtectionDocument14 pages5 Turbine ProtectionSam100% (4)

- NSW Pump Calculation 26-05-2017-r4Document28 pagesNSW Pump Calculation 26-05-2017-r4Ardian200% (1)

- Huawei GSM Network Energy Saving Solution (For Technical)Document17 pagesHuawei GSM Network Energy Saving Solution (For Technical)c2poyraz100% (2)

- 1-Way Solid Concrete Slab Design To Bs 81101997 Table 3.12Document7 pages1-Way Solid Concrete Slab Design To Bs 81101997 Table 3.12asuncionNo ratings yet

- Robot SafetyDocument80 pagesRobot SafetysoumyakantNo ratings yet

- RCC94 Two-Way Slabs (Tables)Document4 pagesRCC94 Two-Way Slabs (Tables)HAFEELNo ratings yet

- Total Head Calculation 4Document4 pagesTotal Head Calculation 4Herberth Silitonga67% (3)

- WP1 - A4 Restrike CapwapDocument5 pagesWP1 - A4 Restrike CapwapMegah Adhi KaryaNo ratings yet

- Tons Tons: CAPWAP (R) 2014-3 Licensed To PT Teno IndonesiaDocument3 pagesTons Tons: CAPWAP (R) 2014-3 Licensed To PT Teno IndonesiaAdiitPuutraNo ratings yet

- RCC91 One-Way Solid Slabs (Tables)Document7 pagesRCC91 One-Way Solid Slabs (Tables)RalfNo ratings yet

- RCC94 Two Way Slabs (Tables) MCY RF CTDocument1 pageRCC94 Two Way Slabs (Tables) MCY RF CTYati ChanNo ratings yet

- F To G: 1 To 2: Spreadsheets To BS 8110 & EC2Document1 pageF To G: 1 To 2: Spreadsheets To BS 8110 & EC2Yasiri LucNo ratings yet

- PDA TestDocument11 pagesPDA TestGeorgeshua ZekonNo ratings yet

- RCC91 One-Way Solid Slabs (Tables)Document7 pagesRCC91 One-Way Solid Slabs (Tables)ery achjariNo ratings yet

- Load Bearing Capacity Test/ Yük Taşima Kapasitesi TestiDocument44 pagesLoad Bearing Capacity Test/ Yük Taşima Kapasitesi TestiKaan TekinturhanNo ratings yet

- Cke900 SpecDocument4 pagesCke900 Spechero dirgantoroNo ratings yet

- Flow Sheet Line-3 1 To 25 PagesDocument25 pagesFlow Sheet Line-3 1 To 25 PagesUsman MazherNo ratings yet

- KN KN: GDT Pile: P107-1 1500 Blow: 1 (Test: 09-May-2021 09:16:) 14-May-2021 K-Geo Solutions Co., Ltd. CAPWAP (R) 2014-3Document12 pagesKN KN: GDT Pile: P107-1 1500 Blow: 1 (Test: 09-May-2021 09:16:) 14-May-2021 K-Geo Solutions Co., Ltd. CAPWAP (R) 2014-3Sothoan Pro ÐGNo ratings yet

- RCC91 One-Way Solid Slabs (Tables)Document8 pagesRCC91 One-Way Solid Slabs (Tables)Murthy GunaNo ratings yet

- 46 Capwap Jemb Kebun Durian Tahap 1Document14 pages46 Capwap Jemb Kebun Durian Tahap 1fatmaNo ratings yet

- Data PDA & Kalendering ABT 1Document16 pagesData PDA & Kalendering ABT 1fatmaNo ratings yet

- RCC91 One-Way Solid Slabs (Tables)Document8 pagesRCC91 One-Way Solid Slabs (Tables)Mohd Said Mohd ZakariaNo ratings yet

- Technical Specifications Premium 2-7/8" OD Drill Pipe, S-135, WT-23 Conn's. NewDocument2 pagesTechnical Specifications Premium 2-7/8" OD Drill Pipe, S-135, WT-23 Conn's. NewAboozar FathinejadNo ratings yet

- 1-WAY SOLID CONCRETE SLAB DESIGN To BS 81101997 Table 3.12Document7 pages1-WAY SOLID CONCRETE SLAB DESIGN To BS 81101997 Table 3.12Tamer. ThekingNo ratings yet

- Qdrain C15 65 14F Eng 1Document1 pageQdrain C15 65 14F Eng 1Thameem SharaafNo ratings yet

- Analisa Harga Sat.Document55 pagesAnalisa Harga Sat.hendrikzainudinNo ratings yet

- Hydraulic Crawler Crane: S P E C I F I C A T I O N SDocument4 pagesHydraulic Crawler Crane: S P E C I F I C A T I O N SwircexdjNo ratings yet

- RCC94 Two Way Slabs (Tables) MCY 1f ChillerDocument1 pageRCC94 Two Way Slabs (Tables) MCY 1f ChillerYati ChanNo ratings yet

- 6.... 100x80 FS HCA (37 KW)Document5 pages6.... 100x80 FS HCA (37 KW)tinhNo ratings yet

- RCC94 Two-Way Slabs (Tables)Document5 pagesRCC94 Two-Way Slabs (Tables)thusiNo ratings yet

- Mat TrueDocument1 pageMat TrueIsma IssyNo ratings yet

- UN3C-T 3M 40-160. 4.0 Booster Pump CatalogueDocument16 pagesUN3C-T 3M 40-160. 4.0 Booster Pump CatalogueFILID MADNo ratings yet

- Hydraulic Crawler Crane: S P E C I F I C A T I O N SDocument4 pagesHydraulic Crawler Crane: S P E C I F I C A T I O N SsquakeNo ratings yet

- SIGUIL-VETM-F-TEC-AWWA0-001-R1 11/19/2019 - 3:27 PM Page 1 of 1 Form: FRP-AWWA-M45-R3Document1 pageSIGUIL-VETM-F-TEC-AWWA0-001-R1 11/19/2019 - 3:27 PM Page 1 of 1 Form: FRP-AWWA-M45-R3gojiNo ratings yet

- CARAT 220 Compact: Injection Unit Hydraulic SystemDocument2 pagesCARAT 220 Compact: Injection Unit Hydraulic System黄学文No ratings yet

- Isolated-Tappered With Actual SurchargeDocument1 pageIsolated-Tappered With Actual SurchargeAnil kumar RNo ratings yet

- Isolated Footing With Actual SurchargeDocument1 pageIsolated Footing With Actual SurchargeZaidNo ratings yet

- Qdrain C15 65 12P Eng 1Document1 pageQdrain C15 65 12P Eng 1Thameem SharaafNo ratings yet

- Isolated Footing DesignDocument8 pagesIsolated Footing DesignSuson DhitalNo ratings yet

- 10 M750 H18 V8 2х1 M LC 52 20x5Document1 page10 M750 H18 V8 2х1 M LC 52 20x5Neil De La Cruz CarlosNo ratings yet

- Spreadsheets To BS 8110 & EC2: Advisory Group 8rd Floor Slab RMW 13-Dec-2018 160 CHG - R68 A F CDocument6 pagesSpreadsheets To BS 8110 & EC2: Advisory Group 8rd Floor Slab RMW 13-Dec-2018 160 CHG - R68 A F CMohammad Twaha JaumbocusNo ratings yet

- RUBENSDocument2 pagesRUBENSAriel Castellanos MacGregorNo ratings yet

- PDF Installation Minimum Straight Section Between Curves A - CompressDocument2 pagesPDF Installation Minimum Straight Section Between Curves A - CompressJamie RichardsNo ratings yet

- Appendix 3 30m RC Box-Girder DesignDocument21 pagesAppendix 3 30m RC Box-Girder DesignebsiNo ratings yet

- Spreadsheets To BS 8110 & EC2: Advisory Group 8rd Floor Slab RMW 16-Aug-2014 116Document1 pageSpreadsheets To BS 8110 & EC2: Advisory Group 8rd Floor Slab RMW 16-Aug-2014 116mathewsujith31No ratings yet

- Qdrain C15 65 10F Eng 1Document1 pageQdrain C15 65 10F Eng 1Thameem SharaafNo ratings yet

- Spreadsheets To BS 8110 & EC2: Advisory Group 8rd Floor Slab RMW 20-Nov-2019 116 CHG - R68 A F CDocument7 pagesSpreadsheets To BS 8110 & EC2: Advisory Group 8rd Floor Slab RMW 20-Nov-2019 116 CHG - R68 A F CKhan EngrNo ratings yet

- F To G: 1 To 2: Spreadsheets To BS 8110 & EC2Document4 pagesF To G: 1 To 2: Spreadsheets To BS 8110 & EC2JigarNo ratings yet

- Sammy Kamau Njunguna-1Document7 pagesSammy Kamau Njunguna-1NewtonNo ratings yet

- Pole CalcDocument11 pagesPole CalcMia SaquingNo ratings yet

- RCC DesignDocument12 pagesRCC DesignRmesh jhaNo ratings yet

- Qdrain C20 65 10F EngDocument1 pageQdrain C20 65 10F EngThameem SharaafNo ratings yet

- SRT/2020-21/11/29 To. M/S Deputy Director Research Lab: Punjab PWD (B&R) PatialaDocument4 pagesSRT/2020-21/11/29 To. M/S Deputy Director Research Lab: Punjab PWD (B&R) PatialaAyush GoyalNo ratings yet

- D75KXDocument28 pagesD75KXDiego Duran MolinaNo ratings yet

- Enerparc - India - Company Profile - September 23Document15 pagesEnerparc - India - Company Profile - September 23AlokNo ratings yet

- Major Department Code Course Title Prerequisites Trimester Course Description: Credit Hours (Hour/week) L Contact Hours (Hour/week) WDocument7 pagesMajor Department Code Course Title Prerequisites Trimester Course Description: Credit Hours (Hour/week) L Contact Hours (Hour/week) Wyash1239No ratings yet

- 3m Filtrete Fap 04 SeriesDocument10 pages3m Filtrete Fap 04 SeriesJP anonymousNo ratings yet

- Apple Inc .: Done By: Yara Jubran Mohammad Eriqat Hussam Salahat Supervised By: Dr. Lutfi JibriniDocument9 pagesApple Inc .: Done By: Yara Jubran Mohammad Eriqat Hussam Salahat Supervised By: Dr. Lutfi JibriniYara RaedNo ratings yet

- Lovehatethings 2008Document107 pagesLovehatethings 2008Anthony MarcoNo ratings yet

- Iso 683-17-2014-10Document30 pagesIso 683-17-2014-10ashav patel100% (1)

- Presentation ZZZZ JJJJ 8-2011Document125 pagesPresentation ZZZZ JJJJ 8-2011jjarrett96No ratings yet

- Session 3 - Track 7 - Wireless Charging PDFDocument37 pagesSession 3 - Track 7 - Wireless Charging PDFPraveen KumarNo ratings yet

- Creative Designer - JDDocument4 pagesCreative Designer - JDJoel SadhanandNo ratings yet

- Resistors: Take A Stance, The Resist StanceDocument35 pagesResistors: Take A Stance, The Resist Stancepavan pujarNo ratings yet

- APL V80 SP2-Readme enDocument16 pagesAPL V80 SP2-Readme enGrant DouglasNo ratings yet

- Plenty of Room - Nnano.2009.356Document1 pagePlenty of Room - Nnano.2009.356Mario PgNo ratings yet

- Computerized Support Systems in Nuclear Power Plants: IAEA-TECDOC-912Document190 pagesComputerized Support Systems in Nuclear Power Plants: IAEA-TECDOC-912jermNo ratings yet

- BuiltIn Proactive Services List - 05 - 12 - 2020Document20 pagesBuiltIn Proactive Services List - 05 - 12 - 2020oorhan41No ratings yet

- Cs Aip Class 10th Boys GroupDocument24 pagesCs Aip Class 10th Boys GroupMahafuj DudhaknojNo ratings yet

- High Performance Cleanrooms - Cleanroom Design Guide - January 2006Document48 pagesHigh Performance Cleanrooms - Cleanroom Design Guide - January 2006Hubert BonamisNo ratings yet

- The Logistics and Supply Chain Innovation Handbook... - (Contents)Document5 pagesThe Logistics and Supply Chain Innovation Handbook... - (Contents)Michelle LieNo ratings yet

- Sr. Devops Engineer Job SampleDocument2 pagesSr. Devops Engineer Job SampleSannithiBalajiNo ratings yet

- Beckhoff Twincat ManualDocument38 pagesBeckhoff Twincat ManualMichael LazzariNo ratings yet

- U18 Hall Sensor FanDocument6 pagesU18 Hall Sensor FanscribdxtestxNo ratings yet

- Advt No.: HSCC/RECT/2019/2: 1 (A) EXECUTIVE ASSISTANT ENGINEER (Civil/Electrical/Mechanical)Document9 pagesAdvt No.: HSCC/RECT/2019/2: 1 (A) EXECUTIVE ASSISTANT ENGINEER (Civil/Electrical/Mechanical)jitu brarNo ratings yet