Professional Documents

Culture Documents

Measurements of Particle Size Distributions (PSD) of Tipo 061 CAE PLUS Lote ML 17-0240 Tipo 061 CFR ML 16-0040 (B) Tipo MMF RA 17-1552

Uploaded by

Miguel RomanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Measurements of Particle Size Distributions (PSD) of Tipo 061 CAE PLUS Lote ML 17-0240 Tipo 061 CFR ML 16-0040 (B) Tipo MMF RA 17-1552

Uploaded by

Miguel RomanCopyright:

Available Formats

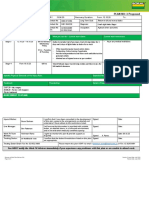

Measurements of

particle size distributions

(psd)

of

Tipo 061 CAE PLUS Lote ML 17-0240

Tipo 061 CFR ML 16-0040 (B)

Tipo MMF RA 17-1552

Analysis Report

CLARIMEX

MX - Atilaquia

NO. 170 999

© 2014, Sympatec GmbH, System-Partikel-Technik,

Am Pulverhaus 1, D-38678 Clausthal-Zellerfeld, Germany

Analysis Report 170 999

CLARIMEX

Page / of 2 / 33

Contents

I. Summary _____________________________________________ 3

Introduction ____________________________________________ 3

Measurement details _____________________________________ 3

Evaluation _____________________________________________ 4

Particle size distribution __________________________________ 5

Conclusion _____________________________________________ 7

II. Detailed documentation of results _________________________ 8

Tipo 061 CAE PLUS Lote ML 17-0240 ______________________ 9

Tipo 061 CFR ML 16-0040 (B)____________________________ 15

Tipo MMF RA 17-1552__________________________________ 22

III. Appendix_____________________________________________ 26

A. General terms ______________________________________ 26

B. HELOS terms ______________________________________ 33

© 2014, Sympatec GmbH, System-Partikel-Technik,

Am Pulverhaus 1, D-38678 Clausthal-Zellerfeld, Deutschland

Analysis Report 170 999

CLARIMEX

Page / of 3 / 33

I. Summary

Introduction

This report contains the results of the analyses of the particle size distributions (psd) performed

with the HELOS laser diffraction analyser for the following samples

Tipo 061 CAE PLUS Lote ML 17-0240

Tipo 061 CFR ML 16-0040 (B)

Tipo MMF RA 17-1552.

With this section a summarising and commenting survey about the measurements and results is

given. In addition to the information about the characteristic values of the distributions the mean

values of the particle size distributions are shown as cumulative curves Q3(x) and density

distribution curves q3lg. The detailed measurement procedure and the analyses results shown in

tabular form and as plots of the Q3(x) and q3lg curves are documented in section II. For all samples

the results of the single measurements as well as the statistical evaluation are presented. The

nomenclature and the graphical presentation used in this report are in accordance with ISO 9276

(refer to section III).

Measurement details

For the analysis the following range modules of the HELOS sensor were chosen:

measuring range f / mm xMb / µm

R3 100 0.5/0.9 – 175.0

R5 500 0.5/4.5 – 875.0

table I-1: Chosen measuring range: f - focal length; xMb - size range of particles that can be

detected by a measuring range (xu/xo of smallest size class, xo of largest size class)

In order to capture the entire spectrum of the broadly distributed samples a combination of the data

measured with different focal distances was necessary.

As dispersing system the dry dispersing system RODOS was applied.

© 2014, Sympatec GmbH, System-Partikel-Technik,

Am Pulverhaus 1, D-38678 Clausthal-Zellerfeld, Deutschland

Analysis Report 170 999

CLARIMEX

Page / of 4 / 33

The sample material for the analyses was taken with a spatula out of the delivered container which

was shaken thoroughly to ensure homogenisation.

The samples were measured several times to show the repeatability of the HELOS system and to

prove the quality of the sampling and dispersing technique applied. Three partial samples were

measured once each. The tables with the statistical evaluation in section II contain also the

calculated mean value of the cumulative distribution Q3(x) as well as the standard deviation. The

maximum of less than 1.00 % standard deviation measured in one class proves the high

repeatability claimed for the Sympatec HELOS system.

Evaluation

For evaluation of the measured data the Fraunhofer theory was used in form of the Sympatec

evaluation mode HRLD. Here the diffraction of the light is assumed to be the dominant interaction

between the particles and the laser light. This assumption is valid for opaque particles in the

micron range and coarser in general. Only in the sub-micron range and/or for transparent particles

other physical interactions between the particles and the laser light (refraction, reflection,

absorption) are also relevant. These effects are taken into account in the Mie theory where optical

information of the particle material (complex index of refraction) is mandatory.

From the analyses by laser diffraction also the volume-specific surface Sv of the particle material

can be calculated. For this calculation the value of the Heywood shape factor fH of the samples is

necessary. With the correct value of the density ρ of the material the mass specific area Sm can be

calculated from the volume related surface area Sv. In this case density and shape factor of the

samples are unknown and therefore set to 1.0.

© 2014, Sympatec GmbH, System-Partikel-Technik,

Am Pulverhaus 1, D-38678 Clausthal-Zellerfeld, Deutschland

Analysis Report 170 999

CLARIMEX

Page / of 5 / 33

Particle size distribution

Characteristic values (x10, x50 and x90) of the measured particle size distributions of all samples are

presented in table I-2 as well as a description of the density distribution curves kq3lg:

Sample x10 / µm x50 / µm x90 / µm kq3lg

Tipo 061 CAE PLUS Lote ML 17-0240 3.22 19.73 47.54 monomodal

Tipo 061 CFR ML 16-0040 (B) 6.76 42.86 184.43 monomodal

Tipo MMF RA 17-1552 4.12 22.64 58.12 monomodal

table I-2: Characteristic distribution values of particle size distribution; xQ: size of Q % of total

particle volume; kq3lg: characteristic of density distribution curve q3lg

© 2014, Sympatec GmbH, System-Partikel-Technik,

Am Pulverhaus 1, D-38678 Clausthal-Zellerfeld, Deutschland

Analysis Report 170 999

CLARIMEX

Page / of 6 / 33

The next two diagrams illustrate the particle size distribution.

100

90 CLARIMEX

Dispersing system: RODOS

Cumulative distribution Q3(x) / %

80 Focal distance: f = 100 & 500 mm

70 Tipo 061 CAE Plus ML 17-0240

Tipo 061 CFR ML 16-0040 (B)

60 Tipo MMF RA 17-1552

50

40

30

20

10

0

0.5 1 5 10 50 100 500

Particle size / µm

figure I-1: Cumulative particle size distribution curve Q3 in %

1.2

1.1

CLARIMEX

1.0

Dispersing system: RODOS

0.9 Focal distance: f = 100 & 500 mm

Density distribution q3lg

Tipo 061 CAE Plus ML 17-0240

0.8

Tipo 061 CFR ML 16-0040 (B)

0.7 Tipo MMF RA 17-1552

0.6

0.5

0.4

0.3

0.2

0.1

0

0.5 1 5 10 50 100 500

Particle size / µm

figure I-2: Density distribution curve q3lg(x)

© 2014, Sympatec GmbH, System-Partikel-Technik,

Am Pulverhaus 1, D-38678 Clausthal-Zellerfeld, Deutschland

Analysis Report 170 999

CLARIMEX

Page / of 7 / 33

Conclusion

As a consequence of the results we can state, that the HELOS system can be advised for the

measured samples without any restrictions.

Mexico-City, July 11th 2017

Kay Mootz

Sales Manager Americas

© 2014, Sympatec GmbH, System-Partikel-Technik,

Am Pulverhaus 1, D-38678 Clausthal-Zellerfeld, Deutschland

Analysis Report 170 999

CLARIMEX

Page / of 8 / 33

II. Detailed documentation of results

Tipo 061 CAE PLUS Lote ML 17-0240

Tipo 061 CFR ML 16-0040 (B)

Tipo MMF RA 17-1552

© 2014, Sympatec GmbH, System-Partikel-Technik,

Am Pulverhaus 1, D-38678 Clausthal-Zellerfeld, Deutschland

Analysis Report 170 999

CLARIMEX

Page / of 9 / 33

Results of the sample

Tipo 061 CAE PLUS Lote ML 17-0240

© 2014, Sympatec GmbH, System-Partikel-Technik,

Am Pulverhaus 1, D-38678 Clausthal-Zellerfeld, Deutschland

Analysis Report 170 999

CLARIMEX

Page / of 10 / 33

MEASUREMENT SPECIFICATION

Product name : Tipo 061 CAE PLUS Lote ML 17-0240

_____________________________________________________________________

Sample preparation : no sample splitting

_____________________________________________________________________

Sensor : HELOS

Dispersing method : RODOS

Measuring range HELOS : R3: 0.5/0.9...175µm (f = 100.00 mm)

Dispersing system : RODOST4

Mass requirement : 6/20/17

Start condition of measurement : c.opt >= 1%

Stop condition of measurement : 5s c.opt <= 1% or 20s real time

Time base : 100.00 ms

Measuring time : 0.90 s (0.75 s - 1.05 s)

Optical concentration : 5.73 % (2.79 % - 8.66 %)

Feed rate VIBRI : 50.00 %

Funnel height : 2.00 mm

Inner diameter of the

injector line : 4.00 mm

Product supply : funnel

Pressure setting : 0.99 bar

Number of measured

partial samples : 2

Measurements per partial sample : 1

HELOS evaluation mode : HRLD

_____________________________________________________________________

Documentation of measured results (following pages)

© 2014, Sympatec GmbH, System-Partikel-Technik,

Am Pulverhaus 1, D-38678 Clausthal-Zellerfeld, Deutschland

Analysis Report 170 999

CLARIMEX

Page / of 11 / 33

Statistical evaluation of analytical data

HELOS (H1490) & RODOST4, R3: 0.5/0.9...175µm (f = 100.00 mm)

Product: Tipo 061 CAE PLUS Lote ML 17-0240 Evaluation:

density: 2.71 g/cm³ evaluation mode: HRLD (5.10.0.0)

shape factor: 1.00 contamination: 0.00 %

sample number:

Measuring condition: standard dry Dispersing method: 1 bar

start condition: c.opt >= 1% doser: VIBRI

stop condition: 5s c.opt <= 1% or 20s real time pressure: 0.99 bar

time base: 100.00 ms vacuum: 39.00 mbar

measuring duration: 0.90 (0.75 - 1.05) s feed rate: 50.00 %

opt. concentration: 5.73 (2.79 - 8.66) % gap width: 2.00 mm

revolution: 0.00 %

inner diameter of injector line: 4.00 mm

Preparation: Customer: MC17F92201/202

sample splitting: T.SCRUGGS

amount of sample: 6/20/17 operator:

additional info: database: Clarimex HELOS

Measurements: Identifiers:

2017-07-10 17:54:42.6410 1490 H 9

2017-07-10 17:52:00.6420 1490 H 8

upper pct. under standard in band mean size distribution

band limit cumulative deviation different for band (log) density (log)

x0 [µm] Q3 [%] abs. [%] dQ3 [%] xm [µm] q3*

0.90 1.72 0.0084 1.72 0.67 0.07

1.10 2.52 0.0179 0.80 0.99 0.09

1.30 3.30 0.0308 0.78 1.20 0.11

1.50 4.07 0.0466 0.77 1.40 0.12

1.80 5.19 0.0740 1.12 1.64 0.14

2.20 6.63 0.1147 1.44 1.99 0.16

2.60 8.00 0.1573 1.37 2.39 0.19

3.10 9.63 0.2095 1.63 2.84 0.21

3.70 11.49 0.2670 1.86 3.39 0.24

4.30 13.27 0.3158 1.78 3.99 0.27

5.00 15.29 0.3607 2.01 4.64 0.31

6.00 18.08 0.4043 2.79 5.48 0.35

7.50 22.13 0.4353 4.05 6.71 0.42

9.00 25.96 0.4372 3.84 8.22 0.48

10.50 29.58 0.4202 3.62 9.72 0.54

12.50 34.20 0.3788 4.62 11.46 0.61

15.00 39.82 0.3054 5.62 13.69 0.71

18.00 46.39 0.1986 6.57 16.43 0.83

21.00 52.64 0.0802 6.26 19.44 0.94

25.00 60.48 0.0811 7.84 22.91 1.03

30.00 69.32 0.2593 8.84 27.39 1.12

36.00 78.32 0.4044 9.00 32.86 1.14

43.00 86.46 0.4635 8.14 39.34 1.06

51.00 92.70 0.4198 6.24 46.83 0.84

61.00 97.01 0.2859 4.31 55.78 0.55

73.00 99.22 0.1127 2.21 66.73 0.28

87.00 100.00 0.0000 0.78 79.69 0.10

103.00 100.00 0.0000 0.00 94.66 0.00

123.00 100.00 0.0000 0.00 112.56 0.00

147.00 100.00 0.0000 0.00 134.47 0.00

175.00 100.00 0.0000 0.00 160.39 0.00

x10 = 3.22 µm +/- 0.07 µm x50 = 19.73 µm +/- 0.06 µm x90 = 47.54 µm +/- 0.56 µm

x16 = 5.26 µm +/- 0.13 µm x80 = 37.45 µm +/- 0.36 µm x99 = 71.80 µm +/- 0.71 µm

Q1 = 2.12 % +/- 0.01 % Q38 = 80.65 % +/- 0.42 % Q45 = 88.02 % +/- 0.45 %

© 2014, Sympatec GmbH, System-Partikel-Technik,

Am Pulverhaus 1, D-38678 Clausthal-Zellerfeld, Deutschland

Analysis Report 170 999

CLARIMEX

Page / of 12 / 33

Measurement 9

HELOS (H1490) & RODOST4, R3: 0.5/0.9...175µm (f = 100 mm)

Product: Tipo 061 CAE PLUS Lote ML 17-0240 Evaluation:

density: 2.71 g/cm³ evaluation mode: HRLD (5.10.0.0)

shape factor: 1.00 contamination: 0.00 %

sample number: reference measurement: 07-10 17:54:24

Measuring condition: standard dry Dispersing method: 1 bar

start condition: c.opt >= 1% doser: VIBRI

stop condition: 5s c.opt <= 1% or 20s real time pressure: 0.99 bar

time base: 100.00 ms vacuum: 39.00 mbar

measuring duration: 0.75 s feed rate: 50.00 %

opt. concentration: 8.66 % gap width: 2.00 mm

revolution: 0.00 %

inner diameter of injector line: 4 mm

Preparation: Customer: MC17F92201/202

sample splitting: T.SCRUGGS measurement: 2017-07-10 17:54:42.6410 1490 H

amount of sample: 6/20/17 operator:

additional info: database: Clarimex HELOS

upper pct. under pct. over in band mean size distribution mean size density pct.

band limit cumulative cumulative different for band (lin) (linear) for band (log) (logarithm.)

x0 [µm] Q3 [%] (1-Q3) [%] dQ3 [%] xm [µm] q3 [1/mm] xm [µm] q3*

0.90 1.73 98.27 1.73 0.70 43.23 0.67 0.07

1.10 2.53 97.47 0.80 1.00 40.22 0.99 0.09

1.30 3.33 96.67 0.79 1.20 39.63 1.20 0.11

1.50 4.10 95.90 0.78 1.40 38.90 1.40 0.13

1.80 5.24 94.76 1.14 1.65 37.96 1.64 0.14

2.20 6.71 93.29 1.46 2.00 36.61 1.99 0.17

2.60 8.11 91.89 1.40 2.40 34.99 2.39 0.19

3.10 9.78 90.22 1.67 2.85 33.36 2.84 0.22

3.70 11.68 88.32 1.90 3.40 31.71 3.39 0.25

4.30 13.50 86.50 1.82 4.00 30.30 3.99 0.28

5.00 15.54 84.46 2.05 4.65 29.23 4.64 0.31

6.00 18.37 81.63 2.83 5.50 28.25 5.48 0.36

7.50 22.43 77.57 4.07 6.75 27.11 6.71 0.42

9.00 26.27 73.73 3.84 8.25 25.58 8.22 0.48

10.50 29.88 70.12 3.61 9.75 24.05 9.72 0.54

12.50 34.47 65.53 4.59 11.50 22.93 11.46 0.61

15.00 40.04 59.96 5.57 13.75 22.28 13.69 0.70

18.00 46.53 53.47 6.49 16.50 21.63 16.43 0.82

21.00 52.70 47.30 6.18 19.50 20.59 19.44 0.92

25.00 60.42 39.58 7.72 23.00 19.31 22.91 1.02

30.00 69.14 30.86 8.71 27.50 17.42 27.39 1.10

36.00 78.03 21.97 8.90 33.00 14.83 32.86 1.12

43.00 86.13 13.87 8.10 39.50 11.57 39.34 1.05

51.00 92.40 7.60 6.27 47.00 7.83 46.83 0.85

61.00 96.81 3.19 4.41 56.00 4.41 55.78 0.57

73.00 99.14 0.86 2.33 67.00 1.94 66.73 0.30

87.00 100.00 0.00 0.86 80.00 0.62 79.69 0.11

103.00 100.00 0.00 0.00 95.00 0.00 94.66 0.00

123.00 100.00 0.00 0.00 113.00 0.00 112.56 0.00

147.00 100.00 0.00 0.00 135.00 0.00 134.47 0.00

175.00 100.00 0.00 0.00 161.00 0.00 160.39 0.00

x10 = 3.17 µm x50 = 19.69 µm x90 = 47.94 µm SMD = 7.47 µm VMD= 23.04 µm

x16 = 5.16 µm x80 = 37.70 µm x99 = 72.30 µm SV = 0.8 m²/cm³ Sm = 3e+03 cm²/g

Q1 = 2.13 % Q38 = 80.35 % Q45 = 87.70 %

© 2014, Sympatec GmbH, System-Partikel-Technik,

Am Pulverhaus 1, D-38678 Clausthal-Zellerfeld, Deutschland

Analysis Report 170 999

CLARIMEX

Page / of 13 / 33

Measurement 8

HELOS (H1490) & RODOST4, R3: 0.5/0.9...175µm (f = 100 mm)

Product: Tipo 061 CAE PLUS Lote ML 17-0240 Evaluation:

density: 2.71 g/cm³ evaluation mode: HRLD (5.10.0.0)

shape factor: 1.00 contamination: 0.00 %

sample number: reference measurement: 07-10 17:51:42

Measuring condition: standard dry Dispersing method: 1 bar

start condition: c.opt >= 1% doser: VIBRI

stop condition: 5s c.opt <= 1% or 20s real time pressure: 1.00 bar

time base: 100.00 ms vacuum: 39.00 mbar

measuring duration: 1.05 s feed rate: 50.00 %

opt. concentration: 2.79 % gap width: 2.00 mm

revolution: 0.00 %

inner diameter of injector line: 4 mm

Preparation: Customer: MC17F92201/202

sample splitting: T.SCRUGGS measurement: 2017-07-10 17:52:00.6420 1490 H

amount of sample: 6/20/17 operator:

additional info: database: Clarimex HELOS

upper pct. under pct. over in band mean size distribution mean size density pct.

band limit cumulative cumulative different for band (lin) (linear) for band (log) (logarithm.)

x0 [µm] Q3 [%] (1-Q3) [%] dQ3 [%] xm [µm] q3 [1/mm] xm [µm] q3*

0.90 1.72 98.28 1.72 0.70 42.93 0.67 0.07

1.10 2.51 97.49 0.79 1.00 39.54 0.99 0.09

1.30 3.28 96.72 0.77 1.20 38.71 1.20 0.11

1.50 4.04 95.96 0.76 1.40 37.79 1.40 0.12

1.80 5.14 94.86 1.10 1.65 36.67 1.64 0.14

2.20 6.55 93.45 1.41 2.00 35.17 1.99 0.16

2.60 7.88 92.12 1.34 2.40 33.48 2.39 0.18

3.10 9.48 90.52 1.59 2.85 31.88 2.84 0.21

3.70 11.30 88.70 1.82 3.40 30.36 3.39 0.24

4.30 13.05 86.95 1.75 4.00 29.15 3.99 0.27

5.00 15.03 84.97 1.98 4.65 28.32 4.64 0.30

6.00 17.80 82.20 2.76 5.50 27.63 5.48 0.35

7.50 21.82 78.18 4.02 6.75 26.82 6.71 0.42

9.00 25.65 74.35 3.83 8.25 25.57 8.22 0.48

10.50 29.28 70.72 3.63 9.75 24.21 9.72 0.54

12.50 33.93 66.07 4.65 11.50 23.23 11.46 0.61

15.00 39.60 60.40 5.67 13.75 22.69 13.69 0.72

18.00 46.24 53.76 6.64 16.50 22.14 16.43 0.84

21.00 52.59 47.41 6.34 19.50 21.14 19.44 0.95

25.00 60.54 39.46 7.95 23.00 19.88 22.91 1.05

30.00 69.50 30.50 8.96 27.50 17.93 27.39 1.13

36.00 78.60 21.40 9.10 33.00 15.17 32.86 1.15

43.00 86.79 13.21 8.18 39.50 11.69 39.34 1.06

51.00 92.99 7.01 6.20 47.00 7.76 46.83 0.84

61.00 97.21 2.79 4.22 56.00 4.22 55.78 0.54

73.00 99.30 0.70 2.09 67.00 1.74 66.73 0.27

87.00 100.00 0.00 0.70 80.00 0.50 79.69 0.09

103.00 100.00 0.00 0.00 95.00 0.00 94.66 0.00

123.00 100.00 0.00 0.00 113.00 0.00 112.56 0.00

147.00 100.00 0.00 0.00 135.00 0.00 134.47 0.00

175.00 100.00 0.00 0.00 161.00 0.00 160.39 0.00

x10 = 3.27 µm x50 = 19.78 µm x90 = 47.14 µm SMD = 7.58 µm VMD= 22.90 µm

x16 = 5.35 µm x80 = 37.19 µm x99 = 71.30 µm SV = 0.79 m²/cm³ Sm = 2.9e+03 cm²/g

Q1 = 2.11 % Q38 = 80.94 % Q45 = 88.34 %

© 2014, Sympatec GmbH, System-Partikel-Technik,

Am Pulverhaus 1, D-38678 Clausthal-Zellerfeld, Deutschland

Analysis Report 170 999

CLARIMEX

Page / of 14 / 33

Graphical presentation of repeat analyses

Identifier Dispersing system Measuring range Evaluation

9 RODOST4 R3: 0.5/0.9...175µm HRLD

8 RODOST4 R3: 0.5/0.9...175µm HRLD

100 1.20

95 1.15

1.10

90

1.05

85

1.00

80 0.95

75 0.90

70 0.85

0.80

Cumulative distribution Q3 / %

65

0.75

Density distribution q3*

60

0.70

55 0.65

50 0.60

45 0.55

0.50

40

0.45

35

0.40

30 0.35

25 0.30

20 0.25

0.20

15

0.15

10

0.10

5 0.05

0 0.00

0.4 0.6 0.8 1.0 2 4 6 8 10 20 40 60 80 100 200

Particle size / µm

© 2014, Sympatec GmbH, System-Partikel-Technik,

Am Pulverhaus 1, D-38678 Clausthal-Zellerfeld, Deutschland

Analysis Report 170 999

CLARIMEX

Page / of 15 / 33

Results of the sample

Tipo 061 CFR ML 16-0040 (B)

© 2014, Sympatec GmbH, System-Partikel-Technik,

Am Pulverhaus 1, D-38678 Clausthal-Zellerfeld, Deutschland

Analysis Report 170 999

CLARIMEX

Page / of 16 / 33

MEASUREMENT SPECIFICATION

Product name : Tipo 061 CFR ML 16-0040 (B)

_____________________________________________________________________

Sample preparation : no sample splitting

_____________________________________________________________________

Sensor : HELOS

Dispersing method : RODOS

Measuring range HELOS : R5: 0.5/4.5...875µm (f = 500.00 mm)

Dispersing system : RODOST4

Mass requirement : 6/20/17

Start condition of measurement : c.opt >= 1%

Stop condition of measurement : 5s c.opt <= 1% or 20s real time

Time base : 100.00 ms

Measuring time : 2.05 s (1.26 s - 2.52 s)

Optical concentration : 10.67 % (5.38 % - 14.91 %)

Feed rate VIBRI : 50.00 %

Funnel height : 2.00 mm

Inner diameter of the

injector line : 4.00 mm

Product supply : funnel

Pressure setting : 0.98 bar

Number of measured

partial samples : 1

Measurements per partial sample : 1

HELOS evaluation mode : HRLD

_____________________________________________________________________

Documentation of measured results (following pages)

© 2014, Sympatec GmbH, System-Partikel-Technik,

Am Pulverhaus 1, D-38678 Clausthal-Zellerfeld, Deutschland

Analysis Report 170 999

CLARIMEX

Page / of 17 / 33

Statistical evaluation of analytical data

HELOS (H1490) & RODOST4, R5: 0.5/4.5...875µm (f = 500.00 mm)

Product: Tipo 061 CFR ML 16-0040 (B) Evaluation:

density: 2.71 g/cm³ evaluation mode: HRLD (5.10.0.0)

shape factor: 1.00 contamination: 0.00 %

sample number:

Measuring condition: standard dry Dispersing method: 1 bar

start condition: c.opt >= 1% doser: VIBRI

stop condition: 5s c.opt <= 1% or 20s real time pressure: 0.98 bar

time base: 100.00 ms vacuum: 38.00 mbar

measuring duration: 2.05 (1.26 - 2.52) s feed rate: 50.00 %

opt. concentration: 10.67 (5.38 - 14.91) % gap width: 2.00 mm

revolution: 0.00 %

inner diameter of injector line: 4.00 mm

Preparation: Customer: MC17F92201/202

sample splitting: T.SCRUGGS

amount of sample: 6/20/17 operator:

additional info: database: Clarimex HELOS

Measurements: Identifiers:

2017-07-10 18:26:31.2760 1490 H 14

2017-07-10 18:15:07.9120 1490 H 13

2017-07-10 18:03:11.2240 1490 H 11

upper pct. under standard in band mean size distribution

band limit cumulative deviation different for band (log) density (log)

x0 [µm] Q3 [%] abs. [%] dQ3 [%] xm [µm] q3*

4.50 6.56 0.1173 6.56 1.50 0.07

5.50 8.10 0.1391 1.55 4.97 0.18

6.50 9.61 0.1571 1.51 5.98 0.21

7.50 11.09 0.1713 1.48 6.98 0.24

9.00 13.24 0.1864 2.15 8.22 0.27

11.00 16.00 0.1965 2.76 9.95 0.32

13.00 18.66 0.1977 2.66 11.96 0.37

15.50 21.85 0.1894 3.20 14.20 0.42

18.50 25.54 0.1704 3.69 16.93 0.48

21.50 29.09 0.1478 3.55 19.94 0.54

25.00 33.07 0.1239 3.98 23.18 0.61

30.00 38.42 0.1064 5.35 27.39 0.68

37.50 45.62 0.1274 7.20 33.54 0.74

45.00 51.75 0.1793 6.13 41.08 0.77

52.50 56.88 0.2391 5.14 48.61 0.77

62.50 62.53 0.3142 5.65 57.28 0.75

75.00 68.28 0.3893 5.75 68.47 0.73

90.00 73.77 0.4556 5.49 82.16 0.69

105.00 78.01 0.4985 4.24 97.21 0.63

125.00 82.32 0.5222 4.30 114.56 0.57

150.00 86.24 0.5065 3.92 136.93 0.50

180.00 89.62 0.4427 3.38 164.32 0.43

215.00 92.59 0.3564 2.96 196.72 0.38

255.00 95.10 0.2873 2.51 234.15 0.34

305.00 97.27 0.2495 2.17 278.88 0.28

365.00 98.92 0.1736 1.65 333.65 0.21

435.00 100.00 0.0000 1.08 398.47 0.14

515.00 100.00 0.0000 0.00 473.31 0.00

615.00 100.00 0.0000 0.00 562.78 0.00

735.00 100.00 0.0000 0.00 672.33 0.00

875.00 100.00 0.0000 0.00 801.95 0.00

x10 = 6.76 µm +/- 0.11 µm x50 = 42.86 µm +/- 0.20 µm x90 = 184.43 µm +/- 4.98 µm

x16 = 11.00 µm +/- 0.15 µm x80 = 114.25 µm +/- 2.37 µm x99 = 370.37 µm +/- 8.91 µm

Q1 = 0.82 % +/- 0.01 % Q38 = 46.03 % +/- 0.13 % Q45 = 51.75 % +/- 0.18 %

© 2014, Sympatec GmbH, System-Partikel-Technik,

Am Pulverhaus 1, D-38678 Clausthal-Zellerfeld, Deutschland

Analysis Report 170 999

CLARIMEX

Page / of 18 / 33

Measurement 14

HELOS (H1490) & RODOST4, R5: 0.5/4.5...875µm (f = 500 mm)

Product: Tipo 061 CFR ML 16-0040 (B) Evaluation:

density: 2.71 g/cm³ evaluation mode: HRLD (5.10.0.0)

shape factor: 1.00 contamination: 0.00 %

sample number: reference measurement: 07-10 18:26:12

Measuring condition: standard dry Dispersing method: 1 bar

start condition: c.opt >= 1% doser: VIBRI

stop condition: 5s c.opt <= 1% or 20s real time pressure: 0.98 bar

time base: 100.00 ms vacuum: 38.00 mbar

measuring duration: 2.52 s feed rate: 50.00 %

opt. concentration: 14.91 % gap width: 2.00 mm

revolution: 0.00 %

inner diameter of injector line: 4 mm

Preparation: Customer: MC17F92201/202

sample splitting: T.SCRUGGS measurement: 2017-07-10 18:26:31.2760 1490 H

amount of sample: 6/20/17 operator:

additional info: database: Clarimex HELOS

upper pct. under pct. over in band mean size distribution mean size density pct.

band limit cumulative cumulative different for band (lin) (linear) for band (log) (logarithm.)

x0 [µm] Q3 [%] (1-Q3) [%] dQ3 [%] xm [µm] q3 [1/mm] xm [µm] q3*

4.50 6.60 93.40 6.60 2.50 16.51 1.50 0.07

5.50 8.16 91.84 1.56 5.00 15.55 4.97 0.18

6.50 9.68 90.32 1.52 6.00 15.19 5.98 0.21

7.50 11.16 88.84 1.48 7.00 14.81 6.98 0.24

9.00 13.31 86.69 2.15 8.25 14.36 8.22 0.27

11.00 16.07 83.93 2.76 10.00 13.80 9.95 0.32

13.00 18.72 81.28 2.65 12.00 13.25 11.96 0.37

15.50 21.91 78.09 3.18 14.25 12.73 14.20 0.42

18.50 25.57 74.43 3.67 17.00 12.22 16.93 0.48

21.50 29.09 70.91 3.52 20.00 11.74 19.94 0.54

25.00 33.04 66.96 3.94 23.25 11.26 23.18 0.60

30.00 38.33 61.67 5.30 27.50 10.60 27.39 0.67

37.50 45.47 54.53 7.14 33.75 9.52 33.54 0.74

45.00 51.55 48.45 6.08 41.25 8.11 41.08 0.77

52.50 56.64 43.36 5.09 48.75 6.79 48.61 0.76

62.50 62.24 37.76 5.59 57.50 5.59 57.28 0.74

75.00 67.93 32.07 5.69 68.75 4.55 68.47 0.72

90.00 73.35 26.65 5.43 82.50 3.62 82.16 0.69

105.00 77.55 22.45 4.20 97.50 2.80 97.21 0.63

125.00 81.83 18.17 4.27 115.00 2.14 114.56 0.56

150.00 85.76 14.24 3.94 137.50 1.57 136.93 0.50

180.00 89.21 10.79 3.45 165.00 1.15 164.32 0.44

215.00 92.26 7.74 3.05 197.50 0.87 196.72 0.39

255.00 94.82 5.18 2.57 235.00 0.64 234.15 0.35

305.00 97.01 2.99 2.19 280.00 0.44 278.88 0.28

365.00 98.74 1.26 1.72 335.00 0.29 333.65 0.22

435.00 100.00 0.00 1.26 400.00 0.18 398.47 0.17

515.00 100.00 0.00 0.00 475.00 0.00 473.31 0.00

615.00 100.00 0.00 0.00 565.00 0.00 562.78 0.00

735.00 100.00 0.00 0.00 675.00 0.00 672.33 0.00

875.00 100.00 0.00 0.00 805.00 0.00 801.95 0.00

x10 = 6.72 µm x50 = 43.09 µm x90 = 189.08 µm SMD = 16.57 µm VMD= 73.48 µm

x16 = 10.95 µm x80 = 116.44 µm x99 = 379.61 µm SV = 0.36 m²/cm³ Sm = 1.3e+03 cm²/g

Q1 = 0.83 % Q38 = 45.88 % Q45 = 51.55 %

© 2014, Sympatec GmbH, System-Partikel-Technik,

Am Pulverhaus 1, D-38678 Clausthal-Zellerfeld, Deutschland

Analysis Report 170 999

CLARIMEX

Page / of 19 / 33

Measurement 13

HELOS (H1490) & RODOST4, R5: 0.5/4.5...875µm (f = 500 mm)

Product: Tipo 061 CFR ML 16-0040 (B) Evaluation:

density: 2.71 g/cm³ evaluation mode: HRLD (5.10.0.0)

shape factor: 1.00 contamination: 0.00 %

sample number: reference measurement: 07-10 18:14:49

Measuring condition: standard dry Dispersing method: 1 bar

start condition: c.opt >= 1% doser: VIBRI

stop condition: 5s c.opt <= 1% or 20s real time pressure: 0.98 bar

time base: 100.00 ms vacuum: 38.00 mbar

measuring duration: 2.37 s feed rate: 50.00 %

opt. concentration: 5.38 % gap width: 2.00 mm

revolution: 0.00 %

inner diameter of injector line: 4 mm

Preparation: Customer: MC17F92201/202

sample splitting: T.SCRUGGS measurement: 2017-07-10 18:15:07.9120 1490 H

amount of sample: 6/20/17 operator:

additional info: database: Clarimex HELOS

upper pct. under pct. over in band mean size distribution mean size density pct.

band limit cumulative cumulative different for band (lin) (linear) for band (log) (logarithm.)

x0 [µm] Q3 [%] (1-Q3) [%] dQ3 [%] xm [µm] q3 [1/mm] xm [µm] q3*

4.50 6.42 93.58 6.42 2.50 16.06 1.50 0.07

5.50 7.94 92.06 1.52 5.00 15.22 4.97 0.17

6.50 9.44 90.56 1.49 6.00 14.92 5.98 0.21

7.50 10.90 89.10 1.46 7.00 14.60 6.98 0.23

9.00 13.03 86.97 2.13 8.25 14.22 8.22 0.27

11.00 15.78 84.22 2.75 10.00 13.74 9.95 0.32

13.00 18.43 81.57 2.66 12.00 13.28 11.96 0.37

15.50 21.64 78.36 3.21 14.25 12.84 14.20 0.42

18.50 25.36 74.64 3.72 17.00 12.39 16.93 0.48

21.50 28.95 71.05 3.59 20.00 11.96 19.94 0.55

25.00 32.97 67.03 4.02 23.25 11.49 23.18 0.61

30.00 38.38 61.62 5.41 27.50 10.83 27.39 0.68

37.50 45.68 54.32 7.30 33.75 9.73 33.54 0.75

45.00 51.90 48.10 6.22 41.25 8.30 41.08 0.79

52.50 57.12 42.88 5.22 48.75 6.96 48.61 0.78

62.50 62.86 37.14 5.74 57.50 5.74 57.28 0.76

75.00 68.70 31.30 5.84 68.75 4.67 68.47 0.74

90.00 74.26 25.74 5.56 82.50 3.70 82.16 0.70

105.00 78.54 21.46 4.29 97.50 2.86 97.21 0.64

125.00 82.87 17.13 4.32 115.00 2.16 114.56 0.57

150.00 86.77 13.23 3.91 137.50 1.56 136.93 0.49

180.00 90.09 9.91 3.32 165.00 1.11 164.32 0.42

215.00 92.96 7.04 2.87 197.50 0.82 196.72 0.37

255.00 95.40 4.60 2.43 235.00 0.61 234.15 0.33

305.00 97.51 2.49 2.12 280.00 0.42 278.88 0.27

365.00 99.08 0.92 1.57 335.00 0.26 333.65 0.20

435.00 100.00 0.00 0.92 400.00 0.13 398.47 0.12

515.00 100.00 0.00 0.00 475.00 0.00 473.31 0.00

615.00 100.00 0.00 0.00 565.00 0.00 562.78 0.00

735.00 100.00 0.00 0.00 675.00 0.00 672.33 0.00

875.00 100.00 0.00 0.00 805.00 0.00 801.95 0.00

x10 = 6.89 µm x50 = 42.71 µm x90 = 179.18 µm SMD = 16.74 µm VMD= 71.14 µm

x16 = 11.17 µm x80 = 111.74 µm x99 = 361.84 µm SV = 0.36 m²/cm³ Sm = 1.3e+03 cm²/g

Q1 = 0.80 % Q38 = 46.09 % Q45 = 51.90 %

© 2014, Sympatec GmbH, System-Partikel-Technik,

Am Pulverhaus 1, D-38678 Clausthal-Zellerfeld, Deutschland

Analysis Report 170 999

CLARIMEX

Page / of 20 / 33

Measurement 11

HELOS (H1490) & RODOST4, R5: 0.5/4.5...875µm (f = 500 mm)

Product: Tipo 061 CFR ML 16-0040 (B) Evaluation:

density: 2.71 g/cm³ evaluation mode: HRLD (5.10.0.0)

shape factor: 1.00 contamination: 0.00 %

sample number: reference measurement: 07-10 18:02:52

Measuring condition: standard dry Dispersing method: 1 bar

start condition: c.opt >= 1% doser: VIBRI

stop condition: 5s c.opt <= 1% or 20s real time pressure: 0.99 bar

time base: 100.00 ms vacuum: 38.00 mbar

measuring duration: 1.26 s feed rate: 50.00 %

opt. concentration: 11.72 % gap width: 2.00 mm

revolution: 0.00 %

inner diameter of injector line: 4 mm

Preparation: Customer: MC17F92201/202

sample splitting: T.SCRUGGS measurement: 2017-07-10 18:03:11.2240 1490 H

amount of sample: 6/20/17 operator:

additional info: database: Clarimex HELOS

upper pct. under pct. over in band mean size distribution mean size density pct.

band limit cumulative cumulative different for band (lin) (linear) for band (log) (logarithm.)

x0 [µm] Q3 [%] (1-Q3) [%] dQ3 [%] xm [µm] q3 [1/mm] xm [µm] q3*

4.50 6.64 93.36 6.64 2.50 16.60 1.50 0.07

5.50 8.20 91.80 1.56 5.00 15.63 4.97 0.18

6.50 9.73 90.27 1.53 6.00 15.26 5.98 0.21

7.50 11.22 88.78 1.49 7.00 14.87 6.98 0.24

9.00 13.38 86.62 2.16 8.25 14.41 8.22 0.27

11.00 16.15 83.85 2.77 10.00 13.85 9.95 0.32

13.00 18.81 81.19 2.66 12.00 13.31 11.96 0.37

15.50 22.01 77.99 3.20 14.25 12.80 14.20 0.42

18.50 25.70 74.30 3.69 17.00 12.29 16.93 0.48

21.50 29.24 70.76 3.55 20.00 11.82 19.94 0.54

25.00 33.21 66.79 3.97 23.25 11.33 23.18 0.61

30.00 38.54 61.46 5.33 27.50 10.66 27.39 0.67

37.50 45.70 54.30 7.16 33.75 9.55 33.54 0.74

45.00 51.79 48.21 6.09 41.25 8.12 41.08 0.77

52.50 56.89 43.11 5.10 48.75 6.80 48.61 0.76

62.50 62.50 37.50 5.61 57.50 5.61 57.28 0.74

75.00 68.22 31.78 5.72 68.75 4.58 68.47 0.72

90.00 73.69 26.31 5.47 82.50 3.65 82.16 0.69

105.00 77.94 22.06 4.25 97.50 2.83 97.21 0.63

125.00 82.25 17.75 4.31 115.00 2.16 114.56 0.57

150.00 86.18 13.82 3.93 137.50 1.57 136.93 0.50

180.00 89.57 10.43 3.39 165.00 1.13 164.32 0.43

215.00 92.54 7.46 2.97 197.50 0.85 196.72 0.38

255.00 95.08 4.92 2.53 235.00 0.63 234.15 0.34

305.00 97.27 2.73 2.19 280.00 0.44 278.88 0.28

365.00 98.93 1.07 1.66 335.00 0.28 333.65 0.21

435.00 100.00 0.00 1.07 400.00 0.15 398.47 0.14

515.00 100.00 0.00 0.00 475.00 0.00 473.31 0.00

615.00 100.00 0.00 0.00 565.00 0.00 562.78 0.00

735.00 100.00 0.00 0.00 675.00 0.00 672.33 0.00

875.00 100.00 0.00 0.00 805.00 0.00 801.95 0.00

x10 = 6.68 µm x50 = 42.79 µm x90 = 185.04 µm SMD = 16.49 µm VMD= 72.39 µm

x16 = 10.89 µm x80 = 114.56 µm x99 = 369.66 µm SV = 0.36 m²/cm³ Sm = 1.3e+03 cm²/g

Q1 = 0.83 % Q38 = 46.11 % Q45 = 51.79 %

© 2014, Sympatec GmbH, System-Partikel-Technik,

Am Pulverhaus 1, D-38678 Clausthal-Zellerfeld, Deutschland

Analysis Report 170 999

CLARIMEX

Page / of 21 / 33

Graphical presentation of repeat analyses

Identifier Dispersing system Measuring range Evaluation

14 RODOST4 R5: 0.5/4.5...875µm HRLD

13 RODOST4 R5: 0.5/4.5...875µm HRLD

11 RODOST4 R5: 0.5/4.5...875µm HRLD

100 0.80

95 0.75

90

0.70

85

80 0.65

75 0.60

70 0.55

Cumulative distribution Q3 / %

65

0.50

Density distribution q3*

60

55 0.45

50 0.40

45 0.35

40

0.30

35

30 0.25

25 0.20

20 0.15

15

0.10

10

5 0.05

0 0.00

0.5 1.0 5 10 50 100 500

Particle size / µm

© 2014, Sympatec GmbH, System-Partikel-Technik,

Am Pulverhaus 1, D-38678 Clausthal-Zellerfeld, Deutschland

Analysis Report 170 999

CLARIMEX

Page / of 22 / 33

Results of the sample

Tipo MMF RA 17-1552

© 2014, Sympatec GmbH, System-Partikel-Technik,

Am Pulverhaus 1, D-38678 Clausthal-Zellerfeld, Deutschland

Analysis Report 170 999

CLARIMEX

Page / of 23 / 33

MEASUREMENT SPECIFICATION

Product name : Tipo MMF RA 17-1552

_____________________________________________________________________

Sample preparation : no sample splitting

_____________________________________________________________________

Sensor : HELOS

Dispersing method : RODOS

Measuring range HELOS : R5: 0.5/4.5...875µm (f = 500 mm)

Dispersing system : RODOST4

Mass requirement : 6/20/17

Start condition of measurement : c.opt >= 1%

Stop condition of measurement : 5s c.opt <= 1% or 20s real time

Time base : 100.00 ms

Measuring time : 2.44 s (0.00 s - 0.00 s)

Optical concentration : 8.51 % (0.00 % - 0.00 %)

Feed rate VIBRI : 50.00 %

Funnel height : 2.00 mm

Inner diameter of the

injector line : 4 mm

Product supply : funnel

Pressure setting : 0.98 bar

Number of measured

partial samples : 3

Measurements per partial sample : 1

HELOS evaluation mode : HRLD

_____________________________________________________________________

Documentation of measured results (following pages)

© 2014, Sympatec GmbH, System-Partikel-Technik,

Am Pulverhaus 1, D-38678 Clausthal-Zellerfeld, Deutschland

Analysis Report 170 999

CLARIMEX

Page / of 24 / 33

Measurement 10

HELOS (H1490) & RODOST4, R5: 0.5/4.5...875µm (f = 500 mm)

Product: Tipo MMF RA 17-1552 Evaluation:

density: 2.71 g/cm³ evaluation mode: HRLD (5.10.0.0)

shape factor: 1.00 contamination: 0.00 %

sample number: reference measurement: 07-10 17:59:39

Measuring condition: standard dry Dispersing method: 1 bar

start condition: c.opt >= 1% doser: VIBRI

stop condition: 5s c.opt <= 1% or 20s real time pressure: 0.98 bar

time base: 100.00 ms vacuum: 38.00 mbar

measuring duration: 2.44 s feed rate: 50.00 %

opt. concentration: 8.51 % gap width: 2.00 mm

revolution: 0.00 %

inner diameter of injector line: 4 mm

Preparation: Customer: MC17F92201/202

sample splitting: T.SCRUGGS measurement: 2017-07-10 17:59:57.7410 1490 H

amount of sample: 6/20/17 operator:

additional info: database: Clarimex HELOS

upper pct. under pct. over in band mean size distribution mean size density pct.

band limit cumulative cumulative different for band (lin) (linear) for band (log) (logarithm.)

x0 [µm] Q3 [%] (1-Q3) [%] dQ3 [%] xm [µm] q3 [1/mm] xm [µm] q3*

4.50 11.06 88.94 11.06 2.50 27.64 1.50 0.12

5.50 13.68 86.32 2.62 5.00 26.20 4.97 0.30

6.50 16.22 83.78 2.54 6.00 25.44 5.98 0.35

7.50 18.69 81.31 2.47 7.00 24.69 6.98 0.40

9.00 22.26 77.74 3.58 8.25 23.83 8.22 0.45

11.00 26.82 73.18 4.56 10.00 22.78 9.95 0.52

13.00 31.17 68.83 4.35 12.00 21.74 11.96 0.60

15.50 36.36 63.64 5.19 14.25 20.76 14.20 0.68

18.50 42.29 57.71 5.94 17.00 19.78 16.93 0.77

21.50 47.95 52.05 5.66 20.00 18.87 19.94 0.87

25.00 54.22 45.78 6.27 23.25 17.90 23.18 0.96

30.00 62.47 37.53 8.26 27.50 16.51 27.39 1.04

37.50 73.08 26.92 10.60 33.75 14.14 33.54 1.09

45.00 81.25 18.75 8.18 41.25 10.90 41.08 1.03

52.50 87.13 12.87 5.88 48.75 7.83 48.61 0.88

62.50 92.24 7.76 5.11 57.50 5.11 57.28 0.67

75.00 95.93 4.07 3.70 68.75 2.96 68.47 0.47

90.00 98.22 1.78 2.28 82.50 1.52 82.16 0.29

105.00 99.30 0.70 1.09 97.50 0.72 97.21 0.16

125.00 100.00 0.00 0.70 115.00 0.35 114.56 0.09

150.00 100.00 0.00 0.00 137.50 0.00 136.93 0.00

180.00 100.00 0.00 0.00 165.00 0.00 164.32 0.00

215.00 100.00 0.00 0.00 197.50 0.00 196.72 0.00

255.00 100.00 0.00 0.00 235.00 0.00 234.15 0.00

305.00 100.00 0.00 0.00 280.00 0.00 278.88 0.00

365.00 100.00 0.00 0.00 335.00 0.00 333.65 0.00

435.00 100.00 0.00 0.00 400.00 0.00 398.47 0.00

515.00 100.00 0.00 0.00 475.00 0.00 473.31 0.00

615.00 100.00 0.00 0.00 565.00 0.00 562.78 0.00

735.00 100.00 0.00 0.00 675.00 0.00 672.33 0.00

875.00 100.00 0.00 0.00 805.00 0.00 801.95 0.00

x10 = 4.12 µm x50 = 22.64 µm x90 = 58.12 µm SMD = 10.68 µm VMD= 27.65 µm

x16 = 6.41 µm x80 = 43.85 µm x99 = 100.79 µm SV = 0.56 m²/cm³ Sm = 2.1e+03 cm²/g

Q1 = 1.38 % Q38 = 73.62 % Q45 = 81.25 %

© 2014, Sympatec GmbH, System-Partikel-Technik,

Am Pulverhaus 1, D-38678 Clausthal-Zellerfeld, Deutschland

Analysis Report 170 999

CLARIMEX

Page / of 25 / 33

Graphical presentation of repeat analyses

Identifier Dispersing system Measuring range Evaluation

10 RODOST4 R5: 0.5/4.5...875µm HRLD

100 1.10

95 1.05

90 1.00

0.95

85

0.90

80

0.85

75

0.80

70

0.75

Cumulative distribution Q3 / %

65

0.70

Density distribution q3*

60 0.65

55 0.60

50 0.55

45 0.50

40 0.45

0.40

35

0.35

30

0.30

25

0.25

20

0.20

15

0.15

10 0.10

5 0.05

0 0.00

0.5 1.0 5 10 50 100 500

Particle size / µm

© 2014, Sympatec GmbH, System-Partikel-Technik,

Am Pulverhaus 1, D-38678 Clausthal-Zellerfeld, Deutschland

Analysis Report 170 999

CLARIMEX

Page / of 26 / 33

III. Appendix

A. General terms

Details regarding particle size analysis using laser diffraction are given in ISO 13320:2009-10

“Particle Size Analysis - Laser Diffraction Methods”.

The symbols and indices employed in the tabular print-outs and graphical representation, as well

as the type and form of the plotted results are in accordance with the following ISO standards:

ISO Title

9276-1:1998-06 Representation of results of particle size analysis

Part 1: Graphical representation

9276-2:2001-04 Representation of results of particle size analysis

Part 2: Calculation of average particle sizes/diameters and moments

from particle size distributions

9276-3:2008-07 Representation of results of particle size analysis

Part 3: Adjustment of an experimental curve to a reference model

9276-4:2001-07 Representation of results of particle size analysis

Part 4: Characterization of a classification process

9276-5:2005-08 Representation of results of particle size analysis

Part 5: Methods of calculation relating to particle size analyses using

logarithmic normal probability distribution

table III-1: List of relevant ISO

The variables used in the Sympatec printouts are briefly described in the following.

The dimension x denotes the equivalent diameter achieved from the evaluation. It is usually

described as “particle size” or “grain size”.

© 2014, Sympatec GmbH, System-Partikel-Technik,

Am Pulverhaus 1, D-38678 Clausthal-Zellerfeld, Deutschland

Analysis Report 170 999

CLARIMEX

Page / of 27 / 33

Upper Band Limit xo

Particle diameter (upper band limit), as referred to the upper limit of the particle size

interval under consideration.

Unit: Micrometers (µm)

Lower Band Limit xu

Particle diameter (lower band limit), as referred to the lower limit of the particle size

interval under consideration.

Unit: Micrometers (µm)

Average for Band xm

Particle diameter (average for band), as referred to the middle of the particle size

interval under consideration.

Unit: Micrometers (µm)

Two different types of average values are employed:

xo,i xu ,i

Arithmetic average: xmlin , i

2

The arithmetic average is used for graphics presented in a linear scale.

Geometric average: xmlg , i xo,i xu ,i

The presentation in a logarithmic scale is based on the geometric average.

Minimum Particle Diameter xmin

The minimum diameter of particles with respect to the entire particle size distribution.

Unit: Micrometers (µm)

Maximum Particle Diameter xmax

The maximum diameter of particles with respect to the entire particle size distribution.

Unit: Micrometers (µm)

The dimensions Q and q respectively denote the particle quantities distributed to the size intervals

(classes). The factor q describes the fraction quantity, which is covered by each particle size

interval. With the factor Q the summed fraction quantity from the finest to the relevant interval

will be given.

© 2014, Sympatec GmbH, System-Partikel-Technik,

Am Pulverhaus 1, D-38678 Clausthal-Zellerfeld, Deutschland

Analysis Report 170 999

CLARIMEX

Page / of 28 / 33

Cumulative Distribution Qr(x)

Cumulative distribution, as given by the defining equation:

Fraction of quantity of particles in the interval ( x min xi )

Qr ( x i )

Total quantity of the particles ( x min x max )

Four different types of quantities r have to be distinguished:

r = 0: number

r = 1: length

r = 2: area

r = 3: volume

r = 3: mass, if density of the material ρ = const

The cumulative distribution Qr(x) indicates the normalised fraction of particles which

are smaller than the particle diameter x.

Usually in the graphical presentation of the results for the particle size analysis the value

of the cumulative distribution Qr is plotted along the linearly subdivided ordinate whilst

the particle diameter x is plotted in µm along the logarithmically subdivided abscissa.

Unit: Number (percentage)

Residue Distribution Rr(x)

Residue distribution, which indicates the normalised fraction of particles being coarser

than the particle diameter.

Fraction of quantity of particles in the interval ( xi x max )

Rr ( x i ) 1 Qr ( x )

Total quantity of the particles ( x min x max )

For the meaning of r refer to the explanation of Qr(x).

Unit: Number (percentage)

Fraction dQr(xm)

Fraction of quantity for the distribution in a particular particle size interval, i.e. class,

expressed as a percentage to the total quantity. For plotting the average particle size xm

of the interval (xu, xo) is used.

dQr ( xm,i ) Qr ( xo,i ) Qr ( xu ,i )

Unit: Number (percentage)

© 2014, Sympatec GmbH, System-Partikel-Technik,

Am Pulverhaus 1, D-38678 Clausthal-Zellerfeld, Deutschland

Analysis Report 170 999

CLARIMEX

Page / of 29 / 33

Density of the Distribution Curve qr(xm,i)

Density distribution curve and frequency distribution curve respectively, indicating the

ratio of a class, that is, the fraction for a particle size interval, to its class width:

dQr ( xm,i ) Qr ( xo, i ) Qr ( xu , i )

q r ( x m ,i )

dxi x o , i xu , i

Unit: mm-1

The graphical presentation of the qr curves is often executed on a double linear grid, that

means both the ordinate and the abscissa are subdivided linearly.

The infinitesimal relationship between the cumulative and density distribution curves is

defined by the following equation:

x'

Qr ( x' ) q ( x)dx

xmin

r

In practice a rather normal relationship is:

i

Qr ( xi ) q (x

j 0

r m, j ) ( xo, j xu , j )

Logarithmic Density Distribution qr*(xm,lg)

The graphical presentation of the logarithmic density distribution curve qr* (often

denoted as qr,lg) is usually executed on a linear-logarithmic grid, that is a linear

subdivision along the ordinate and with a logarithmic subdivision along the abscissa.

The mathematical relationship between qr and qr* is expressed by the following

equation with the use of a transformation on the abscissa:

qr * ( xm,lg ) xm,lg qr ( x) ln 10 qr ,1g ( xm,lg )

In contrast to the plot of the distribution density curve on a linearly subdivided abscissa,

the distribution density curve is without unit dimension for a logarithmically subdivided

abscissa.

Unit: Number

With the following dimension xQ size information is given, which depend on the measured

distribution.

© 2014, Sympatec GmbH, System-Partikel-Technik,

Am Pulverhaus 1, D-38678 Clausthal-Zellerfeld, Deutschland

Analysis Report 170 999

CLARIMEX

Page / of 30 / 33

Characteristic particle Diameter xQ

Characteristic particle diameter (characteristic of fineness), for which the cumulative

distribution Q assumes the specified value (in percent), e.g. x50 denotes the size x for

which 50 % of all particles are finer.

Unit: Micrometers (µm)

Some special dimensions are employed in particle technology. They are listed below:

ktes Moment of the Distribution Mk,r

Complete kth moment of a qr(x)-distribution, it is represented by integrals as defined in

the following equation:

xmax

M k ,r x

k

qr ( x) dx

xmin

M stands for moment. The first subscript k of M indicates the power of x, the second

subscript r of M describes the type of quantity of the density distribution.

Unit: Depends on the power of x (subscript k)

SMD

The weighted surface mean diameter, also known as Sauter Mean Diameter, is

calculated as the moment M1,2. It represents the average particle size that corresponds to

the specific surface area of the entire particle collective.

M 3,0

SMD M 1, 2 D[3,2]

M 2, 0

n

xm,i q2 ( xm,i ) ( xo,i xu ,i )

i 1

Unit: Micrometers (µm)

© 2014, Sympatec GmbH, System-Partikel-Technik,

Am Pulverhaus 1, D-38678 Clausthal-Zellerfeld, Deutschland

Analysis Report 170 999

CLARIMEX

Page / of 31 / 33

VMD

The moment M1,3 is called Volume Mean Diameter, also known as De Brouckere mean

diameter or D[4,3].

M 4, 0

VMD M 1,3 D[4,3]

M 3,0

n

xm,i q3 ( xm,i ) ( xo,i xu,i )

i 1

Unit: Micrometers (µm)

Heywood shape factor fH

The Heywood shape factor is the ratio of the measured specific surface area of the

particle to the specific surface area of a sphere with a diameter x.

6 xs2 x

fH

xv3 6

xs: diameter of the sphere with the same surface area

xv: diameter of the sphere with the same volume

Unit: Number

Heywood shape factor for some kind of particles:

Solid Heywood shape factor

Spheres 1.0

Sand 1.3 – 1.4

Cement 1.8

Coal dust 1.8 – 2.1

Flying dust, sugar 1.2 – 2.3

Quartz 1.8 – 4.0

Mica flakes 9.3

Source: http://www.ipat.tu-bs.de/wp-content/uploads/2012/05/lehre_praktikum_skript_pga.pdf

© 2014, Sympatec GmbH, System-Partikel-Technik,

Am Pulverhaus 1, D-38678 Clausthal-Zellerfeld, Deutschland

Analysis Report 170 999

CLARIMEX

Page / of 32 / 33

Volume related surface area Sv

Volume related specific surface area, description of the ratio between the surface area of

all particles for the distribution and the volume of all particles for the distribution, and

thus proportional to the specific surface area, Sv , as referred to the volume, calculated

from the measured particle size distribution:

SV 6 f H M -1,3

where 6 is the proportionality factor with respect to the volume of spherical particles

and fH denotes the Heywood shape factor:

fH = 1 for spheres

fH > 1 for irregularly shaped particles (see item above)

Unit: m2/cm3

Mass related specific area Sm

The mass related specific area, description of the ratio between the surface area and the

mass. It can be derived with the knowledge of the physical density ρ from the volume

related surface area Sv with the help of the following equation:

Sm SV /

Unit: cm2/g

RRSB-Distribution

RRSB distribution (named by Rosin, Rammler, Sperling, Bennett)

The definition of the RRSB-function is as follows:

R( x) 1 Q( x) exp (( x / x' ) n )

It is a function with two parameters:

x' = position parameter

n = scatter parameter

For the particle size x = x’:

R(x') = e-1 = 0.368 = 36.8 % and with it Q(x) = 0.632 = 63.2 %.

n is the slope of a straight line in the RRSB grid (lglg(1/R)).

Unit: Number (percentage)

© 2014, Sympatec GmbH, System-Partikel-Technik,

Am Pulverhaus 1, D-38678 Clausthal-Zellerfeld, Deutschland

Analysis Report 170 999

CLARIMEX

Page / of 33 / 33

B. HELOS terms

Optical Concentration Copt

The optical concentration is an indicator for the volume flow of the particles.

For the HELOS the optical concentration is the drop of light intensity (extinction) in the

centre of the detector , with respect to the intensity measured without particles

I0 I p

Copt

I0

Whereas I0 denotes the intensity measured without particles and Ip the intensity

measured with particles.

Unit: Number (percentage)

Additional information on the used sensors and dispersing systems such as technical data or

pictures can be found on the website of the Sympatec GmbH at http://www.sympatec.com/.

© 2014, Sympatec GmbH, System-Partikel-Technik,

Am Pulverhaus 1, D-38678 Clausthal-Zellerfeld, Deutschland

You might also like

- CERRO VERDE-HPGRSim - OpenDocument85 pagesCERRO VERDE-HPGRSim - OpenCezar JulNo ratings yet

- Flakiness IndexDocument4 pagesFlakiness IndexTewodros TadesseNo ratings yet

- 1999 ECCE2 Polluted SoilDocument8 pages1999 ECCE2 Polluted SoilDirceu NascimentoNo ratings yet

- Hpgrsim OpenDocument83 pagesHpgrsim OpenCarlos DiazNo ratings yet

- Choo Panya 2016Document5 pagesChoo Panya 2016Kevin LippsNo ratings yet

- 2006 Advances in ComminutionDocument21 pages2006 Advances in ComminutionDirceu NascimentoNo ratings yet

- BET Analysis Book MethodsDocument38 pagesBET Analysis Book MethodsZirrus GlassNo ratings yet

- DispersionDocument8 pagesDispersionAnonymous 3yqNzCxtTzNo ratings yet

- Separator Operation PDFDocument21 pagesSeparator Operation PDFAnoop Tiwari100% (1)

- Traitement Des Minerais-Pages-3Document12 pagesTraitement Des Minerais-Pages-3Malala RakotonirainyNo ratings yet

- HPGRSim Openpractica1Document83 pagesHPGRSim Openpractica1Aldo PabloNo ratings yet

- Homgeneious Section FWDDocument16 pagesHomgeneious Section FWDBilal A BarbhuiyaNo ratings yet

- Garcia 2004 Application of The Rosin-Rammler and Gates-Gaudin-Schuhmann Models To The Particle Size Distribution Analysis of Agglomerated CorkDocument6 pagesGarcia 2004 Application of The Rosin-Rammler and Gates-Gaudin-Schuhmann Models To The Particle Size Distribution Analysis of Agglomerated CorknurulNo ratings yet

- Agglomerated Cork, Particle Size Distribution Analysis PDFDocument6 pagesAgglomerated Cork, Particle Size Distribution Analysis PDFDiego GuerreroNo ratings yet

- Modelling Dense Media SeparationDocument18 pagesModelling Dense Media SeparationbaberoniNo ratings yet

- 2958 WursterDocument15 pages2958 WursterDylan DooleyNo ratings yet

- 5 Correlation of Theoretical and Experimental Efficiencies: 6.1 Size Distribution of Microbe-Carrying ParticlesDocument9 pages5 Correlation of Theoretical and Experimental Efficiencies: 6.1 Size Distribution of Microbe-Carrying ParticlesThisIs MyCatNo ratings yet

- Prakt AirClassification PDFDocument7 pagesPrakt AirClassification PDFovgudebrajNo ratings yet

- File: Tromp Curve - Eng v3 DateDocument9 pagesFile: Tromp Curve - Eng v3 DateMuhammadShoaibNo ratings yet

- Grain Size Distribution and Hydraulic PropertiesDocument17 pagesGrain Size Distribution and Hydraulic PropertiesAngel Alexis Mariño RomeroNo ratings yet

- Risk Assessment in Offshore Structures Design The Advantages of A CFD ApproachDocument8 pagesRisk Assessment in Offshore Structures Design The Advantages of A CFD ApproachMahfoud AMMOURNo ratings yet

- University of Duhok College of Engineering Civil Department 2 Year, 2017-2018Document11 pagesUniversity of Duhok College of Engineering Civil Department 2 Year, 2017-2018Dakheel malekoNo ratings yet

- CT - GE - Precision - Comparison - Brochure - English - 1 PDFDocument4 pagesCT - GE - Precision - Comparison - Brochure - English - 1 PDFugo_rossiNo ratings yet

- Pavement Condition SurveyDocument10 pagesPavement Condition SurveyJeffrey WangNo ratings yet

- External AerodynamicsDocument14 pagesExternal AerodynamicsBharath Dv100% (1)

- Direct Measurement of Crosslink Density: Core Technology Research, Development and TestingDocument1 pageDirect Measurement of Crosslink Density: Core Technology Research, Development and TestingMd Saifur RahamanNo ratings yet

- Scope:: About The Ballbal - Reverse Spreadsheet ..Document14 pagesScope:: About The Ballbal - Reverse Spreadsheet ..lewis poma rojasNo ratings yet

- Ballsim OpenDocument50 pagesBallsim Opensnarf273No ratings yet

- Breakage Chutes TD Edit 2Document6 pagesBreakage Chutes TD Edit 2Luca BenvenutiNo ratings yet

- MicromeriticsDocument60 pagesMicromeriticsamitmgupta3178% (18)

- FEM9.755 Engl - Order - 402133Document6 pagesFEM9.755 Engl - Order - 402133Andrés SánchezNo ratings yet

- 35321Document10 pages35321Hany ShoushaNo ratings yet

- Design Procedure and Experimental Study On Fibre Reinforced Concrete Segmental Rings For Vertical ShaftsDocument24 pagesDesign Procedure and Experimental Study On Fibre Reinforced Concrete Segmental Rings For Vertical ShaftscklconNo ratings yet

- 1521748667rocky Article Breakage ModellingDocument6 pages1521748667rocky Article Breakage ModellingEruaro Guerra CarvajalNo ratings yet

- Flakiness and ElongationDocument6 pagesFlakiness and ElongationMuhammad HafizNo ratings yet

- A Fracture Mechanics Approach For The Crack Growth in Welded Joints With Reference To BS 7910Document8 pagesA Fracture Mechanics Approach For The Crack Growth in Welded Joints With Reference To BS 7910Kittikun JitpairodNo ratings yet

- Optical Microscope Particle CountingDocument7 pagesOptical Microscope Particle CountingVasant bhoknalNo ratings yet

- Ballsim DirectDocument58 pagesBallsim DirectDiego GaliciaNo ratings yet

- Mark HeadDocument49 pagesMark HeadBenexSpecNo ratings yet

- Scope:: Moly-Cop Tools, Version 3.0 About The Hpgrparam - Open Spreadsheet ..Document65 pagesScope:: Moly-Cop Tools, Version 3.0 About The Hpgrparam - Open Spreadsheet ..danielNo ratings yet

- MsctdoseDocument14 pagesMsctdoseMasoud RahmaniNo ratings yet

- Chapter 3 Multiple Linear RegressionDocument32 pagesChapter 3 Multiple Linear RegressionChriss TwhNo ratings yet

- Fitdistrplus R Package Fitting DistributionsDocument22 pagesFitdistrplus R Package Fitting DistributionsJuan TelleriaNo ratings yet

- Study of MEMS Pressure Sensor For TPMS UDocument3 pagesStudy of MEMS Pressure Sensor For TPMS UBasescu Matei-AlexandruNo ratings yet

- Friction and Wear Behavior of ABS - 2014, INDIADocument5 pagesFriction and Wear Behavior of ABS - 2014, INDIAvaxevNo ratings yet

- FEM9.755 Engl PDFDocument6 pagesFEM9.755 Engl PDFserkan0% (1)

- Toaz - Info Fem9755 Englpdf PRDocument6 pagesToaz - Info Fem9755 Englpdf PRFederico SanguinetiNo ratings yet

- 28 TracerDiffusion PDFDocument11 pages28 TracerDiffusion PDFAkash KumarNo ratings yet

- Analysis of Test Methods For Texture Depth Evaluation Applied in PortugalDocument13 pagesAnalysis of Test Methods For Texture Depth Evaluation Applied in PortugalNedim DjuzoNo ratings yet

- Civilab: California Bearing Ratio ResultsDocument1 pageCivilab: California Bearing Ratio ResultsMike MatshonaNo ratings yet

- Iscs 2013 Tm-EngDocument6 pagesIscs 2013 Tm-EngVlad Alexandru FloreaNo ratings yet

- Spatial Droplets Size Distribution in A Diesel Spray Taken by Photography With Super High ResolutionDocument6 pagesSpatial Droplets Size Distribution in A Diesel Spray Taken by Photography With Super High Resolutiondr_s_m_afzali8662No ratings yet

- MSC (Emec) Computer Modelling and Simulation Module Surveying Comminution CircuitsDocument4 pagesMSC (Emec) Computer Modelling and Simulation Module Surveying Comminution CircuitskediliterapiNo ratings yet

- Blaisot 2005Document18 pagesBlaisot 2005ghaderNo ratings yet

- Gas Chromatography and Mass Spectrometry: A Practical GuideFrom EverandGas Chromatography and Mass Spectrometry: A Practical GuideRating: 5 out of 5 stars5/5 (3)

- Computer Processing of Remotely-Sensed Images: An IntroductionFrom EverandComputer Processing of Remotely-Sensed Images: An IntroductionNo ratings yet

- Preparation of Slurry Samples From Flotation ProcessesDocument3 pagesPreparation of Slurry Samples From Flotation ProcessesMiguel RomanNo ratings yet

- QP Rodos CondensedDocument28 pagesQP Rodos CondensedMiguel RomanNo ratings yet

- Herzog - HT350 DESBASTADORADocument4 pagesHerzog - HT350 DESBASTADORAMiguel RomanNo ratings yet

- Wet Cutting-Off GrinderDocument2 pagesWet Cutting-Off GrinderMiguel RomanNo ratings yet

- Herzog PB HAF 2 Englisch FRESADORADocument4 pagesHerzog PB HAF 2 Englisch FRESADORAMiguel RomanNo ratings yet

- QP PAQXOS OutputsDocument16 pagesQP PAQXOS OutputsMiguel RomanNo ratings yet

- Troubleshooting The Q100 - The Q100 Will Not Spark: IssueDocument6 pagesTroubleshooting The Q100 - The Q100 Will Not Spark: IssueMiguel RomanNo ratings yet

- QICPIC TraningDocument51 pagesQICPIC TraningMiguel RomanNo ratings yet

- Automatic CUT-OFF MachineDocument3 pagesAutomatic CUT-OFF MachineMiguel RomanNo ratings yet

- HE ROL Users GuideDocument42 pagesHE ROL Users GuideMiguel RomanNo ratings yet

- Inhaler Pressure SettingsDocument4 pagesInhaler Pressure SettingsMiguel RomanNo ratings yet

- High-Throughput/high-Performance Wear Metal Analysis Using ICPDocument5 pagesHigh-Throughput/high-Performance Wear Metal Analysis Using ICPMiguel RomanNo ratings yet

- LAB27510 - en ADocument2 pagesLAB27510 - en AMiguel RomanNo ratings yet

- To Fuse Samples For XRF, AA and ICP Analysis: Your First ChoiceDocument2 pagesTo Fuse Samples For XRF, AA and ICP Analysis: Your First ChoiceMiguel RomanNo ratings yet

- Platinum Labware... : at Your DisposalDocument2 pagesPlatinum Labware... : at Your DisposalMiguel RomanNo ratings yet

- 4 Measuring Oil in Water & Soil BrochureDocument4 pages4 Measuring Oil in Water & Soil BrochureMiguel RomanNo ratings yet

- LAB18109 - en - SR300Document3 pagesLAB18109 - en - SR300Miguel RomanNo ratings yet

- CaCO3Document6 pagesCaCO3Miguel RomanNo ratings yet

- Solutions For Power Generation and Industrial Plants: Maximize Machine UptimeDocument8 pagesSolutions For Power Generation and Industrial Plants: Maximize Machine UptimeMiguel RomanNo ratings yet

- Intro To Wilks Key Product Lines-2Document45 pagesIntro To Wilks Key Product Lines-2Miguel RomanNo ratings yet

- Product - Info Molino Mezclador MM 500 Control ESDocument13 pagesProduct - Info Molino Mezclador MM 500 Control ESMiguel RomanNo ratings yet

- Mechanochemistry New HorizonsDocument14 pagesMechanochemistry New HorizonsMiguel RomanNo ratings yet

- Task:: 1000 G (Per Batch) Hard Brittle 1 MM, Throughput Approx. 1 - 2 KG Research ProjectDocument1 pageTask:: 1000 G (Per Batch) Hard Brittle 1 MM, Throughput Approx. 1 - 2 KG Research ProjectMiguel RomanNo ratings yet

- Tiempos de Entrega RetschDocument1 pageTiempos de Entrega RetschMiguel RomanNo ratings yet

- Fats, Oils and Grease (FOG) in WastewaterDocument1 pageFats, Oils and Grease (FOG) in WastewaterMiguel RomanNo ratings yet

- Sample Preparation: Quality in For The Cement IndustryDocument17 pagesSample Preparation: Quality in For The Cement IndustryMiguel RomanNo ratings yet

- Measuring Oil in Water & Soil DatasheetDocument2 pagesMeasuring Oil in Water & Soil DatasheetMiguel RomanNo ratings yet

- English Malay DictionaryDocument614 pagesEnglish Malay DictionaryGanesh Balaji100% (1)

- Brgy. Reso BirDocument2 pagesBrgy. Reso BirCazy Mel EugenioNo ratings yet

- Construction, Design and Analysis of A Commercial Building: in Premises of Unibild Engineering & Construction Pvt. LTDDocument19 pagesConstruction, Design and Analysis of A Commercial Building: in Premises of Unibild Engineering & Construction Pvt. LTDRohan RanjanNo ratings yet

- Finite Element Analysis Prof. Dr. B. N. Rao Department of Civil Engineering Indian Institute of Technology, MadrasDocument27 pagesFinite Element Analysis Prof. Dr. B. N. Rao Department of Civil Engineering Indian Institute of Technology, Madrasnataraj deshpandeNo ratings yet

- N60-N60 Quartz Date PDFDocument82 pagesN60-N60 Quartz Date PDFMina KuroNo ratings yet

- Amanda Sephiroth: Amanda Sephiroth - Aasimar/half-Celestial/half-Dragon (Gold) Class: Monk 10/clericDocument7 pagesAmanda Sephiroth: Amanda Sephiroth - Aasimar/half-Celestial/half-Dragon (Gold) Class: Monk 10/clericDaniel MarinhoNo ratings yet

- Fertilizer Recommendation Based On MOETDocument3 pagesFertilizer Recommendation Based On MOETdelacruzjobyNo ratings yet

- Aeronautical Chart Users' Guide VFR Charting Products (Includes Sectional, Terminal Area, Caribbean, Flyway, and Helicopter Charts)Document61 pagesAeronautical Chart Users' Guide VFR Charting Products (Includes Sectional, Terminal Area, Caribbean, Flyway, and Helicopter Charts)MuhammadHassanBashirNo ratings yet

- BF PresentationDocument7 pagesBF PresentationWeb NovelNo ratings yet

- ELS Practice Exam 7Document17 pagesELS Practice Exam 7Deniz ElçinNo ratings yet

- CTT Exam Application FormDocument1 pageCTT Exam Application Formrain06021992No ratings yet

- Q1 WK 7 Las Fabm 2 Ma. Cristina R. JamonDocument8 pagesQ1 WK 7 Las Fabm 2 Ma. Cristina R. JamonFunji BuhatNo ratings yet

- Proposal For Improvement of Infant Toddler Weighing ScaleDocument6 pagesProposal For Improvement of Infant Toddler Weighing ScaleYuna-chan KatsuraNo ratings yet

- Brown Field TNO 0019 RevDocument2 pagesBrown Field TNO 0019 RevDaniele GouveiaNo ratings yet

- NSP/004/109 (OHI 9) Guidance On Anti-Climbing Devices, Safety Signs and Labels Required On Overhead Line SupportsDocument25 pagesNSP/004/109 (OHI 9) Guidance On Anti-Climbing Devices, Safety Signs and Labels Required On Overhead Line SupportsMuhammad BilalNo ratings yet

- Morgan Stanley - Interview GuideDocument9 pagesMorgan Stanley - Interview GuideSidra BhattiNo ratings yet

- SQLAccountWorkBook 5 (Answer Sheet)Document62 pagesSQLAccountWorkBook 5 (Answer Sheet)Muhammad HazlamiNo ratings yet

- Developing Information System SolutionDocument42 pagesDeveloping Information System SolutionAbhijeet Mahapatra71% (7)

- InglesDocument7 pagesInglesMica LetoNo ratings yet

- Dawit Tesfai ResumeDocument4 pagesDawit Tesfai Resumeapi-444700983No ratings yet

- The Old Shop Houses As Part of Malaysian Urban Heritage The Current DilemmaDocument18 pagesThe Old Shop Houses As Part of Malaysian Urban Heritage The Current DilemmaBoon Kean100% (1)

- ReportDocument33 pagesReportBhavesh JoliyaNo ratings yet

- Homeostasis and Rein Control: From Daisyworld To Active PerceptionDocument6 pagesHomeostasis and Rein Control: From Daisyworld To Active PerceptionVeronique PoenelleNo ratings yet

- Introduction To Kinematics and MechanismsDocument25 pagesIntroduction To Kinematics and Mechanismsdhilip_sacetNo ratings yet

- Is China A Friend or Foe?: Bachelor ThesisDocument50 pagesIs China A Friend or Foe?: Bachelor ThesisKaige ChenNo ratings yet

- Recover at Work Plan 5 ProposedDocument2 pagesRecover at Work Plan 5 ProposedSiosiana DenhamNo ratings yet

- Case Study 4aDocument16 pagesCase Study 4aAntonia RauNo ratings yet

- Shao2018 PDFDocument232 pagesShao2018 PDFbichojausen0% (1)

- Renewable Energy For Sustainable Growth Assessment: EditorsDocument2 pagesRenewable Energy For Sustainable Growth Assessment: EditorsPradeep SinglaNo ratings yet

- Chemical Reaction Engineering 1 BKF 2453 SEM II 2015/2016: Mini ProjectDocument26 pagesChemical Reaction Engineering 1 BKF 2453 SEM II 2015/2016: Mini ProjectSyarif Wira'iNo ratings yet