Professional Documents

Culture Documents

Today's Metal Buildings Are Much More Attractive and Versatile Than Their More Industrial Forebears

Uploaded by

apOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Today's Metal Buildings Are Much More Attractive and Versatile Than Their More Industrial Forebears

Uploaded by

apCopyright:

Available Formats

in nearly 70% of new construc-

T

he metal building systems

Today’s metal industry has been an inno- tion (as referenced in the 1996

vative leader in low-rise Business Review, Metal Building

buildings are construction. Because the indus-

try has grown and matured so

Manufacturers Association).

This high market share is due,

rapidly, many misconceptions in no small part, to the engineer-

much more exist that are based on earlier ing and quality assurance that

predecessors of today’s advanced contribute to the excellent per-

attractive and systems. An entire article could

easily be devoted to the histori-

formance of these buildings.

The Metal Building

cal evolution of this industry Manufacturers Association

versatile than that has pioneered many prac- (MBMA) celebrated its 40th

tices that are becoming more anniversary last year.

their more widely utilized. The metal build-

ing industry was first in recog-

Composed of 31 Manufacturer

Members and 36 Associate

nizing the advantage of combin- Members, MBMA has taken the

industrial ing engineering and fabrication industry lead over the years in

to more effectively provide an setting the standard for excel-

forebears optimally designed steel framed

building. Also, the movement

lence. In fact, MBMA has decid-

ed to make AISC Certification a

toward design/build has been an requirement for membership,

By W. Lee integral part of the metal build- effective in the year 2000.

Shoemaker, Ph.D., P.E. ing system industry since its MBMA’s Manufacturer Members

inception. are also Associate Members of

The focus of this article is the AISC.

engineered product furnished by

metal building manufacturers WHAT IS A

that is the basis for the growth METAL BUILDING SYSTEM?

in their market share. Of the Many outside the industry

low-rise, non-residential build- still harbor the notion that a

ings under 150,000 sq. ft., metal metal building is selected from a

building systems are selected by catalog of standard designs,

building owners and architects based on the size of the building.

Modern Steel Construction / November 1997

In fact, most metal building

manufacturers custom design a

building by order to within 1/16”

in any dimension, based on the

building code in effect, the load-

ing conditions, and material

specified. MBMA member com-

panies have registered profes-

sional engineers on staff who are

highly skilled and apply sound

engineering principles to the

optimal design of metal building

systems. Advanced computer

methods are used to help facili-

tate this design customization

and optimization. This is also

why the industry has tried to

eliminate past characterizations

such as “pre-engineered metal

buildings” in lieu of the more

accurate identification of “metal

building systems”. Leon’s Carpet & Tile headquarters (above) in Austin, TX, and the Gold Shore

Metal building systems have Casino (opposite) in Biloxi, MS, demonstrate the versatility of today’s metal

evolved over the years into buildings.

assemblages of structural ele-

ments that work together as a OPTIMIZATION - THE might be in tension and/or a

very efficient structural system. BOTTOM LINE larger compression flange in an

While there are many variations unbraced condition. The frame

In an AISC Marketing, Inc.

on the theme, the basic elements members are also designed with

publication (Myths and Realities

of the metal building system are bolted end-plate connections for

of Steel Buildings), it is noted

constant: primary rigid frames, fast assembly in the field.

that “the cost of a structure is

secondary members composed of MBMA has sponsored extensive

divided among four areas:

wall girts and roof purlins, research over the years to devel-

design, material, fabrication and

cladding, and bracing. Metal op appropriate design methods

erection. The optimum structure

building system design may for bolted end-plate connections.

has the lowest weight consistent

seem trivial at first, but experi- These connections are receiving

with the greatest standardiza-

ence shows that the complex new interest as a possible alter-

tion of parts, the fewest number

interaction of these elements native to welded moment connec-

of pieces and the smallest

into a stable system is a chal- tions in seismic areas (for more

amount of detail work.” Metal

lenging engineering task. information, see Ronald L.

building systems offer an excel-

MBMA member companies have Meng’s and Thomas M. Murray’s

lent optimization solution, tak-

demonstrated this expertise and paper, “Seismic Performance of

ing advantage of lower costs in

are on the leading edge of sys- Bolted End-Plate Moment

all of the four areas noted.

tems design. The reality of this Connections” in the Proceedings

Metal building manufacturers

has been evident in post-disaster of the AISC National Steel

have developed design and fabri-

investigations where metal Construction Conference, May

cation techniques to optimize the

building system “look-a-likes” 1997).

primary frames and put the

have suffered more extensive Cold-formed secondary mem-

material where it is needed.

damage than engineered sys- bers (purlins and girts) offer a

Using welded plate members as

tems subjected to the same high strength to weight ratio.

opposed to hot-rolled sections

extreme loading. These metal Optimized sections can be roll-

provides this opportunity.

buildings are not easily distin- formed by the metal building

Optimization is carried out by

guished from a metal building system manufacturer to the

using tapered webs with

system, however, they are not required depth and thickness to

increased depth in areas of high-

designed with regard to the carry the specified loads.

er moments, and by varying the

interdependence of the structur-

web thickness and flange size as STRUCTURAL REDUNDANCY

al elements. The individual com-

needed. Sections are also fre-

ponents are usually purchased Metal building systems are

quently used with unequal

from one or more vendors and extremely redundant structures.

flanges (monosymmetric) to uti-

often shipped out as a complete Structural redundancy is the

lize a smaller flange where it

metal building. degree to which multiple load

Modern Steel Construction / November 1997

MBMA has also sponsored

research to determine if the

unbalanced snow load specified

in most codes adequately reflects

the propensity for snow to drift

on low slope roofs. Revisions to

ASCE 7 are being considered

based on the results of this work

that should lead to improved

performance for all types of

buildings with low-slope roofs.

EXPANSION/CHANGE OF

BUILDING USE

One of the reasons that metal

building systems are an attrac-

tive economic alternative, as dis-

cussed above, is that materials

are optimized for the specified

loads. Obviously, if substantial

new loads are introduced that

were not accounted for in the

original design, modifications

may be required. An owner

actually has three options with

regard to a new building design:

1) the building can be over-

designed in anticipation of

future potential loads, 2) the

building can be economically

designed with some considera-

tion for future potential loads, or

3) the building can be designed

for the current loads to provide

the lowest initial cost. All three

of these options are available

with a metal building system

and would be designed according

to the applicable building code,

depending on an owner’s antici-

pated needs. The first option

should be evaluated against the

Shown at top is the Transcypt building in Lincoln, NE, while pictured above is the

other two by comparing the ini-

interior of the Wilkof-Morris plant in Canton, OH.

tial costs versus modification

costs in the future given the

paths exist within a structure. structures that offer additional probability that the loads will

That is, if a local failure occurs redundancy. actually be added. In reality,

in a member, does the member MBMA is sponsoring a study most building types that depend

lose all capacity to carry addi- to look into additional design on a limited availability of stan-

tional load, or is the load redis- requirements for overload situa- dard rolled beams and other

tributed and carried by the mem- tions, particularly abnormal structural elements are over-

ber in a different manner or snow loads. Current codes and designed by the nature of the

carried by other members? All standards, such as ASCE 7, selection process (i.e. the next

flexural members used in a require most buildings to be largest available size is used

metal building, including panels designed using loads that repre- based on the required section).

and purlins, are usually continu- sent a 50-year mean recurrence This is where the greater versa-

ous members that permit redis- interval. However, improved tility of welded plate frames and

tribution of loads as opposed to performance under abnormal cold-formed members provides

simply supported members that snow load situations may be lower material costs. The second

provide no redundancy. The pri- achieved through specific loading option for future expansion capa-

mary frames are indeterminate and/or design considerations. bility is often provided for in a

Modern Steel Construction / November 1997

metal building design, by design- tance of serviceability criteria, building manufacturer is respon-

ing the end frame for additional MBMA jointly sponsored with sible only for the structural

future loads. However, even if the American Iron and Steel design of the metal building sys-

this is not pre-planned in the Institute (AISI) and AISC the tem it sells to the end customer

design, using the third option for development of the AISC Guide and for supplying adequate evi-

the lowest initial cost, alter- on Serviceability Design dence of compliance with the

ations can readily be made work- Considerations for Low-Rise specifications, design criteria,

ing with the metal building man- Buildings (see AISC Steel Design and design loads to the design

ufacturer. Guide Series 3, “Serviceability professional to incorporate the

A session is tentatively Design Considerations for Low- metal building system into the

planned for the 1998 AISC Rise Buildings”). This reference construction project. An engi-

National Steel Construction establishes guidelines for many neer of record is not only

Conference to identify how serviceability issues, including involved in this incorporation of

expansions or changes of build- frame-supported cladding. For the metal building system into

ing use can efficiently be carried example, lateral drift of frames the project, but also typically has

out in a metal building system. may range from H/60 for flexible the design responsibility for the

This should be of interest to metal cladding to H/200 for more foundations, floor slabs, interior

engineers involved in such pro- brittle reinforced masonry walls. and exterior concrete masonry

jects, and should help identify Additionally, MBMA has worked walls, or tilt-up walls, and the

the most cost-effective ways to with the National Concrete connection of these walls to the

alter a metal building system. Masonry Association in the metal building framing.

This strategy of providing the development of its manual to Engineers and architects who

most economic building to address serviceability as well as are interested in this growing

accommodate the specified struc- structural design considerations market should consider this as

tural loads, and cost-effective when utilizing concrete masonry an excellent opportunity to

ways to provide for possible walls with metal buildings. The expand their professional ser-

future expansion, should be com- availability of these tools has vices. MBMA will be sponsoring

pared to the alternative of over- helped give architects more con- seminars and short courses in

designing a building for loads fidence in blending different the near future to help inform

that may not ever be realized. architectural finishes such as interested design professionals

precast concrete, brick, stone, on how they can better under-

ARCHITECTURAL INVOLVEMENT wood and glass with metal build- stand and interact with the

The growth of metal building ing systems. However, these metal building systems industry.

systems is also attributable to wall finishes are not just used

more diverse applications that for aesthetic enhancements. STANDING SEAM ROOFS

have evolved due to the increas- For example, in many industrial The introduction and use of

ing awareness by architects of or warehousing operations, the standing seam roof by the

what metal buildings offer. masonry wainscoting can be metal building industry has pro-

Many different architectural fin- employed to improve resistance vided one of the most efficient

ishes may be utilized to provide to impact loading from vehicular structural, weathertight systems

the look required for applications traffic. available today. Over 2 billion

such as churches, schools, shop- With regard to the trend away square feet of standing seam

ping centers, office buildings, from “conventional” construction roofing is installed annually. In

etc., while still offering the cost toward metal building systems, fact, more than 50 percent of all

advantages of the metal building as reflected in the market share commercial/industrial buildings

system. These architectural fin- analysis, more engineering are covered with metal. MBMA

ishes, other than steel cladding, opportunities are anticipated for has worked with AISI over the

are typically not designed or pro- those working in this low-rise last 25 years in sponsoring

vided by the metal building man- segment. An increasing number research to develop design and

ufacturer. The role of the archi- of applications will have an engi- test procedures for standing

tect/engineer of record is neer of record or architect seam roof systems. This

important in ensuring that the involved with the construction research has provided new

design criteria, particularly the project. This design professional requirements for designing and

lateral drift and deflection of the assists in the preparation of the testing purlins supporting stand-

primary frame and/or secondary design specifications for the pro- ing seam roofs in the latest AISI

supports, is consistent with the ject, including the metal building Cold-Formed Specification. The

chosen wall finish. This is true system and its erection, and bracing of purlins supporting

of any type of construction, and where appropriate, assists in standing seam roofs can be han-

is easily coordinated with the supervising the construction dled in several ways, and is one

metal building manufacturer. process for compliance with the of the most important considera-

In recognition of the impor- contract documents. The metal tions for maintaining the struc-

Modern Steel Construction / November 1997

is expected of MBMA members

and inherent in the AISC

Certification program. The pro-

gram ensures that a metal build-

ing manufacturer has achieved a

high level of competency in all

aspects of design and fabrication.

The purpose of the program as

stated by AISC is to “confirm to

the construction industry that a

Certified structural steel fabri-

cating plant has the personnel,

organization, experience, proce-

dures, knowledge, equipment,

capability and commitment to

produce fabricated steel of the

required quality for a given cate-

gory of structural steel work.”

The certification program

examines policies and proce-

dures at each of the manufactur-

tural stability of the system. In zinc, aluminum and er’s facilities, and the application

recognition of this significance, aluminum/zinc alloy coatings of those policies and procedures

MBMA has worked with AISI to has helped increase the life to randomly selected projects. It

produce “A Guide for Designing expectancy of steel cladding. In consists of nearly 200 questions

With Standing Seam Roof fact, a recent survey of 82 covering the areas of general

Panels, CF97-1”, which address- Galvalume roofs up to 22 years management, engineering and

es the design considerations for old located in the industrial drafting, procurement, manufac-

members supporting a standing North and along the South Gulf turing, and quality control.

seam roof. and Atlantic Coasts found them Inspection and evaluation teams

Standing seam roofs are also in excellent condition. Based on from an independent auditing

providing new life for many their appearance, they were pro- firm annually observe and evalu-

buildings with flat roofs that jected to last 30 years or longer ate the manufacturer in almost

have proved to be problematic. in most environments before every aspect of operation. In

A standing seam roof can be requiring major maintenance. addition, unannounced and

designed to be applied directly This survey supports the expec- unscheduled inspections verify

over an existing flat, built-up tations that are the basis for the continuous compliance with the

roof using a substructure to pro- warranties typically supplied for detailed certification standards

vide a low-slope replacement, or paint coating performance. established by AISC, which has

a steeper slope for a new archi- While the aluminum/zinc alloy been setting steel construction

tectural appearance. The new coatings provide the corrosion standards and writing specifica-

standing seam roof will not only protection, various types of paint tions for more than 75 years. As

provide a superior weathertight coatings provide the architect a result of all of these measures,

covering, but life cycle cost with a veritable palette of architects, design professionals,

analyses usually show them to cladding colors. These coatings building code officials and the

be the best economic choice when include specialized painted fluo- insurance industry can be

considering lower costs involved rocarbons and siliconized poly- assured that certified metal

with removing the old roof, mini- ester systems that perform building systems manufacturers

mal disruption of facility opera- extremely well, as evidenced by are capable of meeting the indus-

tions, and energy-saving capabil- the warranties normally sup- try’s highest standards for prod-

ities of new insulation in the plied to cover color retention, uct and design integrity.

created “attic” space. fading, and chalking for a speci-

fied period of time. SUMMARY

DURABILITY Involvement in technical

Metal building systems are AISC CERTIFICATION PROGRAM activities has been a hallmark of

extremely durable and require As previously mentioned, MBMA over the years. MBMA

only minimal maintenance. The MBMA will require AISC has helped advance the industry

engineered coating systems that Certification as a requirement by taking the lead in sponsoring

are available provide a long ser- for membership beginning in the millions of dollars of research

vice life, even in extremely corro- year 2000. This is a major conducted by many eminent

sive environments. The use of endorsement of the quality that investigators at prestigious uni-

Modern Steel Construction / November 1997

versities. This research has ele-

vated the state-of-the-art in such

areas as wind loads on low-rise

buildings, tapered member

analysis and design, bolted end-

plate connections, and cold-

formed steel design. These

efforts have led to technically

advanced systems that are some

of the best low-rise construction

alternatives available. The effi-

cient use of materials is only sur-

passed by the performance of the

metal buildings and the satisfac-

tion of hundreds of thousands of

building owners.

Continued advancements are

planned to help take advantage

of new design methodologies,

new material advances, and new

fabrication and construction

techniques. The metal building

systems of today bear little

resemblance to the Quonset

Huts or “tin-shed” ancestors that

many still associate with the

industry. This is in large part

due to the progressive approach

that has helped metal building

systems remain on the leading

edge of low-rise construction.

W. Lee Shoemaker, Ph.D., P.E.

is Director of Research &

Engineering with the Metal

Building Manufacturers

Association in Cleveland.

You might also like

- Module 14 - Final FilesDocument1,042 pagesModule 14 - Final FilesMinami KotoriNo ratings yet

- Syringe Infusion Pump S300: Technical SpecificationDocument1 pageSyringe Infusion Pump S300: Technical SpecificationJonathan Flores Gutang100% (1)

- Hydrology Notes 4 PDFDocument12 pagesHydrology Notes 4 PDFSudin PradhanNo ratings yet

- MBS Provide Flexible Building Design OptionsDocument8 pagesMBS Provide Flexible Building Design OptionsCLAUDIO RAFAEL DA SILVANo ratings yet

- Metal Buildings: ChangersDocument24 pagesMetal Buildings: ChangersBwabt sathishNo ratings yet

- 1-s2.0-S0079642521001420-mainDocument43 pages1-s2.0-S0079642521001420-mainOğuzhan DündarNo ratings yet

- Lattice Structure Design For AmDocument9 pagesLattice Structure Design For AmNishar Alam Khan 19MCD0042No ratings yet

- latticestructuredesignforAM Researchgate PDFDocument9 pageslatticestructuredesignforAM Researchgate PDFGunaseelanMurugesanNo ratings yet

- Assessment and Design of Steel Frame Structure, Consists Performance of Connection Joints With Tekla & Staad ProDocument8 pagesAssessment and Design of Steel Frame Structure, Consists Performance of Connection Joints With Tekla & Staad ProaeoiuNo ratings yet

- A.lores 2019Document32 pagesA.lores 2019Idan FriedbergNo ratings yet

- latticestructuredesignforAM ResearchgateDocument9 pageslatticestructuredesignforAM ResearchgateChandrakiran AlapatiNo ratings yet

- Advantages of Pre-Engineered Building Over Conventional Steel BuildingsDocument9 pagesAdvantages of Pre-Engineered Building Over Conventional Steel Buildingsdawiw18153No ratings yet

- MBMA2019 Annual Report FinalDocument44 pagesMBMA2019 Annual Report FinalXuân Lâm Vũ100% (1)

- Metal Build/n" Manufacturers Ftssoc/at/onDocument8 pagesMetal Build/n" Manufacturers Ftssoc/at/onCLAUDIO RAFAEL DA SILVANo ratings yet

- Cold-Formed Steel Stud-Plank System For Mid-RiseDocument9 pagesCold-Formed Steel Stud-Plank System For Mid-RiseReaditReadit100% (1)

- Additive ManufacturingDocument8 pagesAdditive Manufacturingshiv ramanNo ratings yet

- MBMA EPD PrimaryDocument12 pagesMBMA EPD Primaryabdo youtubeNo ratings yet

- Assessment of Design Mechanical Parameters and Partial Safety Factors For Wire-And-Arc Additive Manufactured Stainless SteelDocument11 pagesAssessment of Design Mechanical Parameters and Partial Safety Factors For Wire-And-Arc Additive Manufactured Stainless Steeltrongquyet_vhpNo ratings yet

- Applications of Shape Memory Alloys in Structural EngineeringDocument21 pagesApplications of Shape Memory Alloys in Structural Engineeringamp1971No ratings yet

- Design Analysis of Structures For Residential Light Steel Framing Systems IJERTV4IS080612Document5 pagesDesign Analysis of Structures For Residential Light Steel Framing Systems IJERTV4IS080612RAMPRASAD SNo ratings yet

- Light Steel PapaerDocument6 pagesLight Steel PapaerAsebaho BadrNo ratings yet

- Additive Manufacturing of Steels: A Review of Achievements and ChallengesDocument44 pagesAdditive Manufacturing of Steels: A Review of Achievements and ChallengesExp KNo ratings yet

- Benedetti Et Al. - 2021 - Architected Cellular Materials A Review On TheirDocument40 pagesBenedetti Et Al. - 2021 - Architected Cellular Materials A Review On Theirxu.dachong59No ratings yet

- MatToday AlloyDesign 2022Document19 pagesMatToday AlloyDesign 2022Muhammed NayeemNo ratings yet

- Additive Manufacturing: H.R. Kotadia, Associate Professor, G. Gibbons, A. Das, P.D. HowesDocument23 pagesAdditive Manufacturing: H.R. Kotadia, Associate Professor, G. Gibbons, A. Das, P.D. HowesÁlvaro Nieto CastroNo ratings yet

- Design and Analysis of Pre Engineer Frame With Is800 2007Document8 pagesDesign and Analysis of Pre Engineer Frame With Is800 2007Triệu Duy AnhNo ratings yet

- SLM Additive Manufacture of H13 Tool Steel With Conformal Cooling and Structural LatticesDocument16 pagesSLM Additive Manufacture of H13 Tool Steel With Conformal Cooling and Structural LatticesjNo ratings yet

- Investment Casting Design & Applications Lessons from AerospaceDocument7 pagesInvestment Casting Design & Applications Lessons from AerospaceAnonymous 9xvU1FNo ratings yet

- Panelization of Light Gage Steel Framing - From Start To FinishDocument2 pagesPanelization of Light Gage Steel Framing - From Start To FinishDaveNo ratings yet

- A Review of The Wire Arc Additive Manufacturing of Metals: Properties, Defects and Quality ImprovementDocument14 pagesA Review of The Wire Arc Additive Manufacturing of Metals: Properties, Defects and Quality ImprovementSaketh BachuNo ratings yet

- 1 s2.0 S0261306914007857 MainDocument19 pages1 s2.0 S0261306914007857 Mainavsriv07No ratings yet

- Selective Laser Melting SLM of AlSi12Mg Lattice Stru - 2016 - Materials - Desi PDFDocument14 pagesSelective Laser Melting SLM of AlSi12Mg Lattice Stru - 2016 - Materials - Desi PDFJagbir SinghNo ratings yet

- 2006 Umilling Strategies Thin FeaturesDocument9 pages2006 Umilling Strategies Thin Featuresgande10No ratings yet

- Pre Engineered BuildingsDocument10 pagesPre Engineered BuildingsVelu KaruppiahNo ratings yet

- Characterization of Lattice Structures For Additive Manufacturing of Lightweight Mechanical ComponentsDocument9 pagesCharacterization of Lattice Structures For Additive Manufacturing of Lightweight Mechanical ComponentsGunaseelanMurugesanNo ratings yet

- Geometrical Metrology For Metal Additive ManufacturingDocument24 pagesGeometrical Metrology For Metal Additive ManufacturingPhilipe Saraiva CruzNo ratings yet

- Concrete Superstructures - Concrete Construction Magazine - 1Document4 pagesConcrete Superstructures - Concrete Construction Magazine - 1Jason toraldeNo ratings yet

- Digital Twin-Enabled Collaborative Data Management For Metal AdditiveDocument18 pagesDigital Twin-Enabled Collaborative Data Management For Metal Additivedecardo.ivander.simarmataNo ratings yet

- 1 s2.0 S2352710222000195 MainDocument33 pages1 s2.0 S2352710222000195 MainJuanojo RivasNo ratings yet

- Document 2 GobR 07042017Document5 pagesDocument 2 GobR 07042017Rahul KumarNo ratings yet

- Svetsaren Vol 54 Adding NO To The Argon or ArgonDocument8 pagesSvetsaren Vol 54 Adding NO To The Argon or ArgonlvcuichanghuaNo ratings yet

- Health CareDocument12 pagesHealth CareDemetrios GkikasNo ratings yet

- Shed DesignDocument60 pagesShed DesignkrishnakumarjhajharaNo ratings yet

- BCSA - Steel Bridges Book 2010Document94 pagesBCSA - Steel Bridges Book 2010harri.sauvalaNo ratings yet

- COST-EFFECTIVE PEB BUILDINGDocument4 pagesCOST-EFFECTIVE PEB BUILDINGSandeep SolankiNo ratings yet

- Strength - and Beauty: New Steel Systems AddDocument4 pagesStrength - and Beauty: New Steel Systems AddAsaru DeenNo ratings yet

- 3D Printing of Aluminium Alloys Additive Manufacturing of Aluminium Alloys Using Selective Laser MeltingDocument45 pages3D Printing of Aluminium Alloys Additive Manufacturing of Aluminium Alloys Using Selective Laser MeltingGonçalo MonteiroNo ratings yet

- Best Practice IndustrialDocument60 pagesBest Practice Industrialplienovyras100% (3)

- Peb Kbsil Rev 1Document57 pagesPeb Kbsil Rev 1prabhakarsunku100% (2)

- Shape Memory Alloy For Sound VibrationDocument25 pagesShape Memory Alloy For Sound VibrationForsythe LearningNo ratings yet

- Affliated To KadpolyDocument3 pagesAffliated To KadpolyDon MustyNo ratings yet

- Bim and Modular Mep Systems For Super-Tall and Mega-Tall BuildingsDocument10 pagesBim and Modular Mep Systems For Super-Tall and Mega-Tall Buildingsel wahabi omarNo ratings yet

- Bim and Modular Mep Systems For Super-Tall and Mega-Tall BuildingsDocument10 pagesBim and Modular Mep Systems For Super-Tall and Mega-Tall BuildingsHa LamNo ratings yet

- RC ReviewDocument9 pagesRC ReviewMarco PlebaniNo ratings yet

- Industrial Building Design Study Using STAAD ProDocument6 pagesIndustrial Building Design Study Using STAAD ProShubhamNo ratings yet

- Shao 2019Document13 pagesShao 2019Venkatesh PandianNo ratings yet

- An Rfi-Free World: Take These Steps To Avoid Round After Round of RfisDocument8 pagesAn Rfi-Free World: Take These Steps To Avoid Round After Round of RfisekaciptaNo ratings yet

- Utilizing Shape Memory Alloys To Enhance The PerfoDocument14 pagesUtilizing Shape Memory Alloys To Enhance The PerfoEstephanie_GrassiNo ratings yet

- Composites Applied For PistonsDocument4 pagesComposites Applied For PistonsRajendra JadhavNo ratings yet

- Mivan Vs ConvDocument5 pagesMivan Vs ConvAkhil SurendranNo ratings yet

- Spot Welding Interview Success: An Introduction to Spot WeldingFrom EverandSpot Welding Interview Success: An Introduction to Spot WeldingNo ratings yet

- MEMS Product Development: From Concept to CommercializationFrom EverandMEMS Product Development: From Concept to CommercializationNo ratings yet

- Complete Guide Inventory ManagementDocument73 pagesComplete Guide Inventory ManagementJeampierr JIMENEZ MARQUEZNo ratings yet

- 8 YouTube Channels For LearningDocument10 pages8 YouTube Channels For LearningapNo ratings yet

- TCB Role Measurement CalibarationDocument68 pagesTCB Role Measurement CalibarationRidhWanNo ratings yet

- NMMS EXAM NOTIFICATION Dec 2021Document7 pagesNMMS EXAM NOTIFICATION Dec 2021apNo ratings yet

- Cutting HardoxDocument20 pagesCutting HardoxapNo ratings yet

- Tutorial of Mobile Application of AMSDocument16 pagesTutorial of Mobile Application of AMSapNo ratings yet

- PEB Structure To Commence After 1.3 Mtr. High Brick Construction All Around From Plinth LevelDocument4 pagesPEB Structure To Commence After 1.3 Mtr. High Brick Construction All Around From Plinth LevelapNo ratings yet

- Welding CostsDocument13 pagesWelding CostsJohan AviantoNo ratings yet

- 1 2Document4 pages1 2apNo ratings yet

- Practicum ISO 9606 GTAW On The Work FloorDocument6 pagesPracticum ISO 9606 GTAW On The Work FloorapNo ratings yet

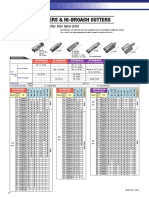

- Annular Cutters Guide: Broach Cutter Benefits & SpecificationsDocument1 pageAnnular Cutters Guide: Broach Cutter Benefits & SpecificationsapNo ratings yet

- Dimensions in Engineering DrawinDocument20 pagesDimensions in Engineering DrawinapNo ratings yet

- Practical Guide To Using Duplex Stainless Steels: A Guide To The Use of Nickel-Containing AlloysDocument20 pagesPractical Guide To Using Duplex Stainless Steels: A Guide To The Use of Nickel-Containing AlloysapNo ratings yet

- Basic Metallurgy For Welding and Fabricating ProfessionalsDocument190 pagesBasic Metallurgy For Welding and Fabricating ProfessionalsPuneet sharmaNo ratings yet

- With The Knowledge of Now Error-Free in The Future-1Document5 pagesWith The Knowledge of Now Error-Free in The Future-1apNo ratings yet

- Installation Procedure For Rotating EquipmentDocument25 pagesInstallation Procedure For Rotating EquipmentapNo ratings yet

- Syllabus Against Vacancy Notice No. 09-2020, 18-2020Document2 pagesSyllabus Against Vacancy Notice No. 09-2020, 18-2020apNo ratings yet

- Mech Forging Fittings Process GuideDocument1 pageMech Forging Fittings Process GuideapNo ratings yet

- Welding ImpuritiesDocument11 pagesWelding ImpuritiesapNo ratings yet

- Prelim Quiz 1 ResultsDocument27 pagesPrelim Quiz 1 Resultsgummy bearNo ratings yet

- Technical Card: Information OnlyDocument1 pageTechnical Card: Information OnlyBhuvnesh VermaNo ratings yet

- Assignment 5: Engineering Utilities IiDocument4 pagesAssignment 5: Engineering Utilities IiRex SabersonNo ratings yet

- Domestic Water-Supply - TheoryDocument19 pagesDomestic Water-Supply - Theoryyarzar17No ratings yet

- Ambiguity in Legal Translation: Salah Bouregbi Badji Mokhtar University Annaba - Algeria - Salihbourg@Document14 pagesAmbiguity in Legal Translation: Salah Bouregbi Badji Mokhtar University Annaba - Algeria - Salihbourg@MerHamNo ratings yet

- Simple 2 Way Motor Control For The ArduinoDocument6 pagesSimple 2 Way Motor Control For The ArduinoDália Rafaela Lopes da Costa PenhaNo ratings yet

- David Kassan DemoDocument3 pagesDavid Kassan DemokingkincoolNo ratings yet

- Communication TasksDocument19 pagesCommunication Taskswaqas08100% (4)

- Organograma ASME IX Art. I PDFDocument4 pagesOrganograma ASME IX Art. I PDFfabiocorreasilvaNo ratings yet

- Ryan Ashby DickinsonDocument2 pagesRyan Ashby Dickinsonapi-347999772No ratings yet

- Cost-Time-Resource Sheet for Rumaila Oil Field Engineering ServicesDocument13 pagesCost-Time-Resource Sheet for Rumaila Oil Field Engineering ServicesonlyikramNo ratings yet

- 2GIG ZWave CT30e Thermostat Installation GuideDocument19 pages2GIG ZWave CT30e Thermostat Installation Guideyamimaker2002No ratings yet

- Human Rights Law IntroductionDocument8 pagesHuman Rights Law IntroductionXander ZingapanNo ratings yet

- Distributed Tic-Tac-Toe: Requirements, Design & AnalysisDocument8 pagesDistributed Tic-Tac-Toe: Requirements, Design & AnalysisRitika AgnihotriNo ratings yet

- BS en 13035-9-2006 + A1-2010Document24 pagesBS en 13035-9-2006 + A1-2010DoicielNo ratings yet

- Organization Management and LeadershipDocument26 pagesOrganization Management and LeadershipOtilia BadeaNo ratings yet

- Casey Cannon: EducationDocument1 pageCasey Cannon: Educationapi-355305449No ratings yet

- Responses to Empiricism and Structuralism in Social SciencesDocument13 pagesResponses to Empiricism and Structuralism in Social Sciencesphils_skoreaNo ratings yet

- 1 s2.0 S1877042816311582 MainDocument8 pages1 s2.0 S1877042816311582 MainAilyn rodilNo ratings yet

- Solution Manual For Macroeconomics 13th Edition Michael ParkinDocument24 pagesSolution Manual For Macroeconomics 13th Edition Michael ParkinBonnieGoodmanxajb100% (45)

- Manual of Establishment Sections 05ff58f7947ffb7 76283342Document271 pagesManual of Establishment Sections 05ff58f7947ffb7 76283342Vijaya KumariNo ratings yet

- 19bcd7246 Assignment2 L27+L28+L31+L32Document7 pages19bcd7246 Assignment2 L27+L28+L31+L32Sriharshitha DeepalaNo ratings yet

- TH - TB Series (Helical GearBox Catalog)Document94 pagesTH - TB Series (Helical GearBox Catalog)poorianaNo ratings yet

- Creating Quizzes in MS PowerPointDocument6 pagesCreating Quizzes in MS PowerPointZiel Cabungcal CardañoNo ratings yet

- B.Tech (ECE) Course Scheme & Syllabus as per CBCSDocument168 pagesB.Tech (ECE) Course Scheme & Syllabus as per CBCSRatsihNo ratings yet

- Sem 656DDocument1 pageSem 656DCarlos Arturo AcevedoNo ratings yet

- Uncertainty in Measurements - Lab ReportDocument4 pagesUncertainty in Measurements - Lab ReportStaniaNo ratings yet