Professional Documents

Culture Documents

SB 11-002 Requirements of Biofuel Usage

SB 11-002 Requirements of Biofuel Usage

Uploaded by

Phil B.Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SB 11-002 Requirements of Biofuel Usage

SB 11-002 Requirements of Biofuel Usage

Uploaded by

Phil B.Copyright:

Available Formats

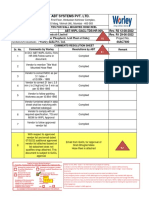

Group: 22- Fuel system

Warranty Code: 121

Bulletin No. SB-11-002

Issue Date: 08-10-2011

SERVICE INFORMATION BULLETIN

Subject:

REQUIREMENTS OF BIOFUEL USAGE FOR 2008MY THRU 2012MY VEHICLES

This document is to inform dealers and workshops of the contents.

1. RELEVANT MODELS:

2008MY 2009MY

2008MY, 2009MY, 2010MY

2010MY, 2011MY and 2012MY

2. CONDITION OF BIOFUEL USAGE:

1) 2008MY, 2009MY, 2010MY

{Up to B5: Available with Conditions}

{Above B5 to below B20: Not available}

2) 2011MY, 2012MY

{Up to B5: Available with Conditions}

{Above B5 to below B20: Available with Conditions}

3. CONDITION DETAILS:

1) 2008MY, 2009MY, 2010MY

{Up to B5: Available with Conditions}

Biofuel blend stock (B100) must be compliant to ASTM D6751, and blended fuel must be

compliant to ASTM D975.

{Above B5 to below B20: Not available}

More than B5 Biofuel can not be used.

The use of Biofuel in excess of B5 will void engine warranty.

Page 1 Vendor Ref: SB–A–22-022

Group: 22- Fuel system

Warranty Code: 121

Bulletin No. SB-11-002

Issue Date: 08-10-2011

SERVICE INFORMATION BULLETIN

2) 2011MY, 2012MY

{Up to B5: Available with Conditions}

1 Biofuel

1. Bi f l blend

bl d stockk (B100) must b be compliant

li to ASTM D6751

D6751, andd bl

blended

d d ffuell must b

be

compliant to ASTM D975.

2. Following materials must not be used in fuel or fuel system components.

Natural rubber, Butyl rubber, Nitrile rubber, Copper, Bronze, Brass, Tin, Lead and zinc

{Above B5 to below B20: Available with Conditions}

1. Biofuel blend stock (B100) must be compliant to ASTM D6751, and blended fuel must be

compliant to ASTM D7467.

2. Use fuel within 6 months from manufacturing date, in addition, use it up within 3 months after

fueling, because the oxidation stability of Biodiesel is lower than diesel fuel.

3. When switching to the Biofuel which tends to dissolve the deposits generated by using

normal diesel fuel, it is required that tank and piping are cleaned and fuel filter elements are

changed.

g

4. Clean storage tank thoroughly, and be careful of water and occurrence of microorganisms.

ENGINE COMPONENT

1. Periodical cleaning with specified injector cleaner is recommended.

Injector cleaner{Part name: Diesel cleaner Part No: S2367-E0010}

q

2. Frequently y check engine

g oil level,, and if oil dilution occurs,, change

g oil.

Oil change interval will be shorter than normal.

3. An additional fuel filter is recommended. Change the filter at 10,000 mile intervals.

4. Comparing to regular fuel, more water accumulates in sedimenter, therefore, frequently drain

the water from sedimenter.

5. In cold climate, the use of an appropriate fuel heater is recommended.

6. Following materials must not be used in fuel or fuel system components.

Natural rubber

rubber, Butyl rubber

rubber, Nitrile rubber

rubber, Copper

Copper, Bronze

Bronze, Brass

Brass, Tin

Tin, Lead and zinc

FUEL DISTRIBUTION

1. Purchase from fuel handlers licensed under BQ9000.

Page 2 Vendor Ref: SB-A-22-022

Group: 22- Fuel system

Warranty Code: 121

Bulletin No. SB-11-002

Issue Date: 08-10-2011

SERVICE INFORMATION BULLETIN

#DLC: Diamond Like Carbon coating on injector nozzle.

g j

Page 3 Vendor Ref: SB–A–22-022

Group: 22- Fuel system

Warranty Code: 121

Bulletin No. SB-11-002

Issue Date: 08-10-2011

SERVICE INFORMATION BULLETIN

#DLC: Diamond Like Carbon coating on injector nozzle.

Page 4 Vendor Ref: SB–A–22-022

You might also like

- RPM Tech LM220 Parts Catalog s0300 Pmef 2676 and More Rev2Document100 pagesRPM Tech LM220 Parts Catalog s0300 Pmef 2676 and More Rev2Phil B.No ratings yet

- John Deere Workshop Manual PDFDocument678 pagesJohn Deere Workshop Manual PDFbagus75% (4)

- 1005 0 Installation ManualDocument65 pages1005 0 Installation ManualKhaledNo ratings yet

- Biland Sa-250: Technical SpecificationsDocument4 pagesBiland Sa-250: Technical SpecificationsNofriagara Davit HarnawanNo ratings yet

- Iocl Tender Bio-DieselDocument21 pagesIocl Tender Bio-DieselHussain Shaikh100% (1)

- 0001 - M25 - e KBB TC HPR6000 ModificationDocument3 pages0001 - M25 - e KBB TC HPR6000 ModificationAnshul AsthanaNo ratings yet

- Sebu8495-03 MDocument87 pagesSebu8495-03 MGabriel Suarez100% (2)

- 44ac7400 5179 Dhse F03 0009 A4 - Abt Wipl Gacl TDS HR 09 R2 C4Document5 pages44ac7400 5179 Dhse F03 0009 A4 - Abt Wipl Gacl TDS HR 09 R2 C4Deepak KaleNo ratings yet

- Vtv-3281-Lit-9511-Pp-Doc-052 - Rev 1Document14 pagesVtv-3281-Lit-9511-Pp-Doc-052 - Rev 1VIVEK TIWARINo ratings yet

- Bizol PDBDocument2 pagesBizol PDBhiramfgarciaNo ratings yet

- BIZOL Allround 5W-30: BenefitsDocument2 pagesBIZOL Allround 5W-30: Benefitsgolden-eagle2015No ratings yet

- Final Oiling of Cold-Rolled Metal Sheets : Supply Specification Rolling Mill Oils/prelubes DBL 6757Document5 pagesFinal Oiling of Cold-Rolled Metal Sheets : Supply Specification Rolling Mill Oils/prelubes DBL 6757Huahua ChuengNo ratings yet

- C211050 01 VCS Iocl Tender 001 - D2Document619 pagesC211050 01 VCS Iocl Tender 001 - D2Aqib Khan VCSPNo ratings yet

- Elite Evolution Long Life 5W-30: LubricantsDocument1 pageElite Evolution Long Life 5W-30: Lubricantstehnicar1No ratings yet

- P004087 Leichtlauf Energy 0W 40 17 en - GBDocument1 pageP004087 Leichtlauf Energy 0W 40 17 en - GBHalil Marcelo SejkicNo ratings yet

- Biodiesel Fuel: ASTM Standard For Biodiesel (ASTM D6751)Document7 pagesBiodiesel Fuel: ASTM Standard For Biodiesel (ASTM D6751)Jaffarudin Janu WahyudiNo ratings yet

- Klüberlub BE 71-501: Special Lubricating Grease For Rolling and Plain BearingsDocument4 pagesKlüberlub BE 71-501: Special Lubricating Grease For Rolling and Plain Bearingsphucdc095041No ratings yet

- Vtv-3281-Lit-9511-Pp-Doc-034 R3Document13 pagesVtv-3281-Lit-9511-Pp-Doc-034 R3VIVEK TIWARINo ratings yet

- Vtv-3281-Lit-9511-Pp-Doc-052 - Rev 0Document14 pagesVtv-3281-Lit-9511-Pp-Doc-052 - Rev 0VIVEK TIWARINo ratings yet

- Section Cover Page: Section 22 13 65 2010-12-01 Sewage Holding TanksDocument5 pagesSection Cover Page: Section 22 13 65 2010-12-01 Sewage Holding Tanksngoclinh87No ratings yet

- HydrostaticDocument7 pagesHydrostatichafzanborhanNo ratings yet

- As For Boiler PackagesDocument17 pagesAs For Boiler PackagesjkNo ratings yet

- Anderol® 555 - en - USDocument3 pagesAnderol® 555 - en - USa3.msaputra0% (1)

- Bpxe 8Z56LRDocument2 pagesBpxe 8Z56LRVusal HasanovNo ratings yet

- VTV-3281-LIT-9511-PP-DOC-030 Rev.2Document9 pagesVTV-3281-LIT-9511-PP-DOC-030 Rev.2VIVEK TIWARINo ratings yet

- UNIREX™ N Series UNIREX™ N Series UNIREX™ N Series UNIREX™ N SeriesDocument3 pagesUNIREX™ N Series UNIREX™ N Series UNIREX™ N Series UNIREX™ N Series121212No ratings yet

- Baldwin Fuel Filters Comp Bio-Diesel Blend Eng BLLTNDocument1 pageBaldwin Fuel Filters Comp Bio-Diesel Blend Eng BLLTNSMcNo ratings yet

- Chapter - 06 - 0199-99-2091-Engine CoolantDocument8 pagesChapter - 06 - 0199-99-2091-Engine CoolantAbbas PartoviNo ratings yet

- Pds Sinopec Compressor Oil Dab 1Document3 pagesPds Sinopec Compressor Oil Dab 1gofino.drNo ratings yet

- Vtv-3281-Lit-9511-Pp-Doc-025 R3Document10 pagesVtv-3281-Lit-9511-Pp-Doc-025 R3VIVEK TIWARINo ratings yet

- 50 Pies 00065 - BBDocument6 pages50 Pies 00065 - BBbsnegi111No ratings yet

- KAJO-BIO-Longlife Grease LZR 2: Product InformationDocument2 pagesKAJO-BIO-Longlife Grease LZR 2: Product InformationMassimiliano VolaNo ratings yet

- Bizol PDB PDFDocument2 pagesBizol PDB PDFCarlos Humbeto Portillo MendezNo ratings yet

- MR ValvesDocument56 pagesMR ValvesIdris SiddiquiNo ratings yet

- Chapter - 08 - 0199-99-2090-Lube OilDocument8 pagesChapter - 08 - 0199-99-2090-Lube OilAbbas PartoviNo ratings yet

- SB 06-002 Fuel Filter UsageDocument2 pagesSB 06-002 Fuel Filter UsagePhil B.No ratings yet

- PHMSA 2017 0158 0001 - Attachment - 37Document300 pagesPHMSA 2017 0158 0001 - Attachment - 37Pammy JainNo ratings yet

- Product Information: Megol Motorenoel New Generation SAE 5W-30Document1 pageProduct Information: Megol Motorenoel New Generation SAE 5W-30Valeriy ValkovetsNo ratings yet

- Copper Indirect Cylinders For Domestic Purposes: Part 1: Open Vented Copper Cylinders - Requirements and Test MethodsDocument22 pagesCopper Indirect Cylinders For Domestic Purposes: Part 1: Open Vented Copper Cylinders - Requirements and Test Methodscaptain sparrowNo ratings yet

- Jenbacher: 1. Range of ApplicationDocument1 pageJenbacher: 1. Range of ApplicationArîfNo ratings yet

- P004283 Molygen New Generation 5W 30 DPF 21 en - GBDocument1 pageP004283 Molygen New Generation 5W 30 DPF 21 en - GBshadow.line.contracting.bhNo ratings yet

- NDE-6407 Rev0Document116 pagesNDE-6407 Rev0konazoiNo ratings yet

- RAVENOL HTC Concentrate Protect MB325.0Document3 pagesRAVENOL HTC Concentrate Protect MB325.0Андрей СилаевNo ratings yet

- Leader Neo 10W-30 enDocument2 pagesLeader Neo 10W-30 ennitty shiggersNo ratings yet

- Application Engineering Bulletin: PurposeDocument9 pagesApplication Engineering Bulletin: PurposeCesar G.No ratings yet

- P003998 Special Tec F 0W 30 33 en - GBDocument1 pageP003998 Special Tec F 0W 30 33 en - GBAXIS LUBRIFICANTESNo ratings yet

- Anderol® 3057M - en - USDocument4 pagesAnderol® 3057M - en - USFederico GomezNo ratings yet

- Bharat Heavy Electricals Limited: Tiruchirappalli-620 014 Fuel Systems/PE (FB)Document5 pagesBharat Heavy Electricals Limited: Tiruchirappalli-620 014 Fuel Systems/PE (FB)bmanojkumar16No ratings yet

- Technical Bulletin: FuelsDocument33 pagesTechnical Bulletin: Fuelsrojilhisdnata1020No ratings yet

- 2291ET55001-0 CeldasDocument12 pages2291ET55001-0 CeldasRoberto Cortés DíazNo ratings yet

- Tender Document - GAIL - MIJ PDFDocument17 pagesTender Document - GAIL - MIJ PDFVeer GangjiNo ratings yet

- p021.46 Db54 Mat Mep Mech 027 Float Valve, Angle Valve, Bibtap Rev 00Document44 pagesp021.46 Db54 Mat Mep Mech 027 Float Valve, Angle Valve, Bibtap Rev 00p4p7 projectsNo ratings yet

- Globe Rev. A SHT 2Document1 pageGlobe Rev. A SHT 2Agus SupriadiNo ratings yet

- Another Biodiesel ThingDocument3 pagesAnother Biodiesel ThingAaron ZinkNo ratings yet

- Technical Circular: 2 ExchangeDocument16 pagesTechnical Circular: 2 Exchangepayman baharehNo ratings yet

- BELL - Спецификации смазочных материалов для самосвалов БеллDocument1 pageBELL - Спецификации смазочных материалов для самосвалов БеллАлександр СимуковNo ratings yet

- DDC OilDocument4 pagesDDC Oilnetemma97No ratings yet

- Product Information: Megol Motorenoel Quality SAE 5W-30Document1 pageProduct Information: Megol Motorenoel Quality SAE 5W-30Valeriy ValkovetsNo ratings yet

- Specification For Ductile Iron Pillar HydrantsDocument12 pagesSpecification For Ductile Iron Pillar HydrantsyogeswaranNo ratings yet

- Sae 20W50 Dana Semi Synthetic Oil Gasoline Engine PDFDocument2 pagesSae 20W50 Dana Semi Synthetic Oil Gasoline Engine PDFChemilomNo ratings yet

- 1 Standard Parts, Service PDFDocument59 pages1 Standard Parts, Service PDFPorfidi FerrariNo ratings yet

- Quality System Document 03 Decorative Finishes-Electroplating SpecificationDocument4 pagesQuality System Document 03 Decorative Finishes-Electroplating Specificationocy1212No ratings yet

- Financing Solutions to Reduce Natural Gas Flaring and Methane EmissionsFrom EverandFinancing Solutions to Reduce Natural Gas Flaring and Methane EmissionsRating: 5 out of 5 stars5/5 (1)

- RPM Tech LM220 Snow Blower BrochureDocument4 pagesRPM Tech LM220 Snow Blower BrochurePhil B.No ratings yet

- RPM Tech LM220 Brochure 01 2020 en SourcewellDocument4 pagesRPM Tech LM220 Brochure 01 2020 en SourcewellPhil B.No ratings yet

- SB-16-034 COE Hydroboost Reservoir Fluid OverflowDocument8 pagesSB-16-034 COE Hydroboost Reservoir Fluid OverflowPhil B.No ratings yet

- SB-16-027 J08E Rocker Arm Torque Bolt Change Workshop Manual CorrectionDocument4 pagesSB-16-027 J08E Rocker Arm Torque Bolt Change Workshop Manual CorrectionPhil B.No ratings yet

- SB-16-022 11MY-14MY Conventional Burner Atomizer Repair ProcedureDocument15 pagesSB-16-022 11MY-14MY Conventional Burner Atomizer Repair ProcedurePhil B.No ratings yet

- SB-16-015 11MY-17MY Conventional DCU Software UpdateDocument3 pagesSB-16-015 11MY-17MY Conventional DCU Software UpdatePhil B.No ratings yet

- SB-15-032 P2030 Workshop Manual CorrectionDocument34 pagesSB-15-032 P2030 Workshop Manual CorrectionPhil B.No ratings yet

- SB-16-006 11MY-16MY Conventional Rear Spring Pad LooseDocument11 pagesSB-16-006 11MY-16MY Conventional Rear Spring Pad LoosePhil B.No ratings yet

- SB-15-035 13MY-16MY COE Seat Bolt Loose or MissingDocument6 pagesSB-15-035 13MY-16MY COE Seat Bolt Loose or MissingPhil B.No ratings yet

- Catalytic Converter), Power Alcohol. Knocking, OctaneDocument1 pageCatalytic Converter), Power Alcohol. Knocking, OctaneHoney SinghNo ratings yet

- 2011 Biofuels Baseline 2008Document553 pages2011 Biofuels Baseline 2008Roxana BerceaNo ratings yet

- Kdi 1903 TCRDocument315 pagesKdi 1903 TCRangelNo ratings yet

- 2012 PTQ q1Document132 pages2012 PTQ q1jainrakeshj4987No ratings yet

- Course Instructor Professor Department of Mechanical Engineering Indian Institute of Technology Kanpur, KanpurDocument44 pagesCourse Instructor Professor Department of Mechanical Engineering Indian Institute of Technology Kanpur, KanpurUPSC PREPARATIONNo ratings yet

- 21CH12-UNIT-II NotesDocument36 pages21CH12-UNIT-II NotesakashNo ratings yet

- RegulationsDocument70 pagesRegulationsTri Wahyu AprilianaNo ratings yet

- Ultramid, Ultradur, Ultraform PDFDocument52 pagesUltramid, Ultradur, Ultraform PDFkfaravNo ratings yet

- Journal of Industrial and Engineering Chemistry: I.M. Atadashi, M.K. Aroua, A.R. Abdul Aziz, N.M.N. SulaimanDocument13 pagesJournal of Industrial and Engineering Chemistry: I.M. Atadashi, M.K. Aroua, A.R. Abdul Aziz, N.M.N. SulaimanAdhemuhammadNo ratings yet

- FH239 Industrial Pro NanonetDocument2 pagesFH239 Industrial Pro NanonetCastro RicardoNo ratings yet

- Combustibles, Lubricantes y FluidosDocument48 pagesCombustibles, Lubricantes y Fluidoswilmar_tovar_10% (1)

- Applied Catalysis A, General: SciencedirectDocument15 pagesApplied Catalysis A, General: Sciencedirectcholila_tamzysiNo ratings yet

- Read The Text and Answers The Questions Below! Biodiesel Please Look at The Picture and Explain With Your Own Words! How Is Glass RecycledDocument1 pageRead The Text and Answers The Questions Below! Biodiesel Please Look at The Picture and Explain With Your Own Words! How Is Glass RecycledRizkhi Ramadhani100% (1)

- Compro PT Jawa Lumbung MasDocument15 pagesCompro PT Jawa Lumbung MasmariyantomarwatNo ratings yet

- 2011 Parts Cat Ride RMDocument50 pages2011 Parts Cat Ride RMMotokoy Sprekitik TakoykoyNo ratings yet

- Markscheme: May 2017 Chemistry Higher Level Paper 3Document41 pagesMarkscheme: May 2017 Chemistry Higher Level Paper 3HUI GABRIEL YAN LUNG G10L-13No ratings yet

- Fuel Quality Monitoring by Color DetectionDocument23 pagesFuel Quality Monitoring by Color DetectionAeriel Venice VergaraNo ratings yet

- Kinetics Sodium PhosphateDocument8 pagesKinetics Sodium Phosphateark04No ratings yet

- IJMEIR - Choirudin Nur Ruyan - 04211840000077Document7 pagesIJMEIR - Choirudin Nur Ruyan - 04211840000077Jaya BayuNo ratings yet

- Alternative Fuels L120G VolvoDocument3 pagesAlternative Fuels L120G Volvokianoush Volvo construction equipmentNo ratings yet

- Catalogue - Filtertec Utama Laksana (FUeL)Document8 pagesCatalogue - Filtertec Utama Laksana (FUeL)yonoNo ratings yet

- Equilibrio Biodiesel (Nuez de Brasil - Metanol) 1Document7 pagesEquilibrio Biodiesel (Nuez de Brasil - Metanol) 1Gerson Larios GilesNo ratings yet

- Journal Pre-Proofs: Bioresource TechnologyDocument51 pagesJournal Pre-Proofs: Bioresource TechnologyLeoo Cotrina FranciaNo ratings yet

- Biomass As An Alternative Source of EnergyDocument8 pagesBiomass As An Alternative Source of EnergyDenielle MarceñoNo ratings yet

- 314e LCRDocument24 pages314e LCRFrancisco CostaNo ratings yet

- Filtration Solutions For HPCRDocument9 pagesFiltration Solutions For HPCRromulozgNo ratings yet

- Planning Waste Cooking Oil Collection SyDocument13 pagesPlanning Waste Cooking Oil Collection SyT. LimNo ratings yet