Professional Documents

Culture Documents

2291ET55001-0 Celdas

Uploaded by

Roberto Cortés DíazCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2291ET55001-0 Celdas

Uploaded by

Roberto Cortés DíazCopyright:

Available Formats

MINERA ESCONDIDA LTDA.

PROYECTO N° 2291

AMPLIACION CAPACIDAD OXIDOS

Nº 2291-ET- 55-001

GENERAL REQUIREMENTS

FOR

POLYMER CONCRETE CELLS

Preparado por:

FLUOR DANIEL CHILE

APROBADO POR

Ingeniero de Disciplina Guillermo Jorquera

Ingeniero de Proyecto Guillermo Jorquera

Gerente de Proyecto Carlos Astorga

Cliente Osvaldo Acevedo

REV. BY ISSUE DATE CHK'D TECH.

APPROV'L

A GJQ Emitido para Coordinación Interna 03- May-00

B GJQ Emitido para aprobación del Cliente 11-May-00

0 GJQ Emitido para Compra 10-Jul-00

MINERA ESCONDIDA LTDA. Technical Specification N°2291-ET-55-001

AMPLIACION CAPACIDAD OXIDOS Pag. 1 de 11

PROYECTO N° 2291 Jul 10, 2000

Rev 0

FLUOR DANIEL CHILE S.A.

TABLE OF CONTENTS

Pag.

1.0 GENERAL 2

2.0 PRODUCTS 3

3.0 EXECUTION 5

4.0 ATTACHMENTS 6

/conversion/tmp/scratch/431390423.doc POLYMER CONCRETE CELLS

MINERA ESCONDIDA LTDA. Technical Specification N°2291-ET-55-001

AMPLIACION CAPACIDAD OXIDOS Pag. 2 de 11

PROYECTO N° 2291 Jul 10, 2000

Rev 0

FLUOR DANIEL CHILE S.A.

1.0 GENERAL

1.1 Summary

A. Scope of Specification

1. This specification describes the minimum requirements for polymer concrete cells for application in

an Electrowinning Circuit.

2. Supplier to design, manufacture and supply monolithic electrowinning cells constructed of polymer

concrete suitable for the process fluid and duty given in Specification Data Sheet 1. Sellers scope

shall include, design of lifting devices, supply of discharge "box" with integral PVC pipe spool,

baffle, level weir, flow measurement weir, support bricks, grout, shims, intercell fill, feed distribution

pipe with siphon break and supports, sludge drain with neoprene plug, decant drain and walkway

supports.

B. Work Not Included

Foundations, cell installation, feed and discharge piping external to cell, anodes and cathodes, wall caps,

pads and cap blocks.

C. Related Specifications

Work in this specification shall be coordinated with, and conform to, Process Data Sheet Attachment 1,

Dimensional Tolerances Data sheet - Attachment 2, Site Conditions Attachment 3.

1.2 References

The publications listed below shall form part of this specification. The latest revision and addendum in effect on

the date of issue for construction shall apply.

UBC (Uniform Building Code)

1.3 Submittals

Seller shall supply documentation in accordance with the latest revision of Form E-212.

1.4 Quality Assurance

A. Seller shall guarantee that the cells meet all specified operating conditions and are satisfactory for the

conditions described in this specification and in the Process, Dimensional Tolerances and Site Data Sheets.

B. Seller shall develop and apply Quality Assurance and Quality Control Procedures and make them available

to Buyer upon request.

C. The cells shall be warranted for a minimum five years against leakage, chemical attack, mechanical abuse

from falling anodes or cathodes, and/or deviations from the specified dimensional tolerances (other than

changes due to thermal expansion). This is in addition to workmanship and material guarantee presented

elsewhere.

/conversion/tmp/scratch/431390423.doc POLYMER CONCRETE CELLS

MINERA ESCONDIDA LTDA. Technical Specification N°2291-ET-55-001

AMPLIACION CAPACIDAD OXIDOS Pag. 3 de 11

PROYECTO N° 2291 Jul 10, 2000

Rev 0

FLUOR DANIEL CHILE S.A.

D. At the end of five years of warranted service, the SELLER will conduct a thorough inspection in

conjunction with Buyer's personnel. After successful inspection and any required repairs made, the cells

will be warranted for an additional five years. The SELLER will be responsible for the cost of the

inspection and repairs.

2.0 PRODUCTS

2.1 Materials of Construction

A. Polymer concrete resin shall be a modified vinylester. The base vinylester resin shall be Derakane 411-PC

100.

B. All aggregate shall be properly cleaned and sized such that the resin used will entirely wet the surface of the

aggregate.

C. All aggregate shall be silica based, dry materials that are inherently resistant to corrosion caused by sulfuric

acid, copper sulfate, ferric sulfate solutions and carry over of organic solvents. The aggregate mixture must

contain either mica flakes, glass strands or equivalent material to provide additional reinforcement.

D. The polymer concrete shall be reinforced as required using FRP rebar and shall be free of any steel

reinforcement or any other electrical conducting materials. The FRP rebar configuration shall hold the cell

shape intact in the event of cell failure.

E. The interior and exterior of the polymer concrete cell shall consist of a modified vinylester mat or synthetic

fiber. The vinylester will be Derakane 411-45. Final vinylester coating shall be lighter in color than the

base polymer concrete resin.

F. The interior, including the inside bottom, of the polymer concrete cell shall have smooth mold contacted

surfaces to provide for ease of cleaning and discharging solids. The cell materials shall not cause

degradation of the electrolyte. The exterior surface shall also have a smooth mold contacted surface. The

area surrounding the drains must be molded to conform to the plane of the cell.

G. The polymer concrete cell bottom shall have a slope and a depressed area for lead sludge collection as

shown on the attached drawing.

H. The polymer concrete cell body shall be unitized and shall not have any cold joints or glued sections. Pipe

and walkway supports may be attached to the cell by cold bonding.

I. The cell wall and bottom thickness shown on attached drawings are for summary purposes only and shall be

verified by engineering calculations as indicated in Section 2.2C. The dimensional tolerances shall be

within the limits indicated on the data sheets (Attachment 2).

2.2 Testing and Quality Control

A. Seller shall appoint a designated person with overall responsibility for quality and performance of the Work

and shall be the Buyer's contact.

B. Buyer reserves the right to approve Seller's suppliers and the extent of subcontract work. After Buyer's

approval changes shall only be made with Buyer's written authorization. Seller shall be responsible for

supervision and coordination of his subcontractors.

/conversion/tmp/scratch/431390423.doc POLYMER CONCRETE CELLS

MINERA ESCONDIDA LTDA. Technical Specification N°2291-ET-55-001

AMPLIACION CAPACIDAD OXIDOS Pag. 4 de 11

PROYECTO N° 2291 Jul 10, 2000

Rev 0

FLUOR DANIEL CHILE S.A.

C. Seller shall submit engineering calculations, showing all design loads, structural analysis, and design

procedures with their proposal for evaluation. Such calculations must be signed and stamped by a civil

engineer registered in the location of manufacture.

The calculations shall conform to the requirements of all applicable sections in Uniform Building Code,

1994 - latest edition.

D. Seller shall submit his program for cell testing, describing number of specimens, test location,

instrumentation, inspection and record procedures, loads and load duration, contents of test reports, etc.,

with their proposal for evaluation. The results shall indicate adequacy of the cell to satisfy the requirements

of Section 3.1 of this Specification.

E. The Seller's quality control program and inspection plan shall include sufficient detail to delineate those

items to be inspected, the manner of inspection, and adequately describe all fabrication quality control

activities contemplated, including provision for adequate documentation of manufacturer's performance of

such quality control inspection. Records of inspections and certified reports of tests performed shall be

retained by Supplier and submitted to Buyer when requested.

F. Documentation showing the resin/aggregate mix, for each lot mixed, shall be submitted to Buyer.

G. Buyer shall have the option of witnessing any fabrication activity or shop tests relating to the cells. Seller

shall advise Buyer in writing at least 2 weeks in advance of any shop testing planned however failure of the

Buyer to witness any test shall neither delay such test nor delay the orderly fulfilment of the specifications.

H. The Seller shall cast 3 test cylinders for each lot mixed. The Seller shall test every twentieth cylinder of

field and laboratory cured samples and submits the data to Buyer. The third cylinder shall be shipped with

the cell from which it was made to the Oxide Plant site.

I. Cells shall be serially numbered and the test cylinders shall have the same number as the cell.

J. The test cylinders shall have minimum porosity.

K. The test cylinders shall have minimum physical properties as determined by the manufacturer.

L. Test cylinders, when fractured, shall show that all aggregate is wetted out and encapsulated in the resin.

M. The resin shall be properly mixed and contain an adequate amount of catalyst and promoters that will fully

cure the polymer. The finished cells shall not exhibit soft spots or porosity.

N. The finished cells shall be manufactured and delivered to the plantsite within the specified dimensional

tolerances indicated on the data sheets (Attachment 2).

O. Seller shall perform a factory leak test on every cell prior to shipment and submit results to Buyer for

evaluation.

P. The Seller shall supply an experienced on-site supervisor to assist during installation.

Q Buyer may elect to conduct field tests at his own expense to verify performance guarantees under actual

working conditions. The field test procedures shall be mutually agreed upon between Buyer and Seller.

Seller may elect to have representation at his own expense during these tests. Where tests reveal deficiencies

/conversion/tmp/scratch/431390423.doc POLYMER CONCRETE CELLS

MINERA ESCONDIDA LTDA. Technical Specification N°2291-ET-55-001

AMPLIACION CAPACIDAD OXIDOS Pag. 5 de 11

PROYECTO N° 2291 Jul 10, 2000

Rev 0

FLUOR DANIEL CHILE S.A.

in the equipment or deviations from the guaranteed performance, Seller shall be completely responsible for

any modifications, repairs, and adjustments required to meet the equipment performance guarantee.

R. Should additional field testing be required to verify performance guarantees, the cost for all field

performance testing, including the first field test, shall be at the Seller's expense.

S. All defects in excess of agreed acceptance criteria shall be reported immediately to the Buyer by the Seller

and evaluated by Seller's engineering department for possible corrective action. All corrections shall be

subject to Buyer's approval.

3.0 EXECUTION

3.1 General Requirements

A. The cells will contain copper sulfate, sulfuric acid, cobalt sulfate, lead sulfate, iron sulfate, and chloride ions

in the electrolyte. The maximum concentration of each is as shown in the Process Data Sheet Attachment 1.

An acid mist suppressing reagent and carry over of organic solvents from the SX Plant will be present at the

electrolyte solution level in the cells.

B. Anode corrosion products, which consist of Lead Sulfate, Lead Oxides, Copper, Silica and other minerals,

will collect on the bottom of the cells.

C. The cells must be capable of supporting the maximum density electrolyte expected to be processed, which is

1.25 specific gravity, 61 Lead-Alloy anodes spaced at 4" intervals, each weighing up to 90.8 kg, 60 cathodes

spaced equidistant between the anodes, each weighing approximately 170 kg, and all other loads (including

seismic and thermal loads) applied to the cell during operation.

D. The empty cells shall be capable of withstanding loads due to lifting, transportation and erection. The cells

must be capable of supporting these short-term and sustained loads during operation without cracking,

breaking, and significant long-time deformations. The principal concern is vertical and horizontal (bowing

in or spreading out) deformations at the top mid-span of the cell walls. Significant deformation is any

deformation greater than 3 mm.

E. In the event that the crane should drop some of the load of either anodes or cathodes, from a height of 1820

mm above the cells, the cells should resist cracking and failure of the cell bottom and walls.

F. The overflow box shall be cast as an integral part of the cell. The overflow discharge system from the cells

should be provided with an effective control system to keep the electrolyte levels near the top of the

cathodes in the cells. Seller shall provide overflow weir bars sufficient to fill the height of the weir opening.

G. A lead sludge drain with neoprene plug and flanged connection shall be located at the discharge end of the

cells.

H. Seller to advise operational restrictions relating to thermal shock eg. maximum allowable temperature

differential between electrolyte and cell.

I. Seller shall provide external supports as follows:

1. Walkway supports: four supports per cell suitable for withstanding a vertical load of 1,135 kg each.

J. Seller to provide lead shims for all cells.

/conversion/tmp/scratch/431390423.doc POLYMER CONCRETE CELLS

MINERA ESCONDIDA LTDA. Technical Specification N°2291-ET-55-001

AMPLIACION CAPACIDAD OXIDOS Pag. 6 de 11

PROYECTO N° 2291 Jul 10, 2000

Rev 0

FLUOR DANIEL CHILE S.A.

K. Seller shall supply cell seismic restraints designed for UBC Zone 4 conditions and suitable for tie-in to the

cell support pedestals supplied by others.

4.0 ATTACHMENTS

Attachment 1: Process Data Sheet A

Attachment 2: Dimensional Tolerances Data Sheet

Attachment 3: Data Sheet B, Information required from Bidder

Attachment 4: Site Conditions

Attachment 5: Drawing No.:

2291.510.55.13 Montaje Anodos y Cátodos – Planta y Secciones

2291.510.55.14 Montaje Anodos y Cátodos – Secciones Transversales y Detalles

2291.510.55.15 Bloques Aisladores y Espaciadors – Planta, Secciones y Detalles

/conversion/tmp/scratch/431390423.doc POLYMER CONCRETE CELLS

MINERA ESCONDIDA LTDA. Technical Specification N°2291-ET-55-001

AMPLIACION CAPACIDAD OXIDOS Pag. 7 de 11

PROYECTO N° 2291 Jul 10, 2000

Rev 0

FLUOR DANIEL CHILE S.A.

Attachment 1 ...Sheet 1 of 1

PROCESS DATA SHEET A

1.0 Quantity: Intermediate cells 40

Type I end cells 1

Type II end cells 1

Total Quantity: 42

Description Fluor Daniel Tag Number

Cells - Electrowinning Section A 510-5PCA-043-A501 to A510

Cells - Electrowinning Section B 510-5PCA-043-B511 to B520

Cells - Electrowinning Section C 510-5PCA-043-C521 to C530

Cells - Electrowinning Section D 510-5PCA-043-D531 to D540

Cells - Electrowinning Type end cells 510-5PCA-043-D541 to D542

2.0 Electrolyte:

The electrolyte content of the cells will have the following maximum concentrations:

Sulfuric acid 175 g/l

Copper 35-45 g/l

Chloride 30 ppm

Max./Min. temperature 60/2C

Operating temperature 45 - 49 C

Specific gravity 1.19

Iron 2.5 g/l (of which approx. 65% is in the oxidized

form as ferric iron)

Lead In the form of PbO sludge in bottom of cell.

Cobalt 100-125 ppm

Note 1: Large quantities of oxygen gas are generated in the cells creating strongly oxidizing conditions in the

electrolyte cells.

Note 2: Organic entrainment: Acorga or Henkel extractant (oximes with tridecanol modifier) and kerosene

accumulates at solution surface, expected 5 ppm entrainment.

/conversion/tmp/scratch/431390423.doc POLYMER CONCRETE CELLS

MINERA ESCONDIDA LTDA. Technical Specification N°2291-ET-55-001

AMPLIACION CAPACIDAD OXIDOS Pag. 8 de 11

PROYECTO N° 2291 Jul 10, 2000

Rev 0

FLUOR DANIEL CHILE S.A.

Attachment 2 ...Sheet 1 of 1

DIMENSIONAL TOLERANCES DATA SHEET

(All referred at perfects planes)

Wall thickness + 4 mm

Internal cell width + 3 mm

External cell width + 4 mm

Floor thickness + 3 mm

External length at bottom cell + 6 mm

External length at top cell + 6 mm

Internal length + 5 mm

External/internal height + 5 mm / + 5 mm

Max. unevenness of the overflow box + 3 mm

Maximum difference between diagonals on cell's top 8 mm

Maximum difference between diagonals on walls 8 mm

Maximum flatness deviation at cell's top 3 mm

(referred at the nearest surface,

which is orthogonal with vertical walls)

Base brick + 2 mm

Flow control bar + 4 mm

/conversion/tmp/scratch/431390423.doc POLYMER CONCRETE CELLS

MINERA ESCONDIDA LTDA. Technical Specification N°2291-ET-55-001

AMPLIACION CAPACIDAD OXIDOS Pag. 9 de 11

PROYECTO N° 2291 Jul 10, 2000

Rev 0

FLUOR DANIEL CHILE S.A.

Attachment 3 ...Sheet 1 of 2

SHEET B

INFORMATION REQUIRED FROM BIDDER

1.0 GENERAL

TAG Number

Quantity 42

Supplier CTI ANCOR

Manufacturer CTI ANCOR

Weight 7.0 ton.

1.0 Cell Requirements

External dimensions

- Intermediate cells, mm 6730 x 1452 x 1550

- End cells, mm 6730 x 1607 x1550

Material Polymer concrete cells

Lateral wall thickness

- Intermediate cells, mm 92 / 70 (top)

- End cells, mm 247

Cells Bottom thickness, mm 100

1.2 Accessories

- Walkway support brick Polymer concrete cells

- Anti-seismic brinck Polymer concrete cells

- Discharge baffle Polymer concrete cells

- Discharge overflow pipe PVC 6” dia. Sch 80

- Drain System FRP 3” dia.

- Intercell brink Polymer concrete cells

- Cell support brick Polymer concrete cells

- Drip cutter bar

- Feed pipe support brick

- Discharge pipe support brick

/conversion/tmp/scratch/431390423.doc POLYMER CONCRETE CELLS

MINERA ESCONDIDA LTDA. Technical Specification N°2291-ET-55-001

AMPLIACION CAPACIDAD OXIDOS Pag. 10 de 11

PROYECTO N° 2291 Jul 10, 2000

Rev 0

FLUOR DANIEL CHILE S.A.

Attachment 3 ...Sheet 2 of 2

SHEET B

INFORMATION REQUIRED FROM BIDDER

1.3 Field’s materials

- Glued material for bricks Polymer concrete morter

- Material for leveling up the wall cell’s top Lead shims

- Molding procedure for intercell brincks Filled site

2.0 MECHANICAL PROPERTIES

- Compressive strength 825 +/- 80 kg/cm²

- Tensile strength Flexural 210 +/- 20 kg/cm²

- Bending strength 210 +/- 20 kg/cm²

- Density 2223

- Hardening time 10 hours for handling

- Barcol C hardness FRP 30

/conversion/tmp/scratch/431390423.doc POLYMER CONCRETE CELLS

MINERA ESCONDIDA LTDA. Technical Specification N°2291-ET-55-001

AMPLIACION CAPACIDAD OXIDOS Pag. 11 de 11

PROYECTO N° 2291 Jul 10, 2000

Rev 0

FLUOR DANIEL CHILE S.A.

Attachment 4 ...Sheet 1 of 1

SITE CONDITIONS

Location 160 km SE of

Elevation Antofagasta

3200 m abovein msl.

the

Climate Arid

Temperature Summer Maximum 32C (90F) with a maximum one hour

average temperature of 27C (81F)

Winter -10C (14F)

Average +10C (50F)

Daily temperature Variation can be as much as 32C (58F)

Precipitation Annual average 4.5 mm

Relative humidity (0.18")

High 55% - 80%

Low 20% - 50%

Evaporation High up to 1 cm/day

Wind Prevailing wind from

Sustained velocity

west with gusts up 10

to

Earthquake km/h (6

UBC mph)

Zone 4

Port of entry Antofagasta

/conversion/tmp/scratch/431390423.doc POLYMER CONCRETE CELLS

You might also like

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- 2-Solar Water HeaterDocument124 pages2-Solar Water Heaterp4p7 projectsNo ratings yet

- 2013 12 09 NIH - 07 Div Thermal Moisture PDFDocument105 pages2013 12 09 NIH - 07 Div Thermal Moisture PDFNathalie ReyesNo ratings yet

- Section Cover Page: Section 22 13 65 2010-12-01 Sewage Holding TanksDocument5 pagesSection Cover Page: Section 22 13 65 2010-12-01 Sewage Holding Tanksngoclinh87No ratings yet

- General: Insulated Aluminium CladdingDocument5 pagesGeneral: Insulated Aluminium Claddingeccos3338No ratings yet

- Spec Water Storage TanksDocument5 pagesSpec Water Storage TanksparthivNo ratings yet

- 11-KU-TWK-50-QA-PRO-2173 - 0 - Wrapping ProcedureDocument8 pages11-KU-TWK-50-QA-PRO-2173 - 0 - Wrapping ProcedureAvak NishanNo ratings yet

- TS For Pipe-Duct DismantlingDocument10 pagesTS For Pipe-Duct DismantlingAmitava SilNo ratings yet

- Pipeline Repair Procedure Final MR 050112Document35 pagesPipeline Repair Procedure Final MR 050112Sadam Bin Muzammal100% (5)

- TS-MES-3203-CGC - Fittings - 13.03.2023Document321 pagesTS-MES-3203-CGC - Fittings - 13.03.2023energy8001No ratings yet

- Carbon Reactivation Kilns - SP 0000-16-0007 2Document21 pagesCarbon Reactivation Kilns - SP 0000-16-0007 2Sleyda MunozNo ratings yet

- Duqm Refinery Project EPC Package 2 - Utilities and OffsitesDocument52 pagesDuqm Refinery Project EPC Package 2 - Utilities and OffsitesAsif ChougleNo ratings yet

- National Oil Corporation: Rev Date Description Checked ApprovedDocument12 pagesNational Oil Corporation: Rev Date Description Checked ApprovedRochdi SahliNo ratings yet

- MQ SP P 5024Document16 pagesMQ SP P 5024jaseel kNo ratings yet

- MontajeDocument7 pagesMontajeLuis ChavezNo ratings yet

- AA 09/15/00 EJL TD DJ KM MWJ Issued For Bid: Rev. NO. Date BY Checked MEI Lead MEI Approval Conoco RevisionDocument26 pagesAA 09/15/00 EJL TD DJ KM MWJ Issued For Bid: Rev. NO. Date BY Checked MEI Lead MEI Approval Conoco RevisionThinh NguyenNo ratings yet

- SP-50-017 - 2 - Pipe SupportsDocument136 pagesSP-50-017 - 2 - Pipe SupportsTem Batbold100% (2)

- SpECcell Polyethylene 40 TDS4Document2 pagesSpECcell Polyethylene 40 TDS4resellana5893No ratings yet

- 22 13 18 - Drainage Waste and Vent Piping - PlasticDocument2 pages22 13 18 - Drainage Waste and Vent Piping - PlasticLangzkie NalipaNo ratings yet

- Joint SealersDocument7 pagesJoint Sealersjack.simpson.changNo ratings yet

- MS A02 S 0002 R00 Epoxy Grout FillingDocument55 pagesMS A02 S 0002 R00 Epoxy Grout FillingRabee BataynehNo ratings yet

- Project Manager Cavdeal PRC Headquarters Supply and Installation of Aluminum and Glass WorksDocument6 pagesProject Manager Cavdeal PRC Headquarters Supply and Installation of Aluminum and Glass WorksSharah QuilarioNo ratings yet

- National Oil Corporation: Rev Date Description Checked ApprovedDocument23 pagesNational Oil Corporation: Rev Date Description Checked ApprovedRochdi SahliNo ratings yet

- Functional Specification Civil Tank Bund Walls and Floors: Rev Date Description Prepared by Reviewed by Approved byDocument17 pagesFunctional Specification Civil Tank Bund Walls and Floors: Rev Date Description Prepared by Reviewed by Approved byMaji OgwuNo ratings yet

- MQ SP P 5011 PDFDocument25 pagesMQ SP P 5011 PDFjaseelNo ratings yet

- Decommissioning Inspection and Repair of 5000 MT Ammonia Storage TankDocument17 pagesDecommissioning Inspection and Repair of 5000 MT Ammonia Storage TankEleonora100% (1)

- Section 07900 - Joint Sealers: Ministry of Housing Housing Project Standard Specification Part 2: BuildingsDocument10 pagesSection 07900 - Joint Sealers: Ministry of Housing Housing Project Standard Specification Part 2: BuildingsreyNo ratings yet

- MQ SP P 5008 PDFDocument11 pagesMQ SP P 5008 PDFjaseelNo ratings yet

- Ke01.00.000.kd.v.ss.0011.000: 180303 No 1 of 8Document8 pagesKe01.00.000.kd.v.ss.0011.000: 180303 No 1 of 8Maffone NumerounoNo ratings yet

- DM Fillerboard - HuntonDocument65 pagesDM Fillerboard - HuntonFahis V MNo ratings yet

- Technical Specification For Welding Piping Shop and Field FabricationDocument28 pagesTechnical Specification For Welding Piping Shop and Field FabricationالGINIRAL FREE FIRENo ratings yet

- Insulation Tech SpecDocument7 pagesInsulation Tech Specferdinand laiNo ratings yet

- CK404Document8 pagesCK404Manoj KumarNo ratings yet

- Induction Bends - COPIDocument12 pagesInduction Bends - COPIAdvis100% (1)

- EOL-Engg-M-001 - R1 - Tank Product Pipeline Hydro Testing Doping and InstallationDocument11 pagesEOL-Engg-M-001 - R1 - Tank Product Pipeline Hydro Testing Doping and InstallationRanjit MandalNo ratings yet

- S2DC-201 2 PDFDocument16 pagesS2DC-201 2 PDFJoan HillNo ratings yet

- 23 07 13 - Duct InsulationDocument3 pages23 07 13 - Duct InsulationLangzkie NalipaNo ratings yet

- Specification For Fire Protection SystemDocument9 pagesSpecification For Fire Protection SystemAmul Amnaje100% (1)

- Cem Kote CW PlusDocument6 pagesCem Kote CW Plusconstruct404No ratings yet

- Preq - Al Jaber Engineering - Wiltz - TemboDocument292 pagesPreq - Al Jaber Engineering - Wiltz - Tembo721917114 47No ratings yet

- C-cs-10-009 Agreg - Pavem.base Rev 1Document12 pagesC-cs-10-009 Agreg - Pavem.base Rev 1Johnny vargas suclupeNo ratings yet

- SECTION 07 21 23 Loose-Fill InsulationDocument5 pagesSECTION 07 21 23 Loose-Fill InsulationJuanPaoloYbañezNo ratings yet

- 1706 - BF HOTEL - Specs - Architectural - Part 2Document233 pages1706 - BF HOTEL - Specs - Architectural - Part 2AhmedMahmoudNo ratings yet

- Specification For Concrete Patch RepairDocument13 pagesSpecification For Concrete Patch Repairnurhidayah218No ratings yet

- Westbay Mechanial SpecsDocument174 pagesWestbay Mechanial SpecsHARISH ROHANNo ratings yet

- Certificate 062 99Document6 pagesCertificate 062 99ferdinandbataraNo ratings yet

- Prequalification of Seal For Life Company PDFDocument137 pagesPrequalification of Seal For Life Company PDFErkan HorasanNo ratings yet

- Section 07 84 00 - Fire StoppingDocument6 pagesSection 07 84 00 - Fire StoppingMohammed AyeshNo ratings yet

- Ims 52 07 06Document14 pagesIms 52 07 06marcio de rossiNo ratings yet

- QC911000-SLC-TEC-MTS-MEC-11A-Z00-00013 - uPVC Storm Water Drainage PipesDocument74 pagesQC911000-SLC-TEC-MTS-MEC-11A-Z00-00013 - uPVC Storm Water Drainage PipesriyasudheenmhNo ratings yet

- Rev. NO. Date BY Checked MEI Lead MEI Approval Conoco Revision AA 9/15/00 EL TD DJ KM MWJ Issued For BidDocument19 pagesRev. NO. Date BY Checked MEI Lead MEI Approval Conoco Revision AA 9/15/00 EL TD DJ KM MWJ Issued For BidThinh NguyenNo ratings yet

- b291-000!02!42-Wsp-0002 Specification For Offshore Pipeline WeldingDocument45 pagesb291-000!02!42-Wsp-0002 Specification For Offshore Pipeline WeldingChris MacMillanNo ratings yet

- BP12A 088000 Glazing D00Document21 pagesBP12A 088000 Glazing D00Chrill DsilvaNo ratings yet

- DGS-AU-055-R1 Thermal and Moisture ProtectionDocument15 pagesDGS-AU-055-R1 Thermal and Moisture ProtectionHalim KazdarNo ratings yet

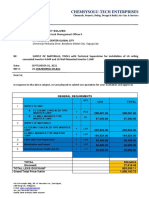

- Chemsysolu-Tech Enterprises: Ms. Mary Joy SolivenDocument5 pagesChemsysolu-Tech Enterprises: Ms. Mary Joy SolivenEdward AlfaroNo ratings yet

- Cold Insulation Procedure-FDocument26 pagesCold Insulation Procedure-FSamira MohamedNo ratings yet

- ETI-3655-3100-003-BEDD-0009 Specification For PilesDocument32 pagesETI-3655-3100-003-BEDD-0009 Specification For PilesGunawan NamakuNo ratings yet

- C-SP-55-017 - Vertical Turbine PuDocument20 pagesC-SP-55-017 - Vertical Turbine PuEsteban Rios PitaNo ratings yet

- CCCC Et Ha Spec ST 650 00 Reply BDocument5 pagesCCCC Et Ha Spec ST 650 00 Reply B黄赛赛No ratings yet

- ENG STD 1602 Cold InsulDocument32 pagesENG STD 1602 Cold Insuldarrybr52No ratings yet

- Spence Geologia General 2007Document11 pagesSpence Geologia General 2007Roberto Cortés DíazNo ratings yet

- Manual de PROFIBUSDocument35 pagesManual de PROFIBUSRoberto Cortés DíazNo ratings yet

- Oxide Plant ShortDocument1 pageOxide Plant ShortRoberto Cortés DíazNo ratings yet

- Spence Geologia General 2007Document11 pagesSpence Geologia General 2007Roberto Cortés DíazNo ratings yet

- Century Vemap PDFDocument5 pagesCentury Vemap PDFMaster MirrorNo ratings yet

- CASBA Directive 2074Document17 pagesCASBA Directive 2074vijaycool85No ratings yet

- INS2015 Fundamentals of Finance HungCV 1Document3 pagesINS2015 Fundamentals of Finance HungCV 1Phương Anh NguyễnNo ratings yet

- Motion in One Dimension QuestionDocument6 pagesMotion in One Dimension Questionabh_omega33% (3)

- ENGLISH TOEFL Structure (3rd Exercise)Document5 pagesENGLISH TOEFL Structure (3rd Exercise)susannnnnnNo ratings yet

- Anaximenes of MiletusDocument4 pagesAnaximenes of MiletusRosel Gonzalo-AquinoNo ratings yet

- MiningDocument3 pagesMiningDherick RaleighNo ratings yet

- Ad 9915Document47 pagesAd 9915Jime nitaNo ratings yet

- Passmore Et Al (2019) Workplace CoachingDocument47 pagesPassmore Et Al (2019) Workplace CoachingMalarvilie KrishnasamyNo ratings yet

- Advanced Office Add-In DevelopmentDocument40 pagesAdvanced Office Add-In DevelopmentReadoneNo ratings yet

- Sheet Metal Cutting Using Geneva MechanismDocument27 pagesSheet Metal Cutting Using Geneva MechanismsingamNo ratings yet

- PienaDocument1 pagePienaMika Flores PedroNo ratings yet

- Theories of PersonalityDocument4 pagesTheories of PersonalityKeshav JhaNo ratings yet

- Beamforming For 4.9G/5G Networks: Exploiting Massive MIMO and Active Antenna TechnologiesDocument12 pagesBeamforming For 4.9G/5G Networks: Exploiting Massive MIMO and Active Antenna TechnologiesAymen Ben zinebNo ratings yet

- Kick-Ass Customer Service-Part 1Document3 pagesKick-Ass Customer Service-Part 1Mahfuzul Haque SujanNo ratings yet

- LogDocument67 pagesLogRudhi Al GhaisanNo ratings yet

- Executive Summary Report Julio13Document8 pagesExecutive Summary Report Julio13exxgineNo ratings yet

- COCCIMORPHDocument13 pagesCOCCIMORPHmiminNo ratings yet

- 2022 Cement Lime Manufacturing Ehs Guidelines enDocument39 pages2022 Cement Lime Manufacturing Ehs Guidelines enSamiNo ratings yet

- PCBDocument5 pagesPCBarampandey100% (4)

- Functional Materials For Sustainable Energy TechnologiesDocument15 pagesFunctional Materials For Sustainable Energy TechnologiesChristhy Vanessa Ruiz MadroñeroNo ratings yet

- Ficha Tecnica Reflector 2000W Led Lluminacion de Campos de Futbol Estadios Goled Philips Osram Opalux LedDocument5 pagesFicha Tecnica Reflector 2000W Led Lluminacion de Campos de Futbol Estadios Goled Philips Osram Opalux Ledluis perdigonNo ratings yet

- Union Metal SemiconductorDocument4 pagesUnion Metal SemiconductorskinhugoNo ratings yet

- Pitch Analysis PaperDocument7 pagesPitch Analysis PaperMunib MunirNo ratings yet

- Ultraviolet Flame Detector: Omniguard Model 660Document2 pagesUltraviolet Flame Detector: Omniguard Model 660carlosNo ratings yet

- Cocoon 8002 PDFDocument24 pagesCocoon 8002 PDFaxisNo ratings yet

- Automatic Control ExercisesDocument183 pagesAutomatic Control ExercisesFrancesco Vasturzo100% (1)

- Wakit, Nico P.Document5 pagesWakit, Nico P.yeng botzNo ratings yet

- Steam TableDocument3 pagesSteam TableMUHAMAD SAUKINo ratings yet

- Python - Data EngineeringDocument34 pagesPython - Data EngineeringChetan PatilNo ratings yet