Professional Documents

Culture Documents

Last Updated: Jan 27, 2006

Uploaded by

박준용0 ratings0% found this document useful (0 votes)

5 views2 pagesOriginal Title

C87500

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

5 views2 pagesLast Updated: Jan 27, 2006

Uploaded by

박준용Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

C87500

Last Updated: Jan 27, 2006

Chemical Composition

(%max., unless shown as range or min.)

Cu Al Pb Si Zn

Min./Max. 79.0 min .50 .50 3.0-5.0 12.0-16.0

Nominal 82.0 - - 4.0 14.0

Note: Cu + Sum of Named Elements, 99.5% min.

Applicable Specifications

Product Specification

Centrifugal ASTM B271

SAE J462, J461

Ingot ASTM B30

Permanent ASTM B806

Sand ASTM B584, B763

Common Fabrication Processes

Casting

Fabrication Properties

Joining Technique Suitability

Soldering Not Recommended

Brazing Fair

Oxyacetylene Welding Fair

Gas Shielded Arc Welding Fair

Coated Metal Arc Welding Not Recommended

Machinability Rating 50

Mechanical Properties (measured at room temperature, 68 F (20 C)

Yield Yield Yield

Izod

Section Cold Typ/ Tensile Strength Strength Strength Rockwell Vickens Brinell Shear Fatigue

Temper Temp El Impact

Size Work Min Strength (0.5% ext. (0.2% (0.05% Hardness Hard. Hard. Strength Strength*

Strength

under load) offset) offset)

in. % F ksi ksi ksi ksi % B C F 30T 500 500 3000 ksi ksi ft-lb

mm. C MPa MPa MPa MPa MPa MPa J

As Sand Cast

M01 0.0 0 TYP 68 67 30 - - 21 - - - - - 115 134 - 22 0.0

0.0 20 462 207 - - 21 - - - - - 115 134 - 152 0.0

As Centrifugal Cast

M02 0.0 0 SMIN 68 60 24 - - 16 - - - - - - - - - 0.0

0.0 20 414 165 - - 16 - - - - - - - - - 0.0

As Permanent Mold Cast

M05 0.0 0 SMIN 68 80 30 - - 15 - - - - - - - - - 0.0

0.0 20 552 207 - - 15 - - - - - - - - - 0.0

As Sand Cast

M01 0.0 0 SMIN 68 60 24 - - 16 - - - - - - - - - 0.0

0.0 20 414 165 - - 16 - - - - - - - - - 0.0

*Fatigue Strength: 100 x 10 6cycles,

unless indicated as [N]X 106.

Physical Properties

<> US Customary Metric

Melting Point - Liquidus 1680 F 916 C

Melting Point - Solidus 1510 F 821 C

Density 0.299 lb/in3 at 68 F 8.28 gm/cm3 @ 20 C

Specific Gravity 8.28 8.28

Electrical Resistivity 154.2 ohms-cmil/ft @ 68 F 25.64 microhm-cm @ 20 C

Electrical Conductivity 6 %IACS @ 68 F 0.039 MegaSiemens/cm @ 20 C

Thermal Conductivity 16.0 Btu · ft/(hr · ft2·oF)at 68F 27.7 W/m · oK at 20 C

Coefficient of Thermal Expansion 10.9 ·10-6 per oF (68-572 F) 19.6 ·10-6 per oC (20-300 C)

Specific Heat Capacity 0.09 Btu/lb/oF at 68 F 377.1 J/kg · oK at 293 K

Modulas of Elasticity in Tension 15400 ksi 106000 MPa

Tempers Most Commonly Used No information available.

Typical Uses

Builders Hardware

Window Hardware

Industrial

Levers, Fittings, Impellers, Gears, Pump Fixtures, Valve Bodies, Bearings

Marine

Small Boat Propellers, Boat Parts

Plumbing

Fixtures

The above data used by permission from the Copper Development Association Inc. A complete

Description of all UNS Copper Alloys is available at www.copper.org

You might also like

- Last Updated: Jan 27, 2006Document2 pagesLast Updated: Jan 27, 2006박준용No ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- C87300 (Silicon Bronze) : Last Updated: Jan 27, 2006Document1 pageC87300 (Silicon Bronze) : Last Updated: Jan 27, 2006박준용No ratings yet

- Database Management Systems: Understanding and Applying Database TechnologyFrom EverandDatabase Management Systems: Understanding and Applying Database TechnologyRating: 4 out of 5 stars4/5 (8)

- A.S.T.M. B584-09a: WWW - Okendo.mxDocument4 pagesA.S.T.M. B584-09a: WWW - Okendo.mxShariq KhanNo ratings yet

- C89520 (Sebiloy Ii (Envirobrass Ii) ) : Last Updated: Jan 27, 2006Document1 pageC89520 (Sebiloy Ii (Envirobrass Ii) ) : Last Updated: Jan 27, 2006박준용No ratings yet

- Steel Equivalent Table: en / BS To SAE - Page 1 of 20Document3 pagesSteel Equivalent Table: en / BS To SAE - Page 1 of 20LASCARZAMFIRESCUNo ratings yet

- C86200 Manganese BronzeDocument1 pageC86200 Manganese BronzeDeepak KumarNo ratings yet

- Jis C3771Document2 pagesJis C3771bkprodhNo ratings yet

- 38 MN VS6Document2 pages38 MN VS6Pramod NautiyalNo ratings yet

- 25crmo4: Steel GradeDocument3 pages25crmo4: Steel GradeCristian Stiven Martinez GonzalezNo ratings yet

- Electrode ComparisionDocument1 pageElectrode ComparisionAnilNo ratings yet

- 6063 VS 63400Document1 page6063 VS 63400siju1974No ratings yet

- 38 MN VS6Document3 pages38 MN VS6Jaison JacobNo ratings yet

- Engineering DetailDocument30 pagesEngineering DetailSatyaprakash PrakashNo ratings yet

- MAT 1210 MCGB - Data Sheet For Suppliers Old MAT No.: 121Document1 pageMAT 1210 MCGB - Data Sheet For Suppliers Old MAT No.: 121MohamedNo ratings yet

- HPL/TC/T/2010/14127 HPL/TC/T/2010/14127 HPL/TC/T/2010/14127 HPL/TC/T/2010/14127 HPL/TC/T/2010/14127 HPL/TC/T/2010/14127Document4 pagesHPL/TC/T/2010/14127 HPL/TC/T/2010/14127 HPL/TC/T/2010/14127 HPL/TC/T/2010/14127 HPL/TC/T/2010/14127 HPL/TC/T/2010/14127Er Umesh RohitNo ratings yet

- CM-9CB TG-S9Cb US-9CbDocument3 pagesCM-9CB TG-S9Cb US-9Cbamit singhNo ratings yet

- C63020 Nickel Aluminum Bronze - ConcastDocument3 pagesC63020 Nickel Aluminum Bronze - ConcastBruno FaveroNo ratings yet

- 34crnimo6: Steel GradeDocument6 pages34crnimo6: Steel GradeBiju KNo ratings yet

- Aluminium Wrought AlloyDocument29 pagesAluminium Wrought AlloyRaj Kumar GiriNo ratings yet

- Cosmos Alminium-Technical - Specifications PDFDocument2 pagesCosmos Alminium-Technical - Specifications PDFmindsopenNo ratings yet

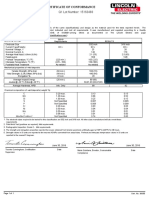

- Certificate of Conformance: Q1 Lot Number: 15163483Document1 pageCertificate of Conformance: Q1 Lot Number: 15163483interx00No ratings yet

- Catalog 14Document1 pageCatalog 14msajanjNo ratings yet

- AW60Document1 pageAW60Fitra VertikalNo ratings yet

- 42crmo6 : Steel GradeDocument2 pages42crmo6 : Steel GradeYonas Dwiananta YuwonoNo ratings yet

- Steel Grade: Material Data SheetDocument7 pagesSteel Grade: Material Data Sheetispat_jagadeeshNo ratings yet

- CZLLCW511L TN enDocument4 pagesCZLLCW511L TN endrgilleNo ratings yet

- Product Catalog AluminiuDocument32 pagesProduct Catalog AluminiusnoofsnoofNo ratings yet

- 34CRNIMO6 - 34CrNiMo6-Nr 1 6582-ENGDocument2 pages34CRNIMO6 - 34CrNiMo6-Nr 1 6582-ENGNarimane BentyNo ratings yet

- Lincoln (Data Sheet) Murex E7024Document2 pagesLincoln (Data Sheet) Murex E7024PubcrawlNo ratings yet

- Yellow: LM6 (EN 1706 AC-44100) Aluminium Casting AlloyDocument3 pagesYellow: LM6 (EN 1706 AC-44100) Aluminium Casting AlloySohail ShaikhNo ratings yet

- 42 CR Mo 4Document4 pages42 CR Mo 4kazdanoNo ratings yet

- S355JRDocument3 pagesS355JRYasmeen HaiderNo ratings yet

- CLC 18-10ti: A Ti Stabilized 18Cr-10Ni Austenitic Stainless Steel (321 Grade)Document4 pagesCLC 18-10ti: A Ti Stabilized 18Cr-10Ni Austenitic Stainless Steel (321 Grade)PeterWayNo ratings yet

- Tin Bronze C90300 PDFDocument1 pageTin Bronze C90300 PDFDeepak KumarNo ratings yet

- C87600 Copper Silicon: Brass & Bronze AlloysDocument1 pageC87600 Copper Silicon: Brass & Bronze AlloysDeepak KumarNo ratings yet

- 18crnimo7-6: Steel GradeDocument5 pages18crnimo7-6: Steel GradeFarid AhmedNo ratings yet

- 18crnimo7-6: Steel GradeDocument5 pages18crnimo7-6: Steel GradeSoumyajit MaitiNo ratings yet

- Al Alloys Chemicals MechanicalsDocument1 pageAl Alloys Chemicals MechanicalsFactory FactoryNo ratings yet

- 20MM - 63.150 TonDocument1 page20MM - 63.150 TonRAJKUMAR CHATTERJEE. (RAJA.)No ratings yet

- 20MM - 63.150 TonDocument1 page20MM - 63.150 TonRAJKUMAR CHATTERJEE. (RAJA.)No ratings yet

- 50CRMO4 - 50CrMo4-Nr 1 7228-ENGDocument2 pages50CRMO4 - 50CrMo4-Nr 1 7228-ENGLuiz Antonio dos AnjosNo ratings yet

- CuZn33 CatalogueDocument9 pagesCuZn33 CataloguefedericoNo ratings yet

- Navy M BronzeDocument1 pageNavy M BronzeDeepak KumarNo ratings yet

- Cable Slickline UHT CarbonDocument1 pageCable Slickline UHT CarbonRafael EspinosaNo ratings yet

- Multiple Conditions Datasheet: Condition # 1 2 3 4 5 6 7 8Document2 pagesMultiple Conditions Datasheet: Condition # 1 2 3 4 5 6 7 8Guillermo GuzmánNo ratings yet

- Certificado de Calidad 6001802 224132 2022 5 19Document1 pageCertificado de Calidad 6001802 224132 2022 5 19David MelendezNo ratings yet

- C10200 (Cu-OF) : ) Incl. AgDocument2 pagesC10200 (Cu-OF) : ) Incl. AgJosue Crespo GonzalezNo ratings yet

- Spheroidal GraphiteDocument1 pageSpheroidal GraphiteS.Mohana sundaramNo ratings yet

- P355GHDocument1 pageP355GHCommercial MarocNo ratings yet

- 42 CR Mo 4Document4 pages42 CR Mo 4eduardomanar1224No ratings yet

- Leaded Tin Bronze C54400Document3 pagesLeaded Tin Bronze C54400nfcastingsNo ratings yet

- C93200 Tin Bronze: Chemical Composition Typical UsesDocument1 pageC93200 Tin Bronze: Chemical Composition Typical UsesDeepak KumarNo ratings yet

- S355JRDocument2 pagesS355JRThanh NguyenNo ratings yet

- Product Code:: Pkg/Ro/41 Special SteelsDocument9 pagesProduct Code:: Pkg/Ro/41 Special SteelsPranav TripathiNo ratings yet

- Steel Grade: Material Data SheetDocument3 pagesSteel Grade: Material Data SheetRushangNo ratings yet

- Cold-Rolled Steel CoilsDocument28 pagesCold-Rolled Steel CoilsX800XLNo ratings yet

- Product Specifications: Specifications For Continuous Cast ProductsDocument4 pagesProduct Specifications: Specifications For Continuous Cast ProductsvejanidbNo ratings yet

- 콘베어벨트 프라이트 (FLIGHT)Document2 pages콘베어벨트 프라이트 (FLIGHT)박준용No ratings yet

- Poly Urethane Timing BeltDocument3 pagesPoly Urethane Timing Belt박준용No ratings yet

- 콘베어 벨트 耐藥品性 (CHEMICAL RESISTANCE)Document4 pages콘베어 벨트 耐藥品性 (CHEMICAL RESISTANCE)박준용No ratings yet

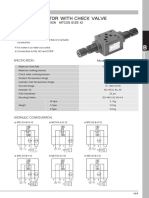

- MTC 03 W Throttle Check ValveDocument4 pagesMTC 03 W Throttle Check Valve박준용No ratings yet

- MTC 03 P Throttle Check ValveDocument3 pagesMTC 03 P Throttle Check Valve박준용No ratings yet

- MTC 02 P Throttle Check ValveDocument3 pagesMTC 02 P Throttle Check Valve박준용No ratings yet

- 콘베어 벨트 가이드 로프 (GUIDE ROPE)Document2 pages콘베어 벨트 가이드 로프 (GUIDE ROPE)박준용No ratings yet

- A160th TDSDocument4 pagesA160th TDS박준용No ratings yet

- MTC 02 W Throttle Check Valve (320BAR)Document4 pagesMTC 02 W Throttle Check Valve (320BAR)박준용No ratings yet

- TDS 5069 EngDocument2 pagesTDS 5069 Eng박준용No ratings yet

- Cloth Rohs2020Document6 pagesCloth Rohs2020박준용No ratings yet

- MTC 04 W Throttle Check ValveDocument4 pagesMTC 04 W Throttle Check Valve박준용No ratings yet

- Astm B 176-08Document4 pagesAstm B 176-08박준용No ratings yet

- Astm A514fDocument31 pagesAstm A514f박준용No ratings yet

- TM 9 2540 205 24 and PDocument408 pagesTM 9 2540 205 24 and P박준용No ratings yet

- M60 Technical ManualDocument220 pagesM60 Technical ManualDerrick Clark71% (7)

- A Pilot Study Into Microstructural Aspects of Fatigue in AA6082-T6 and AA2024-T3Document23 pagesA Pilot Study Into Microstructural Aspects of Fatigue in AA6082-T6 and AA2024-T3박준용No ratings yet

- Hydraulic Accumulator Products: Parker Your Most Complete Source For Hydraulic Accumulators and Related ProductsDocument1 pageHydraulic Accumulator Products: Parker Your Most Complete Source For Hydraulic Accumulators and Related Products박준용No ratings yet

- M50마운트Document62 pagesM50마운트박준용No ratings yet

- Section 1 Threaded Fasteners: STUDS # 835Document1 pageSection 1 Threaded Fasteners: STUDS # 835박준용No ratings yet

- Astm A574Document7 pagesAstm A574박준용No ratings yet

- Inline Pulse-Tone: Hydraulic Shock SuppressorsDocument14 pagesInline Pulse-Tone: Hydraulic Shock Suppressors박준용No ratings yet

- 교범 간편식조립교 (31m)Document139 pages교범 간편식조립교 (31m)박준용No ratings yet

- Casa Grande AldeaDocument23 pagesCasa Grande AldeaTestNo ratings yet

- Is.6452.b.1989 Specifications For HAC For Structural Use (High Alumina Cement) .Document19 pagesIs.6452.b.1989 Specifications For HAC For Structural Use (High Alumina Cement) .SAIKIRAN LNo ratings yet

- IS - 1570 (Part - 2-Sec 2) - 1987Document15 pagesIS - 1570 (Part - 2-Sec 2) - 1987ananda_beloshe75No ratings yet

- Study Takes Comprehensive Look at PVC Life Cycle Assessment Sustainability 1Document3 pagesStudy Takes Comprehensive Look at PVC Life Cycle Assessment Sustainability 1UnibellNo ratings yet

- Building Construction - Refurbishment of Old Buildings - M.wolf - SoSe22 - Part 8Document47 pagesBuilding Construction - Refurbishment of Old Buildings - M.wolf - SoSe22 - Part 8AmalKiranNo ratings yet

- Glo CatalogueDocument78 pagesGlo Cataloguekbltimber100% (5)

- Emerging Trends in Advancement of Formwork: March 2021Document14 pagesEmerging Trends in Advancement of Formwork: March 2021leovinNo ratings yet

- Polyurea HB1010Document3 pagesPolyurea HB1010Tox DexterNo ratings yet

- Masterbrace 4500 TdsDocument3 pagesMasterbrace 4500 TdsfaroukNo ratings yet

- WISS CSWIP Technology Multiple Choice Exam 1 Version A 18 August 2014Document10 pagesWISS CSWIP Technology Multiple Choice Exam 1 Version A 18 August 2014rinhycraNo ratings yet

- Module 6 - FormworksDocument8 pagesModule 6 - FormworksAldrich Francis Ortiz Peñaflor100% (1)

- Building PlanDocument1 pageBuilding Planshaik moizNo ratings yet

- MEC613 Mini Project Sep - Dec 2019Document8 pagesMEC613 Mini Project Sep - Dec 2019MUHAMMAD NURNAJMINo ratings yet

- S250GD Mech. Properties PDFDocument1 pageS250GD Mech. Properties PDFLian HoaNo ratings yet

- A Review On The Potential Use of Austenitic StainlDocument8 pagesA Review On The Potential Use of Austenitic StainlGAS ConsultoriaNo ratings yet

- Quiz QuestionDocument2 pagesQuiz QuestionClaresse SilvaNo ratings yet

- Moihq Abf b01 Arc SHD 2710 00Document1 pageMoihq Abf b01 Arc SHD 2710 00ayman ammarNo ratings yet

- Building Schedule RatesDocument179 pagesBuilding Schedule RatesArzath SajeerNo ratings yet

- Concrete Construction Article PDF - Field Bending of Rebars Partially Embedded in ConcreteDocument2 pagesConcrete Construction Article PDF - Field Bending of Rebars Partially Embedded in ConcretejaiogjhrNo ratings yet

- Ficha Tecnica de Lana MineralDocument1 pageFicha Tecnica de Lana MineralPROYECTOS E INSTALACIONES RTA SA DE CVNo ratings yet

- Hygrothermal Performance of Hempcrete For Ontario (Canada) BuildingsDocument10 pagesHygrothermal Performance of Hempcrete For Ontario (Canada) BuildingsLIZETH ACNo ratings yet

- Introduction On Principles of Steel DesignDocument9 pagesIntroduction On Principles of Steel DesignMaria Therese PrietoNo ratings yet

- ASME StandardsDocument8 pagesASME Standardsanappan100% (1)

- Pig Signaler NigcDocument11 pagesPig Signaler Nigcfatholla593000No ratings yet

- Plumbing SymbolsDocument17 pagesPlumbing SymbolsdonprofaghatiseNo ratings yet

- 12 Samss 007Document33 pages12 Samss 007marghoobNo ratings yet

- Detection and Analysis of Magnetic Particle Testing Defects On Heavy Truck Crankshaft Manufactured by Microalloyed Medium-Carbon Forging SteelDocument10 pagesDetection and Analysis of Magnetic Particle Testing Defects On Heavy Truck Crankshaft Manufactured by Microalloyed Medium-Carbon Forging SteelprabuNo ratings yet

- How Does Steel Corrode in Water?: 2fe 2fe + 4eDocument14 pagesHow Does Steel Corrode in Water?: 2fe 2fe + 4eAlberto Leo SimarmataNo ratings yet

- Rfa RfiDocument118 pagesRfa RfiALFREDO JR. ARIOS CLARO100% (1)

- Tiles, Marble, Granite Work Schedule of Rates (Revised) With ICS - 2022Document10 pagesTiles, Marble, Granite Work Schedule of Rates (Revised) With ICS - 2022ecobuildconstructionltdNo ratings yet