Professional Documents

Culture Documents

Pulp Processing QA Checklist: 01 27-06-2021 Mixed Mango Pulp, Chemically Preserved Royal Food Products, Kabirwala

Uploaded by

Kamran RazaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pulp Processing QA Checklist: 01 27-06-2021 Mixed Mango Pulp, Chemically Preserved Royal Food Products, Kabirwala

Uploaded by

Kamran RazaCopyright:

Available Formats

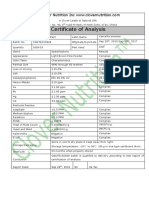

Pulp Processing QA Checklist

Doc. # 01 Date: 27-06-2021 Pulp Description: Mixed Mango Pulp, Chemically preserved

Processing Unit: Royal Food Products, Kabirwala

Parameters Standard 01 02 03 04 05 06 07 08

Fruit inspection at unloading

No overloading, Contamination free, Ok Ok Ok Ok Ok Ok Ok Ok

Fully ripened and undamaged

Fruit sorting at Conveyor

Removal of soiled, infested, unripe Ok Ok Ok Ok Ok Ok Ok Ok

and infested fruits

Fruit washing

Removal of soil, chemicals and Ok Ok Ok Ok Ok Ok Ok Ok

twigs/leaves

Pasteurization temperature 95-1000C 95 98 98 96 96 96 96 96

Chemicals dosing

Citric acid (qty) 0.85% 8 8 10 10 10 10 10 10

Ascorbic acid (qty) 0.03% 0.1 0.1 0.35 0.35 0.35 0.35 0.35 0.35

Sodium Benzoate (qty) 0.1% 1.5 1.5 1.2 1.2 1.2 1.2 1.2 1.2

KMS (qty) 0.145% 2 2 1.75 1.75 1.75 1.75 1.75 1.75

Filling temperature 80-900C 85 85 85 85 85 85 85 85

Brix NLT 18% 18 18 17.8 17.8 18 17.5 17.5 17.5

Acidity NLT 1%

pH 3.4-3.7

Preservative (SO2) `1000ppm 1000 1000 1000 1000 1000 1000 1000 1000

Food grade, Properly cleaned and free

Drums condition from Rust, Contamination and Ok Ok Ok Ok Ok Ok Ok Ok

Obnoxious odors

Drums Tagging

Pulp name, Batch #, Prd/Exp dates, Ok Ok Ok Ok Ok Ok Ok Ok

Brix, Acidity, Preservative

QA Inspector

Remarks and Observations Production stopped due to pump issue.

Chemicals dosages revised after 2nd batch.

You might also like

- Alien Bestiary PDFDocument450 pagesAlien Bestiary PDFDũng Lê100% (13)

- Deosen - F200-Xanthan GumDocument2 pagesDeosen - F200-Xanthan Gumkapil chopra100% (1)

- COA of Raw MaterialDocument10 pagesCOA of Raw MaterialShafaq ALINo ratings yet

- Final Exam Tle Grade 8Document4 pagesFinal Exam Tle Grade 8John leo Claus67% (3)

- Stability Data N Acetyl L Cysteine (AJI92)Document10 pagesStability Data N Acetyl L Cysteine (AJI92)Felipe ResendeNo ratings yet

- Peanut Oil RM COADocument2 pagesPeanut Oil RM COAASHOK KUMAR LENKANo ratings yet

- Am Jetstream Pre-Int Unit 8 Lesson 2Document2 pagesAm Jetstream Pre-Int Unit 8 Lesson 2Jennyfer Guevara50% (2)

- Certificate of Analysis: Quality ControlDocument2 pagesCertificate of Analysis: Quality ControlASHOK KUMAR LENKANo ratings yet

- AspenTech Awareness & Workshop Ebook - 2020 PDFDocument20 pagesAspenTech Awareness & Workshop Ebook - 2020 PDFĐậu BắpNo ratings yet

- Polysorb 85 - 70 - 00 RM COADocument2 pagesPolysorb 85 - 70 - 00 RM COAASHOK KUMAR LENKANo ratings yet

- Certificate of AnalysisDocument1 pageCertificate of AnalysisbluemyNo ratings yet

- AKBA - 10% CoaDocument1 pageAKBA - 10% CoaDeepak VarmaNo ratings yet

- Pure Water SpecDocument2 pagesPure Water SpecRisma Berliana PanjaitanNo ratings yet

- Alginato Sodio AlchiDocument1 pageAlginato Sodio AlchiViviana CarrascoNo ratings yet

- CoA of EgcgDocument1 pageCoA of EgcgMirna Candra RNo ratings yet

- Ascorbic Acid (Vitamin C)Document2 pagesAscorbic Acid (Vitamin C)ASHOK KUMAR LENKANo ratings yet

- ST - SIEVERS - EXOFRUT - Maracuja Succo Conc. 50Bx - 2019Document2 pagesST - SIEVERS - EXOFRUT - Maracuja Succo Conc. 50Bx - 2019neyx66No ratings yet

- Lampiran 3 Dan 4 Proposal DisertasiDocument2 pagesLampiran 3 Dan 4 Proposal DisertasioktariyanaNo ratings yet

- PDS-oil - Rev 2Document1 pagePDS-oil - Rev 2Toon ju lienNo ratings yet

- Certificate of Analysis: Address: No. 43, 6 Road Hi-Tech, Hi-Tech Zone, Xi'an, ChinaDocument1 pageCertificate of Analysis: Address: No. 43, 6 Road Hi-Tech, Hi-Tech Zone, Xi'an, ChinabluemyNo ratings yet

- Green Tea ExtractDocument1 pageGreen Tea Extractajitbadboy2No ratings yet

- Xi'an Haoxuan Bio-Tech Co.,Ltd: Certificate of AnylasisDocument1 pageXi'an Haoxuan Bio-Tech Co.,Ltd: Certificate of AnylasisNilsNo ratings yet

- Canola OilDocument1 pageCanola Oilrizka wahyuni helsinNo ratings yet

- COA of Calcium D Pantothente - RevisedDocument1 pageCOA of Calcium D Pantothente - RevisedJose.SuarezNo ratings yet

- Swati Spentose PVTLTD Coa 1453287214Document3 pagesSwati Spentose PVTLTD Coa 1453287214Sulastari Cahyani IINo ratings yet

- Xi'an Haoxuan Bio-Tech Co.,Ltd: Certificate of AnylasisDocument1 pageXi'an Haoxuan Bio-Tech Co.,Ltd: Certificate of AnylasisNilsNo ratings yet

- 5-HTP CoaDocument1 page5-HTP Coawillyvh99No ratings yet

- VC Ascorbic Acid 100 Mesh 90%: Coversheet For Certificate of AnalysisDocument3 pagesVC Ascorbic Acid 100 Mesh 90%: Coversheet For Certificate of AnalysisNicole Paredes Del AguilaNo ratings yet

- COA of Capsicum Annuum PowderDocument1 pageCOA of Capsicum Annuum PowderJone YingNo ratings yet

- Certificate of Analysis: Sunflower Oil RefinedDocument1 pageCertificate of Analysis: Sunflower Oil RefinedBetrand MuNo ratings yet

- Coa Grape SeedDocument1 pageCoa Grape SeedVinny Fitria ArdyaniNo ratings yet

- Hydroxypropylcellulose CertificadoDocument1 pageHydroxypropylcellulose CertificadoANA MARIA ORTEGON BUITRAGONo ratings yet

- Gotu Kola-%tdsDocument3 pagesGotu Kola-%tdsSANo ratings yet

- Sorbitol 70% Non Crystallizing Liquid RM COADocument2 pagesSorbitol 70% Non Crystallizing Liquid RM COAASHOK KUMAR LENKANo ratings yet

- Pet Flakes ADocument1 pagePet Flakes AReal NanotechNo ratings yet

- MCT Oil Powder 70 - FG - Coconut - Product Specification-001Document1 pageMCT Oil Powder 70 - FG - Coconut - Product Specification-001Jorge Eduardo Murillo Valdés100% (1)

- Hoodia Gordonii Extract COADocument1 pageHoodia Gordonii Extract COAStefani StefaniNo ratings yet

- COA of Fenugreek Powder HP-MET-2303001Document1 pageCOA of Fenugreek Powder HP-MET-2303001Saransh singh BarhaiyaNo ratings yet

- OmegaEquis Fish Oil Technical Data SheetDocument1 pageOmegaEquis Fish Oil Technical Data SheetKatherine Leyla Anchayhua TorresNo ratings yet

- Paramters Removal Efficiency-Pilot UnitDocument6 pagesParamters Removal Efficiency-Pilot UnitRoger T SomundohNo ratings yet

- CoA Sucralose - Supplier Tokped (Shandong Kanbo)Document1 pageCoA Sucralose - Supplier Tokped (Shandong Kanbo)Tantriyani GunadyNo ratings yet

- Glycerin Grade Comparison ChartDocument2 pagesGlycerin Grade Comparison Chartisraa helalNo ratings yet

- Chamomilla TDSDocument3 pagesChamomilla TDSSANo ratings yet

- Certificate of Analysis:: Tongkat Ali Roots HA PE 100-1Document1 pageCertificate of Analysis:: Tongkat Ali Roots HA PE 100-1jo nemesisNo ratings yet

- Virginia Prime Gold Fish Oil Technical Data SheetDocument1 pageVirginia Prime Gold Fish Oil Technical Data SheetKatherine Leyla Anchayhua TorresNo ratings yet

- Thiamine Hydrochloride COA - 07Document2 pagesThiamine Hydrochloride COA - 07ASHOK KUMAR LENKANo ratings yet

- WUT-Biogas 01Document33 pagesWUT-Biogas 01RangaNo ratings yet

- 1, Water Soluble Ginkgo Biloba ExtractDocument1 page1, Water Soluble Ginkgo Biloba ExtractdanilriosNo ratings yet

- Analysis AllDocument8 pagesAnalysis AllDerrick Scott FullerNo ratings yet

- Certificate of Analysis: BiotinDocument1 pageCertificate of Analysis: BiotinAchmad LatiefNo ratings yet

- Certificate of Analysis Green CofeeDocument1 pageCertificate of Analysis Green CofeeEssamNo ratings yet

- Certificate of Analysis Green CofeeDocument1 pageCertificate of Analysis Green CofeeEssamNo ratings yet

- Soya Lecithim PowderDocument1 pageSoya Lecithim PowderASHOK KUMAR LENKANo ratings yet

- Testing Procdure For OilDocument66 pagesTesting Procdure For Oilisaiah mathengeNo ratings yet

- AlimentationDocument19 pagesAlimentationAbdoul Nasser Sarougi GarbaNo ratings yet

- COA FCL XX PALTA (PH2) PDFDocument1 pageCOA FCL XX PALTA (PH2) PDFPaolo CesarNo ratings yet

- Bulk MushroomDocument2 pagesBulk MushroomJesus Vazquez CarranzaNo ratings yet

- General Specification: Muira Puama Extract Poeder (Ratio 10:1)Document5 pagesGeneral Specification: Muira Puama Extract Poeder (Ratio 10:1)melimaulani-1No ratings yet

- Spec Sheet HOSO 2kgDocument2 pagesSpec Sheet HOSO 2kgBryan GuerreroNo ratings yet

- Stability Data For Amitraz, 98%Document8 pagesStability Data For Amitraz, 98%Ronald NyamurowaNo ratings yet

- Fortified Refined Soybean Oil - Soybean OilDocument5 pagesFortified Refined Soybean Oil - Soybean OilLarasNo ratings yet

- COA FCL X PALTA (PH2) PDFDocument1 pageCOA FCL X PALTA (PH2) PDFPaolo CesarNo ratings yet

- Coconut Milk Powder SpecsheetDocument1 pageCoconut Milk Powder SpecsheetMarison J. Pintu Batu0% (1)

- Handbook of Enology, Volume 2: The Chemistry of Wine - Stabilization and TreatmentsFrom EverandHandbook of Enology, Volume 2: The Chemistry of Wine - Stabilization and TreatmentsPascal Ribéreau-GayonNo ratings yet

- Zero Voltage Switching Active Clamp Buck-BoostDocument10 pagesZero Voltage Switching Active Clamp Buck-Boostranjitheee1292No ratings yet

- Upfc PlacementDocument0 pagesUpfc PlacementVamsi KumarNo ratings yet

- NS2-DVN-2540.Rev4 - Profomal Packing List BLR Piping Hanger Support Beam-Unit 2 - 20200710Document27 pagesNS2-DVN-2540.Rev4 - Profomal Packing List BLR Piping Hanger Support Beam-Unit 2 - 20200710PHAM PHI HUNGNo ratings yet

- Sample CISSP ResumeDocument4 pagesSample CISSP ResumeAskia MappNo ratings yet

- Teacher Survey - Outdoor Classroom Feedback: Please Circle All That ApplyDocument3 pagesTeacher Survey - Outdoor Classroom Feedback: Please Circle All That ApplyBrooke Doran RoeNo ratings yet

- The Macquarie Australian Slang DictionarDocument7 pagesThe Macquarie Australian Slang DictionarnetshidoNo ratings yet

- Water Cement RatioDocument5 pagesWater Cement RatioCastro FarfansNo ratings yet

- Resume Arun.A: Career ObjectiveDocument2 pagesResume Arun.A: Career ObjectiveajithkumarNo ratings yet

- Mutant ChroniclesDocument3 pagesMutant ChroniclesZoth BernsteinNo ratings yet

- MaekawaDocument2 pagesMaekawabhaskar_chintakindiNo ratings yet

- Chords, Arcs, and Central and Inscribed AngleDocument14 pagesChords, Arcs, and Central and Inscribed AngleAlice KrodeNo ratings yet

- Spsi 622 Page Quattlebaum-Severecommunicationdisorders W Ecolog Inventory ExDocument25 pagesSpsi 622 Page Quattlebaum-Severecommunicationdisorders W Ecolog Inventory Exapi-270949898No ratings yet

- Table of Contents and Company Profile of JPCOM CARES STAC5Document4 pagesTable of Contents and Company Profile of JPCOM CARES STAC5Ch Ma100% (1)

- DiseasesDocument11 pagesDiseasesapi-307430346No ratings yet

- RTI SpicesDocument226 pagesRTI SpicesvivebajajNo ratings yet

- Segment Reporting Decentralized Operations and Responsibility Accounting SystemDocument34 pagesSegment Reporting Decentralized Operations and Responsibility Accounting SystemalliahnahNo ratings yet

- IBEF Cement-February-2023Document26 pagesIBEF Cement-February-2023Gurnam SinghNo ratings yet

- IIRDocument2 pagesIIRJagan FaithNo ratings yet

- UntitledDocument4 pagesUntitledapi-223522684No ratings yet

- Chapter 2 The Development of Evolutionary TheoryDocument5 pagesChapter 2 The Development of Evolutionary TheoryjohnNo ratings yet

- Can We Define Ecosystems - On The Confusion Between Definition and Description of Ecological ConceptsDocument15 pagesCan We Define Ecosystems - On The Confusion Between Definition and Description of Ecological ConceptsKionara SarabellaNo ratings yet

- The Light BulbDocument6 pagesThe Light Bulbapi-244765407No ratings yet

- National Institute of Industrial Engineering: Part - B (10 Marks) : Answer All The QuestionsDocument4 pagesNational Institute of Industrial Engineering: Part - B (10 Marks) : Answer All The QuestionsTulasi PatleNo ratings yet

- BC Caribou Recovery Program Stakeholders Teleconference MinutesDocument5 pagesBC Caribou Recovery Program Stakeholders Teleconference MinutesRevelstoke MountaineerNo ratings yet

- Aeroacoustic Optimization of Wind Turbine Airfoils by Combining Thermographic and Acoustic Measurement DataDocument4 pagesAeroacoustic Optimization of Wind Turbine Airfoils by Combining Thermographic and Acoustic Measurement DatamoussaouiNo ratings yet

- Management From RamayanaDocument14 pagesManagement From Ramayanasaaket batchuNo ratings yet