Professional Documents

Culture Documents

H1-The New Generation of Hydrostatics 160 CM Bent Axis Variable Motor

Uploaded by

juanchis650Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

H1-The New Generation of Hydrostatics 160 CM Bent Axis Variable Motor

Uploaded by

juanchis650Copyright:

Available Formats

Hydrostatic Pump Repair

www.hydrostaticpumprepair.net

Phone: 800-361-0028

Email: sales@hydrostatic-transmission.com

Data Sheet

H1-The new Generation of Hydrostatics

160 cm3 Bent Axis Variable Motor

For more than 40 years, Danfoss has been

developing state-of-the-art components and

systems for mobile machinery used in off‑highway

operations around the world.

We have become a preferred supplier by offering

the best of what really matters: The hardware

inside your vehicle application.

H1 - our new generation of servo-controlled

hydrostatic pumps and bent axis variable motors is

no exception.

The H1 product is built around an advanced control

and available in a wide range of displacements. It is

designed for quality and reliability and offers

expanded functionality, greater total efficiency,

and easy installation.

All H1 control and sensor options are PLUS+1®

Compliant. PLUS+1® allows you to rapidly develop

and customize electronic machine control. It opens

up the future by combining machine controls and

diagnostics in an integrated operating network.

Features yy Designed for quality and reliability –– Common controls across the entire motor

–– Proven and optimized 9 piston rotating family

group –– PLUS+1® Compliant control and sensor

–– Single piece housing options

–– Electric components with IP67 & IP69K

rating yy Expanded functionality

–– Zero degree capability together with a high

yy Installation and packaging benefits performance 32 degree maximum angle

–– Optimized for shortest length –– Enhanced control functions with

–– Standardized connector interface proportional controls de-energized at

–– Integrated loop flushing device minimum or maximum displacement

–– Radial or axial high pressure ports –– Optional integrated speed sensor with

–– Dual redundant speed sensing

yy Wide range of controls –– Direction indication

–– Electric Two-position Control –– Temperature sensing

–– Electric Proportional Control –– Wire fault detection

–– Hydraulic Two-position Control

–– Hydraulic Proportional Control yy Greater total efficiency

–– Pressure Compensator Override –– Minimized losses

–– Proportional Pressure Compensator –– Improved at high flow conditions

Override

–– Brake Pressure Defeat option

L1124250 • Rev BC • Oct 2014

Data Sheet H1B-The new Generation of Hydrostatics 160 cm3 Motor

Technical Specifications

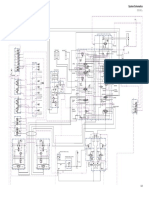

Physical Properties Schematic (example)

Features Units Size 160

Displacement cm3 [in3] 160 [9.76] Electric Proportional Control

Weight (with Electric Proportional Control) (de-energized = max. displacement)

SAE ISO 3019/1 61.9 [136]

L2 MA N

DIN ISO 3019/2 kg [lb] 59.3 [131]

Cartridge 54.7 [121] A

Operating Parameters

at max. displacement 2600

n

Rated at min. displacement (6°) 4250

Output Speed at 0° displacement 4750

min-1

[rpm] at max. displacement 3300

Maximum at min. displacement (6°) 5250

at 0° displacement 5750

Working 450 [6527]

System Pressure max min

Maximum 480 [6960] C1

bar [psi]

Min. low loop 7.5 [109]

L1

Rated 3 [44]

Case Pressure Maximum 5 [73] B

bar [psi]

Minimum 0.3 [4] M4 M5 MB P003426

Installation Drawings

SAE ISO 3019/1 with Electric Proportional Control (de-energized = max. displacement)

Loop Flushing Valve 200

Servo Pressure 97 97

Gauge Port “M4”

System Pressure “A”+“B” 0.5625-18UNF-2B 60 60

9/16 -18UNF-2B

Gauge Port ”MA”+ “MB”

0.5625-18UNF-2B

8x 80.8

9/16 -18UNF-2B

12.45

Y

220

X

∅152.4

[5.99]

200

184

Split Flange Boss “A”+”B”

Speed Sensor Connector: DN 32 Typ I 40MPa Series

Min. Angle Deutsch DTM04-6P 4x 20.6 per ISO 6162

Loop Flushing

Stop Adjustment Solenoid Connector: Thread: M12x1.75

Shuttle Spool

344 ±2 Deutsch DT04-2P View X 21.5 [0.85] full Thread Depth

View Y

DIN ISO 3019/2 with Electric Proportional Control (de-energized = min. displacement)

96 96

Split Flange Boss “A”+”B” Loop Flushing Solenoid Connector: View X

DN 32 Typ I 40MPa Series Shuttle Spool Deutsch DT04-2P 60 60

per ISO 6162 10.8

Thread: M12x1.75

265

8x 79.2

21.5 [0.85] full Thread Depth

Y

Servo Pressure

Gauge Port “M4” X

∅180

[7.09]

4x 17.5

212

0.5625-18UNF-2B

9/16 -18UNF-2B

System Pressure “A”+“B”

138

Gauge Port ”MA”+ “MB”

Speed Sensor Connector: 1.0625-12UN-2B

1 1/16 -12UN-2B

Min. Angle Deutsch DTM04-6P

Loop Flushing Valve Stop Adjustment 212 View Y

308 ±2

Cartridge with Electric Two-Position Control (de-energized = min. displacement) Servo Pressure

113

Gauge Port “M4”

Pressure Compensator Override, Brake Pressure Defeat

View X 0.5625-18UNF-2B

9/16 -18UNF-2B

[4.45]

97 97

Loop Flushing Servo Pressure

Loop Flushing Valve Shuttle Spool Gauge Port “M5”

0.5625-18UNF-2B

9/16 -18UNF-2B

Solenoid Connector:

243

System Pressure “A”+“B”

Deutsch DT04-2P

Gauge Port ”MA”+ “MB”

0.5625-18UNF-2B 2x 21

9/16 -18UNF-2B

Y [0.83]

X

∅200

[7.87]

Split Flange Boss “A”+”B”

138

DN 32 Typ I 40MPa Series

per ISO 6162

Speed Sensor Connector: Thread: M12x1.75

125 125 23 full Thread Depth

Min. Angle Deutsch DTM04-6P 60 60

201 ±2.5 [4.92] [4.92]

Stop Adjustment 286 View Y P301 323E

[11.26]

Danfoss

Power Solutions Trading

Danfoss Danfoss Danfoss (Shanghai) Co., Ltd.

Power Solutions (US) Company Power Solutions GmbH & Co. OHG Power Solutions ApS Building #22, No. 1000 Jin Hai Rd

2800 East 13th Street Krokamp 35 Nordborgvej 81 Jin Qiao, Pudong New District

Ames, IA 50010, USA D-24539 Neumünster, Germany DK-6430 Nordborg, Denmark Shanghai, China 201206

Phone: +1 515 239 6000 Phone: +49 4321 871 0 Phone: +45 7488 2222 Phone: +86 21 3418 5200

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

already on order provided that such alterations can be made without changes being necessary in specifications already agreed.

All trademarks in this material are property of the respective companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

L1124250 • Rev BC • Oct 2014 www.danfoss.com © Danfoss A/S

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Manual de Operaciones y Mantenimiento SEM658C - 659CDocument79 pagesManual de Operaciones y Mantenimiento SEM658C - 659Cjuanchis650No ratings yet

- Martillos FRD (Serie FXJ)Document10 pagesMartillos FRD (Serie FXJ)juanchis650No ratings yet

- True-Rms Multimeter: OK OK V 110 114 115 117 110 114 115 117 115 117Document2 pagesTrue-Rms Multimeter: OK OK V 110 114 115 117 110 114 115 117 115 117juanchis650No ratings yet

- Danfoss Series 18 Axial Piston Pumps MotorsDocument60 pagesDanfoss Series 18 Axial Piston Pumps MotorsYann Van OsselaerNo ratings yet

- NG CD 55a1111 A1-668341Document2 pagesNG CD 55a1111 A1-668341kpNo ratings yet

- Danfoss Series 18 Axial Piston Pumps MotorsDocument60 pagesDanfoss Series 18 Axial Piston Pumps MotorsYann Van OsselaerNo ratings yet

- Danfoss 520L0889 Series 90 55cc Pump Parts Manual 2015Document164 pagesDanfoss 520L0889 Series 90 55cc Pump Parts Manual 2015juanchis650No ratings yet

- Komatsu - Pc220lc-8 - Excavator - Service - Testing and AdjustingDocument65 pagesKomatsu - Pc220lc-8 - Excavator - Service - Testing and Adjustingjuanchis650No ratings yet

- Portable Nitrogen Charging Unit: Fast, Efficient, and Cost-Effective Inert Gas ChargingDocument2 pagesPortable Nitrogen Charging Unit: Fast, Efficient, and Cost-Effective Inert Gas Chargingjuanchis650No ratings yet

- Danfoss MP1 Axial Piston PumpsDocument2 pagesDanfoss MP1 Axial Piston Pumpsjuanchis650No ratings yet

- s40 Parts ManualDocument6 pagess40 Parts Manualjuanchis650No ratings yet

- Manual de Transmision de TL642 Y TL943 CAT ZF - Powershift Trans - 4 WG-92-98 TSCDocument38 pagesManual de Transmision de TL642 Y TL943 CAT ZF - Powershift Trans - 4 WG-92-98 TSCWilson garcia100% (5)

- R65 Hydr Aul I C Hammer Par Ts ManualDocument5 pagesR65 Hydr Aul I C Hammer Par Ts Manualjuanchis650No ratings yet

- Danfoss Load Sensing Steering Units OSPB C F D L LS OLS Priority Valves OSQQ Flow AmplifiersDocument90 pagesDanfoss Load Sensing Steering Units OSPB C F D L LS OLS Priority Valves OSQQ Flow Amplifiersjuanchis650No ratings yet

- H1 Bent Axis Variable Motor: Size 110cmDocument2 pagesH1 Bent Axis Variable Motor: Size 110cmjuanchis650No ratings yet

- Radial Piston Motor MCRDocument56 pagesRadial Piston Motor MCRjuanchis650100% (1)

- Radial Piston Motor (Multi-Stroke) MCR10: RE 15207/07.10 1/16 Replaces: 02.98Document16 pagesRadial Piston Motor (Multi-Stroke) MCR10: RE 15207/07.10 1/16 Replaces: 02.98juanchis650No ratings yet

- DirecTV MANUAL INSTALACIONDocument28 pagesDirecTV MANUAL INSTALACIONjuanchis650No ratings yet

- 02 BombasDocument25 pages02 Bombasjuanchis650No ratings yet

- Axial Piston Variable Pump A10VG Series 10: FeaturesDocument27 pagesAxial Piston Variable Pump A10VG Series 10: Featuresjuanchis650No ratings yet

- Onyx Studio 2Document2 pagesOnyx Studio 2juanchis650No ratings yet

- Esquema Hidráulico Sany SY215C-AND-SY235Document1 pageEsquema Hidráulico Sany SY215C-AND-SY235juanchis650100% (1)

- Radial Piston Motor (Multi Stroke) Type MCR 5: RE 15 206/06.06 1/16 Replaces: 02.98Document16 pagesRadial Piston Motor (Multi Stroke) Type MCR 5: RE 15 206/06.06 1/16 Replaces: 02.98juanchis6500% (1)

- DD 24 DD 22Document2 pagesDD 24 DD 22evega97No ratings yet

- Esquema Hidráulico Sany SY215C-AND-SY235Document1 pageEsquema Hidráulico Sany SY215C-AND-SY235juanchis650100% (1)

- Esquema Hidráulico CAT330B 9HNDocument2 pagesEsquema Hidráulico CAT330B 9HNjuanchis650No ratings yet

- Terex Rough Terrain Cranes Spec cb8dc7Document6 pagesTerex Rough Terrain Cranes Spec cb8dc7juanchis650No ratings yet

- 21 27 Series Parts Service ManualDocument66 pages21 27 Series Parts Service ManualLenin Gullapalli100% (2)

- Uc 3845 BDocument15 pagesUc 3845 BshivguptaNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Harvard Referencing GuideDocument73 pagesHarvard Referencing GuideCassidy WilliamsNo ratings yet

- Advantages and Disadvantages of NanotechnologyDocument31 pagesAdvantages and Disadvantages of NanotechnologyMaribel Tan-Losloso Nayad100% (4)

- The Shrinking and Swelling of Wood and Its Effect On FurnitureDocument26 pagesThe Shrinking and Swelling of Wood and Its Effect On FurnitureHozaifaNo ratings yet

- Blue Sky Innovation Group v. Forcome - ComplaintDocument11 pagesBlue Sky Innovation Group v. Forcome - ComplaintSarah BursteinNo ratings yet

- A Simple Digital Power-Factor CorrectionDocument11 pagesA Simple Digital Power-Factor CorrectionVinoth KumarNo ratings yet

- Police Personnel Management and RecordsDocument26 pagesPolice Personnel Management and RecordsLowie Jay Mier OrilloNo ratings yet

- Test Bank For Project Management Achieving Competitive Advantage 5th Edition PintoDocument6 pagesTest Bank For Project Management Achieving Competitive Advantage 5th Edition PintoCarlosSnydercmtyn97% (36)

- Ch3.2 - HomeworkDocument2 pagesCh3.2 - HomeworkArcherDash Love GeometrydashNo ratings yet

- Skylab 4 PAO Mission Commentary 16 of 32Document188 pagesSkylab 4 PAO Mission Commentary 16 of 32Bob Andrepont100% (1)

- Multi-User Collaboration With Revit WorksetsDocument10 pagesMulti-User Collaboration With Revit WorksetsRafael Rafael CastilloNo ratings yet

- Apparent Density of Free-Flowing Metal Powders Using The Hall Flowmeter FunnelDocument4 pagesApparent Density of Free-Flowing Metal Powders Using The Hall Flowmeter Funnelİrem Şebnem SorucuNo ratings yet

- Datasheet Hitec HS-311 ServoDocument1 pageDatasheet Hitec HS-311 ServoMilo LatinoNo ratings yet

- Course Outline MicroeconomicsDocument6 pagesCourse Outline MicroeconomicsMubashir Ali KhanNo ratings yet

- SD WanDocument32 pagesSD WanAbdalrawoof AlsherifNo ratings yet

- Mesalazine: Mesalazine (INN, BAN), Also Known As Mesalamine (USAN) or 5-Aminosalicylic AcidDocument4 pagesMesalazine: Mesalazine (INN, BAN), Also Known As Mesalamine (USAN) or 5-Aminosalicylic AcidAnkan PalNo ratings yet

- Lesson Plan 3d Printing - World of Part 1Document3 pagesLesson Plan 3d Printing - World of Part 1api-639942719No ratings yet

- CBR A Drug DevelopDocument2 pagesCBR A Drug DevelopAlfieNo ratings yet

- Fundamentals of Cyber Law 2021 t6hzxpREDocument97 pagesFundamentals of Cyber Law 2021 t6hzxpREshivraj satavNo ratings yet

- ICAP Pakistan Final Exams Business Finance Decisions RecommendationsDocument4 pagesICAP Pakistan Final Exams Business Finance Decisions RecommendationsImran AhmadNo ratings yet

- Nec Sl1100 and Sv8100 Sip Trunk Configuration GuideDocument8 pagesNec Sl1100 and Sv8100 Sip Trunk Configuration GuidealcewebNo ratings yet

- De La Salle University College of Business Course Checklist: Basirec SystandDocument2 pagesDe La Salle University College of Business Course Checklist: Basirec SystandncllpdllNo ratings yet

- Digest of CIR v. Arnoldus Carpentry (G.R. No. 71122)Document2 pagesDigest of CIR v. Arnoldus Carpentry (G.R. No. 71122)Rafael PangilinanNo ratings yet

- 5.1.2.8 Lab - Viewing Network Device MAC AddressesDocument5 pages5.1.2.8 Lab - Viewing Network Device MAC Addresseschristian hallNo ratings yet

- TDS - Cu-9 SchultzDocument2 pagesTDS - Cu-9 SchultzFabiola ArceNo ratings yet

- Section 1 Quiz: Reduced Maintenance Real-World Modeling Both ( ) NoneDocument50 pagesSection 1 Quiz: Reduced Maintenance Real-World Modeling Both ( ) NoneNikolay100% (2)

- Soil Fabric LoggingDocument4 pagesSoil Fabric LoggingCaraUnggahNo ratings yet

- Some Definitions: Selection. in Order To Have A Random Selection Method, You Must Set Up Some Process orDocument9 pagesSome Definitions: Selection. in Order To Have A Random Selection Method, You Must Set Up Some Process orAldrinTEñanoNo ratings yet

- 1 Network Layer Firewalls: Figure 1: Screened Host FirewallDocument3 pages1 Network Layer Firewalls: Figure 1: Screened Host FirewallAnonymous xN0cuz68ywNo ratings yet

- Chevron Annual Report SupplementDocument68 pagesChevron Annual Report SupplementLaurentiu CiobotaricaNo ratings yet