Professional Documents

Culture Documents

H1 Bent Axis Variable Motor: Size 110cm

Uploaded by

juanchis650Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

H1 Bent Axis Variable Motor: Size 110cm

Uploaded by

juanchis650Copyright:

Available Formats

Hydrostatic Pump Repair

www.hydrostaticpumprepair.net

Phone: 800-361-0028

Email: sales@hydrostatic-transmission.com

Data Sheet

H1 Bent Axis Variable Motor

Size 110cm³

For more than 40 years, Danfoss has been developing

state-of-the-art components and systems for mobile

machinery used in off-highway operations around the

world.

We have become a preferred supplier by offering the

best of what really matters: The hardware inside your

vehicle application.

H1 - our new generation of servo-controlled

hydrostatic pumps and bent axis variable motors is no

exception.

The H1 product is built around an advanced control

and available in a wide range of displacements. It is

designed for quality and reliability and offers

expanded functionality, greater total efficiency, and

easy installation.

All H1 control and sensor options are PLUS+1®

Compliant. PLUS+1® allows you to rapidly develop

and customize electronic machine control. It opens

up the future by combining machine controls and

diagnostics in an integrated operating network.

Features

Designed for quality and reliability Wide range of controls Expanded functionality

• Proven and optimized 9 piston rotating • Electric Two-position Control • Zero degree capability together with a

group • Electric Proportional Control high performance 32 degree maximum

• Single piece housing • Hydraulic Two-position Control angle

• Electric components with IP67 & IP69K • Hydraulic Proportional Control • Enhanced control functions with

rating • Pressure Compensator Override proportional controls de-energized at

• Proportional Pressure Compensator minimum or maximum displacement

Installation and packaging benefits Override • Optional integrated speed sensor with

• • Brake Pressure Defeat option ‒ Dual redundant speed sensing

Optimized for shortest length

• • Common controls across the entire ‒ Direction indication

Standardized connector interface

• motor family ‒ Temperature sensing

Integrated loop flushing device

• ®

PLUS+1 Compliant control and sensor ‒ Wire fault detection

• Radial or axial high pressure ports

options

Greater total efficiency

Comprehensive technical literature online

• Minimized losses at powersolutions.danfoss.com

• Improved at high flow conditions

© Danfoss | May 2017 AI00000052en-US0204 | 1

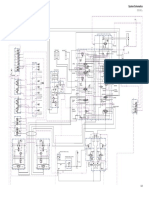

Technical specifications Schematic

Weight SAE ISO 3019/1 48.8 kg [108 lb] H1B with Electric Proportional Control (De-energized = max.

DIN ISO 3019/2 45.0 kg [99 lb]

displacement)

Output speed rated Max. displacement 2900 min-1 (rpm) L2 MA N

Min. displacement (6°) 4800 min-1 (rpm) A

0° displacement 5350 min-1 (rpm)

n

Max. output speed Max. displacement 3700 min-1 (rpm)

Min. displacement (6°) 5950 min-1 (rpm)

0° displacement 6500 min-1 (rpm)

System pressure Working 450 bar [6527 psi]

Maximum 480 bar [6960 psi] max min C1

Min. low loop 7.5 bar [109 psi]

L1

Case pressure Rated 3 bar [44 psi]

B

Max. 5 bar [73 psi]

M4 M5 MB P003426

Min. 0.3 bar [4 psi]

Dimensions

SAE ISO 3019/1 with Electric Proportional Control (de-energized = max. displacement)

Loop Flushing Valve 200

Servo Pressure 89 89

[7.87

Gauge Port “M4” [3.50] [3.50]

System Pressure “A”+“B” 0.5625-18UNF-2B 50 50

9/16 -18UNF-2B

Gauge Port ”MA”+ “MB” [1.97] [1.97]

0.5625-18UNF-2B

8x 80.8

12.45

[3.18]

9/16 -18UNF-2B

[0.49]

[7.76]

Y

197

X

[7.87]

Ø152.4

[6.00]

200

[6.89]

175

Split Flange Boss “A”+”B”

Speed Sensor Connector: DN 25 Typ I 40MPa Series

Min. Angle Deutsch DTM04-6P 4x 20.6 per ISO 6162

Loop Flushing

Stop Adjustment Solenoid Connector: [0.81] Thread: M12x1.75

Shuttle Spool

316±2 Deutsch DT04-2P View X 21.5 [0.85] full Thread Depth

[12.44±0.09] View Y

DIN ISO 3019/2 with Electric Proportional Control (de-energized = min. displacement)

85 85

Split Flange Boss “A”+”B” Loop Flushing Solenoid Connector: View X [3.35] [3.35]

DN 25 Typ I 40MPa Series Shuttle Spool Deutsch DT04-2P 50 50

per ISO 6162 10.8 [1.97] [1.97]

[9.73]

Thread: M12x1.75

247

[0.49]

8x 70.7

21.5 [0.85] full Thread Depth

[2.78]

Y

Servo Pressure

Gauge Port “M4” X

[6.30]

Ø160

4x 17.5

[7.48]

[0.69]

190

0.5625-18UNF-2B

9/16 -18UNF-2B

System Pressure “A”+“B”

[5.15]

131

Gauge Port ”MA”+ “MB”

Speed Sensor Connector: 1.0625-12UN-2B

1 1/16 -12UN-2B

Min. Angle Deutsch DTM04-6P

Loop Flushing Valve Stop Adjustment 190 View Y

279±2 [7.48]

[11±0.09]

Cartridge with Electric Two-Position Control (de-energized = min. displacement) Servo Pressure

113

Gauge Port “M4”

Pressure Compensator Override, Brake Pressure Defeat

View X 0.5625-18UNF-2B

9/16 -18UNF-2B

[4.45]

89 89

Loop Flushing Servo Pressure [3.50] [3.50]

Loop Flushing Valve Shuttle Spool Gauge Port “M5”

0.5625-18UNF-2B

9/16 -18UNF-2B

Solenoid Connector:

[8.74]

222

System Pressure “A”+“B”

Deutsch DT04-2P

Gauge Port ”MA”+ “MB”

0.5625-18UNF-2B 2x 21

9/16 -18UNF-2B

Y [0.83]

X

[7.874]

Ø200

Split Flange Boss “A”+”B”

[5.15]

131

DN 25 Typ I 40MPa Series

per ISO 6162

Speed Sensor Connector: Thread: M12x1.75

125 125 21.5 [0.85] full Thread Depth

Min. Angle Deutsch DTM04-6P 50 50

174±2 [4.92] [4.92]

Stop Adjustment [6.85±0.09] 286 [1.97] [1.97] View Y P003406E

[11.26]

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

already on order provided that such alterations can be made without changes being necessary in specifications already agreed.

All trademarks in this material are property of the respective companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

2 | © Danfoss | May 2017 AI00000052en-US0204

You might also like

- H1 Bent Axis Variable Displacement Motor: Size 210 CMDocument2 pagesH1 Bent Axis Variable Displacement Motor: Size 210 CMBaby VieiraNo ratings yet

- Axial Piston Single Pumps: Data SheetDocument2 pagesAxial Piston Single Pumps: Data SheetDanielNo ratings yet

- IR-Primeroyal-PP Datasheet LowResDocument5 pagesIR-Primeroyal-PP Datasheet LowResDavid GarciaNo ratings yet

- Hydraulic Pitch Pump: Advanced Solutions For Durable and Robust Pitch ControlDocument2 pagesHydraulic Pitch Pump: Advanced Solutions For Durable and Robust Pitch ControlFernando CastroNo ratings yet

- iHSV57-XX Integrated AC Servo Motors: FeaturesDocument5 pagesiHSV57-XX Integrated AC Servo Motors: Featuresbachir diengNo ratings yet

- HexForce Brochure-V4Document8 pagesHexForce Brochure-V4RS Engineers and ConsultantsNo ratings yet

- Fact Sheet Double MotorDocument2 pagesFact Sheet Double MotorDouglas MirandaNo ratings yet

- PS - Og - PCM Driver CD150 - en - BDocument2 pagesPS - Og - PCM Driver CD150 - en - BLUISANA GUEVARANo ratings yet

- 500-1077 Model HT1 Rotary Incremental Actuator Datasheet 122216Document2 pages500-1077 Model HT1 Rotary Incremental Actuator Datasheet 122216mawais15No ratings yet

- Hydraulic Drifter: Innovative DesignDocument2 pagesHydraulic Drifter: Innovative DesignEstyNo ratings yet

- 3150 Spec SheetDocument1 page3150 Spec Sheetps alldilaaaNo ratings yet

- Variable displacement pumps technical dataDocument1 pageVariable displacement pumps technical dataVipin GuptaNo ratings yet

- 1.69" SS100-G2-F: Motor Loads General Dimensional DataDocument1 page1.69" SS100-G2-F: Motor Loads General Dimensional DataTonyNo ratings yet

- Sizing CalculationDocument13 pagesSizing CalculationDaniel DuongNo ratings yet

- T12HP Digital transducer delivers high resolution torque measurementsDocument16 pagesT12HP Digital transducer delivers high resolution torque measurementsAna RuganiNo ratings yet

- Graco Autolube Mode 12Document2 pagesGraco Autolube Mode 12Riyan AditiaNo ratings yet

- Parker 07f31ac DimensionesDocument7 pagesParker 07f31ac DimensionesJair Mata CuencaNo ratings yet

- CCCALBN_en_us_letterDocument1 pageCCCALBN_en_us_letterisaiahsamsonm_948069No ratings yet

- Hartex ALS (Protected-3)Document18 pagesHartex ALS (Protected-3)Eko MardiyantoNo ratings yet

- Primera Etapa AN1 1610Nm3 - NORVAL 375 3 ForzadaDocument1 pagePrimera Etapa AN1 1610Nm3 - NORVAL 375 3 ForzadaPaul Ariel MHNo ratings yet

- Temp 753Document2 pagesTemp 753Neelakandan Krishnan100% (1)

- MiniDocument2 pagesMiniOrr MendelsohnNo ratings yet

- LDS-V650Document2 pagesLDS-V650Jafar JafarNo ratings yet

- "WDPHRHS": Data SheetDocument2 pages"WDPHRHS": Data SheetHans FandinoNo ratings yet

- Gtc-500 Us Sellsheet Vdigital1 2Document2 pagesGtc-500 Us Sellsheet Vdigital1 2scroll pageNo ratings yet

- Adjust pump and governor guide sleeve travelDocument2 pagesAdjust pump and governor guide sleeve travelBest Auto TechNo ratings yet

- HC 95 LM: Hydraulic DrifterDocument2 pagesHC 95 LM: Hydraulic DrifterCésar Cusi LazoNo ratings yet

- f797 PDFDocument2 pagesf797 PDFBest Auto TechNo ratings yet

- Technical Bulletin PVK Pumps: Application Guide LinesDocument4 pagesTechnical Bulletin PVK Pumps: Application Guide LinesRolando RodriguezNo ratings yet

- For Field Service Only Reference No (B) Adjustment of Pump and GovernorDocument2 pagesFor Field Service Only Reference No (B) Adjustment of Pump and GovernorBest Auto TechNo ratings yet

- Test Specifications for Field Service Pump and Governor AdjustmentDocument2 pagesTest Specifications for Field Service Pump and Governor AdjustmentJam BNo ratings yet

- Test Specifications: For Field Service Only Reference No (B) Adjustment of Pump and GovernorDocument2 pagesTest Specifications: For Field Service Only Reference No (B) Adjustment of Pump and GovernorRAVIKANTNo ratings yet

- HMF 45 T4 (A2:6) F300 0,55kW 25º: General DataDocument4 pagesHMF 45 T4 (A2:6) F300 0,55kW 25º: General Databrian mmec2020No ratings yet

- Pompe Serie MA10V PDFDocument44 pagesPompe Serie MA10V PDFAdamNo ratings yet

- Technical Specifications: HC 95 LMDocument1 pageTechnical Specifications: HC 95 LMJuan Enrique Perez VillanuevaNo ratings yet

- Feed Beams Atlas - Copco - Rocket - Boomer - L2C - Technical - Specification - 2003 PDFDocument5 pagesFeed Beams Atlas - Copco - Rocket - Boomer - L2C - Technical - Specification - 2003 PDFZhang JieNo ratings yet

- GMP 1 0Document4 pagesGMP 1 0rasoolNo ratings yet

- CASB-500-2T-15_IE3_ENGDocument3 pagesCASB-500-2T-15_IE3_ENGGonzalo GasparNo ratings yet

- Bran Luebbe Powermon Natriometer 164 01 GBDocument2 pagesBran Luebbe Powermon Natriometer 164 01 GBaelbaroudy390No ratings yet

- Test Specifications: For Field Service Only Reference No (B) Adjustment of Pump and GovernorDocument2 pagesTest Specifications: For Field Service Only Reference No (B) Adjustment of Pump and GovernorJam BNo ratings yet

- Open Circuit Piston Motors: Reverse Displacement Motor (RDM)Document4 pagesOpen Circuit Piston Motors: Reverse Displacement Motor (RDM)CaioNo ratings yet

- Open Circuit Piston Motors: Reverse Displacement Motor (RDM)Document4 pagesOpen Circuit Piston Motors: Reverse Displacement Motor (RDM)CaioNo ratings yet

- RVQG6500 70000 Spec PDFDocument4 pagesRVQG6500 70000 Spec PDFRicardoNo ratings yet

- Blaries 32715Document16 pagesBlaries 32715Jesus JavierNo ratings yet

- Variable Displacement Axial Piston Pump Type V30D: 1. General DescriptionDocument12 pagesVariable Displacement Axial Piston Pump Type V30D: 1. General DescriptionMHS teamNo ratings yet

- CPV enDocument2 pagesCPV enjimmi vasquezNo ratings yet

- Specifications: Heel OaderDocument4 pagesSpecifications: Heel OaderMat Pole LapriNo ratings yet

- Regulating Pumps for Open Loop SystemsDocument24 pagesRegulating Pumps for Open Loop SystemsxxshNo ratings yet

- Reference No Test SpecificationsDocument2 pagesReference No Test SpecificationsBest Auto TechNo ratings yet

- PC130 8Document20 pagesPC130 8anggieNo ratings yet

- FRC Filter/Regulator-Lubricators Technical SpecificationsDocument17 pagesFRC Filter/Regulator-Lubricators Technical SpecificationsNickNo ratings yet

- Size Matters: New Ultra Compact ToolDocument2 pagesSize Matters: New Ultra Compact ToolIuriiNo ratings yet

- 192_063002_NX_Series_CatalogueDocument18 pages192_063002_NX_Series_Cataloguetranhuutri1987quangngaiNo ratings yet

- Manual Servodriver Innovance v2.5 Español y Alarmas Modificado Por SanbemoDocument4 pagesManual Servodriver Innovance v2.5 Español y Alarmas Modificado Por SanbemocentrleuropaNo ratings yet

- Co Rvqg7000 Evap SpecDocument4 pagesCo Rvqg7000 Evap SpecJohn StrackNo ratings yet

- Pump Performance - Additional Data: Modern Erection LTDDocument2 pagesPump Performance - Additional Data: Modern Erection LTDShabbir AhmedNo ratings yet

- For Field Service Only Reference No (B) Adjustment of Pump and GovernorDocument2 pagesFor Field Service Only Reference No (B) Adjustment of Pump and GovernorBest Auto TechNo ratings yet

- Rotator HR6000Document2 pagesRotator HR6000Jose Manuel ReyesNo ratings yet

- Manual de Operaciones y Mantenimiento SEM658C - 659CDocument79 pagesManual de Operaciones y Mantenimiento SEM658C - 659Cjuanchis650No ratings yet

- Martillos FRD (Serie FXJ)Document10 pagesMartillos FRD (Serie FXJ)juanchis650No ratings yet

- True-Rms Multimeter: OK OK V 110 114 115 117 110 114 115 117 115 117Document2 pagesTrue-Rms Multimeter: OK OK V 110 114 115 117 110 114 115 117 115 117juanchis650No ratings yet

- Danfoss Series 18 Axial Piston Pumps MotorsDocument60 pagesDanfoss Series 18 Axial Piston Pumps MotorsYann Van OsselaerNo ratings yet

- NG CD 55a1111 A1-668341Document2 pagesNG CD 55a1111 A1-668341kpNo ratings yet

- Danfoss Series 18 Axial Piston Pumps MotorsDocument60 pagesDanfoss Series 18 Axial Piston Pumps MotorsYann Van OsselaerNo ratings yet

- Danfoss 520L0889 Series 90 55cc Pump Parts Manual 2015Document164 pagesDanfoss 520L0889 Series 90 55cc Pump Parts Manual 2015juanchis650No ratings yet

- Komatsu - Pc220lc-8 - Excavator - Service - Testing and AdjustingDocument65 pagesKomatsu - Pc220lc-8 - Excavator - Service - Testing and Adjustingjuanchis650No ratings yet

- Portable Nitrogen Charging Unit: Fast, Efficient, and Cost-Effective Inert Gas ChargingDocument2 pagesPortable Nitrogen Charging Unit: Fast, Efficient, and Cost-Effective Inert Gas Chargingjuanchis650No ratings yet

- Danfoss MP1 Axial Piston PumpsDocument2 pagesDanfoss MP1 Axial Piston Pumpsjuanchis650No ratings yet

- s40 Parts ManualDocument6 pagess40 Parts Manualjuanchis650No ratings yet

- Manual de Transmision de TL642 Y TL943 CAT ZF - Powershift Trans - 4 WG-92-98 TSCDocument38 pagesManual de Transmision de TL642 Y TL943 CAT ZF - Powershift Trans - 4 WG-92-98 TSCWilson garcia100% (5)

- R65 Hydr Aul I C Hammer Par Ts ManualDocument5 pagesR65 Hydr Aul I C Hammer Par Ts Manualjuanchis650No ratings yet

- Danfoss Load Sensing Steering Units OSPB C F D L LS OLS Priority Valves OSQQ Flow AmplifiersDocument90 pagesDanfoss Load Sensing Steering Units OSPB C F D L LS OLS Priority Valves OSQQ Flow Amplifiersjuanchis650No ratings yet

- H1-The New Generation of Hydrostatics 160 CM Bent Axis Variable MotorDocument2 pagesH1-The New Generation of Hydrostatics 160 CM Bent Axis Variable Motorjuanchis650No ratings yet

- Radial Piston Motor MCRDocument56 pagesRadial Piston Motor MCRjuanchis650100% (1)

- Radial Piston Motor (Multi-Stroke) MCR10: RE 15207/07.10 1/16 Replaces: 02.98Document16 pagesRadial Piston Motor (Multi-Stroke) MCR10: RE 15207/07.10 1/16 Replaces: 02.98juanchis650No ratings yet

- DirecTV MANUAL INSTALACIONDocument28 pagesDirecTV MANUAL INSTALACIONjuanchis650No ratings yet

- 02 BombasDocument25 pages02 Bombasjuanchis650No ratings yet

- Axial Piston Variable Pump A10VG Series 10: FeaturesDocument27 pagesAxial Piston Variable Pump A10VG Series 10: Featuresjuanchis650No ratings yet

- Onyx Studio 2Document2 pagesOnyx Studio 2juanchis650No ratings yet

- Esquema Hidráulico Sany SY215C-AND-SY235Document1 pageEsquema Hidráulico Sany SY215C-AND-SY235juanchis650100% (1)

- Radial Piston Motor (Multi Stroke) Type MCR 5: RE 15 206/06.06 1/16 Replaces: 02.98Document16 pagesRadial Piston Motor (Multi Stroke) Type MCR 5: RE 15 206/06.06 1/16 Replaces: 02.98juanchis6500% (1)

- DD 24 DD 22Document2 pagesDD 24 DD 22evega97No ratings yet

- Esquema Hidráulico Sany SY215C-AND-SY235Document1 pageEsquema Hidráulico Sany SY215C-AND-SY235juanchis650100% (1)

- Esquema Hidráulico CAT330B 9HNDocument2 pagesEsquema Hidráulico CAT330B 9HNjuanchis650No ratings yet

- Terex Rough Terrain Cranes Spec cb8dc7Document6 pagesTerex Rough Terrain Cranes Spec cb8dc7juanchis650No ratings yet

- 21 27 Series Parts Service ManualDocument66 pages21 27 Series Parts Service ManualLenin Gullapalli100% (2)

- Uc 3845 BDocument15 pagesUc 3845 BshivguptaNo ratings yet

- Of Sea Grabs and Alien Species: The New Face of The Biofuels Industry in The PhilippinesDocument13 pagesOf Sea Grabs and Alien Species: The New Face of The Biofuels Industry in The PhilippinesdanNo ratings yet

- Essential For Those Who Want To Use The Radio Transmitters From A Car To Use in Your Home Is You Need A Ham Radio Power Supply DCDocument4 pagesEssential For Those Who Want To Use The Radio Transmitters From A Car To Use in Your Home Is You Need A Ham Radio Power Supply DCdundonaldsNo ratings yet

- Manuale Vela ITDocument44 pagesManuale Vela ITvhcamiloNo ratings yet

- Cds 13 Instruct 1Document53 pagesCds 13 Instruct 1Francisco NetoNo ratings yet

- Mathematical Methods for Engineering Differential Equations IDocument4 pagesMathematical Methods for Engineering Differential Equations IVlad ScortanuNo ratings yet

- York Manual - YOCA - YOHA - ENDocument6 pagesYork Manual - YOCA - YOHA - ENPonto de Presença da RNP no PiauíNo ratings yet

- Bosch WTMC3300US - CNDocument2 pagesBosch WTMC3300US - CNPurcellMurrayNo ratings yet

- Comprehensive Overview On Diesel Additives To Reduce Emissions, Enhance Fuel Properties and Improve Engine PerformanceDocument3 pagesComprehensive Overview On Diesel Additives To Reduce Emissions, Enhance Fuel Properties and Improve Engine PerformanceEduard DinuNo ratings yet

- Iron Roughneck Service ManualDocument42 pagesIron Roughneck Service ManualGiorgiana RosuNo ratings yet

- REVIEWER ACDC SUMMATIVE 1 M1-M3 PDFDocument7 pagesREVIEWER ACDC SUMMATIVE 1 M1-M3 PDFDiether PaderoNo ratings yet

- Wima MKS 4-4147Document13 pagesWima MKS 4-4147Anonymous vKD3FG6RkNo ratings yet

- Current Differential Relay ManualDocument4 pagesCurrent Differential Relay Manualppraveenkumar79No ratings yet

- Powerlink - Asset Management Plan - Volume 3 PUBLIC - January 2016Document186 pagesPowerlink - Asset Management Plan - Volume 3 PUBLIC - January 2016karlNo ratings yet

- Quantum Mechanics - DescriptionDocument2 pagesQuantum Mechanics - DescriptionRafael Nascimento100% (1)

- Physical Quantum MechanicsDocument33 pagesPhysical Quantum MechanicsJerome ColicoNo ratings yet

- FSI-P-CHME Chemical Engineering ExamDocument6 pagesFSI-P-CHME Chemical Engineering ExamAaqib AshrafNo ratings yet

- Woodward Installation & OperationDocument34 pagesWoodward Installation & OperationRiRie RamLee100% (2)

- 2015-05-28 - Major Purchase Order - PDRP - Apr-2015Document2 pages2015-05-28 - Major Purchase Order - PDRP - Apr-2015Hytech Pvt. Ltd.No ratings yet

- Flow Measurement Lab Tests Using Rotameters, Orifice Plates & MoreDocument7 pagesFlow Measurement Lab Tests Using Rotameters, Orifice Plates & MorejanNo ratings yet

- C7 ACERT 205bkWDocument5 pagesC7 ACERT 205bkWsheronNo ratings yet

- Baker Model Fjf-040Document266 pagesBaker Model Fjf-040Хелфор УкраинаNo ratings yet

- FDN For Stationary Equipment-2013!11!07-KOINDocument1 pageFDN For Stationary Equipment-2013!11!07-KOINsinambeladavidNo ratings yet

- LightingDocument11 pagesLightingHafed BaccoucheNo ratings yet

- ESD TR53 01 15 FinalDocument4 pagesESD TR53 01 15 FinalTrantan CdtNo ratings yet

- Physics Chapter 7 Kinetic Energy and Work QuestionsDocument57 pagesPhysics Chapter 7 Kinetic Energy and Work QuestionsJames AguilarNo ratings yet

- Sabp A 043 PDFDocument44 pagesSabp A 043 PDFWalid MegahedNo ratings yet

- Our Changing Climate: How Climate Change Impacts Our Local CommunitiesDocument4 pagesOur Changing Climate: How Climate Change Impacts Our Local CommunitiesNina AzizNo ratings yet

- Special Purpose Motors - Large FontsDocument26 pagesSpecial Purpose Motors - Large FontsAnuradha SkaNo ratings yet

- B10702Document7 pagesB10702mouad naciriNo ratings yet

- Isuzu Trooper 2000 Service Manual MotorDocument544 pagesIsuzu Trooper 2000 Service Manual MotorNotengoNombre TampocoApellido100% (5)