Professional Documents

Culture Documents

Adjusting the Brakes

Uploaded by

Jean-Eric RaoulOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Adjusting the Brakes

Uploaded by

Jean-Eric RaoulCopyright:

Available Formats

THE BRAKES 53

CHAPTER IV

The Brakes

General - Adjustment of Rear and Front Brakes (Chassis previous

to GAF-1) - Adjustment of Foot and Hand Brakes (Chassis GAF-1 and

onwards) - Adjustment of Servo

General.

The only points in the sytem where any adjustment is provided

or is necessary are the following: -

(i) Rear Brakes (Chassis previous to GAF-1).

The threaded rods coupled to the cam operating

levers below the ends of the rear axle

Rear Brakes (Chassis GAF-1 onwards).

A wing nut Wr, for adjustment of the foot brakes,

and the threaded rods coupled to the cam operating

levers, Fig. 29, for adjustment of the handbrake.

(ii) Front Brakes (Chassis previous to GAF-1).

A serrated adjustment on the cam operating shafts.

Front Brakes (Chassis GAF-1 onwards).

A wing nut adjustment, see Fig. 28.

(iii) Servo.

A serrated adjusting nut on the end of the servo shaft.

It is very important to observe that under no circumstances should

adjusment be attempted at any other points, for instance, by altering

the lengths of some of the brake rods or of any of the ropes.

Any alterations to the lengths of these rods or ropes will virtually

shorten the lengths of some of the levers, and will interfere with the

correct functioning of the system.

Adjustment of Rear Brakes. (Chassis previous to GAF-1).

The state of adjustment of the rear brakes - both foot and hand-

operated - should be tested by reference to movement of the brake

cables necessary to take up the clearance between shoes and drums,

or to the movement at the ends of the levers on the axle to which the

cables are connected. For this purpose the cable should be pulled

54 ROLLS-ROYCE 20-25 H.P. CAR THE BRAKES 55

or the lever operated by hand and the movement measured. This The adjustment is effected in a similar manner to that of the

movement should never be less than 1” for both foot and hand foot brake, but it should noticed that the pin H1 of the hand

brakes, but there is no need to adjust the brakes unless it exceeds brake jaw H2 cannot be removed until jaw Y2 is disconnected.

1½” for the foot brake, or 1¾” for the hand brake. Care should be taken that the collar which fits the pin of each jaw

The metohod of adjustment is similar for both hand-operated is in position before fitting the split cotter.

and rear foot-operated brakes, and is illustrated in Fig. 26. This is The adjustment of both brakes should be checked finally by

a view looking from the underside of the axle. measuring the travel of the cable, as already described, when the

cable or lever is moved from the off position to a point where the

shoes just touch the drums.

After replacing the pins and their collars, split cotters should be

fitted to these, and the samll nuts H3 and Y3 tightened up.

The amount of adjustment provided is so proportioned that when

all has been utilised (jaws H2 and Y2 being against the collars

H4 and Y4 respectively), it is a sign that the brake shoes require

recovering, and the makers or one of their “Special Retailers” should

be consulted.

On no account should further adjustment be attempted as, for

instance, by shortening the brake ropes or interfering with adjustments

within the brake drums. Such a course might result in serious injury

to the drums and shoes.

Adjustment of Front Brakes. (Chassis previous to GAF-1).

It should be borne in mind that pedal travel is no indication as to

the front brake adjustment, because these are entirely servo operated

and their adjustment will not influence the pedal travel.

The only indication that they require adjustment (apart from an

observed decrease in front braking) is excessive movement at the

end of the levers Lf, Fig. 27. When lightly depressed by hand the

movement at the end of this lever, for correct adjustment, should be

about 9/16”. It should not exceed ⅞”.

When this figure is exceeded adjustment is imperative.

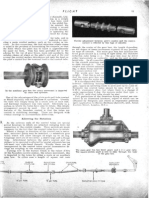

Fig. 26. - REAR WHEEL BRAKE ADJUSTMENT. It is effected as follows: -

(View from Below) Remove the split cotter of the castellated nut J1 and unscrew

The outside rods Y actuate the foot brake shoes, and adjustment the latter. The cover J may then be removed, exposing the serrated

is effected by removing the pin Y1 from the jaw Y2, this pin being adjustment. As this cover also acts as a locking piece, it will be found

secured by a collar and split pin cotter, slackening the small nut Y3, convenient to mark the position of engagement of its teeth with

and screwing the jaw farther on to the rod Y to an extent depending those on the member Rf before removing it.

on the amount of adjustment required. The nut Gf should be unscrewed sufficiently to permit the serrated

The amount of adjustment made to both these rods should usually member Rf to be moved clear of similar serrations on the lever Lf.

be the same. A convenient method of checking this is to measure These two sets of teeth are marked respectively with an arrow and

the distance between the collar Y4 and the jaw Y2. figures 0, 1, 2, 3, 4,and 5. If the brakes are being adjusted for the

Before replacing the pins Y1 in the jaws, attention should be turned first time the arrow will point to “0”.

to adjustment of the hand brake, if any is required. Having noted the relative positions of these serrated parts, they

All adjustment for the hand brake is made on the inside rod H may be disengaged by tapping the lever Lf away from the wheel,

and the corresponding rod at the other end of the axle. carrying with it the serrated member Rf. While holding the latter in

56 ROLLS-ROYCE 20-25 H.P. CAR THE BRAKES 57

the hand, the lever should then be tapped towards the wheel again, Usually it will be necessary to adjust each front brake a like

when the serrations will be disengaged. amount.

It should be observed that when the five teeth of adjustment have

been utilised, this is an indication that the shoes require new facings.

On no account should further adjustment be attempted by, for

instance, interfering with the lengths of any of the brake rods or ropes.

Apart from testing for the need for adjustment of the front brakes,

it is important to test from time to time that the shafts and joints on

the axle are free by pushing down the levers Lf with the hand, or by

moving levers B similarly.

The mechanism should feel free, and be returned sharply to the

off position by the pull-off springs.

If any tightness is found, the cause must be investigated and

removed, otherwise there is a danger of the brakes dragging and

becoming damaged.

Adjustment of Foot Brakes. (Chassis GAF-1 and onwards).

The wing nut adjustment for the front brakes is shown at Wf,

Fig. 28, and that for the rear foot-operated brakes at Wr, Fig. 29.

Fig. 27. - FRONT WHEEL BRAKE ADJUSTMENT.

The cam operating shaft, and with its member Rf, should next

be turned by means od a spanner on the hexagon K of the shaft

until the parts can be re-engaged one serration further towards the

on position of the cam operating shaft than before; that is, after the

first adjustment the arrow will point to “1”.

Finally, re-tighten the nut Gf, re-fit the cover J, which also acts

as a locking piece for this nut, and replace the castellated nut J1,

fitting a split cotter to the latter.

If any difficulty is experienced in getting the teeth of cover J

to engage with those of member Rf, the cover should be rotated

slightly and tried in different positions.

The brake clearances should be tested again after adjustment by

measuring the movement of levers Lf, as described. This movement

musnot be less than 9/16”, otherwise the brakes may drag. Fig. 28. - FRONT BRAKE ADJUSTMENT.

58 ROLLS-ROYCE 20-25 H.P. CAR THE BRAKES 59

Only the fingers must be used in turning these nuts. They are

formed with cam-shaped bosses bearing on cylindrical trunnions in

such a way that rotation of the nut through 90˚ from the position

shown causes the brake shoes to be moved towards the drum as

the cams ride over the trunnion. This movement is carefully pre-

determined, and is equal to the normal clearance between shoes and

drum when the shoes are in the off position. Screwing on the nut

through a further 90, that is, a total of half, allows the shoes to return

to an off position, which is half a turn of the adjustment nearer to the

drum. The adjustment is self-locking.

When making or testing the adjustment, it is preferable that the

wheel should be jacked up and rotated by hand. One is then able both

to hear and to feel when the shoes make contact with the drum.

The nut should be screwed up until the cam action described

prevents further rotation owing to the shoes being applied to the

drums. The setting will then be correct, and the adjustment locked

if the nut be turned back one-quarter of a turn.

It must again be emphasised that on no account must force be

used in turning the nuts, as this will defeat the object of the described

arrangement and result in badly adjusted, probably dragging brakes.

Movement of the brake pedal when the car is standing does not

apply the front brakes, which are operated solely by the action of the

servo. Under such circumstances, pressure on the pedal will only

apply the rear brakes.

Fig. 29 - REAR BRAKE ADJUSTMENT.

Adjustment of the Servo.

Adjustment of Hand Brakes. (Chassis GAF-1 and onwards). The servo is of the dry, disc-clutch type, and should run 20,000

All adjustment of the hand brake is effected at the outside rods miles without the need of any adjustment.

beneath the rear axle, one of which is shown at H, Fig. 29. If adjustment is necessary, it is effected by screwing up the nut,

With the hand brake lever right off, the adjustment should be Z, Fig. 30.

tested by pulling the brake rope J with the hand and measuring This nut is locked by 25 rounded serrations formed on its face,

the travel of the rope necessary just to apply the brake. This travel which engage similar serrations on a washer, which is secured against

should not be less than 1”, but there is no need to adjust the brakes rotation relative to the shaft. The depth of these serrations is carefully

unless it exceeds 1¾”. proportioned to give the correct clearance of the servo, the nut being

turned so that the teeth lightly ride over each other and engage again.

Adjustment is effected by removing the pin K from the jaw, L, this

pin being secured by a collar and split cotter, releasing the locknut, On no account should force be used in this operation, as such

HI, slackening the small nut M, and screwing the jaw farther on treatment would nullify the object of the teeth, namely, ensure the correct

to the rod H to an extent depending on the amount of adjustment clearance with very little trouble.

required. After effecting adjustment in this way, care should be taken to see

that the serrations are in proper engagement.

Usually, this should be the same at both sides. The adjusting nut should not be screwed up more than one serration

Care must be taken to replace the pins K, securing them with - that is, 1/25 of a turn - without testing the servo adjustment.

split cotters and collars, then to re-tighten the nuts M, and finally the To test the servo adjustment the pedal should be depressed lightly

locknuts, HI. by hand to engage the servo and compress the buffer springs, ZI, but

just short of moving the lever A2 rotationally.

60 ROLLS-ROYCE 20-25 H.P. CAR

The pedal travel should then be not less than ½” measured at the

top of the pedal towards the dash.

Fig. 30. - THE SERVO MOTOR AND ITS CONNECTIONS.

It must be realised that this movement is entirely due to operation

of the servo, and does not alter the rear brake clearances. Hence,

lever A2 is not moved rotationally, as mentioned.

After adjustment, the servo clearance should always be checked

again by measuring the pedal movement, as explained.

Emphasis is laid on this point, as obviously a dragging servo, due

to abuse of the adjustment provided, would result in dragging of the

brakes on all wheels.

You might also like

- QST 30Document7 pagesQST 30jengandxb50% (2)

- Multistage Pump RepairDocument5 pagesMultistage Pump RepairCheyanSathishNo ratings yet

- 2012 Components Technical Manual UkDocument154 pages2012 Components Technical Manual UkBrummerNo ratings yet

- Golf Cart Yamaha G1 Repair ManualDocument223 pagesGolf Cart Yamaha G1 Repair ManualDany Tremblay100% (2)

- Sturmey Archer S RF5 Hub InstructionsDocument2 pagesSturmey Archer S RF5 Hub InstructionsAndré VuzNo ratings yet

- A2H Actuator CatalogDocument6 pagesA2H Actuator CatalogahnafNo ratings yet

- Electro-Motive Djvjsion: General Motors Corporation La Grange. Illinois. U. 5. ADocument5 pagesElectro-Motive Djvjsion: General Motors Corporation La Grange. Illinois. U. 5. Aamir barekatiNo ratings yet

- Actuator R431004010Document6 pagesActuator R431004010dianNo ratings yet

- Inclined Plane With Roller 11301.00 11301.88: Operating InstructionsDocument4 pagesInclined Plane With Roller 11301.00 11301.88: Operating InstructionsBarthélemy HoubenNo ratings yet

- Lawn-Boy F Series DriveDocument13 pagesLawn-Boy F Series DrivefogdartNo ratings yet

- E 164 102 112 Brake AdjustmentDocument20 pagesE 164 102 112 Brake AdjustmentTomas Enrique Ramirez GomezNo ratings yet

- Fork Rebuilding PDFDocument2 pagesFork Rebuilding PDFmxckcxzlm.c,No ratings yet

- Manual - 3 Speed HubsDocument1 pageManual - 3 Speed HubsmaqhfirahNo ratings yet

- E39 Handbrake AdjustmentDocument5 pagesE39 Handbrake AdjustmentDragosDimaNo ratings yet

- Show PDF PDFDocument1 pageShow PDF PDFbelchiorNo ratings yet

- Douglas Take-Up-Adjustment-Technical Brochure JEC PDFDocument5 pagesDouglas Take-Up-Adjustment-Technical Brochure JEC PDFAfid MaulanaNo ratings yet

- CBC Couplers: A Report On LHB and Wagon CbcsDocument10 pagesCBC Couplers: A Report On LHB and Wagon CbcsWheel Bogie Parel WSNo ratings yet

- Parking Brake: Models FA and FB With LF05SDocument17 pagesParking Brake: Models FA and FB With LF05SKomatsu Perkins HitachiNo ratings yet

- Belt AdjustmentDocument10 pagesBelt AdjustmentDaffa SaputraNo ratings yet

- 11 1964 CH-ClutchDocument4 pages11 1964 CH-ClutchJose LaproviteraNo ratings yet

- Service Information: Trek Madone 7-Series Brake AssemblyDocument4 pagesService Information: Trek Madone 7-Series Brake AssemblyLucasNo ratings yet

- Install and operate HOSCH scraper belt cleanerDocument13 pagesInstall and operate HOSCH scraper belt cleanerZahoor AhmedNo ratings yet

- ZPMC Section 5 Typical TasksDocument28 pagesZPMC Section 5 Typical Tasksitalo sanhuezaNo ratings yet

- 102 112 Disc Brake Adjustments - OBS 102 075 Monitor E 128Document11 pages102 112 Disc Brake Adjustments - OBS 102 075 Monitor E 128Tomas Enrique Ramirez GomezNo ratings yet

- Section05 DrawworksDocument10 pagesSection05 Drawworkssertecs polNo ratings yet

- Mtto Kompensator DeslizableDocument8 pagesMtto Kompensator DeslizableJames Scott ValderramaNo ratings yet

- Adjust gear selector play and vibrations in Volvo trucksDocument2 pagesAdjust gear selector play and vibrations in Volvo trucksHamilton MirandaNo ratings yet

- 3gr-Fse-Em6-Drive BeltDocument3 pages3gr-Fse-Em6-Drive BeltHuỳnh Minh ĐứcNo ratings yet

- Chapter3 GovernorDocument16 pagesChapter3 GovernorBazli Faiq Zaini100% (1)

- Ranger 1Document1 pageRanger 1qlilovNo ratings yet

- Crane Control Equ PmentsDocument16 pagesCrane Control Equ PmentsslipformNo ratings yet

- Duco Reaction Beam Air Disc Brake: Maintenance Manual For C and D VariantsDocument36 pagesDuco Reaction Beam Air Disc Brake: Maintenance Manual For C and D VariantsLUKASNo ratings yet

- 11 2E 后悬架Document15 pages11 2E 后悬架Alexander cesar neyra sotoNo ratings yet

- Control Linkage AdjustmentDocument42 pagesControl Linkage Adjustmentcampollano14No ratings yet

- Syncro Trak Service ManualDocument26 pagesSyncro Trak Service ManualMelina SbhNo ratings yet

- Installation Guide for Voith Friction Driven Conveyor Belt Motion MonitorDocument4 pagesInstallation Guide for Voith Friction Driven Conveyor Belt Motion Monitoratorresh090675No ratings yet

- Parking Brake GuideDocument8 pagesParking Brake Guideeko sulistyo utomoNo ratings yet

- Installation Guide: Automatic Brake Adjuster Installation Instructions AA1 Model and S-ABA ModelDocument6 pagesInstallation Guide: Automatic Brake Adjuster Installation Instructions AA1 Model and S-ABA ModelPaul Del CarmenNo ratings yet

- Enfield Bullet Workshop Manual 2000 2 PDFDocument53 pagesEnfield Bullet Workshop Manual 2000 2 PDFsivakumar natarajanNo ratings yet

- Install and Adjust Shift Cables for Gasoline Stern DriveDocument15 pagesInstall and Adjust Shift Cables for Gasoline Stern Drivesandie2121No ratings yet

- E 163 92 Brake AdjustmentDocument20 pagesE 163 92 Brake AdjustmentpetNo ratings yet

- Manual Qs Rc5Document1 pageManual Qs Rc5Director Tecnico AdministrativoNo ratings yet

- №27. Methods of Correcting the Longitudinal Balance of JN-6H Airplanes (31 March 1920)Document4 pages№27. Methods of Correcting the Longitudinal Balance of JN-6H Airplanes (31 March 1920)raheyo6168No ratings yet

- Instalación Guaya Pull DownDocument7 pagesInstalación Guaya Pull Downcompraspilotajes garciaNo ratings yet

- Calibration Proceedure Pressure GaugeDocument3 pagesCalibration Proceedure Pressure GaugePanneer SelvamNo ratings yet

- Incorrect Alignment: Feeler GageDocument1 pageIncorrect Alignment: Feeler Gagemesho_titanicNo ratings yet

- Suspension Setup - 2010 Trek Fuel EXDocument4 pagesSuspension Setup - 2010 Trek Fuel EXMartinNo ratings yet

- Suspension AirlinerDocument21 pagesSuspension AirlinerAlexanderNo ratings yet

- !!!WARNING!!!: 2R-Series 2R2500 & 2R3500 Double Acting & Spring Return Scotch Yoke ActuatorsDocument7 pages!!!WARNING!!!: 2R-Series 2R2500 & 2R3500 Double Acting & Spring Return Scotch Yoke ActuatorsAmaury FreireNo ratings yet

- Mantenimiento ShaferDocument12 pagesMantenimiento ShaferMauricio RoldanNo ratings yet

- Section 1F3 Diesel Engine ControlsDocument30 pagesSection 1F3 Diesel Engine ControlsAnonymous wpUyixsjNo ratings yet

- Governor ActuatorDocument12 pagesGovernor ActuatorABDUL GHAFOORNo ratings yet

- Borg Warner T10 OCRDocument12 pagesBorg Warner T10 OCRordersNo ratings yet

- Parking Brake ServiceDocument1 pageParking Brake ServiceNe TwentySixNo ratings yet

- Eje de Levas Emd645Document21 pagesEje de Levas Emd645Terah PioNo ratings yet

- 1942 - 0047 PDFDocument1 page1942 - 0047 PDFpeterpanNo ratings yet

- Crowd System MaintenanceDocument8 pagesCrowd System MaintenanceVentasVarias AntofaNo ratings yet

- Installation: A.E RreDocument1 pageInstallation: A.E Rresopian320No ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Rolls Royce 20-25HP - Handbook - To - XVI - Chap3Document9 pagesRolls Royce 20-25HP - Handbook - To - XVI - Chap3Jean-Eric RaoulNo ratings yet

- Expert guidance for maintaining your Rolls-Royce chassisDocument8 pagesExpert guidance for maintaining your Rolls-Royce chassisJean-Eric RaoulNo ratings yet

- Rolls-Royce 20-25HP - Handbook - To - XVI - Chap2-2Document10 pagesRolls-Royce 20-25HP - Handbook - To - XVI - Chap2-2Jean-Eric RaoulNo ratings yet

- Autovac BookletDocument19 pagesAutovac BookletJean-Eric RaoulNo ratings yet

- Brake System Diagnosis and RepairDocument111 pagesBrake System Diagnosis and RepairLuis NunesNo ratings yet

- XF105 System and Component Information Disc Brake and Drum Brake ConstructionsDocument26 pagesXF105 System and Component Information Disc Brake and Drum Brake ConstructionsAnd DronNo ratings yet

- Passat B5 - Rear Brake DiscDocument28 pagesPassat B5 - Rear Brake DiscBusu CypNo ratings yet

- Calculation Example of Cone Clutch:: Given: It Is Required To Accelerate A Machine From NDocument12 pagesCalculation Example of Cone Clutch:: Given: It Is Required To Accelerate A Machine From N07 Aprinaldo JennerNo ratings yet

- Brake Work Sheet 1Document2 pagesBrake Work Sheet 1VimleshNo ratings yet

- Automotive Braking Systems (Goodnight)Document328 pagesAutomotive Braking Systems (Goodnight)Amjad Hani100% (1)

- Question - QuoraDocument4 pagesQuestion - QuoraSirleh SalehNo ratings yet

- Brake Cooling SystemDocument25 pagesBrake Cooling Systemthabsheer palakkanNo ratings yet

- Parts Kit Complete CataloguesDocument103 pagesParts Kit Complete CataloguesRezhaNo ratings yet

- Automatic Brake Failure Detection With AuxilaryDocument14 pagesAutomatic Brake Failure Detection With AuxilaryJilly ArasuNo ratings yet

- Drum Brakes ManualDocument7 pagesDrum Brakes Manualrobjones33No ratings yet

- Wheel Centering Stand - For Home Use Stojalo Za Centriranje Koles, Za Domačo UporaboDocument5 pagesWheel Centering Stand - For Home Use Stojalo Za Centriranje Koles, Za Domačo UporaboDeta Alvian AnggonoNo ratings yet

- 06-Shoe Drawings and SpecificationsDocument44 pages06-Shoe Drawings and SpecificationsΗλίας ΓεωργιάδηςNo ratings yet

- Brake System Definition Function Types and Applications With PDFDocument13 pagesBrake System Definition Function Types and Applications With PDFAbdulaziz AbdullahiNo ratings yet

- Conventional Brake System PDFDocument27 pagesConventional Brake System PDFCikgu Kakashi100% (1)

- KEFAMENANU - Lampiran Suku Cadang IdleDocument2 pagesKEFAMENANU - Lampiran Suku Cadang IdleWidyaningsih TigaNo ratings yet

- 35A Basic Brake SystemDocument32 pages35A Basic Brake SystemtakedashindenNo ratings yet

- 206-06 Hydraulic Brake Actuation 2019 Ranger Description and OperationDocument14 pages206-06 Hydraulic Brake Actuation 2019 Ranger Description and OperationKerbin Enrique NuñezNo ratings yet

- Anti-Lock Braking System (Abs) PDFDocument3 pagesAnti-Lock Braking System (Abs) PDFAnonymous X7PMfKbNo ratings yet

- AURLTB002Document24 pagesAURLTB002tinasokhal1No ratings yet

- Darylll Jane CatbaganDocument16 pagesDarylll Jane CatbaganSleepy SpettoNo ratings yet

- Brake SystemDocument11 pagesBrake SystemSaima ZaibNo ratings yet

- Cilindro de EmbreagemDocument25 pagesCilindro de EmbreagemGerleton SantosNo ratings yet

- Air Brake Systems for Heavy VehiclesDocument4 pagesAir Brake Systems for Heavy VehiclesYemaneDibetaNo ratings yet

- PB - Parking Brake SystemDocument4 pagesPB - Parking Brake SystemBRILLIANCE AUTO LIFENo ratings yet

- 04 Brake Pads PDFDocument4 pages04 Brake Pads PDFFilipposNo ratings yet

- Disc Brake System ReportDocument20 pagesDisc Brake System ReportGovindaram Rajesh100% (1)

- How To Replace The Front Brake Pads of Disc Brake On Peugeot 407Document6 pagesHow To Replace The Front Brake Pads of Disc Brake On Peugeot 407Razvan ChirilovNo ratings yet

- SM 22 PDFDocument341 pagesSM 22 PDFdanielNo ratings yet

- Hydraulic Disc Brake Hose Length Adjustment & Bleed GuideDocument100 pagesHydraulic Disc Brake Hose Length Adjustment & Bleed GuideIsmael OlayaNo ratings yet