0% found this document useful (0 votes)

369 views4 pagesMeasuring Road Roughness with MERLIN

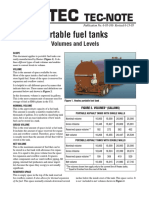

The document describes using a MERLIN apparatus to determine road roughness. The MERLIN apparatus measures the vertical displacement between the road surface under a probe and the center point between two feet contacting the road. Taking 200 measurements along a road and plotting the displacements on a chart allows the roughness to be measured and correlated to standard roughness scales. The procedure involves taking regular measurements with the MERLIN, recording the results on a chart, measuring the spacing between marks on the chart to determine roughness on the MERLIN scale, and using an equation to convert this to the International Roughness Index.

Uploaded by

Lakshmi PriyaCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

369 views4 pagesMeasuring Road Roughness with MERLIN

The document describes using a MERLIN apparatus to determine road roughness. The MERLIN apparatus measures the vertical displacement between the road surface under a probe and the center point between two feet contacting the road. Taking 200 measurements along a road and plotting the displacements on a chart allows the roughness to be measured and correlated to standard roughness scales. The procedure involves taking regular measurements with the MERLIN, recording the results on a chart, measuring the spacing between marks on the chart to determine roughness on the MERLIN scale, and using an equation to convert this to the International Roughness Index.

Uploaded by

Lakshmi PriyaCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd