Professional Documents

Culture Documents

CBLM Stripping Formwork Components

Uploaded by

RYDENOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CBLM Stripping Formwork Components

Uploaded by

RYDENCopyright:

Available Formats

COMPETENCY-BASED LEARNING MATERIAL

Sector: CONSTRUCTION

Qualification Title: CARPENTRY NC II

Unit of Competency: STRIP FORMWORKS COMPONENTS

Module Title: STRIPPING FORMWORKS COMPONENTS

RYDEN INTERNATIONAL TECHNOLOGICAL INSTITUTE

(R.I.T.I), INC.

Zone 2 San Agustin, Canaman, Camarines Sur

Date Document No.

Carpentry NC Developed: Issued by:

II October 2021

STRIP Developed by: Page 1 of 24

FORMWORK Rosalie Mae

P. Satur Revision #

COMPONENTS

HOW TO USE THIS COMPETENCY BASED

LEARNING MATERIAL

Welcome to the module in Stripping formworks. This module

contains training materials and activities for you to complete.

You are required to go through a series of learning activities in order

to complete each learning outcome of the module. In each learning

outcome are Information Sheets, Self-Checks, Operation Sheets and Job

Sheets. Follow these activities on your own. If you have questions, don't

hesitate to ask your facilitator for assistance.

The goal of this course is the development of practical skills. To gain

these skills, you must learn basic concepts and terminology. For the most

part, you'll get this information from the Information Sheets and

multimedia materials.

This module was prepared to help you achieve the required

competency, in "Stripping Formwork Components".

This will be the source of information for you to acquire knowledge

and skills in this particular competency independently and at your own

pace, with minimum supervision or help from your instructor.

Remember to:

Work through all the information and complete the activities in each

section.

Read information sheets and complete the self-check. Suggested

references are included to supplement the materials provided in this

module.

Most probably your trainer will also be your supervisor or

manager. He/she is there to support you and show you the correct way to

do things.

You will be given plenty of opportunity to ask questions and practice

on the job. Make sure you practice your new skills during regular work

shifts. This way you will improve both your speed and memory and also

your confidence.

Use the Self-checks, Operation Sheets or Job Sheets at the end of

each section to test your own progress.

When you feel confident that you have had sufficient practice, ask

your Trainer to evaluate you. The results of your assessment will be

recorded in your Progress Chart and Accomplishment Chart.

You need to complete this module before stripping formworks

assigned to you.

Date Document No.

Carpentry NC Developed: Issued by:

II October 2021

STRIP Developed by: Page 2 of 24

FORMWORK Rosalie Mae

P. Satur Revision #

COMPONENTS

MODULE CONTENT

UNIT OF COMPETENCY : Strip Formwork Components

MODULE TITLE : Stripping Formwork Components

MODULE DESCRIPTOR : This unit covers the knowledge, skills and

attitudes in stripping formworks components

and accessories for concrete work. It

includes preparing tools, equipment and

staging of materials and shoring and re-

shoring operations.

NOMINAL DURATION :

CERTIFICATE LEVEL : NC II

PREREQUISITE :

LEARNING OUTCOMES:

Upon completion of this module, the trainee/student must be able to:

1) Prepare staging area, tools and equipment

2) Strip formworks of building components

3) Shore or/and re-shore and removal

Date Document No.

Carpentry NC Developed: Issued by:

II October 2021

STRIP Developed by: Page 3 of 24

FORMWORK Rosalie Mae

P. Satur Revision #

COMPONENTS

ASSESSMENT CRITERIA:

1) Work instruction is secured from immediate superior according to

company rules and regulations.

2) Appropriate PPE is selected and used according to job requirements

and OSHC specifications.

3) Formwork components and accessories staging area is identified

and prepared based on job requirements.

4) Formwork components power, hand tools and equipment are

selected and prepared consistent with job requirements.

5) Formwork components and accessories are removed carefully,

safely and sequentially.

6) Formwork components and accessories are sorted, arranged

and properly staged according to company rules and

regulations/manufacturer's recommendations.

7) Formwork components and accessories are cleaned, oiled and

stored according to company rules and regulations/manufacturer's

recommendations.

8) Formwork components and accessories, which are beyond repair,

are discarded otherwise repaired in accordance with company

rules and regulations.

9) Formworks components are shored and re-shored in accordance

with stripping procedures.

10) Shores are removed in accordance with standard dismantling

procedures.

11) Shores, tools and equipment are cleaned, maintained and stored

properly according to company rules and regulations.

12) Unexpected situations are responded to in line with company rules

and regulations.

13) Daily report is accomplished according to company rules and

regulations.

14) Housekeeping is performed according to safety regulations.

Date Document No.

Carpentry NC Developed: Issued by:

II October 2021

STRIP Developed by: Page 4 of 24

FORMWORK Rosalie Mae

P. Satur Revision #

COMPONENTS

LEARNING OUTCOME NO. 1 Prepare staging area, tools and

equipment

CONTENTS:

• Company Rules and Regulations

ASSESSMENT CRITERIA

• Work instruction is secured from immediate superior according to company rules

and regulations.

• Appropriate PPE is selected and used according to job requirements and OSHC

specifications.

• Formwork components and accessories staging area is identified and

prepared based on job requirements.

• Formwork components power, hand tools and equipment are selected

and prepared consistent with job requirements.

• Unexpected situations are responded to in line with company rules and

regulations.

• Housekeeping is performed according to safety regulations.

CONDITIONS:

You must be provided with the

following:

1. WORKPLACE LOCATION

2. TOOLS AND EQUIPMENT

Crow bar Hard hat

Claw Hammer Hard shoes

Pliers Goggles

Wrench Gloves

Shovel Circular Saw

Scaffolding

3. TRAINING

MATERIALS Leaning

Packages Bond

paper

Ball

pens

Manuals

Related References

ASSESSMENT METHOD

Portfolio

Date Document No.

Carpentry NC Developed: Issued by:

II October 2021

STRIP Developed by: Page 5 of 24

FORMWORK Rosalie Mae

P. Satur Revision #

COMPONENTS

Learning Experience

Prepare staging area, tools and equipment

Learning Activities Special Instructions

Read Information Sheet No. 4.1-

1 on Company Rules

and Regulations

Compare your answer to the

Answer Self-Check No. 4.1-1

answer

key

Date Document No.

Carpentry NC Developed: Issued by:

II October 2021

STRIP Developed by: Page 6 of 24

FORMWORK Rosalie Mae

P. Satur Revision #

COMPONENTS

INFORMATION SHEET NO. 4.1-1

COMPANY RULES AND REGULATIONS

Learning Objective: After reading this INFORMATION SHEET, YOU

MUST be able to be familiar with the COMPANY RULES AND

REGULATIONS IN STRIPPING OF FORMWORK COMPONENTS

A. Introduction

Stripping formwork can be one of the most hazardous phases of

concrete construction. While falling objects are the primary hazard, there

may also be fall hazards as a result of floor collapse and manual tasks

hazards from a person working in awkward postures, repetitive handling of

materials and limited task variety. As with formwork erection, the stripping

operation must be carried out in an orderly, progressive manner.

B. Exclusion zone

Only persons involved in the stripping operation should be permitted in

the area to be stripped. Stripping are as should be cordoned off and signs

should be displayed. The signs should require persons to keep out of the

area.

Danger

FORMWORK STRIPPING IN PROGRESS

AUTHORISED PERSONS ONLY

It is preferable to restrict access to the whole floor where soffit

stripping is taking place and this should reduce the quantity of signage

and barricades required. Where other trades are required to work on the

same floor during stripping of walls, columns or small sections of soffit,

the principal contractor or employer should ensure that stringent controls

are applied that prevent other persons from entering the stripping area.

Date Document No.

Carpentry NC Developed: Issued by:

II October 2021

STRIP Developed by: Page 7 of 24

FORMWORK Rosalie Mae

P. Satur Revision #

COMPONENTS

C. Removal of the formwork

The period for which forms should be left in place depends upon the

temperature of air, the shape and position of structural member (i.e.

horizontal vertical or inclined), the nature of the loads likely to come and

the character of the cement and cement paste. Generally, the use of rapid

hardening cement, higher temperatures, low water cement ratio and

lighter loads, will permit early removal of formwork.

Under normal conditions where temperature is above 20ºC and

ordinary cement is use, forms may be removed after the expiry of the

period given below:

Particulars of the structural Period of removing of

member formwork

a) Vertical sides of slabs, beams 24 to 48 hours

columns and wall

b) Slabs (props or vertical 3 days

supporting member left

under)

c) Beams soffits (props left 7 days

under)

d) Bottom of slabs up to a span 7 days

of 4.5 m.

e) Bottom of slabs above 4.5 m 14 days

span, bottom of the beams up

to 6 m span, and bottom of

arch ribs up to 6 m span

f) Bottom of beams over 6 m 21 days

span and bottom of arch

ribs over 6 m span

Date Document No.

Carpentry NC Developed: Issued by:

II October 2021

STRIP Developed by: Page 8 of 24

FORMWORK Rosalie Mae

P. Satur Revision #

COMPONENTS

SELF-CHECK NO. 4.1-1

Name of Trainee: Date:

Check your mastery in company rules and regulations of removing

formworks by completing the tasks below.

MATCHING TYPE. Match the structural member to pediod of removing

the formwork by writing your answer on the space provided.

COLUMN A

Particulars of the structural COLUMN B

member Period of removing of

formwork

1. Slabs (props or vertical

supporting member left under) A. 24 – 28 hours

2. Bottom of beams over 6 m

span and bottom of arch ribs over 6 B. 3 days

m span

3. Bottom of slabs above 4.5

m span, bottom of the beams up to C. 5 days

6 m span, and bottom of arch ribs

up to 6 m span

4. Beams soffits (props left

under) D. 7 days

5. Vertical slides of

slabs, beams columns and E. 14 days

wall

6. Bottom of slabs up to a F. 21 days

span of 4.5 m.

Date Document No.

Carpentry NC Developed: Issued by:

II October 2021

STRIP Developed by: Page 9 of 24

FORMWORK Rosalie Mae Revision #

COMPONENTS P. Satur

ANSWER KEY 4.1-1

Check your answer with the answer key below. If you fail to get it

right, refer back to corresponding resources until you make it perfect.

1. B

2. F

3. E

4. D

5. A

6. D

Date Document No.

Carpentry NC Developed: Issued by:

II October 2021

STRIP Developed by: Page 9 of 24

FORMWORK Rosalie Mae

P. Satur Revision #

COMPONENTS

LEARNING OUTCOME NO. 2 Strip formworks of building

components

CONTENTS:

• Removing Formwork

• Maintenance and Storage of Formwork

ASSESSMENT CRITERIA

• Formwork components and accessories are removed carefully,

safely and sequentially.

• Formwork components and accessories are sorted, arranged

and properly staged according to company rules and

regulations/manufacturer's recommendations.

• Formwork components and accessories are cleaned, oiled and

stored according to company rules and

regulations/manufacturer's recommendations.

• Formwork components and accessories, which are beyond

repair, are discarded otherwise repaired in accordance with

company rules and regulations.

• Unexpected situations are responded to in line with company

rules and regulations.

• Housekeeping is performed according to safety regulations.

CONDITIONS:

You must be provided with the

following:

1. WORKPLACE LOCATION

2. TOOLS AND EQUIPMENT

Crow bar Hard hat

Claw Hammer Hard shoes

Pliers Goggles

Wrench Gloves

Shovel Circular Saw

Scaffolding Brooms

3. TRAINING MATERIALS

Date Document No.

Carpentry NC Developed: Issued by:

II October 2021

STRIP Developed by: Page 11 of 24

FORMWORK Rosalie Mae

P. Satur Revision #

COMPONENTS

Leaning Packages

Bond paper

Ball

pens

Manuals

Related References

ASSESSMENT METHOD

Portfolio

Date Document No.

Carpentry NC Developed: Issued by:

II October 2021

STRIP Developed by: Page 11 of 24

FORMWORK Rosalie Mae

P. Satur Revision #

COMPONENTS

Learning Experience

Strip formworks of building components

Learning Activities Special Instructions

Read Information Sheet No.

4.2-1 on Removing Formwork

Compare your answer to the

Answer Self-Check No. 4.2-1

answer

key

Read Information Sheet No.

4.2-2 on Maintenance

and storage of

Formworks

Compare your answer to the

Answer Self-Check No. 4.2-2

answer

key

Perform Operation Sheet No. Evaluate your own work using the

4.2-1 on Stripping Formwork Performance Criteria

Present your work to your trainer

for evaluation

Keep a copy of your work for the

next activities

Perform Operation Sheet No. Evaluate your own work using the

4.2-2 on Maintaining and Performance Criteria

storing of Forms Present your work to your trainer

for evaluation

Keep a copy of your work for the

next activities

Date Document No.

Carpentry NC Developed: Issued by:

II October 2021

STRIP Developed by: Page 11 of 24

FORMWORK Rosalie Mae

P. Satur Revision #

COMPONENTS

INFORMATION SHEET NO. 4.2-1

REMOVING FORMWORK

Learning Objective: After reading this INFORMATION SHEET, YOU

MUST be able to be KNOW the Order and Method of REMOVING

FORMWORK.

Stripping is the operation of removing the forms. Formwork can

either be partially stripped by removing small areas to prevent the slab

from deflecting or completely stripped to allow the slab to deflect.

As a general rule, formwork supporting members should not be

removed before the strength of concrete has reached at least 70

percent of its design value.

A. Order and Method of Removing Formwork

1. Shuttering forming vertical faces of walls, beams & column sides

should be removed first. Shuttering forming sofit to slab should be

removed next.

2. Shuttering forming soffit to beams, girders or other heavily loaded

member should be removed in the end.

B. Striking

The specification will normally give guidance on when forms can be

struck and these times may be governed by the size and shape of the

member, the concrete mix, and the weather.

• To strike the wallform, ties and clamps should be loosened

gradually, a little at a time.

• To remove the props, release the props evenly in small stages

starting at the middle of the span and working out towards the

supports. This can avoid overloading of the props at the centre of

the span due to large deflection at the center.

• Always withdraw or hammer down projecting nails as the

formwork is struck from the concrete.

• Make sure that other trades are kept away from areas below those

where striking is being done.

Date Document No.

Carpentry NC Developed: Issued by:

II October 2021

STRIP Developed by: Page 11 of 24

FORMWORK Rosalie Mae

P. Satur Revision #

COMPONENTS

OPERATION SHEET NO. 4.2-1

Title: Strip Formwork

Performance Objective: Given the necessary tools and equipment,

you should be able to strip column/beam

formwork

Supplies and Materials:

Tools and Equipment: • Crow bar • Hard hat

• Claw Hammer • Hard shoes

• Pliers • Goggles

• Wrench • Gloves

• Shovel • Circular Saw

• Scaffolding Brooms

Steps/Procedure:

1. Prepare tools and equipment needed.

2. Prepare staging area

Note:

a. Always observe safety measures because stripping form is a

very dangerous work on the part of the worker. Be careful

in removing the forms because the materials and fresh and

concrete output when get damaged won’t be used again.

b. Remember that the fresh concrete can already carry its weight

after 24-48 hours or more from the pour of the concrete.

3. Remove braces

4. Remove the cleats

5. Remove/pull out nails used in the 4 sides forms with the use of

claw hammer, claw bar or pincer.

6. Remove tie/wires or bolts with the use of pliers or wrench.

7. Make a soft hammer strike on the form to loosen it from the

concrete.

Assessment Method:

Performance Criteria Checklist

Date Document No.

Carpentry NC Developed: Issued by:

II October 2021

STRIP Developed by: Page 11 of 24

FORMWORK Rosalie Mae

P. Satur Revision #

COMPONENTS

PERFORMANCE CRITERIA CHECKLIST

OPERATION SHEET NO. 4.2-1

Name of Trainee: Date:

CRITERIA YES NO

1. Were I able to stripped without damage to forms

or concrete?

2. Did I use necessary tools and equipment in

stripping formworks?

3. Is the storage area for the formworks organized?

Date Document No.

Carpentry NC Developed: Issued by:

II October 2021

STRIP Developed by: Page 11 of 24

FORMWORK Rosalie Mae

P. Satur Revision #

COMPONENTS

INFORMATION SHEET NO. 4.2-2

MAINTENANCE AND STORAGE OF

FORMWORK

Learning Objective: After reading this INFORMATION SHEET, YOU

MUST be able to MAINTAIN AND STORE FORMWORK COMPONENTS

Provision must be made for the removal and storage large sections of

formwork. A level storage area is required to store formwork after striking.

They should be well cleaned before storing because the grout remaining

on the forms will become hard and stubborn making it difficult to reuse.

Metal panels need a light coating of oil before storage to prevent rust.

All forms need to be carefully stacked and stored. Panels of forms

should be kept horizontal and face to face. The forms and components

should be clearly marked and kept together for easy identification on re-

use. A tidy store reduces wastage, damage and losses.

Cleaning

As soon as the formwork has been struck, it should be cleaned, not left

until it is wanted again.

• Timber and plywood forms should be cleaned with a stiff brush to

remove any grout; a timber scraper should be used for

stubborn bits of grout.

• With glass reinforced plastics, a brush and wet cloth are all that

should be needed.

• When steel forms are to be put in store or are not going to be

used for some time, they should be lightly oiled to prevent

rusting.

• Timber and untreated plywood should also have a coat of release

agent applied for protection if they are not going to be re-used

immediately.

• Any depressions, splits and nail holes should be repaired with

plastic wood or similar material, followed by a light rubbing down.

• Before concreting, the insides of the forms should be cleaned.

Where the forms are deep, temporary openings should be

provided for inspection.

Date Document No.

Carpentry NC Developed: Issued by:

II October 2021

STRIP Developed by: Page 11 of 24

FORMWORK Rosalie Mae

P. Satur Revision #

COMPONENTS

OPERATION SHEET NO. 4.2-2

Title: Maintain and Store Formwork

Performance Objective: Given the necessary tools and equipment,

you should be able to maintain and store

formwork

Supplies and Materials:

Tools and Equipment: • Crow bar • Hard hat

• Claw Hammer • Hard shoes

• Pliers • Goggles

• Shovel • Gloves

• Steel Brush • Brooms

• Scraper

Steps/Procedure:

1. Clean timber and plywood forms with a steel brush to remove any

grout; a timber scraper should be used for stubborn bits of grout.

2. Apply release agent to timber and untreated plywood for protection

if they are not going to be re-used immediately.

3. Repair any depressions, splits and nail holes with plastic wood or

similar material, followed by a light rubbing down.

4. Keep panels horizontal and face to face when storing.

5. Mark the forms and components for easy identification on re-use.

Remember: A tidy store reduces wastage, damage and losses.

Assessment Method:

Performance Criteria Checklist

Date Document No.

Carpentry NC Developed: Issued by:

II October 2021

STRIP Developed by: Page 11 of 24

FORMWORK Rosalie Mae

P. Satur Revision #

COMPONENTS

PERFORMANCE CRITERIA CHECKLIST

OPERATION SHEET NO. 4.2-2

Name of Trainee: Date:

CRITERIA YES NO

1. Did I clean the timber and plywood forms from

stubborn grout?

2. Did I applied release agent to timber and plywood

for protection?

3. Are depressions, splits and nail holes repaired?

4. Are the panels stored horizontally and face to

face?

Date Document No.

Carpentry NC Developed: Issued by:

II October 2021

STRIP Developed by: Page 11 of 24

FORMWORK Rosalie Mae

P. Satur Revision #

COMPONENTS

LEARNING OUTCOME NO. 3 Shore or/and re-shore removal

CONTENTS:

• Shore and reshore removal

ASSESSMENT CRITERIA

• Appropriate PPE is selected and used according to job requirements

and OHSA specifications.

• Formworks components are shored and re-shored in accordance

with stripping procedures.

• Shores are removed in accordance with standard dismantling

procedures.

• Shores, tools and equipment are cleaned, maintained and stored

properly according to company rules and regulations.

• Unexpected situations are responded to in line with company rules

and regulations.

• Daily report is accomplished according to company rules and

regulations.

CONDITIONS:

You must be provided with the

following:

1. WORKPLACE LOCATION

2. TOOLS AND EQUIPMENT

Crow bar Hard hat

Claw Hammer Hard shoes

Pliers Goggles

Wrench Gloves

Shovel Circular Saw

Scaffolding Brooms

3. TRAINING

MATERIALS Leaning

Packages Bond

paper

Ball

pens

Manuals

Related References

ASSESSMENT METHOD

Portfolio

Date Document No.

Carpentry NC Developed: Issued by:

II October 2021

STRIP Developed by: Page 11 of 24

FORMWORK Rosalie Mae

P. Satur Revision #

COMPONENTS

Learning Experience

Shore or/and re-shore and removal

Learning Activities Special Instructions

Read Information Sheet No.

4.3-1 on Shore and

reshore removal

Compare your answer to the

Answer Self-Check No. 4.3-1

answer

key

Date Document No.

Carpentry NC Developed: Issued by:

II October 2021

STRIP Developed by: Page 11 of 24

FORMWORK Rosalie Mae

P. Satur Revision #

COMPONENTS

INFORMATION SHEET NO. 4.3-1

SHORE AND RESHORE

REMOVAL

Learning Objective: After reading this INFORMATION SHEET, YOU

MUST be able to Differentiate Shore and reshore and Know when

to remove Shore/reshore.

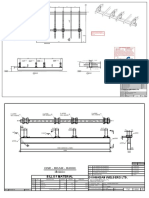

Shores are vertical members made of wood that support recently

built concrete that have not developed full design strength. On the other

hand, reshores are shores placed snugly under a stripped concrete slab

or structural member after the original forms and shores have been

removed from a large area. In reshoring, the concrete slab is allowed to

deflect and, thus, formwork can be removed from a large area. This can

help reduce stripping costs, which is the main advantage of reshores.

Formwork is typically supported by several levels of shores and

reshores that carry the loads until the concrete gains enough

strength to support its own weight and all other externally applied

loads.

Typical frame shoring

Remove Reshores or Backshores

Reshores can be removed after the supported slab or member has

attained sufficient strength to support all loads transferred to it. Removal

of reshores must be carried out with care to avoid subjecting the structure

to impact loads.

Date Document No.

Carpentry NC Developed: Issued by:

II October 2021

STRIP Developed by: Page 11 of 24

FORMWORK Rosalie Mae

P. Satur Revision #

COMPONENTS

SELF-CHECK NO. 4.3-1

Name of Trainee: Date:

Check your mastery in shore and reshore removal by completing the

tasks below.

Discuss the following:

1. Differentiate shore from reshore.

2. When does reshore be removed?

3. How will you carry out the removal of reshore?

Date Document No.

Carpentry NC Developed: Issued by:

II October 2021

STRIP Developed by: Page 11 of 24

FORMWORK Rosalie Mae

P. Satur Revision #

COMPONENTS

ANSWER KEY 4.3-1

Check your answer with the answer key below. If you fail to get it

right, refer back to corresponding resources until you make it perfect.

1. Shores are vertical members made of wood that support recently

built concrete that have not developed full design strength while reshores

are shores placed snugly under a stripped concrete slab or structural

member after the original forms and shores have been removed from a

large area.

2. Reshores can be removed after the supported slab or member

has attained sufficient strength to support all loads transferred to it.

3. Removal of reshores must be carried out with care to avoid

subjecting the structure to impact loads.

Date Document No.

Carpentry NC Developed: Issued by:

II October 2021

STRIP Developed by: Page 11 of 24

FORMWORK Rosalie Mae

P. Satur Revision #

COMPONENTS

You might also like

- CBLM Fabricating FormworksDocument33 pagesCBLM Fabricating Formworksglenn salandananNo ratings yet

- CBLM Installing Framing WorksDocument81 pagesCBLM Installing Framing WorksRYDEN100% (1)

- Unit of Competency 1Document66 pagesUnit of Competency 1Jonathan Po CaasiNo ratings yet

- CBLM Install Formworks ComponentsDocument38 pagesCBLM Install Formworks ComponentsRomally Antonette Tagnipez100% (1)

- CBLM Install Built in and or Pre Fabricated CabinetsDocument123 pagesCBLM Install Built in and or Pre Fabricated Cabinetsgillian marbebeNo ratings yet

- CBLM Install Formworks ComponentsDocument38 pagesCBLM Install Formworks ComponentsRYDENNo ratings yet

- CBLM CeilingDocument71 pagesCBLM CeilingIsrael LugtuNo ratings yet

- Cblm. Common Competency For Carpentry NC Ii Jhan Rey D. Carreon BtvteDocument25 pagesCblm. Common Competency For Carpentry NC Ii Jhan Rey D. Carreon BtvteJhanrey CarreonNo ratings yet

- CBLM Installing Framing WorksDocument82 pagesCBLM Installing Framing WorksJessa Airam LigutomNo ratings yet

- Fabricating Formworks Module Provides SkillsDocument10 pagesFabricating Formworks Module Provides SkillsMoore DahamNo ratings yet

- Carpentry Skills Assessment GuideDocument8 pagesCarpentry Skills Assessment GuideFrancis D. AlvarNo ratings yet

- Competency-Based Learning Materials: SectorDocument1 pageCompetency-Based Learning Materials: SectorFernando Rojas100% (1)

- Interpret Technical DrawingDocument60 pagesInterpret Technical DrawingCarwill Tesda100% (1)

- Carpentrync II LM g9Document79 pagesCarpentrync II LM g9michaelalangcas100% (1)

- Competency-Based Construction Painting CurriculumDocument62 pagesCompetency-Based Construction Painting CurriculumStephanie NicholsNo ratings yet

- Draft Roof Plans Technical Drafting NC II Construction QualificationDocument34 pagesDraft Roof Plans Technical Drafting NC II Construction QualificationPrince Neil SeraphimNo ratings yet

- Competency-Based Learning Material: Memorial School of Arts and Trades San Antonio, Biñan CityDocument72 pagesCompetency-Based Learning Material: Memorial School of Arts and Trades San Antonio, Biñan Citygillian marbebeNo ratings yet

- How To Use This Competency Based Learning Module: Recognition of Prior Learning (RPL)Document74 pagesHow To Use This Competency Based Learning Module: Recognition of Prior Learning (RPL)Marzet DivinagraciaNo ratings yet

- Competency-based Curriculum for Heavy Equipment OperatorsDocument65 pagesCompetency-based Curriculum for Heavy Equipment OperatorsPhillip James Anthony EleminoNo ratings yet

- Basic 4 Practice Occupational Health and Safety ProceduresDocument68 pagesBasic 4 Practice Occupational Health and Safety ProceduresThedsky TrickyNo ratings yet

- Competency Based Learning MaterialsDocument82 pagesCompetency Based Learning MaterialsAlberto T. ToledoNo ratings yet

- CBLM II Computer HardwareDocument165 pagesCBLM II Computer Hardwareebgamba100% (1)

- CBLMDocument30 pagesCBLMrowell ramosNo ratings yet

- Group 6 CBLMDocument79 pagesGroup 6 CBLMDaniel VallesNo ratings yet

- CBLM in Participate in Workplace CommuniDocument80 pagesCBLM in Participate in Workplace CommuniFrancis Rico Mutia RufonNo ratings yet

- TR - Mechatronics Servicing NC III - 12142006Document61 pagesTR - Mechatronics Servicing NC III - 12142006Junna Cua-ArnaezNo ratings yet

- Parts of A Competency-Based Learning MaterialDocument173 pagesParts of A Competency-Based Learning Materialmico alilayaNo ratings yet

- CBC-Tailoring NC IIDocument66 pagesCBC-Tailoring NC IICharmaine Mae RetizaNo ratings yet

- 1 Workshop For Tech Voc HeadsDocument154 pages1 Workshop For Tech Voc HeadsArvie B. MaculNo ratings yet

- Self - Assessment Guide: Can I? YES NODocument3 pagesSelf - Assessment Guide: Can I? YES NOJohn Castillo100% (1)

- CBLM Installing Framing Works PDFDocument81 pagesCBLM Installing Framing Works PDFKhan Mohammad Mahmud Hasan87% (15)

- Common - Lesson 1 - Applying Quality StandardsDocument60 pagesCommon - Lesson 1 - Applying Quality StandardsAnne Atienza GarciaNo ratings yet

- Finishing Carpentry Course DesignDocument80 pagesFinishing Carpentry Course DesignGlenn F. SalandananNo ratings yet

- Competency - Based Learning Materials: Sector: Qualification Title: Unit of Competency: Module TitleDocument14 pagesCompetency - Based Learning Materials: Sector: Qualification Title: Unit of Competency: Module TitleJoven RoqueNo ratings yet

- Identify and Interpret Drawing and PlansDocument55 pagesIdentify and Interpret Drawing and Plansflaviano p tabotada jrNo ratings yet

- NC4 CBLMDocument25 pagesNC4 CBLMrayden22No ratings yet

- Conpetency Based Learning MaterialDocument140 pagesConpetency Based Learning MaterialSamantha SimbayanNo ratings yet

- FLS Powerpoint FinalDocument17 pagesFLS Powerpoint FinalkevinNo ratings yet

- Data Gathering Instrument For Trainee's Characteristics: InstructionDocument21 pagesData Gathering Instrument For Trainee's Characteristics: InstructionFrancis D. AlvarNo ratings yet

- CARPENTRY NC II TRAINING REGULATIONSDocument161 pagesCARPENTRY NC II TRAINING REGULATIONSYeng LugtuNo ratings yet

- COMMON 4 Contribute To Quality System FINALDocument92 pagesCOMMON 4 Contribute To Quality System FINALJoyLyn Sarmiento AmitNo ratings yet

- Portfolio Template 1Document111 pagesPortfolio Template 1ANGELES LANIE GAILNo ratings yet

- Common Competency 3 - Apply Quality StandardsDocument30 pagesCommon Competency 3 - Apply Quality StandardsAngel CastilloNo ratings yet

- 2019 Star-Instrument - Machining NC IIDocument51 pages2019 Star-Instrument - Machining NC IIShanNo ratings yet

- Laying Concrete Hollow Blocks For StructureDocument84 pagesLaying Concrete Hollow Blocks For StructureRobinson Concordia100% (1)

- TR - Masonry NC IIDocument67 pagesTR - Masonry NC IIjoselpalomaNo ratings yet

- Carpentry NC II Self-Assessment GuideDocument1 pageCarpentry NC II Self-Assessment Guideandi2akoNo ratings yet

- Learning Module No. 1 Content StandardsDocument28 pagesLearning Module No. 1 Content StandardsRobert kite ClementeNo ratings yet

- Drafting Course Prepares Skilled TechniciansDocument9 pagesDrafting Course Prepares Skilled TechniciansMiko Salvacion BrazaNo ratings yet

- Competency-Based Learning Mater I ALS: Malinao School For Philippine CraftsmenDocument1 pageCompetency-Based Learning Mater I ALS: Malinao School For Philippine CraftsmenMaria Riza Maaya LaurdausNo ratings yet

- Air Duct Servicing NC IIDocument91 pagesAir Duct Servicing NC IIMEL ANGELESNo ratings yet

- Carpentry NC II Course Structure and CompetenciesDocument42 pagesCarpentry NC II Course Structure and CompetenciesRichard DuranNo ratings yet

- ANIRTDocument119 pagesANIRTAnirt CalugayNo ratings yet

- SP Lay Concrete Hollow BlocksDocument7 pagesSP Lay Concrete Hollow BlocksKhael Angelo Zheus JaclaNo ratings yet

- Module of Instruction PERFORM RECORD KEEPINGDocument6 pagesModule of Instruction PERFORM RECORD KEEPINGHernandez KeithNo ratings yet

- Competency-Based Learning Materials 2 PDFDocument58 pagesCompetency-Based Learning Materials 2 PDFMichael John PedrasaNo ratings yet

- Self-Assessment Guide Trainers Methodology Level I (In-Company Trainer)Document2 pagesSelf-Assessment Guide Trainers Methodology Level I (In-Company Trainer)Michelle Seno Son GonzalesNo ratings yet

- Cblmcss Module 1Document106 pagesCblmcss Module 1Rusty Ugay LumbresNo ratings yet

- Plan Training Session by DahamDocument47 pagesPlan Training Session by DahamMoore DahamNo ratings yet

- CBLM Stripping Formwork Components PDFDocument24 pagesCBLM Stripping Formwork Components PDFRHAYAMIE D. LIBENo ratings yet

- Working in A Team Environment: Basic CompetencyDocument25 pagesWorking in A Team Environment: Basic CompetencyRYDENNo ratings yet

- CBLM Installing Framing WorksDocument81 pagesCBLM Installing Framing WorksRYDENNo ratings yet

- List of Consumables/Materials: (As Listed in The Respective TR)Document2 pagesList of Consumables/Materials: (As Listed in The Respective TR)RYDENNo ratings yet

- CBLM Installing Framing WorksDocument81 pagesCBLM Installing Framing WorksRYDENNo ratings yet

- JDVP-TVL Learner CompetenciesDocument2 pagesJDVP-TVL Learner CompetenciesRYDENNo ratings yet

- Annex 6 JDVP TVL Summary of Learners Competencies and Equivalent Rating 01212020Document2 pagesAnnex 6 JDVP TVL Summary of Learners Competencies and Equivalent Rating 01212020RYDEN100% (2)

- Competency-Based Curriculum A. Course Design: TESDA-OP-CO-01-F11Document44 pagesCompetency-Based Curriculum A. Course Design: TESDA-OP-CO-01-F11RYDENNo ratings yet

- CBLM DressmakingDocument37 pagesCBLM DressmakingRYDEN100% (1)

- School Heading: Ryden International Technological Institute (R.I.T.I), Inc. Dressmaking NC IiDocument18 pagesSchool Heading: Ryden International Technological Institute (R.I.T.I), Inc. Dressmaking NC IiRYDENNo ratings yet

- Course Design Dressmaking NCIIDocument81 pagesCourse Design Dressmaking NCIIRYDENNo ratings yet

- Training Plan in Dressmaking NC IiDocument11 pagesTraining Plan in Dressmaking NC IiRYDENNo ratings yet

- CBC-Beauty Care Services (Nail Care) NC IIDocument62 pagesCBC-Beauty Care Services (Nail Care) NC IIRYDENNo ratings yet

- Schools Division Office of Camarines SurDocument4 pagesSchools Division Office of Camarines SurRYDENNo ratings yet

- CBLM DressmakingDocument37 pagesCBLM DressmakingRYDEN100% (1)

- Course Design Dressmaking NCIIDocument81 pagesCourse Design Dressmaking NCIIRYDENNo ratings yet

- 6 Template For Course Offering 1Document2 pages6 Template For Course Offering 1RYDENNo ratings yet

- School Heading: Ryden International Technological Institute (R.I.T.I), Inc. Dressmaking NC IiDocument18 pagesSchool Heading: Ryden International Technological Institute (R.I.T.I), Inc. Dressmaking NC IiRYDENNo ratings yet

- QMS Document Revision History: Document Title: - Document Code.Document1 pageQMS Document Revision History: Document Title: - Document Code.RYDENNo ratings yet

- F. Training Plan in Dressmaking NC IIDocument8 pagesF. Training Plan in Dressmaking NC IIRYDENNo ratings yet

- School Heading: Ryden International Technological Institute (R.I.T.I), Inc. Dressmaking NC IiDocument18 pagesSchool Heading: Ryden International Technological Institute (R.I.T.I), Inc. Dressmaking NC IiRYDENNo ratings yet

- Course Design Dressmaking NCIIDocument81 pagesCourse Design Dressmaking NCIIRYDENNo ratings yet

- Certification of School Fees: MPU-FO-012Document2 pagesCertification of School Fees: MPU-FO-012RYDENNo ratings yet

- School Heading: Ryden International Technological Institute (R.I.T.I), Inc. Dressmaking NC IiDocument18 pagesSchool Heading: Ryden International Technological Institute (R.I.T.I), Inc. Dressmaking NC IiRYDENNo ratings yet

- Board Resolution On Assigning Signatories in The Voucher Program1311Document2 pagesBoard Resolution On Assigning Signatories in The Voucher Program1311RYDENNo ratings yet

- 6 Template For Course Offering 1Document2 pages6 Template For Course Offering 1RYDENNo ratings yet

- Rates Analysis For Aliens W.ODocument23 pagesRates Analysis For Aliens W.ORAVIKUMAR KONKATINo ratings yet

- Concept of HydrotestDocument16 pagesConcept of HydrotestEverpeeNo ratings yet

- T80-Za-E-2204146 - Quality Control PDFDocument16 pagesT80-Za-E-2204146 - Quality Control PDFNezinNo ratings yet

- Concrete Blinding Inspection & Test PlanDocument1 pageConcrete Blinding Inspection & Test PlanIlyas KhanNo ratings yet

- New CV AymanDocument1 pageNew CV AymanAyman MahfouzNo ratings yet

- 0503223-01-CIV-BOQ-1021-AB (Laundry Shed BOQ Comparision)Document6 pages0503223-01-CIV-BOQ-1021-AB (Laundry Shed BOQ Comparision)CCCCCCC100% (1)

- Overseeing Civil Engineering Projects for 15 YearsDocument10 pagesOverseeing Civil Engineering Projects for 15 YearsMohammed H SaeedNo ratings yet

- Unilux Alu-Clad DoorsDocument88 pagesUnilux Alu-Clad DoorsSandu-Milea LucianNo ratings yet

- Professional Practice 3 ReviewerDocument4 pagesProfessional Practice 3 ReviewerRiana FloresNo ratings yet

- 4 - Doosan Presentation - Wind Power Promotion Seminar - 130411Document25 pages4 - Doosan Presentation - Wind Power Promotion Seminar - 130411Nguyễn Văn BanNo ratings yet

- Wastage CalculationDocument27 pagesWastage Calculationsiwaa94% (33)

- PEB ProfileDocument11 pagesPEB ProfileVSMS8678No ratings yet

- TEC-131100 - MET-DoR-001 (Method Statement For Swimming Pool & Jacuzzi) (K)Document16 pagesTEC-131100 - MET-DoR-001 (Method Statement For Swimming Pool & Jacuzzi) (K)Hoằng Phạm ĐứcNo ratings yet

- EHS Training Matrix - Rev2finalDocument1 pageEHS Training Matrix - Rev2finalMalik Khuram ShazadNo ratings yet

- Set B - Problems On Relevant Decision MakingDocument3 pagesSet B - Problems On Relevant Decision MakingNitin Khare0% (1)

- BMEL305Document12 pagesBMEL305hrushithar27No ratings yet

- Precast Segmental Bridge Construction Precast Segment ManufacturingDocument34 pagesPrecast Segmental Bridge Construction Precast Segment Manufacturingarindam1508No ratings yet

- Hilti Firestop Submittal - Balamand UniversityDocument32 pagesHilti Firestop Submittal - Balamand UniversitybasbousrNo ratings yet

- Gulermak MAGAZINE 11-12 23 29012023 01Document12 pagesGulermak MAGAZINE 11-12 23 29012023 01Vivek G. AbhyankarNo ratings yet

- Manpower Training Record MAY 2023Document14 pagesManpower Training Record MAY 2023Jenalyn Pacris JaymeNo ratings yet

- Telangana Labour Inspection ReportDocument7 pagesTelangana Labour Inspection ReportVishal NannaNo ratings yet

- SATIP-H-002-05 Epoxy For Atmospheric Up To 150CDocument2 pagesSATIP-H-002-05 Epoxy For Atmospheric Up To 150ChossamalsherbinyNo ratings yet

- Method Statement For General Door-Window Fitting-ReplacementDocument12 pagesMethod Statement For General Door-Window Fitting-ReplacementAhmed saberNo ratings yet

- MBA Article Review StrategiesDocument6 pagesMBA Article Review StrategiesEbisa Adamu100% (1)

- COMPLETE-Garver LLC Contract-ApolloParkDocument22 pagesCOMPLETE-Garver LLC Contract-ApolloParkKayode CrownNo ratings yet

- DL Lebus Bulletin Issue 4Document4 pagesDL Lebus Bulletin Issue 4AmirNo ratings yet

- Lpai - Icp Bhittamore On Indo-Nepal BorderDocument14 pagesLpai - Icp Bhittamore On Indo-Nepal BordernainshreeNo ratings yet

- Best Resume Format For Quantity SurveyorDocument7 pagesBest Resume Format For Quantity Surveyorzehlobifg100% (2)

- Mono RailDocument6 pagesMono RailExcelNo ratings yet

- Ceramic Tile Installation MaterialsDocument15 pagesCeramic Tile Installation MaterialsIm ChinithNo ratings yet