Professional Documents

Culture Documents

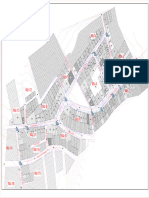

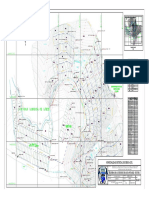

E00248 HTG Cmi DWG 220 400 220 5120 Rev 6 Electrical Sheath Layout - Verif

Uploaded by

BMWGOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

E00248 HTG Cmi DWG 220 400 220 5120 Rev 6 Electrical Sheath Layout - Verif

Uploaded by

BMWGCopyright:

Available Formats

+431.

60

00

33.

+4

1x cable tray - Width 300 mm

LPLPPP

01

01

P

BNI

by

ied

P specif 95

BNI be 31.

db

y be +4

cifie to

s p e

AL

AIT

be

J

06.06 J

J

AIT VP e 2x Ø90

AIT 06.05 .15 06.154

to b

418

A

J

2

06.04

+ +431.60

J

J

VP J

J

A

K

06.156

.60

J

AL

VP

F

FIT C

+431.60 VP 08.79 33

A

06.13 08.77 VP +4

VP 09.55

LCP

J

A

K

J

AL 09.53

J

A

J J

P

BNI

J

by

07

LT

A

ied

V 01.12

ecif

AN

01.07

6

es

p

26 .87 R 1 +432.98

eb +4 TO

K

1x cable tray 14 t o b

ULA .1 8

Width 200 mm 1x cable tray - Width 200 mm C C A + 434

F VP

FLO TK04

01.31

45

VP 31. +429.50

01.32 +4

160

160 1x cable tray - Width 100 mm

VP LT

150

01.30 01.10

x Ø PL3 l .09

trica

V

1 VP

02

0

Ø90 T lec 2 432

01.08 LT

0

LPP

01.33 01.11

5 +

er 1 1x i e d e es 13

h amb Bu h leav d here DING

r AIT

01.05

C Side A t n L

ear rgrou S BUI EA 2x horizontal cable trays on brackets AIT

n d e N T A R AIT 01.03

u G E G E Width 300 mm - 2 Levels LSH 01.04

A A

able

01.09

Side B RE STOR FIT

vail room G1

01.17

a &

Ø90 th

Ear ectrica

l 1 P T LIN

2x 9

BNI SET

e

in 3

l 9 d by

A R

AIT

01.06

cifie

C

ELL TK06

to b

TPL VE spe

ABO LDING LAM

J

J

e be +429.50

e be

350

ICE UI

9

to b VP

OFF NTS B 1

0

1x cable tray .9 4 01.02

+428.00 431

spe

Width 200 mm GE J

J

+ BR

REA

E

4 US +431.99

+4

K

cifie

K

34 .48

J

90 R2 +4

31.

AL

29.

d

TO

J J VP

+4

3

ULA

by B

01.01

94

C

G1 C

FLO TK0

4B

LIN

NIP

D

BNI

P

S ETT

by AR

cifie

d

ELL TK07

spe A M ified

4x Ø 160

P L c

1x Ø

be

.00 LOO ² e

32.

09 spe

T ANK 21 T H m to b 3 +4 e be

+4 EAR 50m 77 to b

C

TER 31.

90

W A +4

A

AR K10A 1

CLE T

I L TER

F 3

5 B

TK1

G2

LIN

2 S ETT BNI

P

K I L TER AR by

TAN F 3 ELL TK08 ified

ER TK2 LA M s p e c

AT A

4 e be

EA R W 10B FIT

02.90 31.

9 to b

CL TK 3 +4 +430.79

C .00 TER

+ 421 FIL 33

5 C TK

1.4 59

+4

2 27.

+4

90

4 2

ING BNI

P

29.

VP

L TER TL by

1x cable tray F I SET ied

08.107

3

+4

Width 200 mm VP

90 TK4 AR sp ecif

2x Ø ELL TK09

A

08.109

e be

17 L AM to b

LCP 05

170

00 .77 +430.22

21. LCP 31 +429.50

0

05 +4 +4 87

22. trica

l

+4 TIO

N P 03 26.

elec +4

VP

RA LP 01.35

34 16 r ied aves ere ILT

22.

VP

u

+4 LCP 06 B h le

nd

h DF 01.36

t SAN

VP

ear rgrou SH

100

01.37

LCP e A 4

und

VP

P

1x cable tray K W OM

01.34

BNI

A C O by

Width 200 mm B PR cified

Ear ectrica

M E 5 spe

TER

in e

12 P U RIN be

LO FIL 53 to b

e

th a

CH LDING TK

l

I 90 1x cable tray - Width 200 mm

10 BU 29.

vail room

+4

+4

able

+422.00 6

30.

to

l

TER +429.50

85

be FIL 63

00

25. be

+420.02 TK

+4 s

70 pe

25.

LT

LSLL 06.02 11 cif +430.18

06.14

LCP +4

LC P 08 +420.02 ie

d 7 +428.00

by TER

BN FIL 73 +429.50

25

IP +428.00 TK 90

23. 29.

+4 +4

11 P +422.00 BNI

P

H LOO ² TER

8

cifie

d by

15 T m FIL 83 spe

D EAR 50m TK

2x horizontal cable trays on brackets

e be

Width 300 mm - 2 Levels to b

From local grid 33kV

(CEB) D

5

111

3.5

+428.26

A

ATS et 1x Ø160 ASH

2

LT

K W ERY

F

+4

in 05.01

Cab C

ING 16 l BA COV

ME

TER

e c trica 02

LSLL

00 RE ANK

X 05.03

Overhead BO l 19.

CE

B e

100 uried aves ere 00 +424.00 LCP +4 T

powerline B h le h A

21 t nd 16. 6

ear rgrou +4

LSLL

Vent Pipe

P 05.04

0 e

114

280 und

05.20

+428.00

16 .45 P

+4

F

30

05.21

20 21.

A

.60

112

Key locke +4

P d with outs 18 15

F

LOO G +4

F

danger an ide LCP

A

TH I N d voltage

EAR BUILD m² level warn B .50

0

6x Ø90 to workshop and office LEGEND:

50m ing 24

+416.0

R er 3

DE mb

P +4

UN ha A B 05.26

C P Note:

LCPxx Local control panel

+4

05.27

F

1x Ø90 from ATS A

19.

+4

1x Ø90 from Generator F

113

Underground cabling methods according to section 2.12 of contract document

A

+424.00 LPP xx Local pneumatic panel

16.

Suitable road

50

si 1x Ø160 from ATS

at the regula de protection barriers to +419.50

00

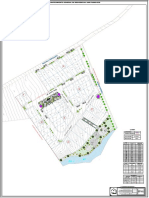

tory distance be placed ar Everything underground is for BNIP (trenches, electrical sheathes (what you call sleeves)) , pulling

not compro s o +422.50 Ground levels of the project

mised. Such from these objects and und Cells, transformer 2x cable tray - Width 200 mm chambers, it’s thin pink line on layout

such that m s

tankers exp

ected on site

protection sh

all be adequ an access to and fuel tank +419.50 Everything above the ground is for John cockerill ( Cable trays ) – it’s large pink line on Layout. Cable trays

during oper ate for the h these object

ation and m eavy cranes s is +419.50

ajor mainte

nance and sludge

2 +416.50

Also , the 33kV line to transformer is for CEB (Ceylon electricity board) Electrical sheath

2x Ø90 m ber

1x Ø160 Cha +421.60 BNIP scope at WTP start after the metering room with trenches and electrical sheathes to

Side A chlorination building and diesel generator.

+419.50

1x Ø90 +416.50 +419.50 Cable tray lower level

TYPE SCOPE

1x cable tray - Width 200 mm Upper cable tray

SLUDGE Cable trays CMI

DRYING SLUDGE 8

+415.25

7 Electrical sheath BNIP Lower cable tray

BED 10 DRYING SLUDGE

+4

BED 9 DRYING SLUDGE

22.

DRYING SLUDGE SLUDGE +419.50

6

BED 8

0

BED 7 DRYING SLUDGE THICKENE

SLUDGE R

BED 6 DRYING

BED 5 DRYING SLUDGE

+421.60 CLIENT

BED 4 DRYING SLUDGE . 00

BED 3 DRYING SLUDGE + 417 DEMOCRATIC SOCIALIST REPUBLIC OF SRI LANKA

+4

LT

17.0

05.02

BED 2 DRYING MINISTRY OF WATER SUPPLY & DRAINAGE

05

0

BED 1 LPP

NATIONAL WATER SUPPLY & DRAINAGE BOARD

Chamber position +416.85 FIT

05.15

& dimensions to

6 0 VP

be confirmed by 22. 05.10

+4

BNIP 124

K

K

124

18 LSH

05.90

K

K

124

K

K

124

+416.30 K

K

124

122 K

K

124

121 K

K GI pipe Ø33

124

121 K

K

124

121 K

K

124

121

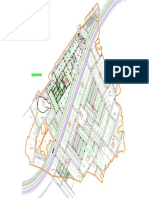

PLAN VIEW ELECTRICAL SHEATH

K

K

124

121 K

K

121 +416.85

121

121 120 BUILDINGS

+416.30

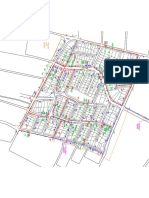

Buried electrical earth 200 1735 1 INLET AREA / USBR

leaves underground here 150 150 SECTION : A-A SECTION : B-B SECTION : C-C SECTION : D-D

2 FLOCCULATOR

HEMMATHAGAMA

200

170

4x Ø90 1x Ø160 TPL4 TPL2 TPL1 2xØ90 to sludge Scale: 1/25 Scale: 1/25 Scale: 1/25 Scale: 1/25

to reagent building thickener Ground level Ground level Ground level Ground level

3 LAMELLAR SETTLING

WATER SUPPLY PROJECT

300

400

1700 100 4 SAND FILTRATION

1xØ160 to sludge

Electrical room = thickener 5 CLEAR WATER TANK

200

=

800

800

800

800

300

845

880

880

880

220 200

6 BACK WASH RECOVERY TANK

=

=

16

0

220 200

ELECTRICAL SHEATH LAYOUT

750 1535

Ø 0 7 SLUDGE THICKENER

Ø9

2285

8 DRYING BEDS

200

3350 Ø9

200

Ø9 0

1x Ø90 LCP05

1x Ø90 LCP06

50 0

400

60

16

9 OFFICE BUILDING

Ø1

Ø

200

60

Ø1

200 200 200 200 10 CHLORINE BUILDING

1x Ø90 from ATS

1x Ø160 from ATS

Chamber 1 Side A Chamber 1 Side B Chamber 2 Side A Chamber 3 Side A 11 BACK WASH WATER TANK Zoning artisanal de Cornemont

Rue de la Légende, 63

BALLAST NEDAM INFRA SPECIALE PROJECTEN

BACK WASH PUMP ROOM

12 (below chlorine building) Ringwade, 71 3439 LM NIEUWEGEIN

Scale: 1/25 Scale: 1/25 Scale: 1/25 Scale: 1/25 B-4141 SPRIMONT - BELGIUM Tél: +31 (0)30 285 33 33

Ground level Ground level Ground level Ground level 13 REAGENTS BUILDING AND STORAGE AREA Tél. : +32 (0)4/253.22.24 - Fax : + 32 (0)4/252.31.15 Website: www.ballast-nedam.nl

Website : www.balteau.eu

14 VEHICLE PARK

1000 1000 1000 IND. DATE DRAW. CHECK. APPR. REVISIONS

15 COVER FOR GENERATOR

1x Ø90

800

800

800

800

880

6 27/07/2021 FLE TCL DCH Update

from Generator

16 TRANSFORMER ABOVE METERING ROOM

1080

1080

5 09/06/2021 FST TCL DCH Update

1280

400 200 190 220 200 200 150 Ø9 4 23/04/2021 FST TCL DCH Update

60

1480

Ø1 0 17 SECURITY HUT (Out of layout field) 3 10/12/2020 FST TCL DCH Update

Ø9 Ø9 2 20/11/2020 FST TCL DCH Update

0 0 18 O.I.C.QUARTERS

200

200

200

200

60 Ø9 Ø1 Ø9 Ø1

Ø1 0 0 60

90

60 1 23/06/2020 FST FPI HMC Update

Ø9 Ø9 Ø9 Ø9

Ø

0 0 0 0

200

200

200 200 200 200 Ø90 19 BACHELOR'S QUARTERS (Out of layout field)

1000 SIZE SCALE PROJECT NUMBER DRAWING N° INDICE

200

20 FUEL TANK

Format A0

100 200 200 200 200 21 METERING ROOM

A0 1/100 HTG-CMI-DWG-220-400-220 5120 06

6x Ø90 to

You might also like

- Method Statement For Pipe Laying Along Road Shoulder - Edurapotha 2Document2 pagesMethod Statement For Pipe Laying Along Road Shoulder - Edurapotha 2BMWGNo ratings yet

- Method Statement For Pipe Laying Along Road Shoulder - Edurapotha 2Document2 pagesMethod Statement For Pipe Laying Along Road Shoulder - Edurapotha 2BMWGNo ratings yet

- 08aa301 Engineering Mathematics - IIIDocument2 pages08aa301 Engineering Mathematics - IIIVIGNESH L R60% (5)

- Desktop Publishing Advertisement RubricDocument1 pageDesktop Publishing Advertisement Rubricapi-364316996No ratings yet

- O&M Manual SPAC-08N-10NDocument46 pagesO&M Manual SPAC-08N-10Nanwar sadat50% (2)

- Universidad Nacional Ciro Alegria: Planta de Cerco - (Paño Tipico)Document2 pagesUniversidad Nacional Ciro Alegria: Planta de Cerco - (Paño Tipico)Daniela Milachay TorresNo ratings yet

- Planos Modelo de UbsDocument1 pagePlanos Modelo de UbsJoel Brayam Lulo MendozaNo ratings yet

- Pushpak NagarDocument1 pagePushpak NagarMoin AnsariNo ratings yet

- For Refernce Only.: Project BoundaryDocument1 pageFor Refernce Only.: Project Boundaryrakesh padateNo ratings yet

- Projeto de Arborização - r0Document1 pageProjeto de Arborização - r0Robson Calleia Kalil HoneimNo ratings yet

- Arhitectura Spatiu Vacant S1-A3.03ADocument1 pageArhitectura Spatiu Vacant S1-A3.03AClaudiu CristeaNo ratings yet

- Pms Vac02.10 Pav - Terreo Vac.02.08Document1 pagePms Vac02.10 Pav - Terreo Vac.02.08GCR ar condicionadoNo ratings yet

- Process Piping Layout - VerifDocument1 pageProcess Piping Layout - VerifBMWGNo ratings yet

- 1 Structural Notes1451415595180Document1 page1 Structural Notes1451415595180Kawser HossainNo ratings yet

- 1.2. - Plano de Conduccion Captacion A Ptap - 1+0.00 A 2+00Document1 page1.2. - Plano de Conduccion Captacion A Ptap - 1+0.00 A 2+00victoria FalconNo ratings yet

- 1685 PlanDocument1 page1685 PlanPeterNo ratings yet

- Plano Clave: Municipalidad ProvincialDocument1 pagePlano Clave: Municipalidad Provincialjose elmer idrogo coluncheNo ratings yet

- 8.plano GeneralDocument1 page8.plano GeneralPaul Aguilar JulcaNo ratings yet

- PROYECTO 14 .MODEL-Model - pdf03Document1 pagePROYECTO 14 .MODEL-Model - pdf03Rafelito NuñezNo ratings yet

- A12TH0922AA-04 1 15341 6f3f7e31.sv$-ModelDocument1 pageA12TH0922AA-04 1 15341 6f3f7e31.sv$-ModelhardidwiNo ratings yet

- Plano Redes Existente-T3Document1 pagePlano Redes Existente-T3Jonathan Miguel Inca ValenzuelaNo ratings yet

- Previo Modelo 3Document1 pagePrevio Modelo 3Andres Mogollon VillamiZarNo ratings yet

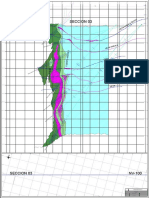

- SECCION 03-Layout1Document1 pageSECCION 03-Layout1Cara BrownNo ratings yet

- EPS - Sedacaj S.A.: Qda. MayopataDocument1 pageEPS - Sedacaj S.A.: Qda. MayopataFernando MantillaNo ratings yet

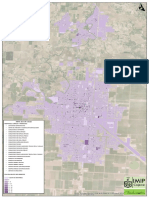

- Pob Con Servicio Imss BienestarDocument1 pagePob Con Servicio Imss BienestarGuillermo Velazquez LopezNo ratings yet

- Premium Enclave Pearl Enclave: 150'-0" WIDE ROADDocument1 pagePremium Enclave Pearl Enclave: 150'-0" WIDE ROADalirazaNo ratings yet

- Tmpe 1 A2 Hid Pla Odl 0021 E04Document1 pageTmpe 1 A2 Hid Pla Odl 0021 E04Philip J FrayNo ratings yet

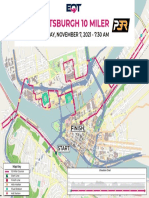

- EQT 10 Miler CourseDocument1 pageEQT 10 Miler CourseMatthew FalcioniNo ratings yet

- Page 1Document1 pagePage 1mdzillurrahman966No ratings yet

- Lucas Divided by Lucas Mod49 DATADocument21 pagesLucas Divided by Lucas Mod49 DATArg2858No ratings yet

- CADPUMACOTO BD-ModelDocument1 pageCADPUMACOTO BD-ModelItig-peru SrlNo ratings yet

- MQ13 600 DR 5810 PL2011 (PDF) - 3Document1 pageMQ13 600 DR 5810 PL2011 (PDF) - 3JEFFERSON NEGREIROS POLONo ratings yet

- Final PPT 2011 Chapter6Document40 pagesFinal PPT 2011 Chapter6A4onlyNo ratings yet

- Perfil Tuberia 188 191-PL 1 PERFILDocument1 pagePerfil Tuberia 188 191-PL 1 PERFILOmar OspinaNo ratings yet

- 10.6.1 Conexiones Domiciliarias de Agua Potable - Sector 1Document1 page10.6.1 Conexiones Domiciliarias de Agua Potable - Sector 1Giovany Levano SaldañaNo ratings yet

- 10.5.1 Esquema de Accesorios de Agua Potable - Sector 1Document1 page10.5.1 Esquema de Accesorios de Agua Potable - Sector 1Giovany Levano SaldañaNo ratings yet

- Trombon 1 ColombiaDocument4 pagesTrombon 1 ColombiaFredneryt QuinteroNo ratings yet

- Trombon 1 ColombiaDocument4 pagesTrombon 1 ColombiaFredneryt QuinteroNo ratings yet

- Arshia Publications ListDocument8 pagesArshia Publications ListSalmanNo ratings yet

- Planta General LocalizcionDocument1 pagePlanta General LocalizcionJOSE ALBERTO JEREZNo ratings yet

- 3.00 PAYA PEÑA - FINAL-ModelDocument1 page3.00 PAYA PEÑA - FINAL-ModelElmer Hurtado GuevaraNo ratings yet

- Makateeb e Sadrul Afazil by Zulfaqar Khan NaimiDocument251 pagesMakateeb e Sadrul Afazil by Zulfaqar Khan Naimisunnivoice100% (2)

- Love Is Far Away - Tbn1Document2 pagesLove Is Far Away - Tbn1LuisNo ratings yet

- JW Ebook DropshipDocument9 pagesJW Ebook DropshipsaddamNo ratings yet

- 2 5440619211976081586Document16 pages2 5440619211976081586manelloucif25No ratings yet

- Urbanizacion Nahla Plano A Cnel Ep Hecho-ModeloDocument1 pageUrbanizacion Nahla Plano A Cnel Ep Hecho-ModeloAlexis CarrascoNo ratings yet

- Guias Mecanicas DepartamentoDocument1 pageGuias Mecanicas Departamentochristian.foxNo ratings yet

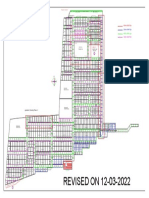

- PHASE - LL LEVELS - 12-03-2022Document1 pagePHASE - LL LEVELS - 12-03-2022Himagiri Rao KunaNo ratings yet

- Mặt Bằng Tổng VINHOMES GRAND PARKDocument1 pageMặt Bằng Tổng VINHOMES GRAND PARKDương Doãn HảiNo ratings yet

- MBTT HẦM XE VHGPDocument1 pageMBTT HẦM XE VHGPQuang Hưng VũNo ratings yet

- Mặt Bằng Tổng VINHOMES GRAND PARKDocument1 pageMặt Bằng Tổng VINHOMES GRAND PARKDương Doãn HảiNo ratings yet

- Em-2006-Mep-Eom-Mt-Sd-Plb-108 BS Floor Water Supply Layout (Rev-3)Document1 pageEm-2006-Mep-Eom-Mt-Sd-Plb-108 BS Floor Water Supply Layout (Rev-3)shreeNo ratings yet

- Munduk RevDocument2 pagesMunduk RevadiNo ratings yet

- Plano AsbuilDocument1 pagePlano AsbuilLeonardo ParraNo ratings yet

- Design ResponseDocument1 pageDesign ResponsekewcottagesNo ratings yet

- Aurora Strings - Violin 2Document2 pagesAurora Strings - Violin 2Pablo Ignacio Carvajal AmboNo ratings yet

- Vedchha SIPDocument1 pageVedchha SIPthalaganaNo ratings yet

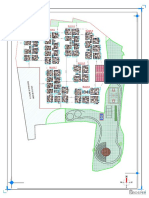

- The Drizzle FloorPlansDocument1 pageThe Drizzle FloorPlansAmit MitraNo ratings yet

- NTR 02 Final 05-12-2022Document1 pageNTR 02 Final 05-12-2022Danish DaniNo ratings yet

- Siteplan GWF September Detailed DrawingDocument8 pagesSiteplan GWF September Detailed DrawingBagio GioNo ratings yet

- Perfil de Conjunto A-A: Esquema de LocalizaciónDocument1 pagePerfil de Conjunto A-A: Esquema de Localizaciónborrosan80No ratings yet

- Acad Plano Badenes Layout1Document1 pageAcad Plano Badenes Layout1Frank Perez ToribioNo ratings yet

- 63-A Gurgaon-PlanDocument1 page63-A Gurgaon-PlanSalil KapoorNo ratings yet

- Strangers' Voices In My Head: A Journey Through What Made Me Who I Am from My MindFrom EverandStrangers' Voices In My Head: A Journey Through What Made Me Who I Am from My MindNo ratings yet

- BOQ Item 3.2 & 4.1.6Document4 pagesBOQ Item 3.2 & 4.1.6BMWGNo ratings yet

- E00248 HTG-CMI-DWG-220-400-220-8570-Rev 0 - Details For Manufacturing Pipes Between Structures - VERIFDocument52 pagesE00248 HTG-CMI-DWG-220-400-220-8570-Rev 0 - Details For Manufacturing Pipes Between Structures - VERIFBMWGNo ratings yet

- 15ft Lamp PostDocument1 page15ft Lamp PostBMWGNo ratings yet

- Progress Presentation: Hemmathagama Water Supply ProjectDocument16 pagesProgress Presentation: Hemmathagama Water Supply ProjectBMWGNo ratings yet

- Process Piping Layout - VerifDocument1 pageProcess Piping Layout - VerifBMWGNo ratings yet

- Re F: 18th Shipment 40ft Container (HLXU5350908) Description HS Code Reference QtyDocument1 pageRe F: 18th Shipment 40ft Container (HLXU5350908) Description HS Code Reference QtyBMWGNo ratings yet

- Safety For ShutdownDocument8 pagesSafety For ShutdownBMWGNo ratings yet

- Installation Guide Water and SewerDocument84 pagesInstallation Guide Water and SewerMohammed sabatinNo ratings yet

- Plastic and Liquid LimitsDocument6 pagesPlastic and Liquid LimitsBMWGNo ratings yet

- Atterburg LimitsDocument6 pagesAtterburg LimitsBMWGNo ratings yet

- PE Pipes (LC - Below 10) Doc-Upload-16!03!2021Document86 pagesPE Pipes (LC - Below 10) Doc-Upload-16!03!2021BMWGNo ratings yet

- Progress Presentation: Hemmathagama Water Supply ProjectDocument6 pagesProgress Presentation: Hemmathagama Water Supply ProjectBMWGNo ratings yet

- 2006 Earth Dams EnggGeologyDocument10 pages2006 Earth Dams EnggGeologyBMWGNo ratings yet

- 2005 Earthen Dams CBIPDocument9 pages2005 Earthen Dams CBIPiwantbooksfornowNo ratings yet

- Doc1 PDFDocument1 pageDoc1 PDFBMWGNo ratings yet

- 3.specification - Civil Engineering ConsDocument2 pages3.specification - Civil Engineering ConsBMWGNo ratings yet

- 3.specification - Galvanized Pipes & FittingsDocument2 pages3.specification - Galvanized Pipes & FittingsBMWGNo ratings yet

- Galvanized Pipes & FittingsDocument9 pagesGalvanized Pipes & FittingsSankalpa KarunarathneNo ratings yet

- 4.building WorksDocument27 pages4.building WorksjanithNo ratings yet

- ACI 308R-16 - Guide o External Curing - PreviewDocument6 pagesACI 308R-16 - Guide o External Curing - PreviewHaniAmin0% (4)

- Depth Semantic SegmentDocument9 pagesDepth Semantic SegmentAivan Dredd PunzalanNo ratings yet

- Brushbond Ultraflex BFLDocument2 pagesBrushbond Ultraflex BFLpeashNo ratings yet

- LinuxDocument206 pagesLinuxDinesh BhawnaniNo ratings yet

- HFC1508EN - Hi-Force Condensed Catalogue PDFDocument76 pagesHFC1508EN - Hi-Force Condensed Catalogue PDFVladimir ShepelNo ratings yet

- CV PDFDocument4 pagesCV PDFSIVA0% (1)

- Compare Models - RitchieSpecsDocument4 pagesCompare Models - RitchieSpecsMochammad JihadNo ratings yet

- Command Configure v41 Install Guide en UsDocument26 pagesCommand Configure v41 Install Guide en Us733No ratings yet

- NAME Dendi Panji Nugraha: Career ExperiencesDocument4 pagesNAME Dendi Panji Nugraha: Career ExperiencesAsep Ricky HerdiansyahNo ratings yet

- Shower CatalogueDocument36 pagesShower CataloguekavyaNo ratings yet

- Atv71 Controller Inside en v3Document25 pagesAtv71 Controller Inside en v3Juan Rodriguez ArevaloNo ratings yet

- High Precision Ball Berings GMNDocument72 pagesHigh Precision Ball Berings GMNSilvio Busdraghi AmorosoNo ratings yet

- Erpi Admin 11123510Document416 pagesErpi Admin 11123510prakash9565No ratings yet

- General Sir John Kotelawala Defence University: Application For A Detailed Degree Certificate/TranscriptDocument3 pagesGeneral Sir John Kotelawala Defence University: Application For A Detailed Degree Certificate/TranscriptNatasha de SilvaNo ratings yet

- Sbi Clerk MainsDocument4 pagesSbi Clerk MainspurushothamNo ratings yet

- Epoxylite TSA 220 - TDS - 2008Document3 pagesEpoxylite TSA 220 - TDS - 2008Anonymous sAmJfcVNo ratings yet

- Kleene ClosureDocument6 pagesKleene ClosurepbhmmmmNo ratings yet

- Investor Presentation (Company Update)Document42 pagesInvestor Presentation (Company Update)Shyam SunderNo ratings yet

- Lab Report For Epoxy Resin Polymer Concrete by GroupbbbbbbbDocument23 pagesLab Report For Epoxy Resin Polymer Concrete by GroupbbbbbbbBetelhem KifleNo ratings yet

- Design CriteriaDocument6 pagesDesign CriteriaAllyssa Jane ErcillaNo ratings yet

- 3D Printing Research Paper - Various Aspects PDFDocument6 pages3D Printing Research Paper - Various Aspects PDFhipovemicNo ratings yet

- Open IVDocument84 pagesOpen IVSokr AbdoNo ratings yet

- SA35AC E01 MergedDocument87 pagesSA35AC E01 MergedClassyNo ratings yet

- Sin EncoderDocument6 pagesSin Encoderboynew87No ratings yet

- Chapter 3 Waveform Coding Techniques PDFDocument33 pagesChapter 3 Waveform Coding Techniques PDFEunielyn SecretoNo ratings yet

- Icom en YcivDocument124 pagesIcom en YcivDavid Lemos SanchezNo ratings yet