Professional Documents

Culture Documents

Phosphate Rock Treatment بحثي مع د.عادل

Uploaded by

Shurooq TaibCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Phosphate Rock Treatment بحثي مع د.عادل

Uploaded by

Shurooq TaibCopyright:

Available Formats

Eng. & Tech. Journal, Vol.30, No.

1, 2012

Phosphate Rock Treatment with Hydrochloric Acid

for Increasing P2O5 Content

Dr.Adel Sharif Hamadi

Chemical Engineering Department, University of Technology/Baghdad

Email:dr-adelsharif@yahoo.com

Dr.Shurooq Talib Remedhan

Chemical Engineering Department, University of Technology/Baghdad

Haider Abd Ali

Chemical Engineering Department, University of Technology/Baghdad

Received on: 31/5/2011 & Accepted on: 3/11/2011

ABSTRACT

The present paper deals with the treatment of phosphate obtained from a commercial

sample of Akashat phosphate ore in hydrochloric acid. The factors studied are effects

of the temperature of dissolution, acid concentration, and the time required for mixing

phases. The experiments were performed with 100 kg/m3 of solid/liquid ratio, the size

of the particles ranged 125-140 µm, the initial acid concentrations were 20, 30 and 40

wt% HCl, and the temperature of dissolution was kept constant at 30, 40, 50, 60 and 70

o

C. The results indicated that the percentage of P2O5 increases as the HCl concentration

increased using different time and temperatures. Also, the results showed that the best

conditions for P2O5 recovery process according were acid concentration 40%, reaction

time of 90 min, and temperature 30 oC.

Keywords: phosphate rock, dissolution, hydrochloric acid, P2O5.

ﻤﻌﺎﻟﺠﺔ ﺍﻟﺼﺨﻭﺭ ﺍﻟﻔﻭﺴﻔﺎﺘﻴﺔ ﺒﺤﺎﻤﺽ ﺍﻟﻬﻴﺩﺭﻭﻜﻠﻭﺭﻴﻙ ﻟﻐﺭﺽ ﺯﻴﺎﺩﺓ ﻤﺤﺘﻭﻯ

ﺨﺎﻤﺱ ﺍﻭﻜﺴﻴﺩ ﺍﻟﻔﺴﻔﻭﺭ

ﺍﻟﺨﻼﺼﺔ

ﻴﺘﻨﺎﻭل ﺍﻟﺒﺤﺙ ﺍﻟﺤﺎﻟﻲ ﻋﻤﻠﻴﺔ ﻤﻌﺎﻟﺠﺔ ﺍﻟﺤﺠﺭ ﺍﻟﻔﻭﺴﻔﺎﺘﻲ ﺍﻟﻤﺴﺘﺨﺭﺝ ﻤﻥ ﻤﻨﻁﻘـﺔ ﻋﻜﺎﺸـﺎﺕ ﺍﻟﻌﺭﺍﻗﻴـﺔ

ﺍﻟﻭﻗـﺕ, ﺘﺭﻜﻴﺯ ﺍﻟﺤﺎﻤﺽ, ﺍﻟﻌﻭﺍﻤل ﺍﻟﺘﻲ ﺘﻡ ﺩﺭﺍﺴﺘﻬﺎ ﻫﻲ ﺘﺎﺜﻴﺭ ﺩﺭﺠﺔ ﺍﻟﺤﺭﺍﺭﺓ.ﺒﺤﺎﻤﺽ ﺍﻟﻬﻴﺩﺭﻭﻜﻠﻭﺭﻴﻙ

ﻜﻐﻡ ﻤﻥ ﺍﻟﻤﺎﺩﺓ ﺍﻟﺼـﻠﺒﺔ ﻟﻜـل ﻤﺘـﺭ100 : ﻟﻘﺩ ﺠﺭﺕ ﺍﻟﺘﺠﺎﺭﺏ ﺒﺎﺴﺘﺨﺩﺍﻡ ﺍﻟﻅﺭﻭﻑ ﺍﻟﺘﺎﻟﻴﺔ.ﺍﻟﻼﺯﻡ ﻟﻠﺨﻠﻁ

ﻤﺎﻴﻜﺭﻭﻤﺘﺭ؛ ﺘﺭﻜﻴﺯ ﺤـﺎﻤﺽ140-125 ﻤﻜﻌﺏ ﻤﻥ ﺍﻟﻤﺎﺩﺓ ﺍﻟﺴﺎﺌﻠﺔ؛ ﺍﻟﻤﻌﺩل ﺍﻟﻌﺎﻡ ﻟﺤﺠﻡ ﺍﻟﺩﻗﺎﺌﻕ ﺍﻟﺼﻠﺒﺔ

70,60,50,40,30 ؛ ﻭ ﺩﺭﺠﺔ ﺍﻟﺤﺭﺍﺭﺓ ﺍﻟﺘﻔﺎﻋل ﻋﻨـﺩ%40 ﻭ30,20 ﺍﻟﻬﻴﺩﺭﻭﻜﻠﻭﺭﻴﻙ ﻜﻨﺴﺒﺔ ﻭﺯﻨﻴﺔ

ﻟﻘﺩ ﺍﺜﺒﺘﺕ ﺍﻟﻨﺘﺎﺌﺞ ﺒﺎﻥ ﺍﻓﻀل ﻨﺴﺒﺔ ﺍﺴﺘﺭﺠﺎﻉ ﻟﺨﺎﻤﺱ ﺍﻭﻜﺴﻴﺩ ﺍﻟﻔﺴﻔﻭﺭ ﻜﺎﻨﺕ ﻋﻨـﺩ ﺘﺭﻜﻴـﺯ.ﺩﺭﺠﺔ ﻤﺌﻭﻴﺔ

. ﺩﺭﺠﺔ ﻤﺌﻭﻴﺔ30 ﺩﻗﻴﻘﺔ ﻭﺩﺭﺠﺔ ﺤﺭﺍﺭﺓ90 ﺯﻤﻥ ﺘﻔﺎﻋل,%40 ﺤﺎﻤﺽ ﺍﻟﻬﻴﺩﺭﻭﻜﻠﻭﺭﻴﻙ

ﺧﺎﻣﺲ اوﻛﺴﯿﺪ اﻟﻔﺴﻔﻮر, ﺣﺎﻣﺾ اﻟﮭﯿﺪروﻛﻠﻮرﯾﻚ, اﻟﺴﻤﺎد اﻟﻔﻮﺳﻔﺎﺗﻲ, اﻟﺼﺨﻮر اﻟﻔﻮﺳﻔﺎﺗﯿﺔ:اﻟﻜﻠﻤﺎت اﻟﺪاﻟﺔ

67

PDF created with pdfFactory Pro trial version www.pdffactory.com

Eng. & Tech. Journal, Vol.30,No.1, 2012 Phosphate Rock Treatment with Hydrochloric

Acid for Increasing P 2O 5 Content

INTRODUCTION

P

hosphorus is a vital resource for sustaining world agriculture. Reserves of

phosphate rock are identified in many regions of the world. Iraq is one of the

largest countries in the world including phosphate ores. Phosphate in Iraq comes

in second place after the sulfur and where large reserves of these raw materials exist in

the composition of Akashat in Western desert, one of the Marine sedimentary origins.

The estimated of workable phosphate ore in excess of 1.7 billion tons most of which

configurations belong to Mastrichian, Eocene and Paleocene [1].

Iraqi phosphate ores with medium quality in terms of content of phosphorus in which

the proportion of phosphorus pent-oxide between 21-22% and need to focus operations

in ways that simple physical for the purpose of industrial use is the main raw

production of different phosphate fertilizers and phosphoric acid and can be the raw

material for many chemical industries in the future.

Phosphate ore is insoluble in humid earth and therefore required treatment

processing to reduce the content of gangue materials such as carbonate, silicate,

feldspar, mica, calcite, dolomite and clays to meet the requirements of phosphate

fertilizers [2, 3, 4]. These processes include conventional methods such as crushing and

screening [5], or washing and desliming, and other beneficiation techniques include,

calcination [6-8], flotation [9-14], or partial acidulation with dilute organic or inorganic

acids [15-24].

The oldest route is via the addition of high concentrations of sulfuric acid to finely

ground phosphate rock. This acidulation step releases phosphoric acid from the

calcium phosphate salts present and produces insoluble gypsum (calcium sulfate

dihydrate) according to following reaction:

Ca3(PO 4)2(s)+3 H2SO4(l) +6 H2O(l) → 2H3PO4(l) + 3 CaSO4 2H2O (s)

The production units include large reaction vessels where finely ground phosphate

rock is first treated with weak phosphate acid and then reacted with approximately

55% sulfuric acid. In wet process with hydrochloric acid, HCl (34%) and phosphate

rock react to form phosphoric acid and calcium chloride.

This process makes it possible to avoid the formation of phosphogypsum, a

phenomena which necessitates the use of larger reaction vessels with higher initial

cost. Since calcium chloride is soluble, it remains in solution with the acid [25].

The high concentration of the calcium cation promotes precipitation of the fluorine

present in the rock. Following the separation of solid impurities, the solution is

contacted with water immiscible organic solvents to minimize losses and that

selectively extracts the phosphoric and hydrochloric acids and leaves the free

coproduct calcium chloride in the aqueous layer as follows [26]:

CaF2 3Ca3(PO4)2 + 20 HCl → 6 H3PO4 + 10 CaCl2 +2 HF

68

PDF created with pdfFactory Pro trial version www.pdffactory.com

Eng. & Tech. Journal, Vol.30, No.1,2012 Phosphate Rock Treatment with Hydrochloric

Acid for Increasing P2O5 Content

However, under specific conditions some of the phosphate is dissolved to form soluble

monocalcium phosphate as follows:

3Ca3(PO4)2 + 2 HCl → CaH4(PO4)2 + 2CaCl2

The main factors affecting the reaction rate of acid attack of phosphate are acid

concentration, time of the reaction, solid/liquid ratio, particular size and temperature [27,

28, 29, 30]

.

The acidulation reaction is more rapid with hydrochloric acid than with sulfuric acid,

and yields soluble products from both the calcium and phosphate. Thus, there is neither

a need to heat the mixture to speed up the reaction, nor are there any crystal form

problems requiring temperature stabilization.

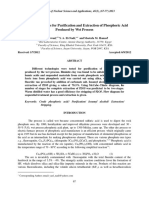

The product acid from this process is often purer than that obtained from sulfuric

acid acidulation, and in addition this process is claimed to recover 98–99% of the

available P2O5 in the rock, as opposed to the 94–95%. The flowsheet of hydrochloric

acid acidulation route to phosphoric acid is shown in figure (1).

EXPERIMENTAL PROCEDURE

Sample Description

The phosphate rock sample was crushed and screened to collect a fraction of

general range size of 125-140 µm, using the mesh sieves of U. S. Tyler. The test

sample was done for various constituents of the rock in Department of standardization

and quality control /Ministry of planning and the results are given in table (1).

Total percentage of the determined constituents was found to be less than 100%. The

remaining may be SiO2, Al2O3, moisture, organic matter etc.

Procedure

The samples of the ground phosphate rock were dried in an electric oven at about

105 oC, cooled to room temperature and stored in closed desiccators for analysis before

and after treatment with hydrochloric acid. A 50 g of the sample was added to a conical

flask reactor (500 ml) a measured volume of diluted hydrochloric acid solution of a

specified concentration. The reaction mixture was been agitated using a magnetic

stirrer at moderate speed for a fixed time and temperature. After the reaction, the

product was filtered using a Buchner funnel and filter paper. The solid matter after

leaching process was washed with fixed amount of distilled water to remove any

soluble matter.

Analytical analysis techniques were used to study P2O5 content. The concentration of

P2O5 was calculated from material balance, and determined by titration with (0.5N)

sodium hydroxide solution and phenolphthalein indicator solution until a pink color

appears. The P2O5 content was calculated from the equation:

% total P2O5 = (3.55 x Vs)/W

Where Vs=Volume of 0.5N sodium hydroxide solution used.(ml), and W=Weight of

sample in the liquor. (g).

69

PDF created with pdfFactory Pro trial version www.pdffactory.com

Eng. & Tech. Journal, Vol.30, No.1,2012 Phosphate Rock Treatment with Hydrochloric

Acid for Increasing P2O5 Content

RESULTS AND DISCUSSION

Effect of Acid Concentration on %P2o 5 Recovery:

Weighted sample of the particle size of 125-140 µm were treated at constant

temperatures at 30, 40, 50, 60, and 70 oC with HCl acid of 20, 30, and 40 wt%

concentrations for different periods. After each period the percentage P2O5 dissolution

was determined as shown plotted in figures 2-6, which observed that at various

reaction temperature, the lower HCl concentration is a greater chance for the reaction

between the phosphate and the HCl acid leading to lower values of P2O5 recoveries,

but as concentration of acid increases, the polarity acid will increase leading in a

decrease in the acid reaction with phosphate with a corresponding increase in the %

P2O5 recovery.

Effect of Acidulation Time on %P2o 5 Recovery

It can be deduced from the figures 7-9, that an increase in acidulation time, lead to

P2O5 content in the concentrate increase. This is due to the fact that HCl reaction can

react as linearly with phosphate in the stages of the reaction forming CaCl2 which is

soluble and can easily lost in the filtrate, which leads to an increase in % P2O5

recovery.

Effect of Temperature on % P2o 5 Recovery:

Temperature can affect the diffusion coefficient, specific reaction rate, and

viscosity, but the gross effects on the process can be obtained only from experimental

results. In this investigation a particle size of 125-140 µm was used at constant

temperatures of 30, 40, 50, 60, 70 oC for different periods of acidulation. At the end of

each period the percentage P2O5 was determined. Figures 10-12 show the results and

observed that the P2O5 percentage increases with increase in temperature. This is

attributed to diffusion coefficient as the conversion is proved later to be controlled by

the rate of diffusion of HCl to the reacting phosphate.

CONCLUSIONS

Akashat phosphate rock can be treatment with hydrochloric acid due to the reaction

with calcium carbonate impurity formed a soluble CaCl2 removed by filtration leaving

a solid residue enriched in the phosphate.

The factors that were studied: acid concentration, acidulation time, and the

temperature.

It was found that the best conditions for P2O5 recovery process according to this study

were acid concentration 40%, reaction time of 90 min, and temperature 30 oC.

REFERENCES

[1]Shirqi I. S., Tawfiq O. A., “Akashat Phosphate Mine”, Report of the Ministry of

Industry and Minerals, Iraqi State Company for Phosphate, Feb. 2010.

[2]Good, P. C., “Beneficiation of un-weathered Indian calcareous phosphate rock by

calcination and hydration”. US Bureau of Mines, Report No.8154, Washington DC,

USA, (1976).

70

PDF created with pdfFactory Pro trial version www.pdffactory.com

Eng. & Tech. Journal, Vol.30, No.1,2012 Phosphate Rock Treatment with Hydrochloric

Acid for Increasing P2O5 Content

[3]Hollick, C.T., Wright, R., “Recent trends in phosphate mineral beneficiation”.

Transactions of IMM Section A 95, 150–154 July, (1986).

[4]Rao, T.C., Rao, L.S., Rao, G.M.,”Beneficiation of Indian low grade phosphate

deposits: problems and prospects”. Transactions of the Indian Institute of Metals 45

(3), 195–205, (1992).

[5]Lodha, T. R, Srivastava, A. C, “Characterization of Low Phosphates and Their

Beneficiation for Fertilizer Industry”, Fertilizer Technology, Vol. 19, pp. 190- 197

(1985).

[6]Iqbal, Z., Anwar, M M., Pritchard, D. W., “Optimization of Thermal Beneficiation

of a low Grade Dolomitic Phosphate rock,” Int. J. Miner Process, Vol. 43, pp. 123-

131 (1995).

[7]Kaljuvee, T., Kuusik, R., “Enrichment of Carbonate-Phosphate Ores by Calcination

and Air Separation,” Int. J. Process, Vol. 43, pp. 113-121(1995).

[8]Galal, I., Mabrouk, A., “Upgrading of Abu Tartur Phosphate Ore”, Arab Gulf J Sci.

Res, Vol. 10 (3), pp. 57-79 (1992).

[9]K.A. Matis, A.I. Zouboulis “An Overview of the Froth Flotation Process,” Flotation

Sci Eng., pp. 1-44 (1995).

[10]Recovery of Phosphate from Florida Phosphatic Clays FIPR Publication Number

02-096-179 (2001).

[11]Development of New Technology for Beneficiation of Florida Phosphate

Resources, FIPR Publication Number 02- 129-167 (1999).

[12]Zheng, X., Smith, R. W., “Dolomite Depressants in the Flotation of Apatite and

Collophane From Dolomite”, Minerals Engineering, Vol. 10 (5), pp. 537-545 (1997).

[13]Prasad, M., Majmudar, A. K., Rao, T. G., “Flotation Studies on a Low Grade

Cherty Calcareous Rock Phosphate Ore From Jhabura India”, Trans. Soc. Min.,

Metall Explor , pp. 92-96/section 3, 298, 1995 (published 1996).

[14]ElGillani, D. A., Abouzeid, A. Z. M., “Flotation of carbonates from phosphate ores

in acidic media”, Int. J. Miner Process, Vol. 38 (3-4), pp. 235-56 (1993).

[15]Sdoukos, A. T., Economou E., “Development of a method for studying selectivity

in Ca5 (PO4)3F- CaCO3- H3PO4 system” Journal of the Applied Chemistry of the

USSR, 58 (9), pp. 1785-1791 (1985).

[16]Sdoukos, A. T., Economou E., “Kinetic Study of the Selectivity and Chemical

Enrichment of Phosphorites from the Epirus in Greece,” Journal of the Applied

Chemistry of the USSR, 58 (9), pp. 1792- 1797 (1985).

[17]McClellan, G. H., Roy, A., Lawendy, T. “Some Characterization and Beneficiation

Data on a Phosphorite from Kaiyang Area of Guinzhou China,” Sci-Geol. Mem, Vol.

77 pp. 125-134 (1985).

[18]Douglas, H. L., “Magnesium Separation From Dolomitic Phosphate by Acid

Leaching”, FIPR Publication (01) pp. 113- 138 (1997).

[19]Shalabi, M. E. H., Mohamed, O. A., ElHussiny, N. A., “Granulation and Partial

Acidulation of Low Grade ElSebaiya West Phosphate Fines by Phosphoric Acid”,

Journal of the Institution of Engineers (India), (83), pp. 55-60 (2003).

71

PDF created with pdfFactory Pro trial version www.pdffactory.com

Eng. & Tech. Journal, Vol.30, No.1,2012 Phosphate Rock Treatment with Hydrochloric

Acid for Increasing P2O5 Content

[20]Demirbas, A., Abali, Y., Mert, E. “Recovery of Phosphate from Calcined Bone by

Dissolution in Hydrochloric Acid Solution”, Resources, Conservation, and

Recycling, (26), pp. 251-258 (1999).

[21]Abu Eishah, S. I., “A New Technique for the Beneficiation of Low Grade

Carbonate Rich Phosphate Rock by Digestion With Dilute Acetic Acid and

Solutions: Pilot Plant Testing Studies,” Minerals Engineering, Vol. 4 (5/6) pp. 573-

586 (1991).

[22]Abu Eishah, S. I., Saddedin, W. “An Experimental Investigation for the

Minimization of the Carbonates in Hard Phosphate Rocks,” Third Congress of

Chemical Engineers Cairo-Egypt, TESCE 14-23, pp. 19-21 (1998).

[23]Sadeddin, W. “Minimization of Free Calcium Carbonates in Hard and Medium

Hard Phosphate Rocks Using Dilute Acetic Acid Solutions. Int. Journal of Mineral

Processing,” Vol. 30, pp. 113- 125 (1990).

[24]Lawver, J. E., McClintock, W. O., Snow, R. E., “Beneficiation of Phosphate

Rocks,” A State of the Art Review. Miner Sci. Eng., Vol. 10 (4) pp. 278-94 (1978).

[25]Zafar, I. Z.; Ansari, T. M.; Ashraf, M.; Abid, M. A.,”Effect of Hydrochloric Acid

on Leaching of Calcareous Phosphates”, Iran J. Chem. Chem. Eng., Vol 25, No. 2,

2006. pp. 47-57.

[26]Phosphoric Acid Manufacturing using Hydrochloric Acid, Phosphorus and Potassium,

125 (1983) 29.

[27]Abali, Y., Colak, S., Yarstri, A.,”Dissolution Kinetics of Phosphate Rock with Cl2

Gas in Water. Hydrometallurgy. 46:13(1997).

[28]Dorozohkin, S. V., Prakt, J., “Dissolution Kinetics of Single Flourapatite Crystals

in Phosphoric Acid Solution under the Conditions of the Wet-Process”, Phosphoric

Acid Production Chem. 338:620 (1996).

[29]Abu-Eishah, S. I., Nizar, M., “Parametric Study on the Production of Phospharic

Acid by the Dihydrate Process”, J. Chem. Eng. 81:231(2001).

[30]Sikdar, S. K., Ore, F., Moore, J. H. “The Digestion of Phosphate Ore in Phosphoric

Acid”. Aiche Symp. Ser. 76:82(1978).

[31]Hydrochloric based route to pure phosphoric acid, Chemical Engineering (N. Y.)

69(52), 34, Dec. 24 (1962).

.

Table (1): Analysis of Low Grade Phosphate Rock before Treatment with

Hydrochloric Acid

P2O5 (%) CaO (%) Na2O (%) K2O (%) MgO (%) FeO (%)

17 18.8 0.8 0.084 1.4 0.1

72

PDF created with pdfFactory Pro trial version www.pdffactory.com

Eng. & Tech. Journal, Vol.30, No.1,2012 Phosphate Rock Treatment with Hydrochloric

Acid for Increasing P2O5 Content

Figure (1): Flow sheet for Hydrochloric Acid Acidulation Rote to

Phosphoric Acid [31]

73

PDF created with pdfFactory Pro trial version www.pdffactory.com

Eng. & Tech. Journal, Vol.30, No.1,2012 Phosphate Rock Treatment with Hydrochloric

Acid for Increasing P2O5 Content

30 40 50 30 40 50

60 70 Deg. C 60 70 Deg. C

85 85

(% ) P 2 O 5 Reco very

(% ) P 2 O 5 Reco very

80 80

Acidulation Time =10 min Acidulation Time =30 min

75 75

15 25 35 45 15 25 35 45

HCl Concentration, (% ) HCl Concentration, (% )

Figure (2): Effect of HCl Concentration on Figure (3): Effect of HCl Concentration

Increasing P2O5 of Phosphate for Different on Increasing P2O5 of Phosphate for

Temperature and Acidulation Time of Different Temperature and Acidulation

10 min. Time of 30 min.

30 40 50 30 40 50

60 70 Deg. C 60 70 Deg. C

85 85

(%) P2O5 Recovery

(%) P2O5 Recovery

80 80

Acidulation Time =50 min Acidulation Time =70 min

75 75

15 25 35 45 15 25 35 45

HCl Concentration, (% ) HCl Concentration, (% )

Figure(4): Effect of HCl Concentration on Figure(5): Effect of HCl Concentration on

Increasing P2O5 of Phosphate for Different Increasing P2O5 of Phosphate for

Temperature and Acidulation Time of Different Temperature and Acidulation

50 min. Time of 70 min.

74

PDF created with pdfFactory Pro trial version www.pdffactory.com

Eng. & Tech. Journal, Vol.30, No.1,2012 Phosphate Rock Treatment with Hydrochloric

Acid for Increasing P2O5 Content

30 40 50 30 40 50

60 70 Deg. C 60 70 Deg. C

85 90

88

(% ) P 2 O 5 Reco very

86

(%) P 2 O 5 Recovery

84

82

80

80

78

76

Acidulation Time =90 min 74

75 72 HCl Conc.=20%

15 25 35 45 70

0 20 40 60 80 100

HCl Concentration, (% )

Acidulation Time, min.

Figure(6): Effect of HCl Concentration on Figure (7): Effect of Acidulation Time on

Increasing P2O5 of Phosphate for Different Increasing P2O5 of Phosphate for

Temperature and Acidulation Time of Different Temperature and HCl

90 min Concentration of 20%.

30 40 50 30 40 50

60 70 Deg. C 60 70 Deg. C

90 90

88 88

86 86

(%) P2O5 Recovery

(%) P2O5 Recovery

84 84

82 82

80 80

78 78

76 76

74

74

72 HCl Conc.=40%

72 HCl Conc.=30%

70

70

0 20 40 60 80 100

0 20 40 60 80 100

Acidulation Time, min.

Acidulation Time, min.

Figure (8): Effect of Acidulation Time on Figure (9): Effect of Acidulation Time on

Increasing P2O5 of Phosphate for Different Increasing P2O5 of Phosphate for

Temperature and HCl Concentration 30%. Different Temperature and HCl

Concentration 40%.

75

PDF created with pdfFactory Pro trial version www.pdffactory.com

Eng. & Tech. Journal, Vol.30, No.1,2012 Phosphate Rock Treatment with Hydrochloric

Acid for Increasing P2O5 Content

90 min 70 min 50 min 90 min 70 min 50 min

30 min 10 min 30 min 10 min

90 90

(% ) P 2 O 5 Reco very

(% ) P 2 O 5 Reco very

85 85

80 80

75 75

HCl Conc. =20% HCl Conc. =30%

70 70

20 40 60 80 20 40 60 80

o o

Temperature, C Temperature, C

Figure (10): Effect of Acidulation Time on Figure (11): Effect of Acidulation Time

Increasing P2O5 of Phosphate for Different on Increasing P2O5 of Phosphate for

Temperature and HCl Concentration of Different Temperature and HCl

20%. Concentration of 30%.

90 min 70 min 50 min

30 min 10 min

90

(%) P2O5 Recovery

85

80

75

HCl Conc. =40%

70

20 40 60 80

o

Temperature, C

Figure (12): Effect of Acidulation Time

on Increasing P2O5 of Phosphate for

Different Temperature and HCl

Concentration of 40%.

76

PDF created with pdfFactory Pro trial version www.pdffactory.com

You might also like

- 1 s2.0 S1383586622026053 MainDocument10 pages1 s2.0 S1383586622026053 MainIkram ADNANENo ratings yet

- ApatitDocument9 pagesApatittrinh xuan hiepNo ratings yet

- Utilization of Spent Petrochemical Sulfuric Acid in The Production of Wet-Process Phosphoric AcidDocument8 pagesUtilization of Spent Petrochemical Sulfuric Acid in The Production of Wet-Process Phosphoric AcidHamidreza AbriNo ratings yet

- K2SO4 Production Via The Double Decomposition Reaction of KCL and PhosphogypsumDocument11 pagesK2SO4 Production Via The Double Decomposition Reaction of KCL and PhosphogypsumGeorge Van Bommel100% (2)

- Inorganic Industries Engineering هيوضعلايرغ تاعانصلا ةسدنه: Dr.: Sameh Araby El-MekawyDocument37 pagesInorganic Industries Engineering هيوضعلايرغ تاعانصلا ةسدنه: Dr.: Sameh Araby El-MekawyMohamed AbdelaalNo ratings yet

- Successive Processes For Purification and Extraction of Phosphoric Acid Produced by Wet ProcessDocument11 pagesSuccessive Processes For Purification and Extraction of Phosphoric Acid Produced by Wet ProcessCedric Omar Hdz RiescoNo ratings yet

- 1 s2.0 S2213343722009496 MainDocument8 pages1 s2.0 S2213343722009496 Maindehkadeh7No ratings yet

- K2 SO4 Productionviathedoubledecompositionreactionof KClandphosphogypsumDocument12 pagesK2 SO4 Productionviathedoubledecompositionreactionof KClandphosphogypsumGy UiNo ratings yet

- Metals: Kinetics of Chalcopyrite Leaching by Hydrogen Peroxide in Sulfuric AcidDocument13 pagesMetals: Kinetics of Chalcopyrite Leaching by Hydrogen Peroxide in Sulfuric AcidlolisfrairegNo ratings yet

- Paro Vuori 1995Document5 pagesParo Vuori 1995Dena MilanyNo ratings yet

- Exergy Analysis of The Process of Production of Dicalcium PhosphateDocument13 pagesExergy Analysis of The Process of Production of Dicalcium Phosphatedehkadeh7No ratings yet

- Preparation of Boric Acid From Low-Grade Ascharite and Recovery of Magnesium SulfateDocument5 pagesPreparation of Boric Acid From Low-Grade Ascharite and Recovery of Magnesium SulfateSaumya JainNo ratings yet

- Effect of Organic and Inorganic Compounds On Dissolution Kinetics of Chalcopyrite in Hydrogen Peroxide - Hydrochloric Acid SystemDocument9 pagesEffect of Organic and Inorganic Compounds On Dissolution Kinetics of Chalcopyrite in Hydrogen Peroxide - Hydrochloric Acid SystemlolisfrairegNo ratings yet

- Phosphorus Industry Processes and ProductsDocument38 pagesPhosphorus Industry Processes and ProductsS S S REDDY100% (1)

- SPE 126719 Matrix Acid Systems For Formations With High Clay ContentDocument15 pagesSPE 126719 Matrix Acid Systems For Formations With High Clay ContentJose Miguel GonzalezNo ratings yet

- Process Industries - Lecture Material 4Document30 pagesProcess Industries - Lecture Material 4Barnabas YohannesNo ratings yet

- 2096682530-Ich 305 Phosphorus Based ChemicalsDocument9 pages2096682530-Ich 305 Phosphorus Based ChemicalsDennis JosephNo ratings yet

- Phosphoric Acid Flow Sheet of Dihydrate ProcessDocument3 pagesPhosphoric Acid Flow Sheet of Dihydrate ProcessPrakash Mylar100% (1)

- Acterization and Flotation of Sulfur From Chalcopyrite Concentrate Leaching ResidueDocument9 pagesActerization and Flotation of Sulfur From Chalcopyrite Concentrate Leaching ResidueSantiago TuestaNo ratings yet

- III Sem ICTDocument56 pagesIII Sem ICToctoviancletusNo ratings yet

- Shela PDFDocument11 pagesShela PDFAzizah AmaliyahNo ratings yet

- K2SO4Document14 pagesK2SO4Dũng LêNo ratings yet

- Ajac 2019030715582355Document11 pagesAjac 2019030715582355Iben Abdallah ZouhourNo ratings yet

- Kinetics and Mechanism Study On Chlorine Dioxide Generation With Hydrogen PeroxideDocument5 pagesKinetics and Mechanism Study On Chlorine Dioxide Generation With Hydrogen PeroxideirNo ratings yet

- Preparation of High Purity Graphite From Alkali RoastingDocument3 pagesPreparation of High Purity Graphite From Alkali RoastingEni Mece100% (1)

- Ozone Chalcopyrite Leaching OptimizationDocument12 pagesOzone Chalcopyrite Leaching OptimizationSEBASTIÁN IGNACIO OÑATENo ratings yet

- Khaitan HazardousDocument15 pagesKhaitan HazardousKamesh TripathiNo ratings yet

- The Study of Neutralization of The Dihydrate Phosphogypsum ImpuritiesDocument7 pagesThe Study of Neutralization of The Dihydrate Phosphogypsum ImpuritiesПредраг КузмановићNo ratings yet

- SPE 165147 An Effective Single-Stage Acid System For Sandstone FormationsDocument13 pagesSPE 165147 An Effective Single-Stage Acid System For Sandstone Formationssuhaimi manNo ratings yet

- Fluorosilicic in WaterDocument7 pagesFluorosilicic in WatertrucbeoNo ratings yet

- Copper Concentrate Leaching in Chloride-Jpibañez-JipinzaDocument12 pagesCopper Concentrate Leaching in Chloride-Jpibañez-JipinzaFelipe GuerreroNo ratings yet

- Treatment of Fluoride Containing Effluent Generated During Uranium Metal Production - PaperDocument7 pagesTreatment of Fluoride Containing Effluent Generated During Uranium Metal Production - PaperYogesh LadolaNo ratings yet

- Naja Heli Driss I 2021Document11 pagesNaja Heli Driss I 2021Iben Abdallah ZouhourNo ratings yet

- What Is DesulfurizationDocument20 pagesWhat Is DesulfurizationYash NandurkarNo ratings yet

- SSP Modelling Paper PDFDocument5 pagesSSP Modelling Paper PDFJai GaneshNo ratings yet

- Synthesis of Potassium Sulfate by Conversion of Potassium Chloride and Magnesium SulfateDocument6 pagesSynthesis of Potassium Sulfate by Conversion of Potassium Chloride and Magnesium SulfateMuhammad AteeqNo ratings yet

- Program: B.Sc. Chemical Engineering Technology Semester: 3rd Lecturer: Engr. Babar SaeedDocument18 pagesProgram: B.Sc. Chemical Engineering Technology Semester: 3rd Lecturer: Engr. Babar SaeedbabarNo ratings yet

- US3689216Document5 pagesUS3689216PABLO URIZ CEREZONo ratings yet

- Processing Rare-Earth Element Concentrate Obtained From PhosphogypsumDocument6 pagesProcessing Rare-Earth Element Concentrate Obtained From PhosphogypsumGyan PrameswaraNo ratings yet

- Investigation On The Phosphoric Acid Production From Low Grade Phosphorites With High Content of MagnesiumDocument6 pagesInvestigation On The Phosphoric Acid Production From Low Grade Phosphorites With High Content of MagnesiumamirNo ratings yet

- 16 Beganskienes 383-386 PDFDocument4 pages16 Beganskienes 383-386 PDFSartikaNo ratings yet

- Reductive Atmospheric Acid Leaching of West Australian Smectitic Nickel Laterite inDocument6 pagesReductive Atmospheric Acid Leaching of West Australian Smectitic Nickel Laterite inandre_lange_1No ratings yet

- Precipitation Methods Using Calcium-Containing Ores For Fluoride Removal in WastewaterDocument12 pagesPrecipitation Methods Using Calcium-Containing Ores For Fluoride Removal in WastewaterIzzul Asyraf ZulkifliNo ratings yet

- Chapter 2sulphuric Acid Manufacture Sept 2014Document5 pagesChapter 2sulphuric Acid Manufacture Sept 2014kvk326No ratings yet

- Sandstone AcidizingDocument24 pagesSandstone AcidizingDarya Khan BhuttoNo ratings yet

- Lixiviacion Copper SulphideDocument12 pagesLixiviacion Copper Sulphidejose amezquita100% (1)

- Metals 11 01567Document17 pagesMetals 11 01567Yahaira Barrueto JhonsonNo ratings yet

- 575 1074 3 PBDocument9 pages575 1074 3 PBAkun 75051No ratings yet

- Minerals 09 00511 v2Document12 pagesMinerals 09 00511 v2navedamu786No ratings yet

- Sol-Gel Processing of HydroxyapatiteDocument9 pagesSol-Gel Processing of HydroxyapatiteSharif IshakNo ratings yet

- " .. ", SciencedirectDocument10 pages" .. ", SciencedirectMehmet Muhtar KocakerimNo ratings yet

- Sciencedirect: Determination of Excess Sodium Hydroxide in Geopolymer by Volumetric AnalysisDocument4 pagesSciencedirect: Determination of Excess Sodium Hydroxide in Geopolymer by Volumetric AnalysisValeria ManriqueNo ratings yet

- A Nano-Sized Solid Acid Synthesized From Rice Hull Ash For Biodiesel ProductionDocument27 pagesA Nano-Sized Solid Acid Synthesized From Rice Hull Ash For Biodiesel ProductionPebrianiNo ratings yet

- Effects of oxalic acid and seawater on xylose and arabinose dehydration kinetics (40 charactersDocument10 pagesEffects of oxalic acid and seawater on xylose and arabinose dehydration kinetics (40 charactersAfshaNo ratings yet

- Experiments To WriteDocument53 pagesExperiments To WriteSUMAIRA ALTAFNo ratings yet

- 06 Process Selection 121 179Document59 pages06 Process Selection 121 179Jaynie Lee VillaranNo ratings yet

- Arsenal Philadelphia, Pa. 19137: FrankfordDocument23 pagesArsenal Philadelphia, Pa. 19137: FrankfordPutri PramodyaNo ratings yet

- Phosphoric AcidDocument6 pagesPhosphoric AcidHananNo ratings yet

- Transition Metal Catalyzed Furans Synthesis: Transition Metal Catalyzed Heterocycle Synthesis SeriesFrom EverandTransition Metal Catalyzed Furans Synthesis: Transition Metal Catalyzed Heterocycle Synthesis SeriesNo ratings yet

- Rattana Phra 2012Document9 pagesRattana Phra 2012Shurooq TaibNo ratings yet

- Fuel Processing Technology: Rabitah Zakaria, Adam P. HarveyDocument7 pagesFuel Processing Technology: Rabitah Zakaria, Adam P. Harveylina bermeoNo ratings yet

- Rapeseed Print - Zakaria2012Document8 pagesRapeseed Print - Zakaria2012Shurooq TaibNo ratings yet

- Print - JSIR 71 (12) 822-828Document7 pagesPrint - JSIR 71 (12) 822-828Shurooq TaibNo ratings yet

- Salam 2016Document20 pagesSalam 2016Shurooq TaibNo ratings yet

- The Second LawDocument6 pagesThe Second LawShurooq TaibNo ratings yet

- Nigam 2000Document8 pagesNigam 2000Shurooq TaibNo ratings yet

- Vander Zee 2005Document16 pagesVander Zee 2005Shurooq TaibNo ratings yet

- Salam 2016Document20 pagesSalam 2016Shurooq TaibNo ratings yet

- Decolourisation of Simulated Reactive Dyebath e Uents by Electrochemical Oxidation Assisted by UV LightDocument7 pagesDecolourisation of Simulated Reactive Dyebath e Uents by Electrochemical Oxidation Assisted by UV Lightapi-3828788No ratings yet

- Vilaseca 2010Document7 pagesVilaseca 2010Shurooq TaibNo ratings yet

- Arfmtsv55 N1 P65 73Document10 pagesArfmtsv55 N1 P65 73Shurooq TaibNo ratings yet

- An Investigation of Direct Glycerol Fuel Cells and Comparison With Direct Methanol and Ethanol Fuel CellDocument9 pagesAn Investigation of Direct Glycerol Fuel Cells and Comparison With Direct Methanol and Ethanol Fuel CellShurooq TaibNo ratings yet

- Herslund 2013Document14 pagesHerslund 2013Shurooq TaibNo ratings yet

- Daneshvar 2007Document7 pagesDaneshvar 2007Shurooq TaibNo ratings yet

- 10 1016@j Procbio 2012 08 014Document26 pages10 1016@j Procbio 2012 08 014Shurooq TaibNo ratings yet

- Decolorizing and Detoxifying Textile Wastewater Using Anaerobic/Aerobic TreatmentDocument9 pagesDecolorizing and Detoxifying Textile Wastewater Using Anaerobic/Aerobic TreatmentShurooq TaibNo ratings yet

- Organic promoters effect on refrigerant gas hydrate thermodynamicsDocument16 pagesOrganic promoters effect on refrigerant gas hydrate thermodynamicsShurooq TaibNo ratings yet

- Graphene Modified Fluorinated Cation-Exchange Membranes For Proton Exchange Membrane Water ElectrolysisDocument7 pagesGraphene Modified Fluorinated Cation-Exchange Membranes For Proton Exchange Membrane Water ElectrolysisShurooq TaibNo ratings yet

- tween 80 بحث منشورDocument24 pagestween 80 بحث منشورShurooq TaibNo ratings yet

- 1 s2.0 S0378381214007389 MainDocument9 pages1 s2.0 S0378381214007389 MainShurooq TaibNo ratings yet

- بحث مع د. محمود بربوتي بالتكنولوجيةDocument11 pagesبحث مع د. محمود بربوتي بالتكنولوجيةShurooq TaibNo ratings yet

- Review MainDocument23 pagesReview MainShurooq TaibNo ratings yet

- بحثي المنشور بمؤتمر الاردنDocument13 pagesبحثي المنشور بمؤتمر الاردنShurooq TaibNo ratings yet

- 170425 بحث مجلة ديالى نضالDocument18 pages170425 بحث مجلة ديالى نضالShurooq TaibNo ratings yet

- بحث منشور خوارزمي ليناDocument11 pagesبحث منشور خوارزمي ليناShurooq TaibNo ratings yet

- Al Mukhtar 2020 Study of The Influence of DifferentDocument11 pagesAl Mukhtar 2020 Study of The Influence of DifferentShurooq TaibNo ratings yet

- seffectofsolidon مع اساور PDFDocument19 pagesseffectofsolidon مع اساور PDFShurooq TaibNo ratings yet

- Experimental Investigation of Thermodynamics, Kinetics, andDocument15 pagesExperimental Investigation of Thermodynamics, Kinetics, andShurooq TaibNo ratings yet

- Chapter 6 Designing Global Supply Chain NetworksDocument22 pagesChapter 6 Designing Global Supply Chain NetworksRashadafaneh100% (1)

- Comparison of methods for determining the plateau modulus and entanglement molecular weightDocument19 pagesComparison of methods for determining the plateau modulus and entanglement molecular weightfaezehNo ratings yet

- EEE Course CurriculumDocument3 pagesEEE Course CurriculumAanshu MishraNo ratings yet

- Manual de Servicio Colimador Ge Sentry 3Document247 pagesManual de Servicio Colimador Ge Sentry 3Jairo Manzaneda100% (1)

- FloodDocument9 pagesFloodapi-352767278No ratings yet

- JBMO ShortLists-2001Document2 pagesJBMO ShortLists-2001OklaNo ratings yet

- Fluid Mechanics EXERCHAP05Document4 pagesFluid Mechanics EXERCHAP05scribdgggNo ratings yet

- Application OF Horizontal Vacuum: THE A Belt Filter TO Smuts Dewatering and Cane Mud FiltrationDocument5 pagesApplication OF Horizontal Vacuum: THE A Belt Filter TO Smuts Dewatering and Cane Mud FiltrationMichel M.No ratings yet

- Peritoneal DialysisDocument26 pagesPeritoneal DialysisKath LeenNo ratings yet

- Sentence Correction Practice Questions 01Document5 pagesSentence Correction Practice Questions 01Dhiman NathNo ratings yet

- Guia TeraSpanDocument73 pagesGuia TeraSpanTim Robles MartínezNo ratings yet

- HW 01Document2 pagesHW 01Hëņřý ØjđNo ratings yet

- AEE 211-Chapter 01-Rev 1Document66 pagesAEE 211-Chapter 01-Rev 1AlexanderNo ratings yet

- Sensing and Fixation of NO by Calixarenes: D. M. RudkevichDocument7 pagesSensing and Fixation of NO by Calixarenes: D. M. RudkevichAwaluddin Iwan PerdanaNo ratings yet

- JavaScript Factorial CalculatorDocument13 pagesJavaScript Factorial CalculatorSandipa ShindeNo ratings yet

- Dynamics - Rotational Motion Lab ReportDocument16 pagesDynamics - Rotational Motion Lab ReportTim Ghent100% (1)

- Advanced Process Modeling 1Document41 pagesAdvanced Process Modeling 1mtahir777945No ratings yet

- A1512 Panasonic SemiconductorDocument2 pagesA1512 Panasonic SemiconductorbrneiNo ratings yet

- MS2680-2017 Energy Efficiency and Use of Renewable Energy For Residential BuildingsDocument61 pagesMS2680-2017 Energy Efficiency and Use of Renewable Energy For Residential BuildingsChern Yue EweNo ratings yet

- Map Grid and Compass RoseDocument3 pagesMap Grid and Compass RosePatricia BelangerNo ratings yet

- Algebra 3 Principles and Sample Problems: 3.1 Probability 3.2 Statistics 3.3 Problems For SolutionsDocument24 pagesAlgebra 3 Principles and Sample Problems: 3.1 Probability 3.2 Statistics 3.3 Problems For SolutionsKrisha Jean MacalinoNo ratings yet

- Bearing CatalogueDocument107 pagesBearing CatalogueSheikh ZakirNo ratings yet

- Fractional Distillation of Ginebra San Miguel GinDocument6 pagesFractional Distillation of Ginebra San Miguel GinHajime NakaegawaNo ratings yet

- Geeks For Geeks - ArrayDocument33 pagesGeeks For Geeks - ArrayLove MehtaNo ratings yet

- ICT SRG Paper-2Document5 pagesICT SRG Paper-2shaumaniNo ratings yet

- Temperature Calibrator Specifications and FunctionsDocument1 pageTemperature Calibrator Specifications and FunctionsvihaanNo ratings yet

- Specifications For Amf Control PanelDocument4 pagesSpecifications For Amf Control Paneltarun aggarwalNo ratings yet

- Diels-Alder Reaction CharacterizationDocument3 pagesDiels-Alder Reaction CharacterizationMohit SinghalNo ratings yet

- Voicemeeter UserManual PDFDocument63 pagesVoicemeeter UserManual PDFjimNo ratings yet

- RecoverPoint With SRMDocument63 pagesRecoverPoint With SRMhemanth-07No ratings yet