Professional Documents

Culture Documents

Awareness On ISO TS 16949 2009-Management

Uploaded by

raja0 ratings0% found this document useful (0 votes)

3 views1 pageOriginal Title

Awareness on ISO TS 16949 2009-management

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

3 views1 pageAwareness On ISO TS 16949 2009-Management

Uploaded by

rajaCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 1

Employee Name: _________________

Date: ____________

TRAINING EFFECTIVENESS MONITORING SHEET

Objective Type Questions:

1. To which industry ISO/TS 16949:2009 is applicable?

a) Automobile industries. b) Textiles. c) Schools, Hospitals. d) All type of industries.

2. What is the lead time to review the Engineering changes received from customer?

a) Within two working weeks. b) Within three working weeks

c) Within Four working weeks d) None of the above.

3. How to calculate COPQ (Cost of Poor Quality)

a) External and internal Failure Cost. b) Internal Failure Cost.

c) External Failure Cost. d) Non-Conformance Cost and Conformance Cost.

4. What are the type suppliers to be considered for process and product audit?

a) All the suppliers those activity pertains to product conformity.

b) RM Suppliers. c) Surface treatment Suppliers. d) Machining Suppliers.

e) Consumable Suppliers.

5. What is the management system to optimize inventory turns over time and assure

Stock rotation?

a) FIFO (First-in First out) b) FILO (First in last out).

c) LIFO (Last-in First out) d) Tag System.

6. For which parameters SPC have to be practiced?

a) Critical characteristics identified by customer.

b) Critical characteristics identified by RKI.

c) Characteristics having 0.1 tolerances on over all.

d) a & b.

Result:-

<60%-Poor- Training to be give again.

60%-70%-Satisfactory.

71%-90%- Good.

Above 90%-Excellent.

F-HR-TRE-01, Rev.00

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Food Safety & Hygiene Level 2 Course For Catering StaffDocument5 pagesFood Safety & Hygiene Level 2 Course For Catering Staffraja100% (1)

- 5 Whys Root Cause Analysis Worksheet SampleDocument4 pages5 Whys Root Cause Analysis Worksheet SampleSANJOY MAJINo ratings yet

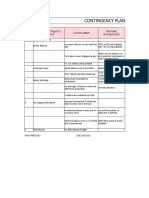

- Contingency Plan Template 30Document2 pagesContingency Plan Template 30rajaNo ratings yet

- Contingency Planning: Current Status Sr. No. Type of Contingency Reviewed Alternate ArrangementsDocument2 pagesContingency Planning: Current Status Sr. No. Type of Contingency Reviewed Alternate ArrangementsSead ZejnilovicNo ratings yet

- Root Cause Analysis Report Form: 1. The EventDocument6 pagesRoot Cause Analysis Report Form: 1. The EventrajaNo ratings yet

- What, Why, and How Is A Contingency PlanDocument5 pagesWhat, Why, and How Is A Contingency PlanrajaNo ratings yet

- Contingency Plan Template 12 - IT-HR ShortageDocument1 pageContingency Plan Template 12 - IT-HR ShortagerajaNo ratings yet

- 7 QC Tools-Check SheetDocument3 pages7 QC Tools-Check SheetrajaNo ratings yet

- 7 QC Tools - StratificationDocument3 pages7 QC Tools - Stratificationraja100% (1)

- Contingency Plan Template 36 - UtilitiesDocument14 pagesContingency Plan Template 36 - UtilitiesrajaNo ratings yet

- Fish Farming Business Plan SummaryDocument23 pagesFish Farming Business Plan Summaryidoko alfaNo ratings yet

- Control Chart and TypesDocument4 pagesControl Chart and TypesrajaNo ratings yet

- Cost of Poor QualityDocument3 pagesCost of Poor QualityrajaNo ratings yet

- 5 6339367665856938523Document36 pages5 6339367665856938523rajaNo ratings yet

- 7 QMS Principles of IATF 16949Document4 pages7 QMS Principles of IATF 16949rajaNo ratings yet

- Level 1 Food Hygiene TrainingDocument4 pagesLevel 1 Food Hygiene TrainingrajaNo ratings yet

- Level 3 Food Hygiene Course in CateringDocument6 pagesLevel 3 Food Hygiene Course in CateringrajaNo ratings yet

- Kalkiyin2 "Parttipan2 Kan2Avu" Parts 1 and 2 in Tamil Script, Tscii FormatDocument183 pagesKalkiyin2 "Parttipan2 Kan2Avu" Parts 1 and 2 in Tamil Script, Tscii FormatrajaNo ratings yet

- Food Training Hygiene TrainingDocument45 pagesFood Training Hygiene TrainingLynne Corpuz BenignoNo ratings yet

- 5 6339367665856938524Document36 pages5 6339367665856938524rajaNo ratings yet

- Risk Assess ToolDocument5 pagesRisk Assess ToolrajaNo ratings yet

- MSL952002A Handle and Transport Samples or Equipment: Revision Number: 1Document14 pagesMSL952002A Handle and Transport Samples or Equipment: Revision Number: 1rajaNo ratings yet

- Risk Assessment Template: Step 1: Identify The HazardsDocument4 pagesRisk Assessment Template: Step 1: Identify The HazardsMyolwinooNo ratings yet

- Quality Policy enDocument1 pageQuality Policy enrajaNo ratings yet

- Cost of Poor QualityDocument17 pagesCost of Poor QualityrajaNo ratings yet

- Training Effectiveness Monitoring Sheet: Objective Type Questions: 1. Define FIFO?Document1 pageTraining Effectiveness Monitoring Sheet: Objective Type Questions: 1. Define FIFO?rajaNo ratings yet

- Usage Guide: Web Site'Document68 pagesUsage Guide: Web Site'rajaNo ratings yet

- Elevating InspectionDocument8 pagesElevating InspectionrajaNo ratings yet

- OLAS Quality Manual SummaryDocument32 pagesOLAS Quality Manual SummaryrajaNo ratings yet