0% found this document useful (0 votes)

352 views3 pagesOperational Control

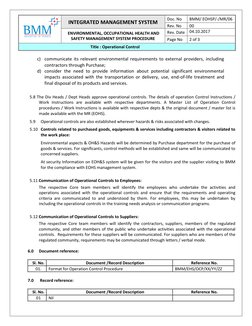

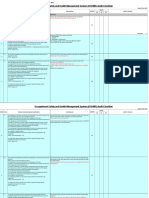

This document outlines procedures for determining operational controls to manage significant environmental, health, and safety aspects and hazards at BMM. It describes establishing controls through work instructions and considering life cycle stages. Division heads approve controls, which are communicated to employees and suppliers. The procedures are applicable to all BMM processes and activities.

Uploaded by

jeyaseelanaCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

352 views3 pagesOperational Control

This document outlines procedures for determining operational controls to manage significant environmental, health, and safety aspects and hazards at BMM. It describes establishing controls through work instructions and considering life cycle stages. Division heads approve controls, which are communicated to employees and suppliers. The procedures are applicable to all BMM processes and activities.

Uploaded by

jeyaseelanaCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd