Professional Documents

Culture Documents

D and T-Series-master

Uploaded by

Javier PerezCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

D and T-Series-master

Uploaded by

Javier PerezCopyright:

Available Formats

D & T SERIES PUMPS

ENGINEERING DATA PACK

D & T SERIES PUMPS | ENGINEERING DATA PACK

TABLE OF CONTENTS

D Series Model Number System........................................................... 3

D Series Mounting Dimensions (Displacements .11 to 2.3)................. 4

T Series Model Number System........................................................... 5

T Series Mounting Dimensions (Displacements 2.6 to 12.)................. 6

Pump Performance Data..................................................................... 7

Temperature Limits............................................................................. 8

Temperature Effect on Magnet Torque................................................ 9

Materials of Construction.................................................................. 10

Regulatory Compliance Information.................................................. 11

WARNING

The magnets in magnetically coupled pumps create very strong magnetic fields. Special care must be taken with the following:

• Pacemakers - Magnets can upset the timing of pacemakers. These magnets should be kept away from all pacemakers. Because of the health risks

involved the importance of this cannot be overstated.

• Credit Cards - Magnets can scramble the information on a credit card’s magnetic tape.

• Computers, Computer Tapes, and Computer Disks - Magnets can scramble the information on the memory device.

• Watches - Magnets can affect the workings of traditional mechanical spring-driven watches as well as chip and electronically controlled designs.

• Electronic Instruments - Sensitive electronic instruments and devices may change calibration or be damaged by a powerful magnetic field.

• Explosive Atmosphere - Rare earth magnets and magnetic materials may create sparks through contact in handling. Never handle rare earth magnets

in explosive atmospheres because sparking may ignite the atmosphere.

• Do not place hand or fingers between the housing and adapter. The magnets are extremely strong and will attract all metallic objects and can be the

source of pinch points. Do not wear watches or other metallic jewelry when working with magnets.

ALSIP, IL | ILKESTON, UK | TUTHILLPUMP.COM 2

D & T SERIES PUMPS | ENGINEERING DATA PACK

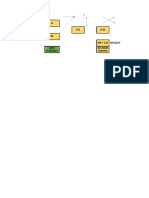

D SERIES MODEL NUMBER SYSTEM

MAGNET TORQUE

CONSTRUCTION

DISPLACEMENT

TEMPERATURE

MATERIALS OF

OPERATING

PORT SIZE

MATERIAL

MOTOR &

BEARING

MAGNET

BYPASS

mL/REV

GEAR &

O-RING

SERIES

DRIVE

OPEN

OPEN

D G S . 6 8 P P P T 1 N M 9 7 O O O

POSITIONS 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18

POS. 1 - PUMP SERIES POS. 10 - O-RING POS. 17 - OPERATING TEMPERATURES

D = 1.67” Diameter Metal Pump V = Viton PTFE = 140˚F (60˚C)

T = PTFE PPS = 250˚F (121˚C) Polyphenylene Sulfide

POS. 2 - MAGNET TORQUE E = EPR PEEK = 350˚F (176˚C) Polyetheretherketone

B* = 30 oz/in Note: Temperatures greater than 140˚F (60˚C) may reduce

G = 65 oz/in

POS. 11 - PORT SIZE flow/pressure. These are approximate gear & bearing

X = 240 oz/in 1* = 1/8” NPT maximum temperature limits

2 = 1/4” NPT

*Not available for 1.2, 1.3, 1.6, 2.0, or 2.3 POS. 18 - OPEN

*Not available for .99, 1.2, 1.3, 1.6, 2.0, or 2.3

POS. 3 - MATERIALS OF CONSTRUCTION 0 = Open

sizes. Not available in Hastelloy or Titanium

S = 316 Stainless Steel SERVICE PACK OPTION

H = Hastelloy C276 POS. 12 - MAGNET

T = Titanium Add "SP" in front of the model number, followed by

N = PPS or PEEK Encapsulated positions 1-10, 16, 17, & 18 of pump model

(Material based on Pos. 7, 8, & 9)

POS. 4, 5, & 6 - DISPLACEMENT mL/REV

Note: SPDB, SPDG, & SPDX default to SPDD

.11 = Nominal 6 GPH at 3500 RPM W = Welded (Example - SPDDS1.2PPPT000)

.19 = Nominal 10 GPH at 3500 RPM (Required for PTFE gears, Hastelloy, Titanium

.23 = Nominal 12 GPH at 3500 RPM pumps. Welded not available in B size magnet) Service Pack Contains:

.38 = Nominal 20 GPH at 3500 RPM

• Gears

.57 = Nominal 30 GPH at 3500 RPM POS. 13 - BYPASS • Bearings

.68 = Nominal 36 GPH at 3500 RPM

N = None • O-Rings

.80 = Nominal 42 GPH at 3500 RPM

M = Medium 60 PSI (Standard) • Lubricant

.99 = Nominal 52 GPH at 3500 RPM

L = Low Pressure 30 PSI (Low Pressure not available • Instruction Sheet

1.2 = Nominal 63 GPH at 3500 RPM

in .99 to 2.3 sizes)

1.3 = Nominal 68 GPH at 3500 RPM

H = High Pressure 130 PSI (High Pressure not available

1.6 = Nominal 84 GPH at 3500 RPM

in .99 to 2.3 sizes)

2.0 = Nominal 105 GPH at 3500 RPM

2.3 = Nominal 121 GPH at 3500 RPM Bypass is not available in Hastelloy or Titanium

POS. 14 & 15 - MOTOR & DRIVE

POS. 7, 8, & 9 - GEAR & BEARING MATERIAL 00 = Pump Only

PPP = PPS (Polyphenylene Sulfide)

EEE = PEEK (Polyetheretherketone) POS. 16 - OPEN

TTT* = PTFE O = Open

* Available in .23, .38, .57, .68, .80, 1.2, and 1.6 only.

Requires PTFE O-rings and welded magnet.

Maximum Differential Pressure = 100 PSI

ALSIP, IL | ILKESTON, UK | TUTHILLPUMP.COM 3

D & T SERIES PUMPS | ENGINEERING DATA PACK

D SERIES PUMP MOUNTING DIMENSIONS

All measurements are in inches [millimeters].

Displacement .11 to 2.3

B

A

1.63

1/4 NPT

D SERIES DISPLACEMENTS .11 TO 2.3

DISPLACEMENT DIMENSION A DIMENSION B DIMENSION C

.11 & .19 0.125" [3.2mm] 1.83" [46.4mm] 5.30" [134.6mm]

.23 & .38 0.250" [6.4mm] 1.95" [49.5mm] 5.42" [137.7mm]

.57 0.375" [9.5mm] 2.07" [52.7mm] 5.54" [140.7mm]

.68 & .80 0.450" [11.4mm] 2.15" [54.7mm] 5.62" [142.7mm]

.99 & 1.2 0.657" [16.7mm] 2.36" [59.9mm] 5.83" [148.1mm]

1.3 0.750" [19.0mm] 2.45" [62.3mm] 5.92" [150.4mm]

1.6 & 2.0 0.900" [22.9mm] 2.60" [66.0mm] 6.07" [154.2mm]

2.3 1.000" [25.4mm] 2.70" [68.6mm] 6.17" [156.7mm]

NOTE: In conjunction with our program of continuous testing and design upgrading, all specifications are subject to change without notice. All data is approximate. Request a quotation for your specific application.

ALSIP, IL | ILKESTON, UK | TUTHILLPUMP.COM 4

D & T SERIES PUMPS | ENGINEERING DATA PACK

T SERIES MODEL NUMBER SYSTEM

MAGNET TORQUE

CONSTRUCTION

DISPLACEMENT

TEMPERATURE

MATERIALS OF

OPERATING

PORT SIZE

MATERIAL

MOTOR &

BEARING

MAGNET

BYPASS

mL/REV

GEAR &

O-RING

SERIES

DRIVE

OPEN

OPEN

T X S 5 - 3 P P P T 3 N N A 2 O O O

POSITIONS 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18

POS. 1 - PUMP SERIES POS. 10 - O-RING POS. 16 - OPEN

T = 3” Diameter Metal Pump V = Viton O = Open

T = PTFE

POS. 2 - MAGNET TORQUE E = EPR POS. 17 - OPERATING TEMPERATURES

X = 240 oz/in PPS = 250˚F (121˚C) Polyphenylene Sulfide

(Required for 2.6, 5.3, and 7.9 sizes)

POS. 11 - PORT SIZE PEEK = 350˚F (176˚C) Polyetheretherketone

3 = 3/8” NPT Note: Temperatures greater than 140˚F (60˚C) may

W = 460 oz/in (Required for 2.6, 5.3, and 7.9 sizes) reduce flow/pressure. These are approximate gear &

(Required for 8.0 and 12. sizes) bearing maximum temperature limits

7 = 3/4” NPT Suction, 1/2" NPT on Discharge

POS. 3 - MATERIALS OF CONSTRUCTION (Required for 8.0 and 12. sizes) POS. 18 - OPEN

(WETTED)

POS. 12 - MAGNET 0 = Open

S = 316 Stainless Steel

H = Hastelloy C276 N = PPS or PEEK Encapsulated SERVICE PACK OPTION

T = Titanium (Material based on Pos. 7, 8, & 9)

Add "SP" in front of the model number, followed

by positions 1-10, 16, 17, & 18 of pump model

POS. 4, 5, & 6 - DISPLACEMENT mL/REV W = Welded

(Required for Hastelloy or Titanium pumps.

2.6 = Nominal 137 GPH at 3500 RPM Service Pack Contains:

Not available for Stainless)

5.3 = Nominal 279 GPH at 3500 RPM • Gears

7.9 = Nominal 416 GPH at 3500 RPM • Bearings

POS. 13 - BYPASS

8.0 = Nominal 421 GPH at 3500 RPM • O-Rings

12. = Nominal 650 GPH at 3500 RPM N = Not available • Lubricant

• Instruction Sheet

POS. 14 & 15 - MOTOR & DRIVE

POS. 7, 8, & 9 - GEAR & BEARING MATERIAL 00 = Pump Only

PPP = PPS (Polyphenylene Sulfide)

EEE = PEEK (Polyetheretherketone)

ALSIP, IL | ILKESTON, UK | TUTHILLPUMP.COM 5

D & T SERIES PUMPS | ENGINEERING DATA PACK

T SERIES PUMP MOUNTING DIMENSIONS

All measurements are in inches [millimeters].

6.50 [165.1] C

B 4.11 [104.4]

Displacement 2.6 to 7.9

3.00

0.50

3/4 NPT 3/8 NPT

INLET OUTLET

0.75

1.50

T SERIES DISPLACEMENTS 2.6 TO 7.9

DISPLACEMENT DIMENSION A DIMENSION B DIMENSION C

2.6 0.313" [7.95mm] 1.82" [46.2mm] 5.93" [150.6mm]

5.3 0.625" [15.8mm] 2.12" [53.8mm] 6.24" [158.5mm]

7.9 0.938" [23.8mm] 2.43" [61.8mm] 6.55" [166.4mm]

6.50 A

B 4.11

Displacement 8.0 to 12.

3.00

0.50

3/4 NPT 1/2 NPT

INLET OUTLET

0.75

1.50

T SERIES DISPLACEMENTS 8.0 TO 12.

DISPLACEMENT DIMENSION A DIMENSION B DIMENSION C

8.0 7.00" [177.8mm] 2.65" [59.7mm] 0.625" [15.9mm]

12. 7.32" [185.9mm] 3.21" [81.4mm] 0.938" [23.8mm]

NOTE: In conjunction with our program of continuous testing and design upgrading, all specifications are subject to change without notice. All data is approximate. Request a quotation for your specific application.

ALSIP, IL | ILKESTON, UK | TUTHILLPUMP.COM 6

D & T SERIES PUMPS | ENGINEERING DATA PACK

D SERIES PUMP PERFORMANCE DATA

MAX DIFFERENTIAL PRESSURE

SIZE (mL/rev) GPH @ 0 PSI and 3500 RPM LPH @ 0 PSI and 3500 RPM

PSI (BAR)

.11 6 GPH 22 LPH 150 PSI (10.3 BAR)

.19 10 GPH 38 LPH 150 PSI (10.3 BAR)

.23 12 GPH 46 LPH 250 PSI (17.2 BAR)

.38 20 GPH 76 LPH 250 PSI (17.2 BAR)

.57 30 GPH 114 LPH 250 PSI (17.2 BAR)

.68 36 GPH 136 LPH 250 PSI (17.2 BAR)

.80 42 GPH 160 LPH 250 PSI (17.2 BAR)

.99 52 GPH 198 LPH 200 PSI (13.8 BAR)

1.2 63 GPH 239 LPH 200 PSI (13.8 BAR)

1.3 69 GPH 259 LPH 175 PSI (12.1 BAR)

1.6 84 GPH 319 LPH 150 PSI (10.3 BAR)

2.0 105 GPH 399 LPH 150 PSI (10.3 BAR)

2.3 121 GPH 459 LPH 150 PSI (10.3 BAR)

NOTE: Maximum system pressure is 500 PSI (34.5 BAR) and viscosity range is 0.3 - 2000 cPs without speed reduction.

T SERIES PUMP PERFORMANCE DATA

MAX DIFFERENTIAL PRESSURE

SIZE (mL/rev) GPH @ 0 PSI and 3500 RPM LPH @ 0 PSI and 3500 RPM

PSI (BAR)

2.6 137 GPH 518 LPH 250 PSI (17.2 BAR)

5.3 279 GPH 1056 LPH 145 PSI (10 BAR)

7.9 416 GPH 1575 LPH 95 PSI (6.6 BAR)

8.0 421 GPH 1593 LPH 150 PSI (10.3 BAR)

12. 650 GPH 2460 LPH 120 PSI (8.3 BAR)

NOTE: Maximum system pressure is 500 PSI (34.5 BAR) and viscosity range is 0.3 - 2000 cPs without speed reduction.

ALSIP, IL | ILKESTON, UK | TUTHILLPUMP.COM 7

D & T SERIES PUMPS | ENGINEERING DATA PACK

D & T SERIES TEMPERATURE LIMITS

˚F D SERIES GEARS & BEARINGS T SERIES GEARS & BEARINGS ˚C

350 177

300 149

250 121

PEEK (Polyetheretherketone)

PEEK (Polyetheretherketone)

200 93

PPS (Polyphenylene Sulfide) (Gear Only)

PPS (Polyphenylene Sulfide)

150 66

100 PTFE (Polytetrafluorothylene) 38

50 10

0 -18

-50 -46

ALSIP, IL | ILKESTON, UK | TUTHILLPUMP.COM 8

D & T SERIES PUMPS | ENGINEERING DATA PACK

TEMPERATURE EFFECT ON MAGNET TORQUE

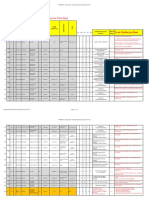

TEMPERATURE TORQUE MAGNET TORQUE

˚C ˚F PERCENT OUNCE INCH MILLINEWTON METER

B, G, X, & W B&G X&W B G X W B G X W

22 72 100% 100% 30.0 65.0 240.0 460.0 211.8 459.0 1694.8 3248.3

30 86 98% 99% 29.4 63.7 238.1 456.4 207.6 449.8 1681.4 3222.9

40 104 96% 98% 28.7 62.1 235.8 452.0 202.6 438.5 1665.1 3191.8

50 122 93% 97% 27.9 60.5 233.5 447.5 197.0 427.2 1648.9 3160.0

60 140 91% 96% 27.2 58.8 231.1 443.0 192.1 415.2 1631.9 3128.3

70 158 88% 95% 26.4 57.2 228.8 438.6 186.4 403.9 1615.7 3097.2

80 176 86% 94% 25.7 55.6 226.5 434.1 181.5 392.6 1599.4 3065.4

90 194 83% 93% 24.9 54.0 224.2 429.6 175.8 381.3 1583.2 3033.6

100 212 81% 92% 24.2 52.3 221.8 425.2 170.9 369.3 1566.3 3002.6

110 230 78% 91% 23.4 50.7 219.5 420.7 165.2 358.0 1550.0 2970.8

120 248 76% 90% 22.7 49.1 217.2 416.3 160.3 346.7 1533.8 2939.7

130 266 73% 90% 21.9 47.5 214.8 411.8 154.6 335.4 1516.8 2907.9

140 284 71% 89% 21.2 45.8 212.5 407.3 149.7 323.4 1500.6 2876.2

150 302 68% 88% 20.4 44.2 210.2 402.9 144.1 312.1 1484.3 2845.1

160 320 66% 87% 19.7 42.6 207.9 398.4 139.1 300.8 1468.1 2813.3

170 338 63% 86% 18.9 41.0 205.5 393.9 133.5 289.5 1451.2 2781.6

180 356 61% 85% 18.2 39.3 203.2 389.5 128.5 277.5 1434.9 2750.5

190 374 58% 84% 17.4 37.7 200.9 385.0 122.9 266.2 1418.7 2718.7

200 392 56% 83% 16.7 36.1 198.6 380.6 117.9 254.9 1402.4 2687.6

210 410 53% 82% 15.9 34.5 196.2 376.1 112.3 243.6 1385.5 2655.9

220 428 51% 81% 15.2 32.8 193.9 371.6 107.3 231.6 1369.2 2624.1

230 446 48% 80% 14.4 31.2 191.6 367.2 101.7 220.3 1353.0 2593.0

240 464 46% 79% 13.7 29.6 189.2 362.7 96.7 209.0 1336.1 2561.2

250 482 43% 78% 12.9 28.0 186.9 358.2 91.1 197.7 1319.8 2529.5

260 500 41% 77% 12.2 26.3 184.6 353.8 86.2 185.7 1303.6 2498.4

ALSIP, IL | ILKESTON, UK | TUTHILLPUMP.COM 9

D & T SERIES PUMPS | ENGINEERING DATA PACK

D & T SERIES PUMPS MATERIALS OF CONSTRUCTION

PART MATERIAL

Stainless Steel - ASTM A276 - 316 SS

BODY Hastelloy - C276

Titanium - ASTM B348

Stainless Steel - ASTM A276 - 316 SS

CAVITY PLATE Hastelloy - C276

Titanium - ASTM B348

Stainless Steel - ASTM A276 - 316 SS

CAP Hastelloy - C276

Titanium - ASTM B348

PPS - 30% Carbon / 15% PTFE

GEARS & BEARINGS PEEK - 15% Carbon

PTFE

Viton

Teflon (PTFE)

0-RINGS

Buna-N

EPR

Stainless Steel - ASTM A276 - 316 SS

SHAFT Hastelloy - C276

Titanium - ASTM B348

Ceramic Encapsulated in PPS

Ceramic Encapsulated in PEEK

Samarium Cobalt Encapsulated in PPS

MAGNET

Samarium Cobalt Encapsulated in PEEK

Samarium Cobalt Weld Encapsulated and Molded Over with PPS

Samarium Cobalt Weld Encapsulated and Molded Over with PEEK

Stainless Steel - ASTM A167

MAGNET CUP Hastelloy - C276

Titanium - ASTM B265

Stainless Steel - AMS 5524

MAGNET SHROUD Hastelloy - C276

Titanium - ASTM B265

ALSIP, IL | ILKESTON, UK | TUTHILLPUMP.COM 10

D & T SERIES PUMPS | ENGINEERING DATA PACK

D SERIES PUMP NPIPr DATA (PSIa)

PUMP SIZE INLET PORT SIZE 1000 RPM 2000 RPM 3000 RPM 4000 RPM 5000 RPM

.11 1/8" NPT 0.05 0.08 0.10 0.13 0.20

.19 1/8" NPT 0.10 0.13 0.26 0.32 0.53

.23 1/8" NPT 0.12 0.15 0.28 0.40 0.56

.38 1/8" NPT 0.18 0.25 0.43 0.90 1.10

.57 1/8" NPT 0.20 0.30 0.55 1.00 1.30

.68 1/8" NPT 0.25 0.35 0.60 1.10 1.54

.80 1/8" NPT 0.34 0.68 1.40 2.20 4.00

.11 1/4" NPT 0.03 0.06 0.10 0.13 0.19

.19 1/4" NPT 0.08 0.10 0.20 0.30 0.50

.23 1/4" NPT 0.09 0.11 0.24 0.33 0.55

.38 1/4" NPT 0.15 0.23 0.40 0.70 0.91

.57 1/4" NPT 0.18 0.28 0.50 0.80 1.10

.68 1/4" NPT 0.20 0.30 0.66 0.85 1.30

.80 1/4" NPT 0.25 0.35 0.70 1.00 1.80

.99 1/4" NPT 0.30 0.40 0.75 1.10 1.90

1.2 1/4" NPT 0.35 0.45 0.80 1.30 2.60

1.6 1/4" NPT 0.40 0.50 1.10 1.80 N/A

2.0 1/4" NPT 0.47 0.57 1.50 2.50 N/A

2.3 1/4" NPT 0.55 0.64 2.00 3.20 N/A

T SERIES PUMP NPIPr DATA (PSIa)

PUMP SIZE INLET PORT SIZE 1000 RPM 2000 RPM 3000 RPM 4000 RPM

2.6 3/8" NPT 0.50 1.50 3.10 5.60

5.3 3/8" NPT 0.53 1.60 3.40 5.90

7.9 3/8" NPT 1.00 1.90 3.80 6.10

8.0 3/4" NPT 1.00 1.90 3.80 6.10

12. 3/4" NPT 1.50 2.40 4.20 6.30

NOTE: D & T are at 1 Cp Viscosity

ALSIP, IL | ILKESTON, UK | TUTHILLPUMP.COM 11

REGULATORY COMPLIANCE INFORMATION

ATEX

The D & T Series pumps' technical file is lodged in accordance with The D & T Series pumps comply with the European Directive 2006/42/EC

Article 13(1)(b)(ii)of ATEX Directive 2014/34/EU of 26 February 2014

THE FOLLOWING STANDARDS WERE USED TO VERIFY CONFORMANCE:

THE FOLLOWING STANDARDS WERE USED TO VERIFY CONFORMANCE:

EN ISO 12100:2010 – Safety of machinery - General principles

2006/42/EC – The Machinery Directive for design

EN 1127-1:2011 – Explosive atmospheres - Explosion prevention and EN 809:1998+A1:2009 – Pumps and pump units for liquids -

protection - Part 1: Basic concepts and methodology Common safety requirements

EN ISO 80079-36:2016 – Explosive atmospheres - Part 36: Non-electrical 2011/65/EU – The Restriction of Hazardous Substances Directive

equipment for explosive atmospheres - Basic method and requirements

EN ISO 80079-37:2016 – Explosive atmospheres - Part 37: Non-electrical

equipment for explosive atmospheres - Nonelectrical type of protection

constructional safety ''c'', control of ignition sources ''b'', liquid

immersion ''k''

TUTHILL ALSIP

12500 South Pulaski Road

Alsip, Illinois 60803 USA

P: 708.389.2500

Alsip@Tuthill.com

TUTHILL ILKESTON

Birkdale Close

Manners Industrial Estate

Ilkeston, Derbyshire DE7 8YA UK

P: 44.0.115.932.5226

Ilkeston@Tuthill.com

XXX-XX-XXX

You might also like

- Colorful Chalkboard Classroom Labels and OrganizersFrom EverandColorful Chalkboard Classroom Labels and OrganizersNo ratings yet

- 2020 I30 G 1.4 Mpi-DiagramDocument1 page2020 I30 G 1.4 Mpi-DiagramcarsexpressNo ratings yet

- Client: Drawing Number Scale Dimensions 'MM' NTS SES 1062/16 Sheet Title 100A Ats Panel Project DetailsDocument7 pagesClient: Drawing Number Scale Dimensions 'MM' NTS SES 1062/16 Sheet Title 100A Ats Panel Project DetailsDinesh GowdNo ratings yet

- 12 DetailsDocument4 pages12 DetailsDon Roseller DumayaNo ratings yet

- (KENR9592-00) Schematic - 793F OHT Power Train SystemDocument2 pages(KENR9592-00) Schematic - 793F OHT Power Train SystemPETTERSON TRUCKS PerformanceNo ratings yet

- General Notes: S Piping and Instrument Diagram - Gen1 - System 0000Document1 pageGeneral Notes: S Piping and Instrument Diagram - Gen1 - System 0000sanjay masoodNo ratings yet

- DTM04-2P-P007: DT04-3P,, DT06-3S,, A Drc16-70sam,, Drc12-70paDocument9 pagesDTM04-2P-P007: DT04-3P,, DT06-3S,, A Drc16-70sam,, Drc12-70paАндрейNo ratings yet

- TSR 007-Trk-Pmj-Terex 60-TR112 - T 8821378-Replace Ecm-Slamet Wahyu WDocument4 pagesTSR 007-Trk-Pmj-Terex 60-TR112 - T 8821378-Replace Ecm-Slamet Wahyu WFrigia IsudibyoNo ratings yet

- Chapter 3 SolmanDocument23 pagesChapter 3 SolmanUchayyaNo ratings yet

- DGS 6600 010 Rev 2-48Document1 pageDGS 6600 010 Rev 2-48Mohamed NasifNo ratings yet

- The Economic Cost of The Pandemic: State by StateDocument12 pagesThe Economic Cost of The Pandemic: State by StateHoover Institution100% (1)

- Eurasian Cities: New Realities along the Silk RoadFrom EverandEurasian Cities: New Realities along the Silk RoadRating: 3.5 out of 5 stars3.5/5 (1)

- CTR-12 - FPSO Firenze - Master Equipt Scope List - r.3 - Revision Tracker ReportDocument20 pagesCTR-12 - FPSO Firenze - Master Equipt Scope List - r.3 - Revision Tracker ReportSriNo ratings yet

- Nursing Home Fatalities Update NYSDocument7 pagesNursing Home Fatalities Update NYSExsar MisaelNo ratings yet

- Engineering Data Pack for D, P, & T Series PumpsDocument14 pagesEngineering Data Pack for D, P, & T Series PumpsAlvaro Jose DíazNo ratings yet

- D EHP: Nidec Sankyo Project M-FAN-1 3P4W-380/220VACDocument1 pageD EHP: Nidec Sankyo Project M-FAN-1 3P4W-380/220VACHoang TungNo ratings yet

- Floor Plan Brochures- Urban SerenoDocument23 pagesFloor Plan Brochures- Urban SerenoSuranjan BhattacharyyaNo ratings yet

- D EHP: Nidec Sankyo Project M-AC-3 3P4W-380/220VACDocument1 pageD EHP: Nidec Sankyo Project M-AC-3 3P4W-380/220VACHoang TungNo ratings yet

- Bato-Cogon Pertcpm (Final)Document1 pageBato-Cogon Pertcpm (Final)MANNY CARAJAYNo ratings yet

- 02.M Fan 1 - SLDDocument1 page02.M Fan 1 - SLDhieule2608No ratings yet

- Tank Punch List ItemsDocument8 pagesTank Punch List ItemsDeepu CNo ratings yet

- D EHP: Nidec Sankyo Project P-200-2 3P3W-200VACDocument1 pageD EHP: Nidec Sankyo Project P-200-2 3P3W-200VACHoang TungNo ratings yet

- Engine Flywheel: Power Take-Off Sae Type 1Document6 pagesEngine Flywheel: Power Take-Off Sae Type 1GdadbhhNo ratings yet

- 24 H Hidraulico PDFDocument2 pages24 H Hidraulico PDFRICHARDNo ratings yet

- 1007 Kur PC Pid 1001 - D3Document3 pages1007 Kur PC Pid 1001 - D3Abdul Wajid AliNo ratings yet

- Synergix Scanner Service Manual PDFDocument218 pagesSynergix Scanner Service Manual PDFgabiNo ratings yet

- Detailed drawing of machine process timesDocument2 pagesDetailed drawing of machine process timesAshraf MuhtarNo ratings yet

- Technical Specification - Mangalore Station PipingDocument21 pagesTechnical Specification - Mangalore Station PipingbecpavanNo ratings yet

- Ceccato CSM MAXI 7 5-20 FM Metric Dimesion Drawing EN Brendola 9828083260-01Document1 pageCeccato CSM MAXI 7 5-20 FM Metric Dimesion Drawing EN Brendola 9828083260-01Ioan Emil VostinarNo ratings yet

- CTR-12 - FPSO Firenze - Clarification Report - Ph-1 Presv ItemsDocument3 pagesCTR-12 - FPSO Firenze - Clarification Report - Ph-1 Presv ItemsSri100% (1)

- Air Flow Accumulator Granulator Drum Granulator Hose Ammonia SpargerDocument1 pageAir Flow Accumulator Granulator Drum Granulator Hose Ammonia SpargerBharathiNo ratings yet

- D-200-MAC-GEN-LLP-001 - RevC1 Line List - 24 Oct (After Issued)Document17 pagesD-200-MAC-GEN-LLP-001 - RevC1 Line List - 24 Oct (After Issued)abduhNo ratings yet

- Brochure Air Application Map Fisher en 138202Document1 pageBrochure Air Application Map Fisher en 138202Habib A. IslamNo ratings yet

- Sensor Probe Monitoring Unit: Not in Our Scope of Supply. Front View Without Cover Front View With CoverDocument1 pageSensor Probe Monitoring Unit: Not in Our Scope of Supply. Front View Without Cover Front View With CoverAlexander SolomonNo ratings yet

- CPA 10-20 TM Dimension Drawing EN Pune 9097 5110 92-01Document1 pageCPA 10-20 TM Dimension Drawing EN Pune 9097 5110 92-01youcef alimNo ratings yet

- Esquema Transmissao PDFDocument2 pagesEsquema Transmissao PDFMarco OlivettoNo ratings yet

- Terminal de Contenedores de Callao - Fase 2: Peso Nominal ASTM A615 G60Document1 pageTerminal de Contenedores de Callao - Fase 2: Peso Nominal ASTM A615 G60RCarlos PTNo ratings yet

- Revisions C: AG9 REDRAWN PER ECO-19-005708 BKW SFDocument1 pageRevisions C: AG9 REDRAWN PER ECO-19-005708 BKW SFMarcos MoraisNo ratings yet

- Quality control report summarizes engine testsDocument1 pageQuality control report summarizes engine testsjulio buitragoNo ratings yet

- TGPDocument40 pagesTGPRizal BahteranNo ratings yet

- 10 March 2018 - 15 March 2018Document4 pages10 March 2018 - 15 March 2018Abdul Ahad LoneNo ratings yet

- Branch For Additional Details and Information. Consult With Diebold Installation/ServiceDocument4 pagesBranch For Additional Details and Information. Consult With Diebold Installation/ServiceDNSXNo ratings yet

- WB3241210 DRC STDocument1 pageWB3241210 DRC STImpulsora DemaNo ratings yet

- 1 s2.0 S0016236119323130 MainDocument7 pages1 s2.0 S0016236119323130 Main황의홍No ratings yet

- For Final: IT IsDocument7 pagesFor Final: IT IsbabuNo ratings yet

- Avance DiarioDocument3 pagesAvance DiarioOsvaldo HernandezNo ratings yet

- Caterpillar IPP Product Line Diesel 3516 GensetsDocument28 pagesCaterpillar IPP Product Line Diesel 3516 GensetsDelio DuranNo ratings yet

- Samsung Bloomington r0.9 SchematicsDocument44 pagesSamsung Bloomington r0.9 SchematicsDomingo79No ratings yet

- PM-CLINIC SERVICE INSPECTION SHEET OptimizationDocument9 pagesPM-CLINIC SERVICE INSPECTION SHEET OptimizationNaughty VongNo ratings yet

- SA04C2-03-WP-D-43003-01-1: 3. FJ - Field Joint 4. SJ - Shop JointDocument1 pageSA04C2-03-WP-D-43003-01-1: 3. FJ - Field Joint 4. SJ - Shop JointABAID ULLAHNo ratings yet

- CA-033700-011 - 00a - P&id - Interconnects - Process Waste WaterDocument1 pageCA-033700-011 - 00a - P&id - Interconnects - Process Waste Watermigen0831No ratings yet

- Mv7a Electrical PlanDocument1 pageMv7a Electrical PlanNeil LongnoNo ratings yet

- Detail C - Cable Detail D - Height Detail A - : Routing Powertail/FeederDocument1 pageDetail C - Cable Detail D - Height Detail A - : Routing Powertail/Feedervinod 7No ratings yet

- Worthington - RLR - 800-1900 Infologic-B - Reservoir Secheur - 9828083262-01 - Ed - 01Document1 pageWorthington - RLR - 800-1900 Infologic-B - Reservoir Secheur - 9828083262-01 - Ed - 01Abdoul-latif HammaNo ratings yet

- Magnet MTN W Hinge & FrameDocument1 pageMagnet MTN W Hinge & FrameChirdeNo ratings yet

- Welding Procedure For BOXNR Wagon (WPS)Document8 pagesWelding Procedure For BOXNR Wagon (WPS)Shekher NikhilNo ratings yet

- PZV Pressurerelief ValveDocument3 pagesPZV Pressurerelief Valvepraveenice23No ratings yet

- Standard Pengukuran Pressure - Presure Komponen D65P-12Document1 pageStandard Pengukuran Pressure - Presure Komponen D65P-12Oktoviandi AlexandroNo ratings yet

- Report 1Document1 pageReport 1julio buitragoNo ratings yet

- 301-239.1 - Difusores de Succion BAF-01-02Document3 pages301-239.1 - Difusores de Succion BAF-01-02AINECOL - Ramiro Andres EscobarNo ratings yet

- ALSTOM Property DocumentDocument16 pagesALSTOM Property DocumentAung MyathtetNo ratings yet

- BEA 7608 SMK Hillcrest - ExistingDocument1 pageBEA 7608 SMK Hillcrest - ExistingMuhammad Faiz NasirNo ratings yet

- 7 Colour RGB 24V AC/DC Stack Light ModuleDocument1 page7 Colour RGB 24V AC/DC Stack Light ModuleJavier PerezNo ratings yet

- 44 Button 78820 GorbelDocument1 page44 Button 78820 GorbelJavier PerezNo ratings yet

- EagleBurgmann - AP4-BKTE - E4 - API 682 4th Edition Piping Plans - EN - 30.05.2017Document68 pagesEagleBurgmann - AP4-BKTE - E4 - API 682 4th Edition Piping Plans - EN - 30.05.2017Saqib AminNo ratings yet

- EagleBurgmann - TSA6 Barrier - Buffer Fluid System - ENDocument5 pagesEagleBurgmann - TSA6 Barrier - Buffer Fluid System - ENJavier PerezNo ratings yet

- EagleBurgmann - Cartex ANSI Dual Seals - ENDocument4 pagesEagleBurgmann - Cartex ANSI Dual Seals - ENJavier PerezNo ratings yet

- SellosDocument40 pagesSellosJavier PerezNo ratings yet

- Precise Flow Rate Magnetically Coupled PumpsDocument4 pagesPrecise Flow Rate Magnetically Coupled PumpsDaboiaNo ratings yet

- Tabla de Compatibilidad QuímicaDocument26 pagesTabla de Compatibilidad QuímicaReinaldo UrpinNo ratings yet

- Complete - HelixDocument47 pagesComplete - HelixJavier PerezNo ratings yet

- Kit Instructions - D P & T Series Motor Mate InstructionsDocument1 pageKit Instructions - D P & T Series Motor Mate InstructionsJavier PerezNo ratings yet

- Catalogo IWAKIAIRDocument6 pagesCatalogo IWAKIAIRJavier PerezNo ratings yet

- Seko DosingDocument28 pagesSeko DosingOtavio CarvalhoNo ratings yet

- Strength Based Lean Six Sigma Book FlyerDocument2 pagesStrength Based Lean Six Sigma Book Flyerdsplus7741No ratings yet

- Model Scheme IS CFS Fcfe BS Irr Coc NPV/DCF Development ScheduleDocument11 pagesModel Scheme IS CFS Fcfe BS Irr Coc NPV/DCF Development ScheduleMilind VatsiNo ratings yet

- Admission of A PartnerDocument5 pagesAdmission of A PartnerHigreeve SrudhiNo ratings yet

- The Effect of Geo Cultural Product Attractiveness On Marketing Performance A Conceptual FrameworkDocument6 pagesThe Effect of Geo Cultural Product Attractiveness On Marketing Performance A Conceptual FrameworkVidya HerawatiNo ratings yet

- Bola Bola StoreDocument7 pagesBola Bola StorePeter Andrew G. RegenciaNo ratings yet

- Personal Finance 4th Edition Madura Solutions ManualDocument25 pagesPersonal Finance 4th Edition Madura Solutions ManualElaineStewartrbdt100% (52)

- Process Costing: Article by Rosemarie Kelly, PHD, Fca, MBS, Dip Acc Examiner in Formation 2 Management AccountingDocument6 pagesProcess Costing: Article by Rosemarie Kelly, PHD, Fca, MBS, Dip Acc Examiner in Formation 2 Management AccountingNisir AyinochNo ratings yet

- Jagmeet Singh StatementDocument6 pagesJagmeet Singh StatementBALKAR SINGHNo ratings yet

- Fiveaoneed Ndia India Non Judicial ARDocument18 pagesFiveaoneed Ndia India Non Judicial ARVIJAY PAREEKNo ratings yet

- Dominance of MNCsDocument11 pagesDominance of MNCssuchitaNo ratings yet

- Brother BAS-311E, ELDocument123 pagesBrother BAS-311E, ELAgnaldo VanzuitaNo ratings yet

- Find Question 4Document2 pagesFind Question 4hasgonde123No ratings yet

- ENGlogue 1 TextbookDocument3 pagesENGlogue 1 TextbookDhruvraj Solanki50% (2)

- Salaar FlourDocument71 pagesSalaar FlourZubair TradersNo ratings yet

- 414a-Em - Sst-A Series Eng Manual 3Document102 pages414a-Em - Sst-A Series Eng Manual 3poche1987No ratings yet

- Strictly Confidential: (For Internal and Restricted Use Only)Document27 pagesStrictly Confidential: (For Internal and Restricted Use Only)bhaiyarakeshNo ratings yet

- Tutorial 4 QuestionsDocument3 pagesTutorial 4 QuestionshrfjbjrfrfNo ratings yet

- 4 - Market StructureDocument17 pages4 - Market Structuremonica rajuNo ratings yet

- Chapter 5 - Problem and Application - MicroeconomicDocument4 pagesChapter 5 - Problem and Application - MicroeconomicVu Duc ThinhNo ratings yet

- Code of EthicsDocument2 pagesCode of EthicsHimani sailabNo ratings yet

- 12 Beaker Glass Pyrex 100mlDocument1 page12 Beaker Glass Pyrex 100mlzulfadli zainalNo ratings yet

- Goldin - Economist As DetectiveDocument20 pagesGoldin - Economist As DetectiveNatali Castaneda PreciadoNo ratings yet

- Pfaff Smart 200C Sewing Machine Instruction ManualDocument64 pagesPfaff Smart 200C Sewing Machine Instruction ManualiliiexpugnansNo ratings yet

- ReportTransactionStatement - Do - 1522Document4 pagesReportTransactionStatement - Do - 1522Shaikh Hassan AtikNo ratings yet

- Assignment 1 - QM3345Document10 pagesAssignment 1 - QM3345Châu GiangNo ratings yet

- 18386 Nemtek Security Quick Reference SDocument12 pages18386 Nemtek Security Quick Reference Ssecurytec5No ratings yet

- sss-foreclosed-properties-HAA For Sale As of July 31 2020 PDFDocument18 pagessss-foreclosed-properties-HAA For Sale As of July 31 2020 PDFFrances PaulineNo ratings yet