Professional Documents

Culture Documents

Standard Pengukuran Pressure - Presure Komponen D65P-12

Uploaded by

Oktoviandi AlexandroCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Standard Pengukuran Pressure - Presure Komponen D65P-12

Uploaded by

Oktoviandi AlexandroCopyright:

Available Formats

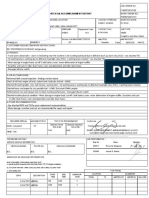

Machine

MCR

UNIT ENGINE ATTACHMENT

Model

D65P-12

Serial No.

63360

Code No.

14-Jan

Model

S6D125E-2

Serial No.

84298

Front

BLADE

Rear

Condition

Customer Name

Machine Location

PT. RMK ENERGY

MUSI 2 SUMSEL

SERVICE METER

At Inspection Daily

Report

INSPECTOR

Name Date

BULLDOZER

21,536 14

D65P-12

ITEM CONDITION UNIT STANDARD ACTUAL CORECTION MADE FINAL ANALISYS

Result

ENGINE

Eng. Low 825 ± 25

Eng. High 2100 ± 50

Engine Speed Rpm

T/C Stall 1770 ± 100

T/C & Hyd. Relief

Blow-by Press. Eng. High mm H2O Max. 50

Lub Oil Press. Eng. Rated Speed Kg/cm² 3-5

Eng. Low Min. 1,5

Boost Press. T/C Stall mm Hg Min 480

Exhaust Gas Temp. Ambient Temp. °C

All Speed Max. 630

TORQUE CONVERTER Serial No

Relief Press. (Inlet) Eng. High 7.5 ± 1.5

Outlet Press. Eng. Low Oil Temp. 40 - 60° C Kg/cm² 2±1

Eng. High 4,5 ± 1

TRANSMISSION

Relief Press. Eng. Low Oil Temp. 40 - 60° C Kg/cm² 34,0 ± 1,0

Eng. High

STEERING

Clutch Press. Eng. Low 25,0 ± 1,0

Eng. High 25,0 ± 1,0

Oil Temp. 40 - 60° C Kg/cm²

Brake Press. Eng. Low 25,0 ± 1,0

Eng. High 25,0 ± 1,0

Brake Performance Apply Brake at Eng. High T/M in F2 No Movement

HYDRAULIC

Relief Press. Eng. High, Oil Temp. 40 - 60° C Kg/cm² 210

PPC Valve Press. Eng. High, Oil Temp. 40 - 60° C 43 ± 3

Blade Lift Speed Raise 1.5 - 2.2

Lower 1,38 - 1,42

Sec.

Ripper Tilt Speed Eng. Low

Eng. High

Hyd. Oil Temp. Engine Stop °C

Hyd. Drift Blade Lift Engine Stop 300 mm From mm / 15 min. Max. 100

Hyd Drift Ripper Lift Ground

UNDER CARRIAGE Terlampir

FINAL DRIVE

Drain Plug Visual Check, Engine Stopped No excessive

Oil Leak Metalic Powder

ELECTRICAL

Electrical Function Fuction Check

OPTIONAL

Attachment & Frame Crack Detection

GENERAL MACHINE CONDITION BASEON VISUAL CHECK

Kondisi Unit Secara Keseluruhan Berdasarkan Hasil Visual Check

Keterangan / Note :

You might also like

- Colorful Chalkboard Classroom Labels and OrganizersFrom EverandColorful Chalkboard Classroom Labels and OrganizersNo ratings yet

- Machine Condition Report PC400-8 MCR: EngineDocument2 pagesMachine Condition Report PC400-8 MCR: EngineZidanNo ratings yet

- Summary Vehicle Health Monitoring System: Model Unit C/N Engine Model S/NDocument3 pagesSummary Vehicle Health Monitoring System: Model Unit C/N Engine Model S/NJokoNo ratings yet

- Machine Condition Report WA 380-3: Data SheetDocument9 pagesMachine Condition Report WA 380-3: Data Sheetnanda adisNo ratings yet

- PPM BHK PC400-8Document5 pagesPPM BHK PC400-8Naura Adreena meccaNo ratings yet

- Machine Condition D85ESS - 2: GroupDocument1 pageMachine Condition D85ESS - 2: GrouplilikNo ratings yet

- 10/01/2020 HK 461535 B29 CEI Cei-Hangar 03 X Quality Control Report No. 20101Document1 page10/01/2020 HK 461535 B29 CEI Cei-Hangar 03 X Quality Control Report No. 20101julio buitragoNo ratings yet

- Report 1Document1 pageReport 1julio buitragoNo ratings yet

- Form PPM S 500 LCVDocument28 pagesForm PPM S 500 LCVandi purnomoNo ratings yet

- Tsr-Sd22e Bd106 TurrbocharrgeDocument2 pagesTsr-Sd22e Bd106 Turrbocharrgedwi supraptoNo ratings yet

- TSR Sd22e Bd108Document3 pagesTSR Sd22e Bd108dwi supraptoNo ratings yet

- Tsr216 DifferentialDocument3 pagesTsr216 Differentialdwi supraptoNo ratings yet

- Final: Equipment Sectional Drawing With Part ListDocument23 pagesFinal: Equipment Sectional Drawing With Part ListInsertec LtdaNo ratings yet

- Report TSRDocument4 pagesReport TSRayu diahNo ratings yet

- supplierBid20Notices1113206120TPT20SLD2020Procure20rail20clamps2020420sets20f 5Document82 pagessupplierBid20Notices1113206120TPT20SLD2020Procure20rail20clamps2020420sets20f 5Dalton HircineNo ratings yet

- DBGVC2314NZ: ModelDocument2 pagesDBGVC2314NZ: ModelMiguel RojasNo ratings yet

- 10 March 2018 - 15 March 2018Document4 pages10 March 2018 - 15 March 2018Abdul Ahad LoneNo ratings yet

- Form MCR PC2000-8Document2 pagesForm MCR PC2000-8Dwi IswantoNo ratings yet

- Datasheet SK8LC-9 STGDocument3 pagesDatasheet SK8LC-9 STGFayez Al-ahmadiNo ratings yet

- Air Flow Accumulator Granulator Drum Granulator Hose Ammonia SpargerDocument1 pageAir Flow Accumulator Granulator Drum Granulator Hose Ammonia SpargerBharathiNo ratings yet

- D and T-Series-masterDocument12 pagesD and T-Series-masterJavier PerezNo ratings yet

- 9686-PO0025-CPP-PL-001 - Honeywell Reply Confirmance For PL 26-Dec-2020 - CPPE ReplyDocument2 pages9686-PO0025-CPP-PL-001 - Honeywell Reply Confirmance For PL 26-Dec-2020 - CPPE ReplyANIL PLAMOOTTILNo ratings yet

- 545 7489 (Eag349) - PfmeaDocument3 pages545 7489 (Eag349) - PfmeaDurai NaiduNo ratings yet

- TSR 007-Trk-Pmj-Terex 60-TR112 - T 8821378-Replace Ecm-Slamet Wahyu WDocument4 pagesTSR 007-Trk-Pmj-Terex 60-TR112 - T 8821378-Replace Ecm-Slamet Wahyu WFrigia IsudibyoNo ratings yet

- QW-QAL-626 - (Rev-00) - Prod. and QC Process Flow Chart - Ventura Motor No. 13 (35804)Document6 pagesQW-QAL-626 - (Rev-00) - Prod. and QC Process Flow Chart - Ventura Motor No. 13 (35804)Toso BatamNo ratings yet

- PP Aaa PP1 124Document19 pagesPP Aaa PP1 124Rabah AmidiNo ratings yet

- Irq 303 2022Document1 pageIrq 303 2022Gumisiriza ChristopherNo ratings yet

- TSR KuDocument16 pagesTSR KuAngsaNo ratings yet

- IT SchematicDocument2 pagesIT SchematicsamanhgsNo ratings yet

- Reporting PPM D155A-6 Baskhara Sinar SaktiDocument9 pagesReporting PPM D155A-6 Baskhara Sinar SaktiCandy 888No ratings yet

- J06 PT PDT 5988 5989 PDFDocument10 pagesJ06 PT PDT 5988 5989 PDFnashittNo ratings yet

- 132-33-15kV WOLAYITA (Old) - Relay Setting CalculationDocument23 pages132-33-15kV WOLAYITA (Old) - Relay Setting CalculationEyasu YemataNo ratings yet

- Abu Hadriyah Summary For Ds-09Document3 pagesAbu Hadriyah Summary For Ds-09mmmNo ratings yet

- PC 200-7 Ex 01 KEDDocument8 pagesPC 200-7 Ex 01 KEDlilikNo ratings yet

- April 2021 Production SheetDocument26 pagesApril 2021 Production SheetPrakash kumarTripathiNo ratings yet

- Machine Condition Report: United Tractors TBKDocument2 pagesMachine Condition Report: United Tractors TBKnanda adisNo ratings yet

- Adobe Scan Mar 28, 2024Document1 pageAdobe Scan Mar 28, 2024surajjaiswal4289No ratings yet

- Daily Weld Production Report: Date ApprovedDocument1 pageDaily Weld Production Report: Date ApprovedYohannan ThomasNo ratings yet

- Analysis Report: Marginal NormalDocument2 pagesAnalysis Report: Marginal NormalJohn Choquemaque MendozaNo ratings yet

- Ismail 3241Document116 pagesIsmail 3241Gold d Roger twoNo ratings yet

- Standard Detail Wall Anchor Clips Saudi ArabiaDocument1 pageStandard Detail Wall Anchor Clips Saudi ArabiaJohn Paul ApostolNo ratings yet

- Pioneer Xr-A550md SMDocument115 pagesPioneer Xr-A550md SMDONNYNo ratings yet

- 220v Vrla Battery Sizing Calc Manasarovar - Rev ADocument17 pages220v Vrla Battery Sizing Calc Manasarovar - Rev ASwagat PradhanNo ratings yet

- Mondeo MY10 - 5Document135 pagesMondeo MY10 - 5t77100% (2)

- 3271007327XX314F3001 As On 280422Document29 pages3271007327XX314F3001 As On 280422Trần Văn HiếuNo ratings yet

- Atac 20331 22Document8 pagesAtac 20331 22parth sapariaNo ratings yet

- 24 H Hidraulico PDFDocument2 pages24 H Hidraulico PDFRICHARDNo ratings yet

- 000 SLT2101318 El DGDocument115 pages000 SLT2101318 El DGjaidikarimNo ratings yet

- Saudi Arabian Oil Company Valve Data Sheet General DataDocument2 pagesSaudi Arabian Oil Company Valve Data Sheet General Datasalihmohammed533No ratings yet

- Ground Floor - Public Address & Voice Evacuation Layout (Sheet 1 of 2)Document1 pageGround Floor - Public Address & Voice Evacuation Layout (Sheet 1 of 2)毕文强No ratings yet

- PC 200-7 Ex 02 KEDDocument8 pagesPC 200-7 Ex 02 KEDlilikNo ratings yet

- Service Dispatch && Accomplishment Report: MAXIMA Machineries IncorporatedDocument2 pagesService Dispatch && Accomplishment Report: MAXIMA Machineries IncorporatedJulie Ann VeyraNo ratings yet

- TSR Info Unit Accident PTSBM Site Muara Lawa (1) 230921 144623Document5 pagesTSR Info Unit Accident PTSBM Site Muara Lawa (1) 230921 144623Ifan saputroNo ratings yet

- Modeldbgfc 635-: Catalog Pagit NoDocument2 pagesModeldbgfc 635-: Catalog Pagit NoMiguel RojasNo ratings yet

- Name of Project:: 2 X 4.4Mw Rudi Khola HepDocument4 pagesName of Project:: 2 X 4.4Mw Rudi Khola HepapsNo ratings yet

- Compactador CB534D Plano HYD 2007 SIS PDFDocument2 pagesCompactador CB534D Plano HYD 2007 SIS PDFFabrizio Jesus Morales SalirrosasNo ratings yet

- EX18195003 - 001-6901-01 Rev 0 OBSDocument2 pagesEX18195003 - 001-6901-01 Rev 0 OBSRichardNo ratings yet

- FORM MASTER DATA MATERIAL 13 Mar 20 EMRDocument2 pagesFORM MASTER DATA MATERIAL 13 Mar 20 EMRM Iqbal AdmanNo ratings yet

- 126 C 2Document9 pages126 C 2AndreaNo ratings yet

- Maintenance Schedule Hilux 2006 2016Document1 pageMaintenance Schedule Hilux 2006 2016Afiq AkhtarNo ratings yet

- 2005 Marzocchi Rebuild ManualDocument59 pages2005 Marzocchi Rebuild ManualConrad LueckeNo ratings yet

- Pilingmaster: Gross Power: 81kW (109hp) Maximum Drilling Depth: 14m (45' 11") Maximum Head Torque: 12500NmDocument20 pagesPilingmaster: Gross Power: 81kW (109hp) Maximum Drilling Depth: 14m (45' 11") Maximum Head Torque: 12500NmSzilárd SNo ratings yet

- Isuzu D Max Owners Manual Combined 12 17myDocument578 pagesIsuzu D Max Owners Manual Combined 12 17myMauricio Gonzalez100% (1)

- Hyster 46 33Document8 pagesHyster 46 33Amit TawteNo ratings yet

- Hyundai AT 1 TextbookDocument15 pagesHyundai AT 1 TextbookMichael IanNo ratings yet

- P112 - 115 WP HinoDocument4 pagesP112 - 115 WP HinoWilmer VasquezNo ratings yet

- New Age Baleno - Ready ReckonerDocument5 pagesNew Age Baleno - Ready ReckonerRhino 2981No ratings yet

- Reference Value: Engine CompartmentDocument2 pagesReference Value: Engine CompartmentmaximchacaNo ratings yet

- 2011 Ford Fusion SE ALL Technical Service Bulletins - Mitchell 1 DIYDocument6 pages2011 Ford Fusion SE ALL Technical Service Bulletins - Mitchell 1 DIYsylvionetoNo ratings yet

- Nissan - 100 NX (B13) - 1.6 PDFDocument2 pagesNissan - 100 NX (B13) - 1.6 PDFRadivoje PesicNo ratings yet

- Scania Trucks Fault Codes PDF - CAN Interface For BodyworkDocument139 pagesScania Trucks Fault Codes PDF - CAN Interface For BodyworkVictor Sampa100% (7)

- Dirt Track Car Setup 13 PagesDocument13 pagesDirt Track Car Setup 13 PagesTeresa Holliday100% (1)

- All New EcoSport Accessory BrochureDocument6 pagesAll New EcoSport Accessory Brochureyoyo2btbNo ratings yet

- Catalogo Del Sensor MafDocument69 pagesCatalogo Del Sensor MafjaimeNo ratings yet

- Aeroad CF SL 8 Disc CANYON USDocument1 pageAeroad CF SL 8 Disc CANYON USJonny WilsonNo ratings yet

- Vahan Info - Check Vehicle RC Status Online - Know Your Vehicle RC - Registration Certificate Status OnlineDocument1 pageVahan Info - Check Vehicle RC Status Online - Know Your Vehicle RC - Registration Certificate Status OnlineAsdfgNo ratings yet

- Beml MachineDocument1 pageBeml MachineKARTHICKRAJ KANDASAMYNo ratings yet

- BRCDocument237 pagesBRCHitachiNo ratings yet

- Trojan Trailer ComponentsDocument44 pagesTrojan Trailer ComponentsMarty DelimaNo ratings yet

- Woodworking Plans Farm Truck ToyDocument11 pagesWoodworking Plans Farm Truck Toyfrankcorbet100% (7)

- Lincoln (Formally The Lincoln Motor Company) Is The LuxuryDocument33 pagesLincoln (Formally The Lincoln Motor Company) Is The LuxuryrobertoNo ratings yet

- Autocar - October 14, 2015Document92 pagesAutocar - October 14, 2015Reka EvaNo ratings yet

- Aprilia RSV4 1100 Factory Data Sheet enDocument2 pagesAprilia RSV4 1100 Factory Data Sheet enFYZ GameNo ratings yet

- Arpit PPT On Automotive TestingDocument16 pagesArpit PPT On Automotive TestingTarakanta BiswalNo ratings yet

- Chandigarh List PDFDocument17 pagesChandigarh List PDFAnonymous ERK3RfOSzaNo ratings yet

- LLR Test General Driving Principles EnglishDocument23 pagesLLR Test General Driving Principles Englishu2mailrahulNo ratings yet

- DBuild PSA TRNAVA C3Citroen 02032024Document32 pagesDBuild PSA TRNAVA C3Citroen 02032024alaaaboalmagd434No ratings yet

- Mercedes-Benz W123 - WikipediaDocument18 pagesMercedes-Benz W123 - WikipediaMohamed HoushNo ratings yet