Professional Documents

Culture Documents

Bioreactor Monitoring, Modeling, and Simulation: Chapter One

Bioreactor Monitoring, Modeling, and Simulation: Chapter One

Uploaded by

Sharanappa AOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bioreactor Monitoring, Modeling, and Simulation: Chapter One

Bioreactor Monitoring, Modeling, and Simulation: Chapter One

Uploaded by

Sharanappa ACopyright:

Available Formats

B I O R E A C T O R S CHAPTER ONE

Bioreactor Monitoring,

Modeling, and Simulation

Christian Julien and William Whitford

M

athematical model–based the difference in control objectives

simulations of actual between the two types of culture. In

bioreactor runs suggest how continuous mode, the objective is to

process variables such as maximize the amount of desired

substrate and product concentrations product per unit time, whereas in

change and how nutrient feeding batch or fed-batch modes the goal is

should be “tuned” with respect to to maximize product at the end of

time, pattern, concentration, and each batch, leading to control

composition to elicit a desired challenges of a different nature.

response. Insights gained from Note that another culture mode is

modeling can guide us in the sometimes used in industrial settings:

adjustment of a process, reducing the perfusion cell culture. Although

number of characterization rounds continuous by design, perfusion

required. Furthermore, comparing NOVARTIS AG (WWW.NOVARTIS.COM)

requires cell retention devices (31–33)

actual experimental results with model that present yet another category of

predictions helps improve the models repressing existing ones in an effort to challenges for dynamic modeling (34).

themselves. It is important to note find a renewed cellular homeostasis. Judging from the limited publication

that outputs can vary in unpredictable The overall effect of the underlying of results so far, this technique is still

ways if processes are simulated outside mechanisms of cellular regulation in its infancy (35).

boundaries set by the models that dictates a nonlinear behavior in cell Some unstructured models have

describe them, especially if the true culture processes. been developed for fed-batch

operating ranges of actual processes The prevalence of fed-batch or microbial (36–39) and mammalian cell

are inadequately captured (58). repeated fed-batch operation in most culture (40–43) processes that model

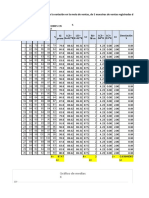

Figure 3 lists bioreactor operational commercial cell culture manufacturing cell growth, substrate consumption,

modes used in bioproduction, which processes means that most producers and product formation. Some describe

are prerequisite to appreciating the are operating not only in an absence of the use of (artificial) neural networks

differences in modeling approaches. the true steady state, but also under (NN) and fuzzy logic (FL). Those

The modeling of cellular productivity conditions in which many individual latter so-called “expert” systems (44–

in bioreactors presents a formidable processes follow multiple, divergent 56) are introducing intriguing

challenge because of many inherent trajectories through the operational possibilities.

high-degree nonlinearities (especially cycle. This adds to the complexity of Furthermore, reliable sensor

in batch and fed-batch culture modes), modeling such operations. Early technologies are seldom found that

which are ultimately related to the modeling experiences from industrial can provide real-time assessment of

complexities of living cells and the microbial culture processes (22) are of many intra- and extracellular

dynamics of in vitro culture. In rather limited and merely conceptual activities. Those currently available

response to changes in their culture modeling value for our fed-batch tend to suffer from high complexity,

environment, and driven by their processes. They are predominantly insufficient accuracy, risk of

genetic information, living cells alter operated in the “steady state” contamination, or insufficient

the rate of their biochemical reactions continuous mode (23–30) and rely on robustness altogether, which makes

(or the nature of those reactions) by, the optimization of steady-state inherently dynamic process states very

e.g., inducing new enzymes while culture conditions. That comes from difficult to characterize.

10 BioProcess International JANUARY 2007 SUPPLEMENT

Figure 3: Classification of bioreactor operational modes — batch culture is the only closed culture FOUNDATIONS IN BIOREACTOR

mode. Fed-batch, continuous, and perfusion culture are semicontinuous or continuous modes of

operation as compared with repeated batch and medium exchange, which are discrete culture

PROCESS MODELING

modes of operation. Figure 4 (next page) depicts a

nonexhaustive classification of model

����� ��������� ���������� ���������

forms useful in bioreactor modeling and

simulation.

Qualitative Models and Fuzzy Logic: A

qualitative model often can be

formulated even when the course of a

culture process is not amenable to

mathematical modeling. For example,

discontinuities (e.g., induction steps that

��������������������� ������������������ ����������������� �������������� require a culture to be operated at

��������������������� ������������������ ���������������������� ����������������� abruptly changing operating regions or

���������������� ��������������� ���������������� ����������������� discrete time and volume changes) occur

��������������������� ���������������������� ������������������� �������������������

���������������������� ����������������� ������������������� ���������������� during medium exchange in repeated-

����������������� ��������������������� ��������������������� ����������������� batch culture. The simplest form is the

���������������������� ��������������� ������������������ “rule-based” model that makes use of “IF–

����������� ��������������� �����������������������

����������������������� AND–THEN–ELSE” language to describe

� ������������������������� process behavior. Such rules are often

�������������� elicited from human experts (skilled

operators). For example, rather than

attempting to model feed requirements

mathematically, terms are used such as “IF

� glucose level is too low AND cellular

oxygen uptake rate is high THEN add

glucose ELSE do not add glucose.”

����� ������� ����� �������

“Fuzzy logic” (FL) is intended to rectify

�����������������������������������������������������������������������������������������������

���������������������������������������������������������������������������������������������� disadvantages in purely rule-based

������������������������������������������������������������������������������������������������ models by invoking some form of

������������������������� algebra to enhance accuracy. In

particular, popular FL algorithms

��������������� combine algebra with linguistics to

facilitate descriptions of complex

systems and cope effectively with

� process uncertainty. Fuzzy reasoning

incorporates real-world system

knowledge into a model and uses sets

����� ��������������� ����� ������� of “partial membership,” instead of

traditional data sets. Those are then

���������������������������������������������������������������������������������������������

���������������������������������������������������������������������������������������������������� qualified as true or false depending on

��������������������������������������������������������������������������������������� whether each element is or is not

��������������������������������������������������������������������������������������������������

�������������������������������������� included in a particular data set.

Mechanistic Models: Among the most

commonly used are mechanistic models

Despite all those difficulties, conditions. Readers unfamiliar with derived from fundamental physics,

process modeling has gained the nonlinear modeling classification chemistry, and biology governing a

enormous popularity among and its techniques can refer to the process. Equations describing process

bioprocessors because it so facilitates “Foundations in Bioreactor Process conditions are developed from two

process optimization. That holds the Modeling” box. basic sources: metabolite and

recombinant product level values from

promise of affecting quite an array of Process modeling is both a science

actual bioreactor experiments

production characteristics, including and an art because a good dose of

(heuristic); or the more theoretical

increasing product quality and creativity is required to make mass/energy conservation balances and

reducing manufacturing cost (57), risk, assumptions for a computationally kinetics of metabolic reactions

and time. In meeting such objectives, simple yet predictive model. Modeling (deterministic). A set of nonlinear

valuable process models must capture inherently involves a compromise ordinary differential equations (ODE)

the dynamic, multivariate, and between accuracy (complexity) and the and/or partial differential equations

nonlinear information that enables cost and effort involved in developing (PDE) with related algebraic equations

prediction of process trajectories and a model. Even after having are compiled to produce mathematical

helps us deal effectively with the determined the boundaries and models that simulate real systems.

consequences of changing process load validating a model, preferably with continued

SUPPLEMENT JANUARY 2007 BioProcess International 11

FOUNDATIONS IN BIOREACTOR Figure 4: Classification of nonlinear model forms used in bioreactor modeling

PROCESS MODELING, CONTINUED ���������

������

ODEs refer to lumped parameters and

are used to describe behavior in one

dimension (normally time), whereas

PDEs refer to distributed parameters and

����������� ������������ �����������

account for spatial differences (e.g.,

substrate gradients in large bioreactors).

A distributed parameter model can be

considered as unstructured and

segregated because, although it �����������

������� ����������� ��������� ����������� ������������� �����������

accounts for spatial differences within a �������������

bioreactor, it is still governed by the

same unstructured model equations

������ ���������

that describe what an entire �����������

��������

subpopulation does in that particular ���������

area. Although distributed parameter

models are more complex and more

difficult to develop and solve, their Figure 5: Common architecture of a feed-forward neural network showing highly interconnected

nodes akin to the vast network of neurons in a human brain and consisting of three groups of

significance is amplified in large

layers: four input units connected to one output unit through five hidden units

bioreactors where, e.g., mixing kinetics

and times may become critical to ������������ ������������� ������������

successful bioreactor operation.

“Black Box” Models and Neural

Networks (Expert Systems): The terms Input 1

black box and empirical models simply

describe the functional relationships

between system inputs and system

outputs. The algorithm parameters Input 2

involved do not necessarily have any

physical meaning in terms of Output

equivalence to actual process variables, Input 3

which present an obvious limitation.

However, they can often accurately

model process trajectories.

Neural networks (NN) are particularly Input 4

suited to modeling complex nonlinear

processes. Whereas conventional

computerized approaches solve control

problems based on algorithms using a

reliable experimental data sets, those line data from process variables) or to

cognitive computational approach (the

algorithm to the problem must be who develop and apply such models handle data sets that may be corrupted

understood a priori, or the computer will appreciate the adage, “All models by noise or missing data points

cannot solve it), neural networks take a are wrong, but some are useful.” altogether. Although neural networks

completely different approach. They are Modern Software Tools: Although are noise tolerant, it is accepted that

composed of a large number of highly process modeling and simulation tools the best approach for analysis is to

interconnected processing units have been available for many years, the identify and remove outlying data

working in parallel, a concept originally first such software products dedicated points (either discarding such data or

inspired by the way the human brain for bioprocessing showed up in the converting outliers into missing

processes information (Figure 5). Here, mid-1990s. Today, several values) by using statistical tools.

the number of component input and

commercially available programs,

output “nodes” used is determined by

often using enhanced graphic features SCALE-DOWN MODELING

the nature of a process modeling

problem being tackled along with the and ranging from dedicated packages Mathematically based simulations

input data representation and the form to fully integrated suites, even include have much value in process design,

of the required output. advanced NN and FL technologies optimization, and operation, but much

(Table 4). Many process simulation original data must still be obtained in

continued software packages also incorporate real-world experimentation. Because

data mining and analysis features doing so in actual production

either to find underlying relevant environments is too expensive and

relationships within culture data time-consuming, it is often

matrices (featuring both on- and off- accomplished in scale-down

12 BioProcess International JANUARY 2007 SUPPLEMENT

FOUNDATIONS IN BIOREACTOR PROCESS MODELING, CONTINUED

bioreactors (2–5 L) that imitate the

conditions of full-scale production Neural networks deploy “hidden” units to stacked neural networks. A dynamic

reactors (≥1,000 L). A first principle conceptualize model parameters that are neural network (DNN) adapts the static

in scale-down design is that often the not directly accessible, which explains the feed-forward network concept by using

best small-scale conditions must be “black-box” nature of the model. The past process inputs and outputs to predict

sacrificed in favor of approximating activity of each hidden unit and output currently appropriate process outputs.

those that actually can be achieved in unit is determined by both the activities Because the number of process variables

of the previous layer and the weighting

a large-scale system. Development of and data are often limited, neuro-fuzzy

of the interconnections. Those networks combine fuzzy logic and neural

scale-down bioreactor models requires

interconnections determine whether it is network technology allowing “expert

evaluating two distinct sets of possible for one unit to influence others, rules” to be added to data sets for

parameters: bioreactor design criteria and scalar weights specify the strength of improving overall model robustness. That

(design parameters) and actual culture such influence. can be very useful in bioreactor processes

operating parameters (process Because neural networks cannot be where controlled variables are often

variables). programmed, they must be “taught” to restricted to a limited range for design

Unfortunately, no (stirred-tank) perform each particular task by presenting reasons (e.g., minimum or maximum

bioreactor scale-down design criteria the network with training examples using achievable feed rates) or safety reasons

are universally applicable. Not all historical process data obtained from (e.g., maximum allowable liquid volume

design parameters can be maintained previous culture runs. Such examples height, vessel pressure, and so on).

as identical between large and small consist of a pattern of activities for the Capturing real-life experiences from

scales: e.g., volumetric oxygen transfer input units together with a desired pattern skilled operators (expert knowledge) for a

coefficient (K La), shear rate (a of activities for the output units. To reduce problem domain augmented with a fair

the error between desired and actual dose of common sense can compensate

function of the impeller tip speed),

outputs, the scalar weight of each for sparse and noisy data, often resulting

and impeller pumping capacity (or

connection is adjusted using, for example, in a faster learning phase. Stacked neural

flow). A scale-down model using a the popular back propagation algorithm. networks have been proposed to further

culture vessel of geometrically similar Neural networks “learn” by example similar enhance model accuracy and robustness

scale can be based on to the way biological systems learn by by aggregating several different

• equal gassed power input per adjusting the inhibition and excitation networks, the output of which are

volume effectiveness of synaptic connections determined by weighing each individual

• equal K La between neurons. Because the network network output against the others for a

• equal shear rate discovers how to solve a problem by itself, final consensus.

• equal mixing time its operation can be unpredictable. Statistical Models: A statistical approach

• or a combination of oxygen However, an appropriately trained neural is often required because of uncertainties

network can be thought of as an “expert”

transfer rate (OTR), shear rate, and surrounding some process variables.

capable of analyzing data and making According to some, this is the only true

mixing parameters.

estimations of process values. measure of process uncertainty

That final option recognizes that

The most commonly used NN (compared with fuzzy reasoning).

two or more parameters may be of

architectures for process modeling and Probabilistic models are characterized by

comparable importance, e.g., shear

control are the feed-forward neural probability density functions of the

rate and oxygen transfer rate (itself a network (which allows signals to travel process variables involved, with normal

function of K La and dissolved oxygen from input to output only) and the distribution being the most commonly

concentration). Conservation of the recurrent network (which can have used. Correlation models quantify the

hydrodynamic behavior between scale- signals traveling in both directions by degree of similarity between two

down and production reactors has introducing loops with an implied variables by monitoring their variations.

been a concern for some time, but it is temporal dependence). One difficulty System dynamics are not captured by

much more attainable now than ever with recurrent networks is determination statistical methods per se, but they play

before with the use of an up-and- of the best network architecture with an important role in data mining and

coming technique known as respect to the number of hidden units. analysis, data compression, principal

component analysis (PCA), and statistical

computational fluid dynamics (CFD) Other proposed advanced network

architectures include dynamic, fuzzy, and process control (SPC).

(59, 60). CFD software packages (e.g.,

www.fluent.com, www.cd-adapco.

com) illustrate and calculate velocity Bioreactors include many miniaturizing such accessories. So for

profiles within culture fluid (across a accessories (e.g., spargers, probes, and scale-down models using conventional

reactor). They are very effective in dip tubes) that are added to the basic stirred-tank technology, the smallest

assessing mixing characteristics (shear vessel structure. But their overall practical volume is about a liter. The

rate, shear stress, and mixing time), influence upon hydrodynamic first step is always identifying critical

gas hold-up, gas dispersion, mass behavior appears inconsequential for design parameters that will provide

transfer, and even nutrient addition large-scale units. That may not be so, acceptable criteria upon scale-down.

gradients. however, for small-scale bioreactor For a proposed scale-down

models because of limitations in bioreactor model to meaningfully

14 BioProcess International JANUARY 2007 SUPPLEMENT

Table 4: A nonexhaustive list of commercially available software for data mining and analysis, bioreactor process modeling and simulation, and beyond

Software Technology Applications Reference

Aspen One Genetic algorithm, hybrid neural Comprehensive suite for process industries; www.aspentech.com

network, fuzzy logic and linearized recipe-based process modeling, analysis,

rigorous models simulation, inferential sensors, scale-up, and

optimization

dataEngine Statistical methods combined with Data analysis and soft computing for process www.mitgmbh.de

neural network and fuzzy logic industries; integrates into LabView brand or

other existing control systems

Desire/Neunet Neural networks and fuzzy logic Interactive modeling and simulation of http://members.aol.com/

dynamic systems gatmkorn

G2 NeuOn-Line Neural network Comprehensive suite for process industries www.gensym.com

(data mining, modeling, sensor evaluation,

prediction, optimization and control)

Lucullus Neural fuzzy network Simulation and modeling as part of a process www.biospectra.ch

information management system

Neuframe Neural network and fuzzy logic Simulation and process control with expert www.neusciences.com

rules

Neunet Pro Neural network Data mining, modeling and prediction www.cormactech.com

NeuroGenetic Optimzer Neural network Older well established data modeling tool www.bio-comp.com

NeuroModel GenOpt Neural network and genetic Data mining, modeling, plant and process www.atlan-tec.com

algorithms analysis, simulation and optimization

NeuroSolutions Neural network, fuzzy logic, and Various neural networks for data mining and www.nd.com

genetic algorithms modeling

Matlab and Simulink Model-based design for physical Popular multipurpose platform for simulation www.mathworks.com

system behavior and control with particular appeal to

engineers.

Statistica Statistical process control Data mining, process monitoring, predictive www.statsoft.com

combined with neural network, modeling, and visualization

and clustering algorithms

SuperPro Designer Material and energy balances with Integrated platform for process development, www.intelligen.com

comprehensive resource database manufacturing process modeling, equipment

sizing, evaluation, scheduling, economics and

optimization

Viscovery SOMine Self organizing maps, clustering Data mining, modeling, analysis and www.eudaptics.de

techniques, and correlation visualization

compensation

represent performance for a particular homogenous bioreactor, without gas- There is a continuing desire to

large-scale culture process, a liquid diffusion limitations. Poor decrease culture volumes (and

systematic validation study must be mixing can lead to substrate and pH consequently culture populations) to

conducted. Key process variables need gradients, which are in some cases maximize throughput for cell-line

to be identified, e.g., mixing, amplified by addition of concentrated screening, media optimization, and

temperature, pH, dissolved oxygen nutrients and reagents at the liquid process development in fully

(DO) and dissolved carbon dioxide surface. Inadequate mixing also controlled “miniature” bioreactor

(DCO2). Their relationships with promotes DO fluctuations because of systems (<100 mL) with conservation

bioreactor performance (such as cell gas–liquid transfer limitations. Those of full predictive model power for

density and viability, product quality phenomena were first described in scaled bioreactors. That has spurred

and yield, substrate feeding, and waste large-scale production reactors used in significant research activities in both

product accumulation) must be industrial microbiology settings (61) industry and academia (65–68). Such

understood through comparisons with where broth rheology is often non- efforts are likely to challenge the

profiles from the large-scale process. Newtonian — but they may also apply boundaries of our understanding of

Those relationships are then to ultrahigh-density animal cell cellular microenvironments —

characterized as fully as possible and culture systems. In such cases, especially with the advent of future

the operating ranges for their multicompartment model systems miniaturization down to the “micro”

respective variables determined. (e.g., a stirred-tank reactor integrated level (<1 mL), which will probably

Particular scale-down modeling with a plug flow reactor) have been require entirely new approaches to

challenges arise when the assumption proposed to model and account for modeling and validation.

no longer holds true of a well-mixed spatial fluctuations (62–64).

16 BioProcess International JANUARY 2007 SUPPLEMENT

REFERENCES 38 Kristensen NR, Madsen H, Jorgensen 55 Patnail PR. Neural Control of an

22 Rani KY, Rao R. Control of SB. A Method for Systematic Improvements of Imperfectly Mixed Fed-Batch Bioreactor for

Fermentors: A Review. Bioprocess. Biosyst. Eng. Stochastic Grey-Box Models. Comput. Chem. Recombinant ß-Galactosidase. Biochem. Eng. J.

21(1) 1999: 77–88. Eng. 28(8) 2004: 1431–1449. 3(2) 1999: 113–120.

23 Jyothi SN, Chidambarum M. Nonlinear 39 Rodrigues JAD, Toledo ECV, Tilho 56 Duan S, et al. An On-line Adaptive

Feedforward Control of Bioreactors with Input RM. A Tuned Approach of the Predictive- Control Based on DO/pH Measurements and

Multiplicities. Bioprocess. Biosyst. Eng. 24(2) Adaptive GPC Controller Applied to Fed-Batch ANN Pattern Recognition Model for Fed-Batch

2001: 123–129. Bioreactor Using Complete Factorial Design. Cultivation. Biochem. Eng. J. 30(1) 2006: 88–96.

Comput. Chem. Eng. 26(10) 2002: 1493–1500. 57 Lübbert A, Jørgensen SB. Bioreactor

24 Wu W, Chang H-Y. Nonlinear PI

Controllers for Continuous Bioreactors Using 40 Lee J-H, et al. Optimization of Feed Rate Performance: A More Scientific Approach for

Population Balance Models. Bioprocess. Biosyst. Profile for the Monoclonal Antibody Production. Practice. J. Biotechnol. 85(2) 2001: 187–212.

Eng. 28(1) 2005: 63–70. Bioprocess Biosyst. Eng. 20(2) 1999: 137–146. 58 Ramaswamy S, Cutright TJ, Qammar

25 Wu W., Huang M-Y. Output 41 Namjoshi AA, Hu W-S, Ramkrishna D. HK. Control of a Continuous Bioreactor Using

Regulation of a Class of Unstructured Models Unveiling Steady-State Multiplicity in Model Predictive Control. Process Biochem.

of Continuous Bioreactors: Steady-State Hybridoma Cultures: The Cybernetic 40(8) 2005: 2763–2770.

Approaches. Bioprocess. Biosyst. Eng. 25(5) Approach. Biotechnol. Bioeng. 81(1) 2003: 80–91. 59 Bezzo F, Macchietto S, Pantelides CC.

2005: 323–329. 42 Xie L, Wang DIC. High Cell Density General Hybrid Multizonal/CFD Approach

26 Radhakrishnan TK, Sundaram S, and High Monoclonal Antibody Production for Bioreactor Modeling. AIChE J. 49(8) 2004:

Chidambaram M. Non-Linear Control of through Medium Design and Rational Control 2133–2148.

Continuous Bioreactors. Bioprocess. Biosyst. Eng. in a Bioreactor. Biotechnol. Bioeng. 51(6) 1996: 60 Davidson KM, et al. Using

20(2) 2005: 173–178. 725–729. Computational Fluid Dynamics Software to

27 Satishkumar B, Chidambaram M. 43 Xie L, Wang DIC. Material Balance Estimate Circulation Time Distributions in

Control of Unstable Bioreactor Using Fuzzy Studies on Animal Cell Metabolism Using a Bioreactors. Biotechnol. Prog. 19(5) 2003: 1480–

Tuned PI Controller. Bioprocess. Biosyst. Eng. Stoichiometrically Based Reaction Network. 1486.

20(2) 2005: 127–132. Biotechnol. Bioeng. 52(5) 1996: 579–590. 61 Larsson G, et al. Substrate Gradients in

28 Reddy GP, Chidambaram M. 44 Muralikrishnan G, Chidambaram M. Bioreactors: Origin and Consequences.

Nonlinear Control of Bioreactors with Control of Bioreactors Using a Neural Network Bioprocess. Biosyst. Eng. 14(6) 1996: 281–289.

Multiplicities. Bioprocess. Biosyst. Eng. 11(3) Model. Bioprocess. Biosyst. Eng. 12(1–2) 1995: 62 Amanullah A, et al. Scale-Down Model

1994: 97–100. 35–39. to Simulate Spatial pH Variations in Large-

29 Sauvaire P, Mellichamp DA, Agrawal 45 Srinivas M, Chidambaram M. Fuzzy Scale Bioreactors. Biotechnol. Bioeng. 73(5)

P. Nonlinear Adaptive Optimization of Logic Control of an Unstable Bioreactor. 2001: 390–399.

Biomass Productivity in Continuous Bioprocess. Biosyst. Eng. 12(3) 1995: 135–139. 63 Bylund F, et al. Scale-Down of

Bioreactors. Bioprocess. Biosyst. Eng. 7(3) 1991: 46 Chtourou M, et al. Control of a Recombinant Protein Production: A

101–114. Bioreactor Using a Neural Network. Bioprocess. Comparative Study of Scaling Performance.

30 Martens DE, et al. A Combined Cell- Biosyst. Eng. 8(5–6) 1993: 251–254. Bioprocess. Biosyst. Eng. 20(5) 1999: 377–389.

Cycle and Metabolic Model for the Growth of 47 Karim MN, et al. Global and Local 64 George S, Larsson G, Enfors S-O. A

Hybridoma Cells in Steady-State Continuous Neural Network Models in Biotechnology: Scale-Down Two-Compartment Reactor with

Culture. Biotechnol. Bioeng. 48(1) 1995: 49–65. Applications to Different Cultivation Controlled Substrate Oscillations: Metabolic

31 Castilho LR, Medronho RA. Cell Processes. J. Ferment. Bioeng. 83(1) 1997: 1–11. Response of Saccharomyces cerevisiae. Bioprocess.

Retention Devices for Suspended-Cell 48 Oysal Y, Becerikli Y, Konar AF. Biosyst. Eng. 9(6) 1993: 249–257.

Perfusion Cultures. Adv. Biochem. Eng./ Modified Descend Curvature Based Fixed 65 Vallejos JR, et al. Optical Analysis of

Biotechnol. 74, 2002: 129–169. from Fuzzy Optimal Control of Nonlinear Liquid Mixing in a Minibioreactor. Biotechnol.

32 Woodside SM, Bowen BD, Piret JM. Dynamical Systems. Comput. Chem. Eng. 30(5) Bioeng. 93(5) 2006: 906–911.

Mammalian Cell Retention Devices for Stirred 2006: 878–888. 66 Zanzotto A, et al. In Situ Measurement

Perfusion Bioreactors. Cytotechnol. 28(1–3) 49 Oliveira R. Combining First Principles of Bioluminescence and Fluorescence in an

1998: 163–175. Modelling and Artificial Neural Networks: A Integrated Microbioreactor. Biotechnol. Bioeng.

33 Volsard D, et al. Potential of Cell General Framework. Comput. Chem. Eng. 28(5) 93(1) 2006: 40–47.

Retention Techniques for Large-Scale High- 2004: 755–766. 67 Kumar S, Wittman C, Heinle E.

Density Perfusion Culture of Suspended 50 Tholudur A, Ramirez WF. Review: Minibioreactors. Biotechnol. Lett. 26(1)

Mammalian Cells. Biotechnol. Bioeng. 82(7) Optimization of Fed-Batch Bioreactors Using 2004: 1–10.

2003: 751–765. Neural Network Parameter Function Models. 68 Betts JI, Doig SD, Baganz F.

34 LaPorte TK, et al. Long Term Shear Biotechnol. Prog. 12(3) 1996: 302–309. Characterization and Application of a

Effects on a Hybridoma Cell Line By Dynamic 51 Honda H, Kobayashi T. Industrial Miniature 10-mL Stirred-Tank Bioreactor

Perfusion Devices. Bioprocess. Biosyst. Eng. Application of Fuzzy Control in Bioprocesses. Showing Scale-Down Equivalence with a

22(3) 2006: 681–688.

15(1) 1996: 1–7. Adv. Biochem. Eng./Biotechnol. 87, 2004: 151–171. Conventional 7-L Reactor. Biotechnol. Prog.

35 Ozturk SS. Engineering Challenges in 52 Marique T, et al. A General Artificial

High Density Cell Culture Systems. Neural Network for the Modelization of

Cytotechnol. 22(1–3) 1996: 3–15. Culture Kinetics of Different CHO Strains.

36 Zelic B, et al. Modeling of the Pyruvate Cytotechnol. 36(1–3) 2001: 55–60. Christian Julien is a bioprocessing

Production with Escherichia coli in a Fed-Batch 53 Coleman MC, Buck KKS, Block DE. consultant at 340 Paseo Camarillo, Camarillo,

Bioreactor. Bioprocess. Biosyst. Eng. 26(4) 2004: An Integrated Approach to Optimization of CA 93010; 1-908-698-7795, christian.

249–258. Escherichia coli Fermentations Using Historical julien@adelphia.net. William Whitford is

37 Chen L, et al. Modeling and Data. Biotechnol. Bioeng. 84(3) 2003: 274–285. manager of Research and Product

Optimization of Fed-Batch Fermentation 54 Tholudur A, Ramirez WF. Neural- Development at ThermoFisher Scientific, 925

Processes Using Dynamic Neural Networks Network Modeling and Optimization of West 1800 South Logan, UT 84321; 1-435-792-

and Genetic Algorithms. Biochem. Eng. J. 22(1) Induced Foreign Protein Production. AIChE J. 8277, bill.whitford@thermofisher.com.

2004: 51–61. 45(8) 1999: 1660–1670.

SUPPLEMENT JANUARY 2007 BioProcess International 17

You might also like

- INFORS HT White Paper Continuous CultureDocument6 pagesINFORS HT White Paper Continuous CulturebiocloneNo ratings yet

- Lecture Notes-Bioreactor Design and Operation-1Document19 pagesLecture Notes-Bioreactor Design and Operation-1LCtey100% (1)

- History of Industrial Microbiology PDFDocument11 pagesHistory of Industrial Microbiology PDFOni Port43% (7)

- Process Model Comparison and Transferability Across Bioreactor Scales and Modes of Operation For A Mammalian Cell BioprocessDocument11 pagesProcess Model Comparison and Transferability Across Bioreactor Scales and Modes of Operation For A Mammalian Cell BioprocessDeepak Kumar100% (1)

- Fast Automated Reconstruction of Genome-Scale Metabolic Models For Microbial Species and CommunitiesDocument12 pagesFast Automated Reconstruction of Genome-Scale Metabolic Models For Microbial Species and CommunitiesjuangbuenoNo ratings yet

- Developing A Computational Framework To Advance Bioprocess Scale-UpDocument11 pagesDeveloping A Computational Framework To Advance Bioprocess Scale-UpSomesh MishraNo ratings yet

- Metabolomics and Systems Pharmacology: Why and How To Model The Human Metabolic Network For Drug DiscoveryDocument12 pagesMetabolomics and Systems Pharmacology: Why and How To Model The Human Metabolic Network For Drug DiscoveryMeilani Patrecia LimbonganNo ratings yet

- Aquaculture ModelsDocument21 pagesAquaculture ModelsSotelo Moctezuma AndrésNo ratings yet

- LPR 100108610Document40 pagesLPR 100108610Flavia guedesNo ratings yet

- Towards A Widespread Adoption of Metabolic Modeling Tools inDocument5 pagesTowards A Widespread Adoption of Metabolic Modeling Tools inmattschinnNo ratings yet

- Pattern-Oriented Modelling of Plant Architecture A New Approach For Constructing Functional-Structural Plant ModelsDocument10 pagesPattern-Oriented Modelling of Plant Architecture A New Approach For Constructing Functional-Structural Plant ModelsaNo ratings yet

- Harder 1982Document53 pagesHarder 1982daxel123No ratings yet

- Peniakresnowati 2011Document9 pagesPeniakresnowati 2011José Luis García ZamoraNo ratings yet

- Review Madeira 2015Document18 pagesReview Madeira 2015silvarjfNo ratings yet

- μBialSim PDFDocument11 pagesμBialSim PDFMónica Adriana Rodríguez CadenaNo ratings yet

- Concepts and Tools For Predictive Modeling of Microbial DynamicsDocument12 pagesConcepts and Tools For Predictive Modeling of Microbial DynamicsWahyu Mutia RizkiNo ratings yet

- First-Principle Models: Learning ObjectivesDocument39 pagesFirst-Principle Models: Learning ObjectivesSandra Patricia SierraNo ratings yet

- Scale Down Biopharma - EIB 2013 PDFDocument17 pagesScale Down Biopharma - EIB 2013 PDFGeetanjali HubliNo ratings yet

- Models of Biological Pattern Formation: Common Mechanism in Plant and Animal DevelopmentDocument12 pagesModels of Biological Pattern Formation: Common Mechanism in Plant and Animal DevelopmentKevin PinedaNo ratings yet

- Automation Application Note Improving Consistency Cell MaintenanceDocument4 pagesAutomation Application Note Improving Consistency Cell MaintenancehiteshguptaNo ratings yet

- Alrubeai 1999Document1 pageAlrubeai 1999Mehedi HossainNo ratings yet

- Yu2019 Article DesignAndControlOfAPiezoactuatDocument12 pagesYu2019 Article DesignAndControlOfAPiezoactuatAlioune Badara DioufNo ratings yet

- Dynamic Modeling of The Central Carbon Metabolism of Escherichia ColiDocument21 pagesDynamic Modeling of The Central Carbon Metabolism of Escherichia ColiclapatriciasaNo ratings yet

- Biot 201200345Document11 pagesBiot 201200345lakshay raoNo ratings yet

- The Engineering of Spatially Linked Microbial Consortia - Potential and PerspectivesDocument9 pagesThe Engineering of Spatially Linked Microbial Consortia - Potential and PerspectivesRoberto José Haro SevillaNo ratings yet

- The Stabilizing Effect of Inventory in Supply Chains: Operations ResearchDocument13 pagesThe Stabilizing Effect of Inventory in Supply Chains: Operations ResearchEdgar AstorgaNo ratings yet

- Microelectronic Engineering: SciencedirectDocument15 pagesMicroelectronic Engineering: SciencedirectIvana Gadjanski StanićNo ratings yet

- Raman Ch01Document26 pagesRaman Ch01Hrithik BaradiaNo ratings yet

- A Systems-Level Approach For Metabolic Engineering of Yeast Cell FactoriesDocument21 pagesA Systems-Level Approach For Metabolic Engineering of Yeast Cell FactoriesFernando Alexis Gonzales ZubiateNo ratings yet

- Turner (2020)Document37 pagesTurner (2020)Dhara Kusuma WardhaniNo ratings yet

- Micromachines 08 00094Document23 pagesMicromachines 08 00094Letícia CharelliNo ratings yet

- Nature Protocols 2020Document29 pagesNature Protocols 2020gorkhmazabbaszadeNo ratings yet

- 1 s2.0 S1474667016356658 MainDocument6 pages1 s2.0 S1474667016356658 MainFernando Nicolas Ureta GodoyNo ratings yet

- Proceedings - Towards A New Model of Sustainable Production - ManuFuturing - C. R. Boer, F. Jovane, 1996Document6 pagesProceedings - Towards A New Model of Sustainable Production - ManuFuturing - C. R. Boer, F. Jovane, 1996Juliorivera79No ratings yet

- A Methodology For Knowledge Management in Biopharmacuetical ProductionDocument5 pagesA Methodology For Knowledge Management in Biopharmacuetical ProductionNgoc Sang HuynhNo ratings yet

- Kondo Miura - Reaction-Diffusion Model As A Framework For Understanding Biological Pattern FormationDocument6 pagesKondo Miura - Reaction-Diffusion Model As A Framework For Understanding Biological Pattern FormationMinjung KimNo ratings yet

- Tevlek Et Al 2023 Spheroid Engineering in Microfluidic DevicesDocument20 pagesTevlek Et Al 2023 Spheroid Engineering in Microfluidic DevicessebasgoryNo ratings yet

- A Genome-Scale, Constraint-Based Approach To Systems Biology of Human MetabolismDocument6 pagesA Genome-Scale, Constraint-Based Approach To Systems Biology of Human MetabolismPatriciaNo ratings yet

- Comprehensive ModelingDocument4 pagesComprehensive ModelingBababa EkeNo ratings yet

- Discriminating Between Individual-Based Models of Col-Lective Cell Motion in A Benchmark Flow Geometry Using Standardised Spatiotemporal PatternsDocument20 pagesDiscriminating Between Individual-Based Models of Col-Lective Cell Motion in A Benchmark Flow Geometry Using Standardised Spatiotemporal PatternsakhilvarNo ratings yet

- TIBS 2021 - Enablers of Continuous Processing of Biotherapeutic ProductsDocument12 pagesTIBS 2021 - Enablers of Continuous Processing of Biotherapeutic ProductslaasyagudiNo ratings yet

- Hyper-Morphology: Experimentations With Bio-Inspired Design Processes For Adaptive Spatial Re-UseDocument10 pagesHyper-Morphology: Experimentations With Bio-Inspired Design Processes For Adaptive Spatial Re-Use黃智雅No ratings yet

- Multi-Level and Hybrid Modelling Approaches For Systems BiologyDocument7 pagesMulti-Level and Hybrid Modelling Approaches For Systems BiologyComputational and Structural Biotechnology JournalNo ratings yet

- A Framework For Flexible Simulation of Batch PlantDocument9 pagesA Framework For Flexible Simulation of Batch Plantaztechero004No ratings yet

- Rev-Chimene2016 Review AdvancedBioinksFor3DPrintingAMDocument13 pagesRev-Chimene2016 Review AdvancedBioinksFor3DPrintingAMAlejandra CastillaNo ratings yet

- A Periodic Review, Production Planning Model With Uncertain Capacity and Uncertain Demand-Optimality of Extended Myopic PoliciesDocument14 pagesA Periodic Review, Production Planning Model With Uncertain Capacity and Uncertain Demand-Optimality of Extended Myopic PoliciesIsabel Zanella ZancaNo ratings yet

- Computer SimulationDocument31 pagesComputer SimulationShivangi VermaNo ratings yet

- Perfusion Cell Culture ProcessesDocument26 pagesPerfusion Cell Culture ProcessesPosh Arts and CraftsNo ratings yet

- (2022) Machine Learning Techniques To Model A Full-Scale Wastewater Treatment Plant With Biological Nutrient - Zaghloul, AchariDocument18 pages(2022) Machine Learning Techniques To Model A Full-Scale Wastewater Treatment Plant With Biological Nutrient - Zaghloul, Achariabel ciezaNo ratings yet

- Droplet Microfluidics-Enabled High-Throughput Screening For Protein EngineeringDocument21 pagesDroplet Microfluidics-Enabled High-Throughput Screening For Protein EngineeringlwnnrcNo ratings yet

- Morphogenetic Fields in Embryogenesis, Regeneration, and Cancer - Non-Local Control of Complex PatterningDocument41 pagesMorphogenetic Fields in Embryogenesis, Regeneration, and Cancer - Non-Local Control of Complex PatterningritaNo ratings yet

- Automated Bacteria Genera ClassificationDocument11 pagesAutomated Bacteria Genera ClassificationjitendraNo ratings yet

- Synthesis of Biochemical Production Routes: Engng, VolDocument15 pagesSynthesis of Biochemical Production Routes: Engng, VolozoNo ratings yet

- Revue Modelisation LafDocument21 pagesRevue Modelisation LafHarold fotsingNo ratings yet

- Scale Up Scale Down of Microbial BioprocessesDocument3 pagesScale Up Scale Down of Microbial BioprocessesROBERTO JHALVER VEGA PAULINONo ratings yet

- Metabolic Engineering of Saccharomyces CerevisiaeDocument17 pagesMetabolic Engineering of Saccharomyces CerevisiaelukeNo ratings yet

- Control of Batch Processes: D. W. T. RippinDocument11 pagesControl of Batch Processes: D. W. T. RippinJonathan Ferney CastroNo ratings yet

- Modeling Network DynamicsDocument6 pagesModeling Network DynamicsirisNo ratings yet

- (Single Strain) A Protocol For Metabolic ReconstructionDocument57 pages(Single Strain) A Protocol For Metabolic ReconstructionThisis AccforsitesNo ratings yet

- Single Cell Models, Shuler 1999Document4 pagesSingle Cell Models, Shuler 1999Marcelo Martinez CajigasNo ratings yet

- Protocolos de BiofilmesDocument29 pagesProtocolos de BiofilmesAnaRafaelaSilvaNo ratings yet

- Information Text Information Text Information Text: Fish Bone Text Block Fish Bone Text Block Fish Bone Text BlockDocument1 pageInformation Text Information Text Information Text: Fish Bone Text Block Fish Bone Text Block Fish Bone Text BlockAbi Alex VelNo ratings yet

- Graficos X, R, SDocument11 pagesGraficos X, R, SAbi Alex VelNo ratings yet

- Solution Manual Engineering Principles by Pauline M. Doran PDFDocument170 pagesSolution Manual Engineering Principles by Pauline M. Doran PDFAbi Alex VelNo ratings yet

- Humans Human: Health Care Delivery Article StandardsDocument1 pageHumans Human: Health Care Delivery Article StandardsAbi Alex VelNo ratings yet

- MSDS-OHS (Material Safety Data Sheets - OHS) : Subject Coverage File Type FeaturesDocument15 pagesMSDS-OHS (Material Safety Data Sheets - OHS) : Subject Coverage File Type FeaturesAbi Alex VelNo ratings yet

- Process Biochemistry: Xiang Zou, Jing Yang, Xu Tian, Meijing Guo, Zhenghua Li, Yunzheng LiDocument8 pagesProcess Biochemistry: Xiang Zou, Jing Yang, Xu Tian, Meijing Guo, Zhenghua Li, Yunzheng LiSaul OsmarNo ratings yet

- Enabling Butanol Production From Crude Sugarcane Bagasse Hemicellulose PDFDocument6 pagesEnabling Butanol Production From Crude Sugarcane Bagasse Hemicellulose PDFDawson AbigailNo ratings yet

- Cell Culture Bioreactors: DVC FC FC RV DTDocument23 pagesCell Culture Bioreactors: DVC FC FC RV DTcubewormNo ratings yet

- Thermodynamics - Biotech & Bioprocess EngineeringDocument23 pagesThermodynamics - Biotech & Bioprocess EngineeringAaron Tan ShiYiNo ratings yet

- (DASBIO) Chemostat + Recycle - 4Document36 pages(DASBIO) Chemostat + Recycle - 4Ibnu Athoillah NaufalNo ratings yet

- Pack Bed BioreactorsDocument12 pagesPack Bed BioreactorsalirezamdfNo ratings yet

- Design of Robust Fault Detection Scheme For Penicillin Fermentation ProcessDocument6 pagesDesign of Robust Fault Detection Scheme For Penicillin Fermentation ProcessZim411No ratings yet

- Microalgal Mass Culture Systems and Methods PDFDocument2 pagesMicroalgal Mass Culture Systems and Methods PDFAmmar BouzouerNo ratings yet

- Bioplastics-Classification, Production and Their Potential Food ApplicationsDocument13 pagesBioplastics-Classification, Production and Their Potential Food ApplicationsAditya ShrivastavaNo ratings yet

- Fed-Batch Techniques in Microbial ProcessesDocument48 pagesFed-Batch Techniques in Microbial ProcessesRaúl DíazNo ratings yet

- AdvancedFermentationProcesses PDFDocument23 pagesAdvancedFermentationProcesses PDFMujtaba HaseebNo ratings yet

- Complet ProDocument64 pagesComplet ProGabriel AyauNo ratings yet

- M TechsyllabusbeDocument30 pagesM Techsyllabusbeaarya adarsh kumar aryaNo ratings yet

- Bioethanol Production NotesDocument42 pagesBioethanol Production NotesJhanvi SharmaNo ratings yet

- Improvement of Yarrowia Lipolytica Lipase ProductionDocument4 pagesImprovement of Yarrowia Lipolytica Lipase ProductionjuanNo ratings yet

- 1 s2.0 S0141022999001556 MainDocument21 pages1 s2.0 S0141022999001556 MainRenata ScoralickNo ratings yet

- Bioreactor: This Article NeedsDocument41 pagesBioreactor: This Article NeedsUtkarsh MehrotraNo ratings yet

- Modes of FermentationDocument9 pagesModes of FermentationLouellaNo ratings yet

- Illustrative Example: A Blending Process: An Unsteady-State Mass Balance For The Blending SystemDocument23 pagesIllustrative Example: A Blending Process: An Unsteady-State Mass Balance For The Blending Systemsneha_21No ratings yet

- LeeDocument8 pagesLeeKaren DayanaNo ratings yet

- Production of Amino Acids (Glutamate)Document48 pagesProduction of Amino Acids (Glutamate)Shiv SiddhNo ratings yet

- Design of Experiments: There Are Many Books That Address Experimental Design and Present FactoDocument33 pagesDesign of Experiments: There Are Many Books That Address Experimental Design and Present Factorarunr1No ratings yet

- 1,2 Dipropanol From Crude Glycerol PDFDocument7 pages1,2 Dipropanol From Crude Glycerol PDFPablo PaganiNo ratings yet

- Growing E. Coli To High Cell Density-A Historical Perspective On Method DevelopmentDocument13 pagesGrowing E. Coli To High Cell Density-A Historical Perspective On Method DevelopmentHui Zhang0% (1)

- Fed Batch Reactor PDFDocument2 pagesFed Batch Reactor PDFJoshNo ratings yet

- Fed BatchDocument3 pagesFed BatchKrishnadev Madhavan NairNo ratings yet

- Enzymes in The IndustryDocument76 pagesEnzymes in The Industrymarkfliance100% (1)

- Report of Bio ReactorDocument15 pagesReport of Bio ReactorAtif MehfoozNo ratings yet