Professional Documents

Culture Documents

Katalog Heat Carry

Katalog Heat Carry

Uploaded by

t_i_f_ano0 ratings0% found this document useful (0 votes)

5 views8 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

5 views8 pagesKatalog Heat Carry

Katalog Heat Carry

Uploaded by

t_i_f_anoCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 8

BANDO

HEAT CARRY

CONVEYOR BELT

Too hot to convey?

BANDO

HEAT CARRY

No.710 and No.oi3

will

volunteer to do it

for you.

Heat carry conveyor belt is used for

transportation of hot materials. Since

service conditions are different from one

‘ease to another, the causes of damage are

also diversified. The causes of damage to

belts in general are considered mostly

physical, such as wearing or scratching.

However, in the case of heat carry belts,

the damage lies not onlyin physical factors,

but more often in chemical factors, which

result from heat impact. In other words,

the service life of heat carry belts is

determined by the multiple effects two

factors, i.e., wear resistance and heat

resistance.

Characteristics indispensably required for

heat resistant conveyor belt are as follows:

L.Rubber cover and carcass should not

eteriorate duetoheat

2Rubber cover and carcass should

maintain exellent properties, even at

high temperatures.

3.Rubber cover and carcass should

maintain good adhesion to from one

unit even when they are exposed to high

temperatures,

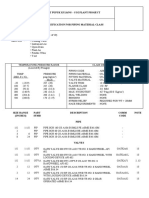

Heat Carry Conveyor Belt No.710

Customer

‘Steel Worke

Specification

800 x87 x6.0x3.0.x270m $T-400

Con:

CCoreying Material Sintered

(0000)

(eprinking at tal en

‘Ton per hour Bove

Speed + 80m/min,

Horizontal Distance : 125m

Vertes Hight im

‘As cooling machine were out of order, thie belt was

used without cooler

Belt life + more than 6 month

Heat Carry Conveyor Belt No.513

Customer

‘Stee! Works

Specification

1000 x ST %7.0.x5.0 x 483m ST.750

Condition

cw ‘Sintered Ore (160-250)

ing Meter

with Sprinker

Ton perhour —:610¥Mnr

Speed 2 85m/min.

Horizontal Distance : 217m

10m (with movable Tripper)

3 years.

‘Vertical Hight

Bele life

Heat Carry Conveyor Belt No.710

Customer

coment Works

Specification

700 «3p x9.6x1.5x185m HV-100

Condition

Carrying Material: Cement Crinker (300-600°C)

with Sprinker at tail end

‘Ton per hour oun

Speed 48m/min.

Horizontal Distenee= 7.0m

Usual Bet life 1-3 month (Butyle Rubber)

HC.710 Bee life 7 month

Bando | Bando Heat Carry No.710 Conveyor Belt composed of eth

applications where a beltisrequired tocarrya very hotload

Heat Carry | Ethylene-propylene type rubber has excellent heat-resistance,

No.710.. ‘and chemical resistance. Bando Heat Carry No.710 Conveyo!

properties by Bando's highly advanced technology that was born

Bando Heat Carry No.710 Conveyor Belt is most sultable for

‘temperature suchas the transportations of:

* Products and return sludge of high temperature inter

* Red heat cement clinker

* Dried Clay

* Chemicals

* Cement products (wear resistance not alwaysrequire

Recommended Application

oaraaa Temperature Range Applicable

Item of olor

Rubber Temp. of material | Temp. of belt

transported, surface c

BandoHeat | ethylene seet 130-400 70-180°C a

CarryNo, 710 Propylene type (180-750° (160-350° F)

Bando| Bando Heat Carry No.S13 Convayor Belt is recommended for

where high wear resistancels required

Heat Carry, 2 %

No.513.

“Bando Heat Carry No.710 & No.513

Conveyor Belt” was born tofulfillthe

afore-mentionedrequirements. Bando Heat Carry No.513 Conveyor Belt consists mainly of SBRt

resistant use. Itcan serve not only for heat resistance but also fo

made of organic material is exposed to high temperature, it und

surface. Bando Heat Carry No.513 cover rubber belongs tothe t

the surface layer to Increase its wear resistance and yet its Ins

evidently shown its special advantage.

This belt displays its excellent property especially when the tem

‘mechanical wear such as by skirt or scraper etc. is very intensive.

Itiswidely used for the applicationsin which wear resistance isp

* sinteredore

Coke

Lime stone

Driedclay

Chemical fertilizers

Recommended Application

Compound ‘Temperature Range Applicable

tem of Color

Rubber Temp. of material | Temp. of belt cE

transported surface (ua

Bando Hest iN s0-100°¢

‘san Black 60-150°C &

Carry No, 513, aces (120.210°F)

‘inthe case of temperature at 150°-400°C (300°-750°F},itisadv

‘The pointistomaintainthe temperature of belt surface betwee!

-propylene rubber is the number-one choice in

ging property, ozone resistance, weather resistance

has been developed to combine these excellent

9 ts long years of experience inthis field.

here high wear-resistance is required under high

e

the belt should be perfectly free from cracks)

oe eee

ae

| care

a

sea ete |e

a alchol)

in the relatively moderate-temperature range and

nthetic rubber, which is commonly applied for heat.

Jr resistance. Generally speaking, when rubber cover

such changes as softening or hardening of the belt

hardening. However, such hardening occurs only on.

eserves the characteristics of elastomer, where is.

ure of belt surface is less than 100° C (220°), while

arly important such as for transportation of:

ar Resistance:

carcass | Belt surface

100-120° ¢

F) | (@20-240°F)

Vinylon

Good or Cracks:

Steel cord

ous to.use the belt, sprinkling water on thebelt.

[00°C. (130°F-220°F)

se

Excellent Wear Resistance

Butyl rubber and other rubbers used for rubber covers undergo

deterioration due to heat or exposure to heat, and thelr wear resistance

generally becomesinferiorunderheat.

Inthe case of Bando Heat Carry No.710 & No.513, however, the rubber

s the least influence of heat among all kinds of synthetic

Consequently its wearing under heat is also small, being practically the

same with that under normal temperature. The figures below indicate

the results of anti-wearing tests conducted on various kinds of heat

resistant rubber under the same test conditions,

(1) In case of temperature of belt surface at 150-160°C (300-320°F)

HENo. 710

=== Buty! Type He

| T

T

Natural rubberbert PHCNo. 513,

Abrasion Loss in Thickness (mm)

f

7 z 3

Running Time (Month)

(2) In case of temperature of belt surface at 60-70°C (140-160? F)

P= tic no. 513

HCNo, 710

Buty! Type HC

‘Natural rubber belt

[Abcasion Loss in Thickness (mm)

1 2 3

Running Time (Month)

———— ee

‘The pictures below indicate the surface condition of rubber cover

of heat resistant conveyor belts which run for 3 months under

the following conditions.

Bando Heat Carry No.710

‘No particular change of the surface condition

temperature of belt surface 150-160°C (300-320°F)

‘temperature of material 350-400°C (660-750°F)

Bando Heat Carry No.513

Although SBR Heat Resistant Rubber compound is normaly

caused cracks on its surface under hot operation, Bando HC

No.S13 shows no particular change in case of the conditions

mentioned below.

temperature of belt surface 70-80°C (160-180°F)

‘temperature of material —_100-200°C.(220-400°F)

Bando Heat Carry No.513

Rubber compound of the belt was hardened, and cracks caused by

hardening of only surface membrane changing from rubber

clastomer to a kind of carbon, which keeps the inside of rubber

cover off from getting heat.

temperature of belt surface 100-120°C (220-240°F)

temperature of material 150-250°C (300-480°F)

Spuceation of

[stm

ears

ware

EENELERDNUTAE CE Aaa)

“S voutee

oo xspxeana xT

Sreunre

a

emer [sser ao]

3

eae

aro

a eK AHH

meedow |= 99-100

sea

Representative Examples of Bando Heat Carry No. 710 Conveyor Belt

Representative Examples of Bando Heat Carry No.513 Conveyor Belt

‘Speceton ofl

Saas arn]

‘i ro)

emake

‘narage ite

teas lit Bie

omngpxaexaa%stn|

vow iin

Weert

|... ss

BANDO

PT. BANDO INDONESIA

Office & Factary.

Jin. Gajah Tunggal Km 7 Tangerang,

Kel Pasir Jaya, Kecamatan Jati Uwung,

Kotamadya Tangerang

Phone = (021) 5903920

(021) 5903937-38

Fax: (021) 5901274-5903037

Marketing Office

Wisma Hayam Wuruk, 6th Floor, Suite 600

Ji Hayam WurukK No. 8

Jakarta 10120 Indonesia

Phone : (021) 3517590 (Hunting)

Fax — : (021) 3517591

E-mail : bandojkt@centrin.net id

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Daily Activity Report 28 Des 2022Document28 pagesDaily Activity Report 28 Des 2022t_i_f_anoNo ratings yet

- Daily Activity Report 30 Nov 2022Document25 pagesDaily Activity Report 30 Nov 2022t_i_f_anoNo ratings yet

- Daily Activity Report 17 Okt 2022Document23 pagesDaily Activity Report 17 Okt 2022t_i_f_anoNo ratings yet

- Daily Activity Report 28 Okt 2022Document27 pagesDaily Activity Report 28 Okt 2022t_i_f_anoNo ratings yet

- Daily Activity Report 29 Sept 2022Document23 pagesDaily Activity Report 29 Sept 2022t_i_f_anoNo ratings yet

- Daily Activity Report 2 Okt 2022Document23 pagesDaily Activity Report 2 Okt 2022t_i_f_anoNo ratings yet

- Daily Activity Report 27 Sept 2022Document25 pagesDaily Activity Report 27 Sept 2022t_i_f_anoNo ratings yet

- Daily Activity Report 5 Okt 2022Document23 pagesDaily Activity Report 5 Okt 2022t_i_f_anoNo ratings yet

- Daily Activity Report 30 Okt 2022Document26 pagesDaily Activity Report 30 Okt 2022t_i_f_anoNo ratings yet

- Daily Report 02 Sept 22Document2 pagesDaily Report 02 Sept 22t_i_f_anoNo ratings yet

- Daily Activity Report 3 Okt 2022Document23 pagesDaily Activity Report 3 Okt 2022t_i_f_anoNo ratings yet

- Daily Report 04 Sept 22Document2 pagesDaily Report 04 Sept 22t_i_f_anoNo ratings yet

- Daily Report 01 Sept 22Document2 pagesDaily Report 01 Sept 22t_i_f_anoNo ratings yet

- Daily Report 05 Sept 2022Document2 pagesDaily Report 05 Sept 2022t_i_f_anoNo ratings yet

- Daily Report 03 Sept 22Document2 pagesDaily Report 03 Sept 22t_i_f_anoNo ratings yet

- Attachment - 1 Reference List N-GEN Omega AirDocument51 pagesAttachment - 1 Reference List N-GEN Omega Airt_i_f_anoNo ratings yet

- Insania Energi COMPANY PROFILEDocument50 pagesInsania Energi COMPANY PROFILEt_i_f_anoNo ratings yet

- Piping Material ClassesDocument42 pagesPiping Material Classest_i_f_anoNo ratings yet

- SMC Production SampleDocument14 pagesSMC Production Samplet_i_f_anoNo ratings yet

- D-ILA Series Heatless Desiccant Dryers 2.7-141.6 m3 - Min, 90-5,000 CFMDocument2 pagesD-ILA Series Heatless Desiccant Dryers 2.7-141.6 m3 - Min, 90-5,000 CFMt_i_f_anoNo ratings yet

- General Brochure - Johnson ControlsDocument4 pagesGeneral Brochure - Johnson Controlst_i_f_anoNo ratings yet

- Tesla Literature BrochureDocument16 pagesTesla Literature Brochuret_i_f_anoNo ratings yet

- Bellmer Group CataloqueDocument20 pagesBellmer Group Cataloquet_i_f_anoNo ratings yet

- 2011 Cat Biomass GBDocument8 pages2011 Cat Biomass GBt_i_f_anoNo ratings yet

- TRAIN AWAY E-Ticket PDFDocument2 pagesTRAIN AWAY E-Ticket PDFt_i_f_anoNo ratings yet