Professional Documents

Culture Documents

Data Sheet Compression Spring:: Spring Test Acc. To DIN ISO 2859/1 Test Level II

Data Sheet Compression Spring:: Spring Test Acc. To DIN ISO 2859/1 Test Level II

Uploaded by

RajeshOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Data Sheet Compression Spring:: Spring Test Acc. To DIN ISO 2859/1 Test Level II

Data Sheet Compression Spring:: Spring Test Acc. To DIN ISO 2859/1 Test Level II

Uploaded by

RajeshCopyright:

Available Formats

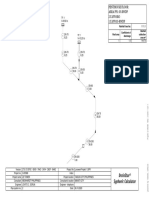

Data sheet Compression spring : D-182

d mm Wire diameter Fn N Maximum force in static use nt pc. Total coils 08.2022

D mm Mean coil diameter Fc N Theoretic maximum force at Lc R N/mm Spring rate

Dd mm Diameter of mandrel L0 mm Length of unstressed spring S mm Pitch (distance between coils)

De mm Outer coil diameter L1 mm Prestressed spring length s1 mm Prestressed spring deflection

Dh mm Diameter of bush L2 mm Loaded spring length s2 mm Loaded spring deflection

e1 mm Perm.dev. perpendicular line Lk mm Buckling length sh mm Maximum stroke in static use

e2 mm Perm.dev. parallel line Ln mm Minimum length in static use sn mm Maximum spring deflection in static use

F1 N Prestressed spring force Lc mm Block length Weight g Weight of one spring in grammes

F2 N Loaded spring force n pc. Aktive coils

Fndyn N Maximum force in dynamic force

Fndtol N (+/-) tolerance of maximum dynamic force

Lndyn mm Minimum length in dynamic use

Dd 14,20 shdyn mm Maximum stroke in dynamic use

e2 * The spring data for the dynamic applications is relevant only

for springs having a shot peened hardened surface !

e1

s1

S

F1

s2 L0

62,00 + 2,04

F2 sh -

+

sn L1

De 17,25 - 0,35 +

Fn 51,95 - 3,08 47,05

D 16,00 L2

Fc

1,25

Ln

Dh 18,50 14,95

d

Form 2: Lc

Spring ends

closed

Form 1:

Spring ends n 5,50 nt R 1,104 Weight 3,657

closed and ground

Spring test acc. to DIN ISO 2859/1 test level II

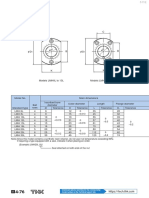

1 Coiling direction 7 Guidance and seat to DIN EN 13906-1 12 Tolerances to DIN EN 15800

mandrel bush Grade De,Di,D L0 F1,F2 e1,e2 Wire

left X right diameter

1 d to

Buckling length Lk at 2 X X X X DIN 2076

2 Dynamic load * 3 X

Fndyn 45,38 v=0,5 / Bild 5 0,00 mm

13 Prouction compensation through

A spring resistance and

Fndtol 3,06 L0

associated length of tensed spring

8 Material

Lndyn 20,90 A spring resistance, associated n, d X

EN 10270-1 length of tensed spring and L0 n, De, Di

shdyn 14,93

Two spring resistances and L0, n, d

9 Wire or rod surface associated lengths of tensed spring L0,n,De,Di

3 Excursion sh mm X drawn rolled metal-cut

14 Setting springs

4 Stress cyc. end. N All springs which show setting tendency because of

10 Springs deburred inside outside their size are pre-set within the production process.

5 Stress cycle frequ. n / 11 Surface treatment shot peened Prices

6 Application temp. °C Quantity scale Single price [EUR]

1 2,6800 €

7 1,6400 €

Remarks

17 0,8300 €

37 0,5200 €

Country of origin: DE | Customs tariff number: 73202081

75 0,3600 €

125 0,3156 €

175 0,2714 €

250 0,2493 €

350 0,2216 €

450 0,1662 €

Gutekunst + Co.KG Spring Factories · Carl-Zeiss-Straße 15 · D-72555 Metzingen

Sales +49 7123 960-192 · Customize springs +49 7123 960-193 · Main +49 7123 960-0

Fax +49 7123 960-195 · E-mail: order@gutekunst-co.com

You might also like

- Face GroovingDocument1 pageFace GroovingWilson DantasNo ratings yet

- Nec Tokin PDFDocument2 pagesNec Tokin PDFAntero RafaelNo ratings yet

- Ds Ah 00658800Document2 pagesDs Ah 00658800acorkeryuNo ratings yet

- LS800E (Multiple Levels Large Size Alloys)Document3 pagesLS800E (Multiple Levels Large Size Alloys)Kj_bdNo ratings yet

- Solenoid Operated Valves: ES-10W-X-Y-Z-05Document1 pageSolenoid Operated Valves: ES-10W-X-Y-Z-05Michał A.No ratings yet

- DS Linear Motors P01-23x80Document24 pagesDS Linear Motors P01-23x80carlos030476No ratings yet

- Inductive Sensor NJ2-12GM40-E2-5M: DimensionsDocument2 pagesInductive Sensor NJ2-12GM40-E2-5M: DimensionsTâm NguyễnNo ratings yet

- API 650 - Using WRC 297 With RepadDocument1 pageAPI 650 - Using WRC 297 With RepadGuochao SongNo ratings yet

- 5 (x2) M X 6 Useful Depth: Solenoid Shown Under VoltageDocument1 page5 (x2) M X 6 Useful Depth: Solenoid Shown Under VoltageIker BasqueAdventureNo ratings yet

- Mur 3020 CTDocument4 pagesMur 3020 CTzainalabdeen81No ratings yet

- Datasheet Mola de Torção 16161RDocument1 pageDatasheet Mola de Torção 16161RBruno SantosNo ratings yet

- NAFSA Serie Ech40 10bm 24vdc 100%Document1 pageNAFSA Serie Ech40 10bm 24vdc 100%Iker BasqueAdventureNo ratings yet

- Appendix F - Lifting Padeye DesignDocument12 pagesAppendix F - Lifting Padeye DesignNguyễn QuânNo ratings yet

- Tension SpringsDocument17 pagesTension SpringsAnonymous w13t9bNo ratings yet

- WK 450 540 Check Valve Type S: DM /min Up To 260 Up To 31,5 Mpa Ns 6 To 30Document4 pagesWK 450 540 Check Valve Type S: DM /min Up To 260 Up To 31,5 Mpa Ns 6 To 30Gizem MuhendislikNo ratings yet

- Penthouse Floor Area PF1 ISO .PDF 06.10.2020Document1 pagePenthouse Floor Area PF1 ISO .PDF 06.10.2020Fed ValdezNo ratings yet

- Drawings: SD 01B08B01-01EDocument4 pagesDrawings: SD 01B08B01-01EAuberNo ratings yet

- MULTIPLEXERDocument1 pageMULTIPLEXERShraavani TopleNo ratings yet

- Mechanical Melt Pressure Gauge: Pt135 Series Pt135 SeriesDocument2 pagesMechanical Melt Pressure Gauge: Pt135 Series Pt135 SeriesSousou SanyNo ratings yet

- Spring CalculationDocument24 pagesSpring Calculationmahaprabhu78100% (1)

- Varistor para Luminarias Cree 20d - 1-3003069Document16 pagesVaristor para Luminarias Cree 20d - 1-3003069Gabriel SanjurNo ratings yet

- N N NM NM MM MM MM MM MMDocument2 pagesN N NM NM MM MM MM MM MMJhon GrandaNo ratings yet

- Shear Reistance Bolts EC3Document2 pagesShear Reistance Bolts EC3David O'MearaNo ratings yet

- Bosh Hand Brake ValveDocument2 pagesBosh Hand Brake ValveosobaxNo ratings yet

- Contact Stress of The Cylinder in The Cylindrical SocketDocument3 pagesContact Stress of The Cylinder in The Cylindrical Socketmet-calcNo ratings yet

- NAFSA Serie Ech40 10bd 24vdc 25%Document1 pageNAFSA Serie Ech40 10bd 24vdc 25%Iker BasqueAdventureNo ratings yet

- SNS2 - Bare Pump DimensionDocument1 pageSNS2 - Bare Pump DimensionChaiporn LimawararatNo ratings yet

- Model LMH-L: Download Data by Searching For The Corresponding Model Number On The Technical Support SiteDocument2 pagesModel LMH-L: Download Data by Searching For The Corresponding Model Number On The Technical Support SitedjhklertyuiNo ratings yet

- Input Data: Project Usan Deep Water Attachment XXXXXX To Calculation Note Ref. Yyyyyyyyy Rev. ZZDocument5 pagesInput Data: Project Usan Deep Water Attachment XXXXXX To Calculation Note Ref. Yyyyyyyyy Rev. ZZcatullusNo ratings yet

- Pier Pile Cap DesignDocument5 pagesPier Pile Cap DesigndulancivilNo ratings yet

- Under Voltage Led FlasherDocument1 pageUnder Voltage Led FlasherJean-Michel MARTINNo ratings yet

- Pad Eye Designwww - Thenavalarch.com Rev B SI UnitsDocument10 pagesPad Eye Designwww - Thenavalarch.com Rev B SI UnitsndesigngmailNo ratings yet

- Powder Brake Mitsubishi ZKG-20YNDocument2 pagesPowder Brake Mitsubishi ZKG-20YNTjhandNo ratings yet

- UNIT-V-E Book - PPCEDocument62 pagesUNIT-V-E Book - PPCEVELMURUGAN MNo ratings yet

- SIGUIL-VETM-F-TEC-AWWA0-001-R1 11/19/2019 - 3:27 PM Page 1 of 1 Form: FRP-AWWA-M45-R3Document1 pageSIGUIL-VETM-F-TEC-AWWA0-001-R1 11/19/2019 - 3:27 PM Page 1 of 1 Form: FRP-AWWA-M45-R3gojiNo ratings yet

- Winters - 1WPS - Pressure SwitchDocument3 pagesWinters - 1WPS - Pressure SwitchJesus PerezNo ratings yet

- Shuttle Valve: LS-13A-X-Y-ZDocument1 pageShuttle Valve: LS-13A-X-Y-ZService - Anda Hydraulics Asia Pte LtdNo ratings yet

- Lindapter Type f3 DatasheetDocument1 pageLindapter Type f3 DatasheetTarun SharmaNo ratings yet

- Design of Gears V1.0Document6 pagesDesign of Gears V1.0Cassandra DunnNo ratings yet

- Inductive Sensor NCB2-12GM35-N0-V1: DimensionsDocument3 pagesInductive Sensor NCB2-12GM35-N0-V1: DimensionsmhaioocNo ratings yet

- Magnetic Field Sensor MB60-12GM50-E2: DimensionsDocument4 pagesMagnetic Field Sensor MB60-12GM50-E2: DimensionsHemant RasamNo ratings yet

- Weld Metal CertificateDocument1 pageWeld Metal CertificatePhương Do QuangNo ratings yet

- Bas 70Document1 pageBas 70Ricardo UrioNo ratings yet

- Column DesignDocument3 pagesColumn DesignvaideehNo ratings yet

- Pure Precision Sure Performance: Precision-Made Hydraulic SealsDocument3 pagesPure Precision Sure Performance: Precision-Made Hydraulic SealshufuentsNo ratings yet

- SoftStart L-TypeDocument19 pagesSoftStart L-TypeSamuel VerdeflorNo ratings yet

- CJ - Cables - Catálogo InglêsDocument34 pagesCJ - Cables - Catálogo InglêsPaulo SergioNo ratings yet

- Hta (Halfen Deha)Document4 pagesHta (Halfen Deha)Anonymous zvQGXzNo ratings yet

- Ac Peak Voltmeter: Assignment 2Document4 pagesAc Peak Voltmeter: Assignment 2Piara SinghNo ratings yet

- TunaTin2 ARRL 35anniversay SchematicDocument1 pageTunaTin2 ARRL 35anniversay Schematicwayan.wandira8122No ratings yet

- 20 - Anchor Bolt PERI 14-20 X 130Document2 pages20 - Anchor Bolt PERI 14-20 X 130Gaetano ScorsoneNo ratings yet

- Design of Tension Members Allowable Stresses (F)Document9 pagesDesign of Tension Members Allowable Stresses (F)Gerd del RosarioNo ratings yet

- RD, 1 RD, 2 RD, 3 RD, 4 RD, 5 RD, 6 RD, 7 RD, 8: Doc. ID-Code Rev. CategoryDocument25 pagesRD, 1 RD, 2 RD, 3 RD, 4 RD, 5 RD, 6 RD, 7 RD, 8: Doc. ID-Code Rev. CategoryHanuman Sharma83% (6)

- Halfen Design PDFDocument5 pagesHalfen Design PDFNitin SharmaNo ratings yet

- CEN TOOL Standard Padeyes V4 Rollup Padeye SheaveDocument5 pagesCEN TOOL Standard Padeyes V4 Rollup Padeye SheaveMarvan100% (1)

- Auto Start Gu320b Cummins Mana 18 PlanoDocument42 pagesAuto Start Gu320b Cummins Mana 18 PlanoGONZALONo ratings yet

- Diode, Transistor & Fet Circuits Manual: Newnes Circuits Manual SeriesFrom EverandDiode, Transistor & Fet Circuits Manual: Newnes Circuits Manual SeriesRating: 4.5 out of 5 stars4.5/5 (7)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsRating: 5 out of 5 stars5/5 (1)

- Cylindrical Compression Helix Springs For Suspension SystemsFrom EverandCylindrical Compression Helix Springs For Suspension SystemsNo ratings yet

- Honeycomb Barrier - New Approach - Shell ModelisationDocument18 pagesHoneycomb Barrier - New Approach - Shell ModelisationKevin ChackochanNo ratings yet

- Datasheet 2R/RXA sg-0 F40 BlackDocument1 pageDatasheet 2R/RXA sg-0 F40 BlackProyectos Trans roll, C.A. OficinaNo ratings yet

- MCQ ChemDocument49 pagesMCQ ChemAnas AlamNo ratings yet

- Chemical Compatibility TableDocument28 pagesChemical Compatibility TableBea LubaoNo ratings yet

- Universal Testing MachineDocument28 pagesUniversal Testing MachineMarc Anthony de VillaNo ratings yet

- Construction of New Terminal Building at Nepalgunj Airport: Block 'A'Document1 pageConstruction of New Terminal Building at Nepalgunj Airport: Block 'A'Subash PoudelNo ratings yet

- Eni Antifreeze Spezial G BX: BenefitsDocument2 pagesEni Antifreeze Spezial G BX: BenefitsPabloNo ratings yet

- PhysRevB 108 014412Document11 pagesPhysRevB 108 014412mdmukadamNo ratings yet

- Desalination of Water - Vapour CompressionDocument1 pageDesalination of Water - Vapour CompressionGorantla Murali KrishnaNo ratings yet

- Laporan Data Dan Stok Office 2000 Keseluruhan (Khusus Stationery)Document90 pagesLaporan Data Dan Stok Office 2000 Keseluruhan (Khusus Stationery)Dina SyaffutriNo ratings yet

- R410A Catalogue: ProductDocument11 pagesR410A Catalogue: ProductMugundan MurugananthamNo ratings yet

- Comparison of Classical Chemical and Electrochemical Processes For Treating Rose Processing WastewaterDocument6 pagesComparison of Classical Chemical and Electrochemical Processes For Treating Rose Processing WastewaterfebyNo ratings yet

- Lecture Notes - Ligand Field Theory Part IDocument36 pagesLecture Notes - Ligand Field Theory Part Ivasut.nakNo ratings yet

- Introduction To PolymersDocument180 pagesIntroduction To PolymersDaffa Talitha Widyadhana WidyadhanaNo ratings yet

- 0007335-Course - Segmented and Perforated Shear WallsDocument15 pages0007335-Course - Segmented and Perforated Shear Wallsmeda012No ratings yet

- BZ01 Aircraft Warning SphereDocument3 pagesBZ01 Aircraft Warning SphereDaniNo ratings yet

- 12th Chemistry 11 Years Pyq (SB) (REFLECTor)Document98 pages12th Chemistry 11 Years Pyq (SB) (REFLECTor)Ansh GoelNo ratings yet

- Publication - Painting, Coating & Corrosion Protection - AkzoNobel - International Paints - Mining and Minerals ApplicationsDocument44 pagesPublication - Painting, Coating & Corrosion Protection - AkzoNobel - International Paints - Mining and Minerals Applicationszinha_alNo ratings yet

- Vehicles and BindersDocument7 pagesVehicles and Bindersberchard100% (1)

- ÜRÜN LİSTESİ - Gakgo Gayrimenkul 2020-2021Document9 pagesÜRÜN LİSTESİ - Gakgo Gayrimenkul 2020-2021sefa ünalNo ratings yet

- CC TPLDocument12 pagesCC TPLHeemanthz Sai Krishna MNo ratings yet

- 04 TabletIngredients PDFDocument18 pages04 TabletIngredients PDFgina inNo ratings yet

- 1 AdsorptionDocument68 pages1 AdsorptionUsman KhanNo ratings yet

- Role of Gypsum in Cement and Its EffectsDocument3 pagesRole of Gypsum in Cement and Its Effectsvenkateswara rao pothinaNo ratings yet

- Group 5 Industrial Waste ManagementDocument30 pagesGroup 5 Industrial Waste Managementjoshuawalters329No ratings yet

- #2 Literasi Bahasa InggrisDocument18 pages#2 Literasi Bahasa InggrisCalesta AlexandraNo ratings yet

- Chem 4Document3 pagesChem 4Lovey ChandiNo ratings yet

- Ultrasonic MicroheatersDocument4 pagesUltrasonic Microheaterskadam_nitsi2046No ratings yet

- SCHDocument6 pagesSCHAmiya Ranjan PaniNo ratings yet

- Jss 6850-22 Requirement of Packaging For InhibitorDocument13 pagesJss 6850-22 Requirement of Packaging For InhibitorMinal ParapannawarNo ratings yet