Professional Documents

Culture Documents

Operating Instructions VTB 2011

Uploaded by

Siva Raman0 ratings0% found this document useful (0 votes)

34 views1 pageVector control

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentVector control

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

34 views1 pageOperating Instructions VTB 2011

Uploaded by

Siva RamanVector control

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

Do Not Drain Boiler or Pull Feedwater Pump Switch while Boiler is Hot

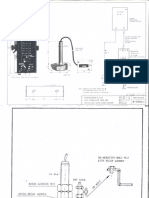

OPERATING & MAINTENANCE INSTRUCTIONS

MODEL VTB ALL SIZES & ALL FUELS

Hang these cards where burner is installed. Also hang where the fuel equipment is located in case of a fire. The contractor installing the

equipment will furnish copies of diagrams showing all of the main oil lines & controlling valves. Hang one copy of this diagram

adjacent to each instruction card.

DAILY PROCEDURE Check valves for proper operations & replace if necessary

1. Blow-down the boiler using bottom blow-off. Blow-down G. Fill the boiler by means of the feedwater pump & reset the

when burner is firing. Burner should shut off at low water low water cut off.

level. Investigate & correct failure to shut off. 2. Clean the fire side of the boiler as follows:

2. Blow-down the water column to the low water cut-off point. A. Remove the bottom rear casing assembly

3. Check level of oil in the storage tank B. Remove the flue baffle & wrapper assembly

4. Check the temperature of the water supplied to the unit. If the C. Brush all surface between the fins & remove soot & scale.

water is below 160ºF, preheat return to not more than 200 ºF. D. Replace flue baffle & wrapper assembly using new gaskets.

WEEKLY PROCEDURE E. Replace the bottom rear casing assembly.

1. Check the combustion control operation as outlined in the check F. Add a few drops of a good grade of light motor oil, No. 10

list section of the service manual. Investigate & correct at once, or 20 S.A.E., to the burner motor.

any failure to shut-off fuel valve. 3. Add a few drops of a good grade of light motor oil, No. 10 or

2. Check the pressure limit shut-down as outlined in the service 20 S.A.E., to the burner motor.

manual check list. During this check, observe the operation of 4. Remove the oil strainer & clean.

the programming control to make sure that the operation is as 5. At the time of this yearly inspection & cleaning, it is

described in the sequence of operation section of this manual. recommended to have the condition of the equipment

3. Wipe clean the entire unit, particularly any operating parts, so checked.

that oil & dust does not accumulate. TO START THE BOILER

4. If water treatment is being used, check water against check list With main power breakers in the “on” position, the water supply

supplied by water treatment company. & fuel supply systems are aligned to support boiler operation, &

5. Never introduce feed water treatment through feed water pump the burner switch is in the “off” position, perform the following

or condensate tank. Treatment should be introduced directly steps.

into the boiler or device located on discharge side of the feed 1. Fill unit with water to the prescribed level.

water pump. 2. Reset low water cut-off switch (on cut-off at top).

MONTLY PROCEDURE 3. If the unit is gas-fired, purge the air from the line.

1. Lift the steam safety valve by the manual lever to make sure it is 4. Check oil pressure on the suction discharge side of the pump.

operating freely. The pressure should remain constant.

5. If the motor does not start, check the limit controls to

SEMI-ANNUAL PROCEDURE determine which control is breaking the control circuit.

1. Cool boiler slowly to room temperature & ensure pressure is 6. When the motor starts, observe the sequence of operation. Be

relieved prior to any attempt to open access openings. sure it is in accordance within those shown in the service

(WARNING: failure to cool boiler slowly will effect life of manual for the installed control system.

the boiler & possibly cause tubes to leak). 7. Check pressure limit controls by actually causing limit to

2. Remove the bottom rear casing assembly break, remove front cover of control & observe operation of

3. Remove the flue baffle & wrapper assembly control.

4. Brush all surface between the fins & remove soot & scale. 8. Check operation of condensate tank with relation to keeping

5. Replace flue baffle & wrapper assembly using new gaskets. sufficient water supply available.

6. Replace the bottom rear casing assembly.

7. Add a few drops of a good grade of light motor oil, No. 10 or 20 TO STOP BURNER

S.A.E., to the burner motor. 1. Pull blower & control switch.

2. Do not pull feedwater pump switch until boiler has cooled.

ANNUAL PROCEDURE

1. Clean water side of boiler as follows: IF BURNER DOES NOT START

A. Drain the boiler through the blow-down valve. 1. Check all electric fuses.

B. Remove all handhole covers & the manhole cover & replace 2. Check water level in boiler.

with new gaskets. 3. Check limit controls to make sure they are working.

C. Wash down the inside (water side) of the boiler with a hose, 4. Push the motor reset button.

making sure to loosen & remove all sludge out of the bottom 5. Push reset button on the programming control. If burner

of the boiler. then fails to start call your York-Shipley Global

D. Inspect shell & tube surfaces for signs of corrosion or scale Representative.

formation. If scale is forming (to any degree) on internal Installed by

surfaces, consult your chemical supplier for boiler treatment. Address

E. Using new gaskets, install the handhole covers.

Phone

F. Disconnect the piping on the discharge side of the feedwater

pump & inspect for scale build up. Check valves for proper Date of Installation

693 North Hills Road

York, PA 17402-2211 USA

Tel: (+1) 717-755-1081

Fax: (+1) 717-755-0020

You might also like

- Scanboilerr TextDocument7 pagesScanboilerr TextAntonio AvilesNo ratings yet

- Lawler Series 66 Thermostatic Water Controller PDFDocument4 pagesLawler Series 66 Thermostatic Water Controller PDFStacy OneillNo ratings yet

- Daily boiler blowdown and maintenance instructionsDocument2 pagesDaily boiler blowdown and maintenance instructionsKarthik AnandanNo ratings yet

- 104 BdivDocument2 pages104 BdivClara FelitaNo ratings yet

- Start/stop of The Boiler: 1 GeneralDocument4 pagesStart/stop of The Boiler: 1 GeneralphuocNo ratings yet

- 1070XL UmDocument4 pages1070XL UmFrancisco ArellanoNo ratings yet

- V1-4Document24 pagesV1-4Alexander BaziotisNo ratings yet

- Ai Boiler Routine Maintenance Guide: AmerecDocument10 pagesAi Boiler Routine Maintenance Guide: Amerecأبو نبيل سلامNo ratings yet

- Ek GeneralDocument24 pagesEk GeneralCadet ABDUL REHMANNo ratings yet

- Disassemble IMBRC PartsDocument4 pagesDisassemble IMBRC PartsJoseph DavidNo ratings yet

- Ek GeneralDocument24 pagesEk GeneralPRASHANT SAWANTNo ratings yet

- BoilerDocument7 pagesBoilerAlexander LakraNo ratings yet

- SOP BMC Commisioning Operation MaintanceDocument18 pagesSOP BMC Commisioning Operation MaintanceElumalai NarayananNo ratings yet

- Boiler Operation InstructionDocument1 pageBoiler Operation InstructionВиталий ГрибинецNo ratings yet

- Imai Ek General Q ADocument88 pagesImai Ek General Q APranjyoti SaikiaNo ratings yet

- Instruction Operation For Packaged BoilerDocument37 pagesInstruction Operation For Packaged BoilerHasnul Hisyam Harun0% (1)

- Steam Boiler Operating AND Maintenance Manual: Prepared by Meksis A.Ş. Service and R&D DepartmentDocument19 pagesSteam Boiler Operating AND Maintenance Manual: Prepared by Meksis A.Ş. Service and R&D DepartmentShambhu Mehta100% (1)

- 2510 Pentair FleckDocument36 pages2510 Pentair Fleckeyumaru13No ratings yet

- AGuideforFireTubeBoiler PDFDocument23 pagesAGuideforFireTubeBoiler PDFsidikNo ratings yet

- Steam Boiler Operating and Maintenance Manual 2497bDocument19 pagesSteam Boiler Operating and Maintenance Manual 2497bEngr. Shamim Hossain HridoyNo ratings yet

- Filling and Maintaining BoilersDocument15 pagesFilling and Maintaining BoilersJosé MacedoNo ratings yet

- Re85v Reda Centrifugal Separator Eng 2009Document107 pagesRe85v Reda Centrifugal Separator Eng 2009Berhanu GebreyohannesNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Service Manual SM1-10-6.0: Steering Pump, R & IDocument2 pagesService Manual SM1-10-6.0: Steering Pump, R & IMohamed RashedNo ratings yet

- Print MeDocument10 pagesPrint MeBryan TanNo ratings yet

- Install, Operate & Maintain Reimers Electra Steam BoilersDocument9 pagesInstall, Operate & Maintain Reimers Electra Steam BoilersRomário CaribéNo ratings yet

- Proceso de Mantenimiento Maquina AnestesiaDocument20 pagesProceso de Mantenimiento Maquina AnestesiaSHIRLEY GIRALDONo ratings yet

- ISO 9001 Maintenance Guide for Cooling TowersDocument9 pagesISO 9001 Maintenance Guide for Cooling TowersShanooziya KhanNo ratings yet

- Maintenance Working Hours Flow For Gas TurbineDocument7 pagesMaintenance Working Hours Flow For Gas TurbineHilmi HanoinNo ratings yet

- Maintenance Préventive Du SULLAIR 260Document17 pagesMaintenance Préventive Du SULLAIR 260MMF PLUSNo ratings yet

- General Residential Valve InstallationDocument22 pagesGeneral Residential Valve InstallationFlorin Cristian GheorgheNo ratings yet

- AV-ME-WI-20 BoilerDocument5 pagesAV-ME-WI-20 BoilerjfejfeNo ratings yet

- Me Lab 2 Experiment 1Document4 pagesMe Lab 2 Experiment 1John Allen EstillomoNo ratings yet

- Section-3 Hydraulic Test: ISGEC John ThompsonDocument4 pagesSection-3 Hydraulic Test: ISGEC John ThompsonMithilesh YadavNo ratings yet

- Boiler Commissioning and Operation Check ListDocument14 pagesBoiler Commissioning and Operation Check Listtsrinivasan5083100% (3)

- Hand Pump Manual of MaintenanceDocument28 pagesHand Pump Manual of MaintenanceManuel LozanoNo ratings yet

- 1kr Fe CoolingDocument128 pages1kr Fe Coolingfguij100% (1)

- Burner Management SystemDocument11 pagesBurner Management SystemS Bharadwaj ReddyNo ratings yet

- Liflus: Operating ManualDocument41 pagesLiflus: Operating ManualausfliegeNo ratings yet

- SA - PA - Purifier System - Service Manual - 2006Document12 pagesSA - PA - Purifier System - Service Manual - 2006Centrifugal SeparatorNo ratings yet

- Servicing of Cooling System and Engine Trouble Shootings-1Document19 pagesServicing of Cooling System and Engine Trouble Shootings-1Hafiz Asfahan100% (1)

- Mep Oral AnswersDocument28 pagesMep Oral AnswersAshjo Gamer100% (1)

- Teste A Las Bombas, RevisionesDocument2 pagesTeste A Las Bombas, RevisionesMario PazNo ratings yet

- Powers Photopanel ManualDocument10 pagesPowers Photopanel Manualic-racerNo ratings yet

- Model 800 Steam Humidifier Troubleshooting ManualDocument8 pagesModel 800 Steam Humidifier Troubleshooting Manualcab13guyNo ratings yet

- Weekly Fire Pump InspectionDocument6 pagesWeekly Fire Pump InspectionShabaaz Mohammed AbdulNo ratings yet

- Direct Drive Rotary Cup Burner Maintenance ManualDocument47 pagesDirect Drive Rotary Cup Burner Maintenance ManualJaipal S. Nagi100% (4)

- Type Mha & Mla: Instructions On Installation Operation and Maintenance For Kirloskar PumpDocument30 pagesType Mha & Mla: Instructions On Installation Operation and Maintenance For Kirloskar Pumparunpsts100% (1)

- Descale Your Noritz Water Heater in 20 StepsDocument7 pagesDescale Your Noritz Water Heater in 20 StepsMichael HoriiNo ratings yet

- 2016 Grand Cherokee - 3.0L TURBO DIESEL PDFDocument665 pages2016 Grand Cherokee - 3.0L TURBO DIESEL PDFprueba2No ratings yet

- MaintenanceInformation OptiMaxDocument20 pagesMaintenanceInformation OptiMaxcombaheeNo ratings yet

- AttTesting and AdjustingDocument8 pagesAttTesting and Adjustingchanlin100% (1)

- Watts 500800 User-Manual PDFDocument8 pagesWatts 500800 User-Manual PDFfogdartNo ratings yet

- Boiler Sop RevDocument17 pagesBoiler Sop RevDhilip AnNo ratings yet

- Natural Gas Patio Heater: IndexDocument8 pagesNatural Gas Patio Heater: IndexwadeNo ratings yet

- Valvula Unitrol CalentadorDocument4 pagesValvula Unitrol CalentadorJose MarcanoNo ratings yet

- ALFA LAVAL Service Manual PA605Document12 pagesALFA LAVAL Service Manual PA605Mery A. Dominguez100% (1)

- Marvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SFrom EverandMarvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SNo ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Connecting cable specifications for Radio Holland EL4040 and MU4041ADocument7 pagesConnecting cable specifications for Radio Holland EL4040 and MU4041ASiva RamanNo ratings yet

- C C C C: Stork-Werkspoor Diesel BVDocument29 pagesC C C C: Stork-Werkspoor Diesel BVSiva RamanNo ratings yet

- Dev"Iation-From-.A.Verage-System TW 9 710 TM: of The Themcco.O Le Wire orDocument5 pagesDev"Iation-From-.A.Verage-System TW 9 710 TM: of The Themcco.O Le Wire orSiva RamanNo ratings yet

- SEO-Optimized Title for Document on Various Programming ConceptsDocument2 pagesSEO-Optimized Title for Document on Various Programming ConceptsSiva RamanNo ratings yet

- Commercial Invoice Vishvamata WOODWARD FINAL DRIVER BOXDocument1 pageCommercial Invoice Vishvamata WOODWARD FINAL DRIVER BOXSiva RamanNo ratings yet

- Copy Bill: 4: Pay Mode Bill Amount Bill No Bill Date 05/10/2021 07:55011447 900.00 Credit / Debit CardDocument1 pageCopy Bill: 4: Pay Mode Bill Amount Bill No Bill Date 05/10/2021 07:55011447 900.00 Credit / Debit CardSiva RamanNo ratings yet

- PT-G041 PCB DatasheetDocument2 pagesPT-G041 PCB DatasheetSiva RamanNo ratings yet

- Product Datasheet for PK-G021 PCB KEYBOARD GDS101 ColourDocument2 pagesProduct Datasheet for PK-G021 PCB KEYBOARD GDS101 ColourSiva RamanNo ratings yet

- Sounding Better! Helpful Hints To Troubleshoot HYPACK: Q 1: Hypack® O E G ODocument3 pagesSounding Better! Helpful Hints To Troubleshoot HYPACK: Q 1: Hypack® O E G OSiva RamanNo ratings yet

- Introducing The GEK Gasifier Systems - Rev5Document7 pagesIntroducing The GEK Gasifier Systems - Rev5Dimuthu Prasad Wijethunge100% (1)

- Eletrical Machines 1Document35 pagesEletrical Machines 1Vallery Dela CruzNo ratings yet

- Test and Demonstration of - MW Wellhead Generator: Helical Screw Expander Power Plant, ModelDocument254 pagesTest and Demonstration of - MW Wellhead Generator: Helical Screw Expander Power Plant, ModelAhmed AbdulnaimNo ratings yet

- 1106D Fuel System DiagnosisDocument2 pages1106D Fuel System DiagnosisdubimouNo ratings yet

- AAF Diesel Engine Clean Air Solutions - EN PDFDocument4 pagesAAF Diesel Engine Clean Air Solutions - EN PDFsundarNo ratings yet

- Jreda Nib 31Document4 pagesJreda Nib 31Ashish Kumar VermaNo ratings yet

- Complete Physics For Cambridge IGCSE Grid FinalDocument15 pagesComplete Physics For Cambridge IGCSE Grid FinalIteoluwakishi AlukoNo ratings yet

- Use of Bernoulli Equation For Pumps - Physics Forums - The Fusion of Science and CommunityDocument5 pagesUse of Bernoulli Equation For Pumps - Physics Forums - The Fusion of Science and Communitychemsac2No ratings yet

- Watt's#95 Global Energy Update 2Document2 pagesWatt's#95 Global Energy Update 2JoDueckNo ratings yet

- Exam 1 of Statistical PhysicsDocument1 pageExam 1 of Statistical PhysicsA'an ZahrotulNo ratings yet

- Commutation in DC Machines PDFDocument2 pagesCommutation in DC Machines PDFTom0% (1)

- Aqm Lecture 8Document12 pagesAqm Lecture 8sayandatta1No ratings yet

- Electrical Installation Devices PDFDocument306 pagesElectrical Installation Devices PDFvehocurriNo ratings yet

- Scope of Transmission DistributionDocument7 pagesScope of Transmission DistributionEga FauziahNo ratings yet

- MOM held between Tata Sponge Iron and Encon on CT fan inspectionDocument3 pagesMOM held between Tata Sponge Iron and Encon on CT fan inspectionPramod SharmaNo ratings yet

- 8DH10 enDocument44 pages8DH10 enRohit ShrivastavaNo ratings yet

- PX Model NomenclatureDocument1 pagePX Model NomenclaturenammarisNo ratings yet

- SRNE ASF-series 48V 8-10kW Split-Phase Solar-Charger-Inverter Usermanual 1.4Document41 pagesSRNE ASF-series 48V 8-10kW Split-Phase Solar-Charger-Inverter Usermanual 1.4Carlos Vasquez100% (1)

- UPS System ConfigurationsDocument38 pagesUPS System ConfigurationsRM PatilNo ratings yet

- Cem em Casestudy Yansab SaudiarabiaDocument8 pagesCem em Casestudy Yansab Saudiarabia周恩深No ratings yet

- CleanLinePt2 Appendix 10 JDocument233 pagesCleanLinePt2 Appendix 10 JChristos ApostolopoulosNo ratings yet

- LNT MCCBs Technical CatalogueDocument20 pagesLNT MCCBs Technical CataloguembhangaleNo ratings yet

- Beginners Dowsing Chapter 5Document4 pagesBeginners Dowsing Chapter 5Jesús Molina SeguraNo ratings yet

- Emision StandardsDocument4 pagesEmision StandardsAshish RoongtaNo ratings yet

- Coal Specs Sheet GAR 6400Document2 pagesCoal Specs Sheet GAR 6400Adhitya AchmadNo ratings yet

- Service Manual: Air ConditionersDocument93 pagesService Manual: Air ConditionersFlorinHarhasNo ratings yet

- Infrared Plastic Solar Cells Overcome LimitationsDocument23 pagesInfrared Plastic Solar Cells Overcome LimitationsPriyanka50% (4)

- Comment Sheet Electrical DocumentDocument9 pagesComment Sheet Electrical Documentdhanny maNo ratings yet

- Pub - Quantum Mechanics For Chemists PDFDocument196 pagesPub - Quantum Mechanics For Chemists PDFDouglas SampaioNo ratings yet

- MTU1550Document4 pagesMTU1550Duy KhaNo ratings yet