Professional Documents

Culture Documents

Global SUPP OTH 000047390 Implementation Assessment Global SOP QC 0000003582 2.0 1.0 副本111111

Uploaded by

Ruslim SenLinCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Global SUPP OTH 000047390 Implementation Assessment Global SOP QC 0000003582 2.0 1.0 副本111111

Uploaded by

Ruslim SenLinCopyright:

Available Formats

Implementation Assessment for Instructive Global QM Documents

For any published global QM Document which was assessed as “applicable” and GxP relevant by the local organization (documented in local

document library) the implementation mode must be documented in Table 2 and the detailed gap assessment in Table 3.

See as well Global-SOP-QM-000002376 for further explanation (decision tree in Figure 1).

For organizations or global QM Documents in scope for the Pharmaceutical Quality System please refer to Global-SOP-QM-000002714

“Pharmaceutical Quality System” for further rules concerning the implementation modes.

Table 1 General Information

Local organization:

Document ID: Global-SOP-QC-000003582

Document Version: version 2.0

Document Title: Growth Promotion of Microbiological Media

Application note:

This implementation assessment takes into account the adjustments that were incorporated in version 2 of the Global-SOP-QC-000003582

(see yellow background). The impact of the changes made must be reassessed. Requirements that have not changed with regard to version

2 do not have to be reassessed if an initial implementation assessment has already been carried out. If an implementation assessment for

this instruction/guiding document is carried out for the first time, all requirements must be taken into account (please remove the diagonal

strikethrough).

Source of Form: Global-FORM-QM-000002753 Version: 3.0 Page: 1 of 19

Implementation Assessment for Instructive Global QM Documents

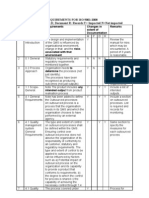

Table 2 Implementation Approach: What is the approach for implementing the Instructive Global QM Document?

# Implementation Mode Action Selection Justification

1 Instructive global QM Document will Complete Implementation Assessment Form for Yes No

be implemented „as-is” in English. traceability and maintain within local QMS.

2 Instructive global QM Document will Complete Implementation Assessment Form for Yes No

be implemented „as-is” after traceability and maintain within local QMS.

translation into local language. No Create an exact translation and implement the

content modifications allowed. global translated document into the local QMS

(use Global-FORM-QM-000002796 for

translation)

3 Instructive global QM Document will Complete Implementation Assessment Form for Yes No

be implemented „as-is” (in English or traceability and maintain within local QMS.

after translation into local language) Reference to local Annex or WI to be included;

adding local supplementary content to (title, number and version)

the document in form of a local Annex

or supplementary Working

Instruction. No content change or

deletion of the global QM Document

allowed.

4 Instructive global QM Document will Complete Implementation Assessment form for Yes No

be used to create/modify a local QM traceability and maintain within local QMS.

Document; additional requirements Assessment must include reference to local QM

can be included or not all Document (title, number and version).

requirements will be included.

Additional local requirements to be

implemented must be described in justification.

Any global requirements which will not be

implemented must be described in justification.

Source of Form: Global-FORM-QM-000002753 Version: 3.0 Page: 2 of 19

Implementation Assessment for Instructive Global QM Documents

Table 3 Gap Assessment for Implementation: Which process steps are implemented? Where are gaps identified and how is the plan to close the gaps?

Process(step) Applicable Already Describe the gap and the details for implementation:

Implemented For already existing process steps, list local QM Document(s)

which will be replaced by the global QM Document

For not yet existing process steps describe the actions

planned to implement

Refer to a KabiTrack Record# for the process change(s)

Scope of testing Yes No Yes No

If a supplier for Ready-to-Use (RTU) media is fully certified and

the transport of media can be verified to be within proper storage

conditions (e.g., via temperature loggers), no additional growth

promotion test with ATCC organisms may be performed as long

as the manufacturer has demonstrated the growth-promoting

properties of the medium using the ATCC strains (i.e.,

compendial strains).

However, the growth promoting properties of the individual, site-

specific in-house microorganisms must be regularly verified (see

Global-SOP-QC-000002969 “Best Practices in the Microbiology

Laboratory", Special considerations for RTU media), meaning in-

house isolates must be tested per batch and delivery and reliance

on the supplier verification for the compendial strains per batch

(provided that the temperature record of the delivery was

acceptable).

A complete test of media, including in-house isolates (exceptions

see footnote Error: Reference source not found in section Error:

Reference source not found) and compendial strains, must be

performed annually in order to maintain the supplier’s

certification status.

Source of Form: Global-FORM-QM-000002753 Version: 3.0 Page: 3 of 19

Implementation Assessment for Instructive Global QM Documents

Check of pH value /Check of supplier COA Yes No Yes No No content-related changes compared to version 1. If

The pH value of the media from each lot prepared in-house Implementation Assessment version 1 has already been filled

should be measured after cooling down to room temperature. out, there is no need to re-evaluate this requirement. If this IA is

being filled out for the first time, this should be mentioned in

Table 2 and the requirement on the left shall be answered in

terms of applicability and implementation status (see columns 2

and 3).

Check of pH value /Check of supplier COA Yes No Yes No No content-related changes compared to version 1. If

If individual units (e.g., small bottles, vials, ampoules) of liquid Implementation Assessment version 1 has already been filled

media are available, one unit is tested with an immersion pH out, there is no need to re-evaluate this requirement. If this IA is

probe, and the remainder of the unit should be discarded. being filled out for the first time, this should be mentioned in

Table 2 and the requirement on the left shall be answered in

terms of applicability and implementation status (see columns 2

and 3).

Check of pH value /Check of supplier COA Yes No Yes No No content-related changes compared to version 1. If

For large volume units (e.g., large bottles, bags), an aliquot may Implementation Assessment version 1 has already been filled

be taken aseptically, where the remainder of that aliquot can be out, there is no need to re-evaluate this requirement. If this IA is

used. being filled out for the first time, this should be mentioned in

Table 2 and the requirement on the left shall be answered in

terms of applicability and implementation status (see columns 2

and 3).

Check of pH value /Check of supplier COA Yes No Yes No No content-related changes compared to version 1. If

Even if no physical pH test is required for purchased media, the Implementation Assessment version 1 has already been filled

pH value specified by the manufacturer (COA) must be checked out, there is no need to re-evaluate this requirement. If this IA is

for acceptance. being filled out for the first time, this should be mentioned in

Table 2 and the requirement on the left shall be answered in

terms of applicability and implementation status (see columns 2

and 3).

Source of Form: Global-FORM-QM-000002753 Version: 3.0 Page: 4 of 19

Implementation Assessment for Instructive Global QM Documents

Check of pH value /Check of supplier COA Yes No Yes No No content-related changes compared to version 1. If

A lot of media not conforming to the pH limit cannot be released Implementation Assessment version 1 has already been filled

for use and must be investigated per Global-SOP-QM-000002473 out, there is no need to re-evaluate this requirement. If this IA is

“Event Handling & CAPA Process”. being filled out for the first time, this should be mentioned in

Table 2 and the requirement on the left shall be answered in

terms of applicability and implementation status (see columns 2

and 3).

Sterility check Yes No Yes No No content-related changes compared to version 1. If

A lot of media not conforming to the sterility cannot be released Implementation Assessment version 1 has already been filled

for use and must be investigated per Global-SOP-QM-000002473 out, there is no need to re-evaluate this requirement. If this IA is

“Event Handling & CAPA Process”. being filled out for the first time, this should be mentioned in

Table 2 and the requirement on the left shall be answered in

terms of applicability and implementation status (see columns 2

and 3).

Frequency of the testing Yes No Yes No No content-related changes compared to version 1. If

GPT must be performed for each lot and each delivery of media Implementation Assessment version 1 has already been filled

to be used in microbiological testing or used in the Environmental out, there is no need to re-evaluate this requirement. If this IA is

Monitoring program, whether manufactured in-house or being filled out for the first time, this should be mentioned in

purchased from an external supplier. Table 2 and the requirement on the left shall be answered in

terms of applicability and implementation status (see columns 2

and 3).

Frequency of the testing Yes No Yes No

For purchased ready-to-use media, each shipment received from

the supplier must undergo independent GPT (for exception see

Error: Reference source not found)

Frequency of the testing Yes No Yes No No content-related changes compared to version 1. If

For in-house prepared media, GPT shall be performed for each Implementation Assessment version 1 has already been filled

sterilization lot (i.e. autoclave load). out, there is no need to re-evaluate this requirement. If this IA is

being filled out for the first time, this should be mentioned in

Table 2 and the requirement on the left shall be answered in

terms of applicability and implementation status (see columns 2

and 3).

Source of Form: Global-FORM-QM-000002753 Version: 3.0 Page: 5 of 19

Implementation Assessment for Instructive Global QM Documents

Frequency of the testing Yes No Yes No

Microbiological media used in the laboratory support activities not

directly influencing test results (e.g., stock culture maintenance)

are exempt from GPT.

Frequency of the testing Yes No Yes No

GPT is always required when establishing a shelf life for the

media. For media manufactured in-house, determination of shelf

life is mandatory to verify the growth suitability, while for RTU

media, the shelf life specified by the manufacturer can be used

without the need for additional shelf-life establishment (provided

that the storage conditions specified by the supplier are used –

otherwise validation shall be performed).

Frequency of the testing Yes No Yes No No content-related changes compared to version 1. If

Shelf life is validated using GPT to confirm that the performance Implementation Assessment version 1 has already been filled

of the media still meets acceptance criteria up to and including out, there is no need to re-evaluate this requirement. If this IA is

the expiration date. being filled out for the first time, this should be mentioned in

Table 2 and the requirement on the left shall be answered in

terms of applicability and implementation status (see columns 2

and 3).

Frequency of the testing Yes No Yes No No content-related changes compared to version 1. If

If a validated shelf life has not been determined, the GPT should Implementation Assessment version 1 has already been filled

be repeated as follows: out, there is no need to re-evaluate this requirement. If this IA is

being filled out for the first time, this should be mentioned in

every two weeks for media stored in unsealed

Table 2 and the requirement on the left shall be answered in

containers (e.g. plates, tubes)

terms of applicability and implementation status (see columns 2

every three months for media stored in sealed and 3).

containers (e.g. flasks)

Frequency of the testing Yes No Yes No No content-related changes compared to version 1. If

After shelf life has been established, a periodic stability check to Implementation Assessment version 1 has already been filled

confirm the shelf life should be performed once every two years. out, there is no need to re-evaluate this requirement. If this IA is

being filled out for the first time, this should be mentioned in

Table 2 and the requirement on the left shall be answered in

terms of applicability and implementation status (see columns 2

and 3).

Source of Form: Global-FORM-QM-000002753 Version: 3.0 Page: 6 of 19

Implementation Assessment for Instructive Global QM Documents

Frequency of the testing Yes No Yes No

In order to prove that medium shows growth-promoting

properties even after the intended shelf life has been exceeded

by the incubation period (i.e., if using the medium for incubation

on the last day of expiry), GPT should be carried out with

medium that has also exceeded the shelf life by the

corresponding incubation time. This study shall be carried out

according to Global-SOP-QC-000003495 “Incubation, Reading

and Subculturing of Microbial Samples and Potentially

Contaminated Units”.

Frequency of the testing Yes No Yes No

For RTU media, there may be a declaration from the

manufacturer that the medium has growth-promoting properties

beyond its shelf life; if such information is not available,

validation is required as for in-house prepared medium.

Selection of microorganisms Yes No Yes No No content-related changes compared to version 1. If

The growth-promoting properties of media are demonstrated by Implementation Assessment version 1 has already been filled

the use of suitable microbiological cultures. Generally accepted out, there is no need to re-evaluate this requirement. If this IA is

cultures for GPT can be found in the relevant chapters of the being filled out for the first time, this should be mentioned in

USP, Ph. Eur. or JP and can be obtained as stocks from culture Table 2 and the requirement on the left shall be answered in

collections (such as ATCC) or secondary qualified suppliers. terms of applicability and implementation status (see columns 2

and 3).

Selection of microorganisms Yes No Yes No

In addition to standard stock cultures sourced from a national

culture collection, selected in-house isolates (at least one strain,

and typically not more than two different strains) isolated from

the EM program (isolated from grade A & B), positives of sterility

test or aseptic process simulation (media fill) failures should be

included in GPT of relevant media1.

Source of Form: Global-FORM-QM-000002753 Version: 3.0 Page: 7 of 19

Implementation Assessment for Instructive Global QM Documents

Footnote 1: The production facilities of non-sterile APIs are Yes No Yes No

exempt from the requirement to include in-house isolates in the

test. For those sites, use of compendial strains is sufficient. If

there is an obligation to use in-house isolates as part of the GPT,

but there are no isolates available from the corresponding

locations/analyzes, strains isolated from the next lower

cleanroom area could also be used (e.g., Grade C). In any case,

the choice of inhouse isolates used in the GPT must be justified in

the annual microbiological assessment and, if necessary,

adjusted.

Selection of microorganisms Yes No Yes No No content-related changes compared to version 1. If

The recommended number and types of in-house isolates to be Implementation Assessment version 1 has already been filled

included within the GPT should reflect the generally present, out, there is no need to re-evaluate this requirement. If this IA is

predominant microorganisms. being filled out for the first time, this should be mentioned in

Table 2 and the requirement on the left shall be answered in

terms of applicability and implementation status (see columns 2

and 3).

Selection of microorganisms Yes No Yes No No content-related changes compared to version 1. If

The rationale for the selection of the in-house isolates shall be Implementation Assessment version 1 has already been filled

documented and reviewed annually as part of annual review of out, there is no need to re-evaluate this requirement. If this IA is

microbial flora as per gGD-PH-OT-002 “Determination, being filled out for the first time, this should be mentioned in

Preservation and Use of Microbial In-house Flora”. Table 2 and the requirement on the left shall be answered in

terms of applicability and implementation status (see columns 2

and 3).

Selection of microorganisms Yes No Yes No

In the case of a customer complaint with a fatal or severe

outcome resulting from potential microbial contamination,

relevant medium should be tested in regard to its growth-

promoting properties for the microbial strain originating from the

complaint (if available). This should be done as part of the

investigation program and does not need to be included in the

routine testing for media release.

Source of Form: Global-FORM-QM-000002753 Version: 3.0 Page: 8 of 19

Implementation Assessment for Instructive Global QM Documents

Selection of microorganisms Yes No Yes No No content-related changes compared to version 1. If

While the treatment (e.g. storage, rehydration) of purchased Implementation Assessment version 1 has already been filled

stock cultures should be carried out according to the out, there is no need to re-evaluate this requirement. If this IA is

manufacturer’s instructions, in-house cultures must be cultivated being filled out for the first time, this should be mentioned in

and conserved as described in the internal SOPs. Table 2 and the requirement on the left shall be answered in

terms of applicability and implementation status (see columns 2

and 3).

Selection of microorganisms Yes No Yes No No content-related changes compared to version 1. If

Challenge microorganisms for each media type are selected Implementation Assessment version 1 has already been filled

according to the usage of the media: out, there is no need to re-evaluate this requirement. If this IA is

being filled out for the first time, this should be mentioned in

• General standard purpose media (e.g., TSA, TSB) are

Table 2 and the requirement on the left shall be answered in

challenged with a wide range of microorganisms

terms of applicability and implementation status (see columns 2

representing gram-positive, gram-negative, Bacillus

and 3).

spp. and fungi.

• Selective or differential media (e.g., MacConkey) are

challenged with individual strains designed to show

growth promoting, inhibitory or indicative properties of

the media. Selection of these microorganisms may be

based on compendial test chapters or manufacturer’s

recommendation for a particular medium.

Table 1: New requirements/conditions in Table 1. Yes No Yes No

Selection of incubation temperatures Yes No Yes No

Where the incubation temperatures described in Table 1

correspond to specific compendial chapters that include fixed

pre-defined incubation temperatures (as i.e., the Pharmacopeial

chapter for sterility testing), those conditions must be chosen.

Source of Form: Global-FORM-QM-000002753 Version: 3.0 Page: 9 of 19

Implementation Assessment for Instructive Global QM Documents

Selection of incubation temperatures Yes No Yes No

Where the incubation temperatures as described in Table 1

correspond to specific compendial chapters or other GMP

standards that do not include fixed pre-defined incubation

temperatures, but give a range for incubation (as i.e., for EM,

bioburden testing), the plant specific incubation conditions should

be used instead (for all microorganisms).

Selection of incubation temperatures Yes No Yes No

For the GPT of media that is to be used for aseptic process

simulation, it is appropriate to incubate the different compendial

strains according to the separate temperature ranges preferred

for their detection.

GPT procedure Yes No Yes No No content-related changes compared to version 1. If

Method 1: Media inoculated through in-house cultures are usually Implementation Assessment version 1 has already been filled

reactivated from a stock solution and adjusted to the level of use out, there is no need to re-evaluate this requirement. If this IA is

by serial dilution. Therefore, the actual colony-forming value being filled out for the first time, this should be mentioned in

must be tested and verified on control plates (usually the already Table 2 and the requirement on the left shall be answered in

approved batch of media). terms of applicability and implementation status (see columns 2

and 3).

GPT procedure Yes No Yes No No content-related changes compared to version 1. If

Method 2: The standardized inocula refer to the value of the Implementation Assessment version 1 has already been filled

colony-forming units in the final volume specified by the out, there is no need to re-evaluate this requirement. If this IA is

manufacturer and can be used for the GPT without further being filled out for the first time, this should be mentioned in

dilution series (including verification approaches). Table 2 and the requirement on the left shall be answered in

terms of applicability and implementation status (see columns 2

and 3).

GPT procedure Yes No Yes No

When testing inhouse-prepared cultures it is recommended to

perform the test on the new and previously approved (control)

medium by the same technician in parallel in order to exclude

additional influential variables such as temperature, technique,

incubation time or inoculum. If RTU cultures are used, cell

comparison on old media is not required since the manufacturer

provides a standardized inoculum with an appropriate cell count.

Source of Form: Global-FORM-QM-000002753 Version: 3.0 Page: 10 of 19

Implementation Assessment for Instructive Global QM Documents

Method 1 - Use of in-house prepared inoculum Yes No Yes No No content-related changes compared to version 1. If

suspensions of challenge microorganisms Implementation Assessment version 1 has already been filled

Prepare suspensions of each required challenge microorganism out, there is no need to re-evaluate this requirement. If this IA is

from a freshly revived culture not more than five passages being filled out for the first time, this should be mentioned in

removed from the reference seed lot. Table 2 and the requirement on the left shall be answered in

terms of applicability and implementation status (see columns 2

and 3).

Method 1 - Use of in-house prepared inoculum Yes No Yes No No content-related changes compared to version 1. If

suspensions of challenge microorganisms Implementation Assessment version 1 has already been filled

Use buffered Sodium Chloride Peptone solution (pH 7.0) or out, there is no need to re-evaluate this requirement. If this IA is

Phosphate buffer solution (pH 7.2) to make serial dilutions of the being filled out for the first time, this should be mentioned in

challenge microorganism to obtain a final inoculum suspension Table 2 and the requirement on the left shall be answered in

yielding in 10 - 100 CFU/ml. terms of applicability and implementation status (see columns 2

and 3).

Method 1 - Use of in-house prepared inoculum Yes No Yes No No content-related changes compared to version 1. If

suspensions of challenge microorganisms Implementation Assessment version 1 has already been filled

Use the suspensions within 2 hours, or within 24 hours if stored out, there is no need to re-evaluate this requirement. If this IA is

between 2 – 8 °C. being filled out for the first time, this should be mentioned in

Table 2 and the requirement on the left shall be answered in

terms of applicability and implementation status (see columns 2

and 3).

Method 1 - Use of in-house prepared inoculum Yes No Yes No

suspensions of challenge microorganisms

Inoculate each medium (test at least in duplicates per strain)

with an appropriate volume (e.g., 100 to 250 µL for agar plates)

corresponding to NMT 100 CFU of a relevant challenge

microorganism according to Error: Reference source not found.

When testing liquid medium, the volume of the inoculum should

not exceed 1% of the volume of the media to be tested. Where

quantitative determinations are to be carried out (i.e., non-

selective agar plates), testing must be carried out at least in

duplicate per strain. Repeat on additional sets of media units for

each of the remaining challenge microorganisms required.

Source of Form: Global-FORM-QM-000002753 Version: 3.0 Page: 11 of 19

Implementation Assessment for Instructive Global QM Documents

Method 1 - Use of in-house prepared inoculum Yes No Yes No

suspensions of challenge microorganisms

In parallel, inoculate as above each challenge microorganism on

a previously approved media lot that is within expiry. These units

will represent the inoculum control. For non-selective media

(e.g., TSA), the plating must be performed in duplicates due to

quantitative measurement (for each microbial strain use two

plates from the new medium and two from the already approved

medium, i.e., a total of 4 plates).

Method 1 - Use of in-house prepared inoculum Yes No Yes No

suspensions of challenge microorganisms

If the media being tested is a liquid (broth), inoculate TSA plates

as an additional inoculum control (as described above). The

inoculum must also be controlled when using selective liquid

media (such as MacConkey broth). For that purpose, also the

usage of non-selective media such as TSA is accepted.

Method 1 - Use of in-house prepared inoculum Yes No Yes No No content-related changes compared to version 1. If

suspensions of challenge microorganisms Implementation Assessment version 1 has already been filled

Incubate tests according to the conditions as described in Table out, there is no need to re-evaluate this requirement. If this IA is

1. being filled out for the first time, this should be mentioned in

Table 2 and the requirement on the left shall be answered in

terms of applicability and implementation status (see columns 2

and 3).

Method 1 - Use of in-house prepared inoculum Yes No Yes No No content-related changes compared to version 1. If

suspensions of challenge microorganisms Implementation Assessment version 1 has already been filled

For solid media where colonies can be counted, calculate the out, there is no need to re-evaluate this requirement. If this IA is

average of the colony forming units of the new media and of the being filled out for the first time, this should be mentioned in

inoculum control media. Table 2 and the requirement on the left shall be answered in

terms of applicability and implementation status (see columns 2

and 3).

Source of Form: Global-FORM-QM-000002753 Version: 3.0 Page: 12 of 19

Implementation Assessment for Instructive Global QM Documents

Method 1 - Use of in-house prepared inoculum Yes No Yes No No content-related changes compared to version 1. If

suspensions of challenge microorganisms Implementation Assessment version 1 has already been filled

For liquid media, check turbidity/growth for each challenge out, there is no need to re-evaluate this requirement. If this IA is

microorganism on the test media and on the inoculum control being filled out for the first time, this should be mentioned in

media. Table 2 and the requirement on the left shall be answered in

terms of applicability and implementation status (see columns 2

and 3).

Method 1 - Use of in-house prepared inoculum

suspensions of challenge microorganisms

Old medium that has expired for not more than 4 weeks may be

used as a control in exceptional cases. If this case occurs

regularly or if it cannot be guaranteed that the medium does not

expire, the establishment of method 2 should be considered as

the test can be carried with the newly delivered medium only.

Method 2 – Use of RTU cultures (such as Quanticult, Yes No Yes No No content-related changes compared to version 1. If

BioBall™ or BEC growth kits) Implementation Assessment version 1 has already been filled

Each culture lot must be accompanied by a COA demonstrating a out, there is no need to re-evaluate this requirement. If this IA is

min-max count (e.g. 10-100 CFU/volume) and may include a being filled out for the first time, this should be mentioned in

mean CFU count on general culture media. Table 2 and the requirement on the left shall be answered in

terms of applicability and implementation status (see columns 2

and 3).

Method 2 – Use of RTU cultures (such as Quanticult, Yes No Yes No No content-related changes compared to version 1. If

BioBall™ or BEC growth kits) Implementation Assessment version 1 has already been filled

Suppliers of RTU cultures must be qualified prior to use and out, there is no need to re-evaluate this requirement. If this IA is

applicable steps for supplier qualification must be considered being filled out for the first time, this should be mentioned in

(information can be found in Global-SOP-MM-000002564 Table 2 and the requirement on the left shall be answered in

“Supplier Selection & Qualification”). terms of applicability and implementation status (see columns 2

and 3).

Source of Form: Global-FORM-QM-000002753 Version: 3.0 Page: 13 of 19

Implementation Assessment for Instructive Global QM Documents

Method 2 – Use of RTU cultures (such as Quanticult, Yes No Yes No No content-related changes compared to version 1. If

BioBall™ or BEC growth kits) Implementation Assessment version 1 has already been filled

Each supplier Lot must be released by verifying the COA claim out, there is no need to re-evaluate this requirement. If this IA is

and results be within min-max count unless the supplier is being filled out for the first time, this should be mentioned in

certified. Table 2 and the requirement on the left shall be answered in

terms of applicability and implementation status (see columns 2

and 3).

Method 2 – Use of RTU cultures (such as Quanticult, Yes No Yes No No content-related changes compared to version 1. If

BioBall™ or BEC growth kits) Implementation Assessment version 1 has already been filled

In case the supplier has been certified, one lot of each out, there is no need to re-evaluate this requirement. If this IA is

representative challenge microorganism (1 gram-positive and 1 being filled out for the first time, this should be mentioned in

gram-negative strain) must be tested annually as part of Table 2 and the requirement on the left shall be answered in

maintaining the certified status of the supplier. terms of applicability and implementation status (see columns 2

and 3).

Method 2 – Use of RTU cultures (such as Quanticult, Yes No Yes No No content-related changes compared to version 1. If

BioBall™ or BEC growth kits) Implementation Assessment version 1 has already been filled

RTU cultures are used in an undiluted volume which corresponds out, there is no need to re-evaluate this requirement. If this IA is

to a count NMT 100 microorganisms per test. being filled out for the first time, this should be mentioned in

Table 2 and the requirement on the left shall be answered in

terms of applicability and implementation status (see columns 2

and 3).

Method 2 – Use of RTU cultures (such as Quanticult, Yes No Yes No

BioBall™ or BEC growth kits)

Inoculate each medium with the corresponding volume (typically

between 100 to 250 µL for agar plates) of a relevant challenge

microorganism according to Error: Reference source not found.

When testing liquid medium, the volume of the inoculum should

not exceed 1% of the volume of the media to be tested.

Source of Form: Global-FORM-QM-000002753 Version: 3.0 Page: 14 of 19

Implementation Assessment for Instructive Global QM Documents

Acceptance criteria of method 1 Yes No Yes No No content-related changes compared to version 1. If

Solid media acceptance criteria are as follows: Implementation Assessment version 1 has already been filled

out, there is no need to re-evaluate this requirement. If this IA is

There must be NMT 100 CFU on each agar plate.

being filled out for the first time, this should be mentioned in

Table 2 and the requirement on the left shall be answered in

terms of applicability and implementation status (see columns 2

and 3).

Acceptance criteria of method 1 Yes No Yes No

Solid media acceptance criteria are as follows:

The average number of colonies from the new lot of

medium must be within a factor of 2 (corresponds to the

same as 50 to 200%) of the average number of colonies

from the previously approved lot of medium (represents

the positive control)5.

Footnote 5: Count comparison according to the factor 2 concept Yes No Yes No

is not required for selective media. However, it shall be verified

that the challenge microorganisms actually grow on the media

and, if defined, show characteristic morphology as described in

the Pharmacopoeia. For some selective media it must also be

shown that other microorganisms do not grow (e.g.,

MacConkey).

Acceptance criteria of method 1 Yes No Yes No No content-related changes compared to version 1. If

Liquid media acceptance criteria are as follows: Implementation Assessment version 1 has already been filled

out, there is no need to re-evaluate this requirement. If this IA is

There must be growth/turbidity in the test tubes from

being filled out for the first time, this should be mentioned in

both the new lot of media and the previously approved

Table 2 and the requirement on the left shall be answered in

lot of media, as well as on the control agar plates.

terms of applicability and implementation status (see columns 2

and 3).

Source of Form: Global-FORM-QM-000002753 Version: 3.0 Page: 15 of 19

Implementation Assessment for Instructive Global QM Documents

Acceptance criteria of method 1 Yes No Yes No No content-related changes compared to version 1. If

Liquid media acceptance criteria are as follows: Implementation Assessment version 1 has already been filled

out, there is no need to re-evaluate this requirement. If this IA is

The non-selective control plate should have NMT 100

being filled out for the first time, this should be mentioned in

CFU.

Table 2 and the requirement on the left shall be answered in

terms of applicability and implementation status (see columns 2

and 3).

Acceptance criteria of method 1 Yes No Yes No No content-related changes compared to version 1. If

Liquid media acceptance criteria are as follows: Implementation Assessment version 1 has already been filled

out, there is no need to re-evaluate this requirement. If this IA is

The turbidity/growth in the tubes from the tested

being filled out for the first time, this should be mentioned in

medium should be visually comparable to the turbidity

Table 2 and the requirement on the left shall be answered in

in the tubes from the previously approved lot of

terms of applicability and implementation status (see columns 2

medium. A quantitative definition of “comparable” is not

and 3).

established by USP, Ph. Eur. or JP; visual comparability

is sufficient and accepted.

Acceptance criteria of method 2 Yes No Yes No No content-related changes compared to version 1. If

Solid media acceptance criteria are as follows: Implementation Assessment version 1 has already been filled

out, there is no need to re-evaluate this requirement. If this IA is

There must be NMT 100 CFU on each agar plate.

being filled out for the first time, this should be mentioned in

Table 2 and the requirement on the left shall be answered in

terms of applicability and implementation status (see columns 2

and 3).

Acceptance criteria of method 2 Yes No Yes No No content-related changes compared to version 1. If

Solid media acceptance criteria are as follows: Implementation Assessment version 1 has already been filled

out, there is no need to re-evaluate this requirement. If this IA is

The average number of colonies from the tested

being filled out for the first time, this should be mentioned in

medium must be within the min – max values given on

Table 2 and the requirement on the left shall be answered in

the supplier COA.

terms of applicability and implementation status (see columns 2

and 3).

Source of Form: Global-FORM-QM-000002753 Version: 3.0 Page: 16 of 19

Implementation Assessment for Instructive Global QM Documents

Acceptance criteria of method 2 Yes No Yes No No content-related changes compared to version 1. If

Liquid media acceptance criteria are as follows: Implementation Assessment version 1 has already been filled

out, there is no need to re-evaluate this requirement. If this IA is

There must be growth/turbidity in the test tubes from

being filled out for the first time, this should be mentioned in

the new lot of media.

Table 2 and the requirement on the left shall be answered in

terms of applicability and implementation status (see columns 2

and 3).

Acceptance criteria of method 2 Yes No Yes No

Liquid media acceptance criteria are as follows:

The control must show NMT 100 CFU.

Handling of failing results Yes No Yes No No content-related changes compared to version 1. If

An invalid GPT is defined if more than 100 CFU are countable on Implementation Assessment version 1 has already been filled

inoculum control plates. Results must be recorded, and test is out, there is no need to re-evaluate this requirement. If this IA is

repeated only with the microorganisms and medium that did not being filled out for the first time, this should be mentioned in

meet the acceptance criteria. Table 2 and the requirement on the left shall be answered in

terms of applicability and implementation status (see columns 2

If the repeat test also fails, the failure should be

and 3).

addressed per Global-SOP-QM-000002473 “Event

Handling & CAPA Process”.

Handling of failing results Yes No Yes No

In case the acceptance criteria are not met by growth of less

than a factor of 2, or growth not comparable to previous

approved batch:

If the inoculum control plate showed an average of NMT

10 CFU, then the inoculum is considered to be too low

and the test can be invalidated and repeated. Results

shall be recorded, and test is repeated only with the

challenge microorganisms and medium that did not

meet the acceptance criteria.

If the repeat test also fails, the failure should be

addressed per Global-SOP-QM-000002473 “Event

Handling & CAPA Process”.

Source of Form: Global-FORM-QM-000002753 Version: 3.0 Page: 17 of 19

Implementation Assessment for Instructive Global QM Documents

Handling of failing results Yes No Yes No

Note: When using Method 1, on the new media cell counts above

100 CFU may be accepted as long as the control plates show

NMT 100 CFU and the factor of 2 is met. Counts between 5 and

10 CFU are acceptable as long as the factor of 2 is met.

Responsibilities Yes No Yes No

The responsibilities and duties of key personnel as defined by

Global-SOP-QM-000002830 “Authority, Responsibilities and

Duties of Local Key Personnel and Organizations” apply. The

department conducting the GPT is responsible for implementing

and maintaining the described process on site level and that

personnel involved in these activities are qualified and trained

(see also Global-SOP-HR-000002835 “Personnel Qualification and

Training”).

[fill in single process steps described in global QM Document] Yes No Yes No

Yes No Yes No

Yes No Yes No

Source of Form: Global-FORM-QM-000002753 Version: 3.0 Page: 18 of 19

Implementation Assessment for Instructive Global QM Documents

Reviewed and

Generated by:

Approved by:

[Name] [Name]

[Function] [Function – QA Head local organization]

[Organization] [Organization]

[Signature] [Date] [Signature] [Date]

Source of Form: Global-FORM-QM-000002753 Version: 3.0 Page: 19 of 19

You might also like

- Method Statement For Fuel System (Diesel Supply System For Generator)Document16 pagesMethod Statement For Fuel System (Diesel Supply System For Generator)BAVA M.H100% (1)

- API Q1 Approved InterpretationsDocument4 pagesAPI Q1 Approved InterpretationsKrishna VachaNo ratings yet

- MINI R56 N12 Valve Stem Seal ReplacementDocument9 pagesMINI R56 N12 Valve Stem Seal ReplacementJohn DoeNo ratings yet

- Lear-75-GM Quality System Basics Audit FormDocument12 pagesLear-75-GM Quality System Basics Audit FormalexrferreiraNo ratings yet

- CAPA Reply for Audit FindingsDocument101 pagesCAPA Reply for Audit FindingsAbdellatef Hossam100% (1)

- KI Quality Manual Rev. D 12-28-2012Document35 pagesKI Quality Manual Rev. D 12-28-2012kzl009No ratings yet

- MSIL Training On VSA Check SheetDocument145 pagesMSIL Training On VSA Check Sheetsumit_saraf_550% (16)

- LPA Line Walk Audit MethodologyDocument4 pagesLPA Line Walk Audit Methodologymougib soltaniNo ratings yet

- ISO450012018AuditChecklistEng 13Document1 pageISO450012018AuditChecklistEng 13Anabela GibraltarNo ratings yet

- Training On VSA Check Sheet PDFDocument151 pagesTraining On VSA Check Sheet PDFSwapnil Bachhav100% (2)

- MoDOT Route XX Project Quality Management PlanDocument17 pagesMoDOT Route XX Project Quality Management PlanKhaled Abdelbaki100% (1)

- Gap Analysis ISO 13485 2016 - IsO 9001 2015 TemplateDocument36 pagesGap Analysis ISO 13485 2016 - IsO 9001 2015 Templateشیخ صادقNo ratings yet

- LanguageCert PP2 A2 IESOL SpeakingDocument7 pagesLanguageCert PP2 A2 IESOL SpeakingRuslim SenLinNo ratings yet

- LanguageCert PP2 A2 IESOL SpeakingDocument7 pagesLanguageCert PP2 A2 IESOL SpeakingRuslim SenLinNo ratings yet

- The Preparation of Validation Master Plan: Manual: 035Document6 pagesThe Preparation of Validation Master Plan: Manual: 035Rambabu komati - QA71% (7)

- Audit Report Template SummaryDocument4 pagesAudit Report Template Summaryivonastrid552No ratings yet

- Compliance Monitoring Report New FormatDocument5 pagesCompliance Monitoring Report New FormatPatrick Antony Ngojo100% (1)

- Establishing A CGMP Laboratory Audit System: A Practical GuideFrom EverandEstablishing A CGMP Laboratory Audit System: A Practical GuideNo ratings yet

- ABS Rules For Piping and FittingsDocument2 pagesABS Rules For Piping and Fittingsmaha100% (1)

- Matrice de Conformite - Norme API q1Document30 pagesMatrice de Conformite - Norme API q1Mohamed BencharifNo ratings yet

- 7.1.4 Transfer of Work Worksheet Template and Checklists 1OCT2016Document12 pages7.1.4 Transfer of Work Worksheet Template and Checklists 1OCT2016cover filterNo ratings yet

- Ilide - Info Msil Training On Vsa Check Sheet PRDocument145 pagesIlide - Info Msil Training On Vsa Check Sheet PRShubham SainiNo ratings yet

- Fly 10 Your Super FutureDocument3 pagesFly 10 Your Super FutureRichard Colón67% (3)

- PRO-FORMA COMPLIANCE MONITORING REPORTDocument7 pagesPRO-FORMA COMPLIANCE MONITORING REPORTSolNo ratings yet

- Audit GuideDocument20 pagesAudit GuideJuanaNo ratings yet

- Compliance Monitoring ReportDocument6 pagesCompliance Monitoring ReportJelor Gallego100% (1)

- A Walker Presentation - IsO 17000 Process Models 2013 08 15Document9 pagesA Walker Presentation - IsO 17000 Process Models 2013 08 15ediNo ratings yet

- Scale Up Process Approval Changes (Supac)Document21 pagesScale Up Process Approval Changes (Supac)Shibbu Gangwar100% (1)

- LanguageCert PP3 A2 IESOL SpeakingDocument7 pagesLanguageCert PP3 A2 IESOL SpeakingRuslim SenLinNo ratings yet

- LanguageCert PP3 A2 IESOL SpeakingDocument7 pagesLanguageCert PP3 A2 IESOL SpeakingRuslim SenLinNo ratings yet

- ISO 20000-1 Transition GuideDocument10 pagesISO 20000-1 Transition GuideCarlos Arley Gonzalez Rocha100% (4)

- Section 2 Fire Safety Measures 2.1.1 Structural Fire ProtectionDocument15 pagesSection 2 Fire Safety Measures 2.1.1 Structural Fire ProtectionsinghajitbNo ratings yet

- Quality Management Plan Template835214620210412Document6 pagesQuality Management Plan Template835214620210412nandiniNo ratings yet

- ISTQB CTAL-TA Release-Notes v3.1.0Document4 pagesISTQB CTAL-TA Release-Notes v3.1.0AmiraNo ratings yet

- Template QA QC ProceduresDocument16 pagesTemplate QA QC Proceduresdadz mingiNo ratings yet

- Title Pages QMSDocument61 pagesTitle Pages QMSJohn JosephNo ratings yet

- Corrective Action Plan Procedure AB-DOC-21-024.0Document6 pagesCorrective Action Plan Procedure AB-DOC-21-024.0SALES AL ABERNo ratings yet

- Title Pages QMSDocument42 pagesTitle Pages QMSJohn JosephNo ratings yet

- IATF Rules for Achieving Recognition 2nd Edition Sanctioned InterpretationsDocument4 pagesIATF Rules for Achieving Recognition 2nd Edition Sanctioned InterpretationsRodolfo LunaNo ratings yet

- PQR Procedure Review MatrixDocument9 pagesPQR Procedure Review MatrixMARY JOY PAMBIDNo ratings yet

- Quality Management PlanDocument14 pagesQuality Management PlanPradeep GoswamiNo ratings yet

- Appendix A - Supplier ISO-TS16949 Checklist-Rev.1 PDFDocument45 pagesAppendix A - Supplier ISO-TS16949 Checklist-Rev.1 PDFPurushothama Nanje GowdaNo ratings yet

- EIS POM ControllingDocument29 pagesEIS POM ControllingKurosawa MazurukiNo ratings yet

- Phase Transition MonitoringDocument2 pagesPhase Transition Monitoringمحمود علي الخطيبNo ratings yet

- Pro-Forma Proponent Compliance Monitoring Report (CMR) : Semi-Annual Module 5 of SMRDocument4 pagesPro-Forma Proponent Compliance Monitoring Report (CMR) : Semi-Annual Module 5 of SMRJennylyn RodriquezNo ratings yet

- Am Tool 11 v3.0.1Document4 pagesAm Tool 11 v3.0.1Kenyo Reynaldo Quispe TurpoNo ratings yet

- Use of Extl Docs in Product RealizationDocument3 pagesUse of Extl Docs in Product RealizationJeyakumarNo ratings yet

- Pro-Forma Proponent Compliance Monitoring Report (CMR) : Semi-Annual Module 5 of SMRDocument4 pagesPro-Forma Proponent Compliance Monitoring Report (CMR) : Semi-Annual Module 5 of SMRekweriNo ratings yet

- 2017 - Compliance Monitoring ReportDocument27 pages2017 - Compliance Monitoring ReportaseascanNo ratings yet

- SQM - WC - Koeberg Dassenberg 132kV - Cat 2Document10 pagesSQM - WC - Koeberg Dassenberg 132kV - Cat 2Tiaan EsterhuyseNo ratings yet

- Reminders For QMS Documentation of DBTC MatiDocument7 pagesReminders For QMS Documentation of DBTC MatiCamelle Kate BarbasNo ratings yet

- Compliance and Impact Monitoring ReportDocument4 pagesCompliance and Impact Monitoring ReportJennylyn RodriquezNo ratings yet

- CMR Compliance SummaryDocument5 pagesCMR Compliance SummaryGlaiza Marie DimaculanganNo ratings yet

- Template 3 Qa QC Procedures 1Document17 pagesTemplate 3 Qa QC Procedures 1Narendra100% (1)

- Pro-Forma Proponent Compliance Monitoring Report (CMR) : Semi-Annual Module 5 of SMRDocument5 pagesPro-Forma Proponent Compliance Monitoring Report (CMR) : Semi-Annual Module 5 of SMRCharles Edison GalleroNo ratings yet

- GAP ANALYSIS ISO 27001 - 2022 v1 1Document21 pagesGAP ANALYSIS ISO 27001 - 2022 v1 1arbiNo ratings yet

- ISO 9001 Certification Audit Report for PNP-DRDDocument3 pagesISO 9001 Certification Audit Report for PNP-DRDRaymond SmithNo ratings yet

- Sop Change ManagementDocument3 pagesSop Change ManagementHanitha (Digital & Technology)No ratings yet

- Proponent Compliance Monitoring Report AnnexDocument4 pagesProponent Compliance Monitoring Report AnnexKendall Paul LaureanoNo ratings yet

- Annex 3-1 Pro-Forma Proponent Compliance Monitoring Report (CMR) Semi-Annual Module 5 of SMRDocument4 pagesAnnex 3-1 Pro-Forma Proponent Compliance Monitoring Report (CMR) Semi-Annual Module 5 of SMRPaolo Q. SangalangNo ratings yet

- CMR Submission FormDocument5 pagesCMR Submission FormMARIBEL LENDIONo ratings yet

- 5 - Chapter05 - Software Quality Infrastructure ComponentsDocument26 pages5 - Chapter05 - Software Quality Infrastructure Componentsphạm thị thương kcnttNo ratings yet

- Documentation Requirements For ISO 9001:2008Document4 pagesDocumentation Requirements For ISO 9001:2008C P Chandrasekaran100% (15)

- Project Quality Assurance and Control GuidanceDocument25 pagesProject Quality Assurance and Control GuidancemblancolNo ratings yet

- Annex 3-1 Pro-Forma Proponent CMRDocument4 pagesAnnex 3-1 Pro-Forma Proponent CMRTata Rato100% (1)

- Excel de Checklist+ISO9001Document22 pagesExcel de Checklist+ISO9001Jaime Verdugo100% (1)

- Parents Report: Week29-Day2Document2 pagesParents Report: Week29-Day2Ruslim SenLinNo ratings yet

- PK1 Week 22 Day 2Document1 pagePK1 Week 22 Day 2Ruslim SenLinNo ratings yet

- PK1 Week 22 Day 2Document1 pagePK1 Week 22 Day 2Ruslim SenLinNo ratings yet

- Letters From Japan 39 S Sixteenth and Seventeenth CenturiesDocument229 pagesLetters From Japan 39 S Sixteenth and Seventeenth CenturiesRuslim SenLinNo ratings yet

- Main Tendencies of Legal Regulation of Termination of The Violated Contract in Foreign and Kazakhstan Civil LawDocument2 pagesMain Tendencies of Legal Regulation of Termination of The Violated Contract in Foreign and Kazakhstan Civil LawRuslim SenLinNo ratings yet

- INTERNATIONAL LEGAL PROTECTION OF INTELLECTUAL PROPERTY WITHIN THE FRAMEWORK OF THE WORLD TRADE ORGANIZATION AND OBLIGATIONS OF THE KAZAKHSTAN IN CONNECTION WITH THE EURASIAN ECONOMIC UNION PARTICIPATIONDocument3 pagesINTERNATIONAL LEGAL PROTECTION OF INTELLECTUAL PROPERTY WITHIN THE FRAMEWORK OF THE WORLD TRADE ORGANIZATION AND OBLIGATIONS OF THE KAZAKHSTAN IN CONNECTION WITH THE EURASIAN ECONOMIC UNION PARTICIPATIONRuslim SenLinNo ratings yet

- Ruslim Shegebayev: (Linkedin)Document1 pageRuslim Shegebayev: (Linkedin)Ruslim SenLinNo ratings yet

- LicenseDocument1 pageLicenseRuslim SenLinNo ratings yet

- International Legal Regulation of Food SafetyDocument3 pagesInternational Legal Regulation of Food SafetyRuslim SenLinNo ratings yet

- ProfileDocument2 pagesProfileRuslim SenLinNo ratings yet

- InvoiceDocument1 pageInvoiceRuslim SenLinNo ratings yet

- Kahn Freund 1974 The Modern Law ReviewDocument27 pagesKahn Freund 1974 The Modern Law ReviewNoelia ArceNo ratings yet

- Ruslim Shegebayev: Personal SummaryDocument1 pageRuslim Shegebayev: Personal SummaryRuslim SenLinNo ratings yet

- Habitat International: Yani Lai, Yi Peng, Bin Li, Yanliu LinDocument10 pagesHabitat International: Yani Lai, Yi Peng, Bin Li, Yanliu LinRuslim SenLinNo ratings yet

- Russell Shegebayev: Personal SummaryDocument1 pageRussell Shegebayev: Personal SummaryRuslim SenLinNo ratings yet

- Legal Transplants and European Private LawDocument11 pagesLegal Transplants and European Private LawRuslim SenLinNo ratings yet

- Languagecert Access A2 Entry Level 2 International Esol (Speaking) Practice Paper 6Document7 pagesLanguagecert Access A2 Entry Level 2 International Esol (Speaking) Practice Paper 6Ruslim SenLinNo ratings yet

- Kahn Freund 1974 The Modern Law ReviewDocument27 pagesKahn Freund 1974 The Modern Law ReviewNoelia ArceNo ratings yet

- Critical ComparisonsDocument47 pagesCritical ComparisonsRuslim SenLinNo ratings yet

- Customary and modern law in Madagascar's environmental protectionDocument15 pagesCustomary and modern law in Madagascar's environmental protectionRuslim SenLinNo ratings yet

- Critical ComparisonsDocument47 pagesCritical ComparisonsRuslim SenLinNo ratings yet

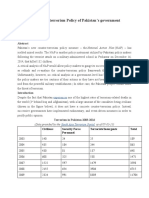

- Counterterrorism Policy of Pakistn's Government. by HussianDocument13 pagesCounterterrorism Policy of Pakistn's Government. by HussianRuslim SenLinNo ratings yet

- Mobile and Wireless Communication Complete Lecture Notes #4Document20 pagesMobile and Wireless Communication Complete Lecture Notes #4Student Lecture Notes100% (1)

- Notified Autonomous Bodies of The Federal Government PDFDocument7 pagesNotified Autonomous Bodies of The Federal Government PDFGull SabeerNo ratings yet

- Lagnas CharacterDocument14 pagesLagnas CharactertechkasambaNo ratings yet

- RXF-C: Air Conditioning Technical DataDocument18 pagesRXF-C: Air Conditioning Technical DataJuan LezamaNo ratings yet

- Aplac TR 001 Issue 2Document48 pagesAplac TR 001 Issue 2gaunananguyenNo ratings yet

- 80312A-ENUS Error LogDocument10 pages80312A-ENUS Error LogSafdar HussainNo ratings yet

- Calculating The Pinnacle Numbers - NumerologistDocument2 pagesCalculating The Pinnacle Numbers - NumerologistPanther PrimeNo ratings yet

- From The Conventional Total Station To The Prospective Image Assisted Photogrammetric Scanning Total Station: Comprehensive ReviewDocument7 pagesFrom The Conventional Total Station To The Prospective Image Assisted Photogrammetric Scanning Total Station: Comprehensive ReviewLeroy Lionel SonfackNo ratings yet

- Selection and Characterisation of The Predominant Lactobacillus Species As A Starter Culture in The Preparation of Kocho, Fermented Food From EnsetDocument12 pagesSelection and Characterisation of The Predominant Lactobacillus Species As A Starter Culture in The Preparation of Kocho, Fermented Food From EnsetHelen WeldemichaelNo ratings yet

- Modelling of Graphene Nano-Ribbon Transistors (Gnr-Fets) With Enhanced Drive CurrentsDocument9 pagesModelling of Graphene Nano-Ribbon Transistors (Gnr-Fets) With Enhanced Drive CurrentsShailendra YadavNo ratings yet

- Security in Communications and StorageDocument27 pagesSecurity in Communications and StorageAfonso DelgadoNo ratings yet

- Commissioning FPFH SettingDocument6 pagesCommissioning FPFH SettingYulius IrawanNo ratings yet

- Full Download Law and Ethics For The Health Professions 6th Edition Judson Harrison Test Bank PDF Full ChapterDocument20 pagesFull Download Law and Ethics For The Health Professions 6th Edition Judson Harrison Test Bank PDF Full Chapterhorriblebaculite0ly6t100% (15)

- Create Database VentasDocument11 pagesCreate Database VentasAnonymous BwTccxNo ratings yet

- Important NoteDocument4 pagesImportant NotemikiNo ratings yet

- NRD Idg Gy Fiyf FofkDocument7 pagesNRD Idg Gy Fiyf FofkMERA MENTALNo ratings yet

- Natural Lighting at The Kimbell Museum: Gifford Pierce of IdahoDocument5 pagesNatural Lighting at The Kimbell Museum: Gifford Pierce of IdahoPriscilia ElisabethNo ratings yet

- Cc-5 SQL TableDocument5 pagesCc-5 SQL TableK.D. computerNo ratings yet

- BCS - SS-CRM 460 - 2 Jun2019Document2 pagesBCS - SS-CRM 460 - 2 Jun2019Peterson SudlabNo ratings yet

- Ophelia SyndromeDocument10 pagesOphelia SyndromeJulioroncal100% (1)

- Pathway 4 Unit 2Document9 pagesPathway 4 Unit 2Andrea ParedesNo ratings yet

- De Bono 6 Action Shoesdoc - CompressDocument12 pagesDe Bono 6 Action Shoesdoc - CompressHazel RománNo ratings yet

- Concrete Mix Design Report for M20 GradeDocument5 pagesConcrete Mix Design Report for M20 GradesatishNo ratings yet

- 2.1.1.5 Packet Tracer - Create A Simple Network Using Packet Tracer PDFDocument15 pages2.1.1.5 Packet Tracer - Create A Simple Network Using Packet Tracer PDFTeixeira JorgeNo ratings yet

- Panasonic Phone System KXT308Document6 pagesPanasonic Phone System KXT308Kellie CroftNo ratings yet