Professional Documents

Culture Documents

Acronal PRO 7600: Exemplary Applications Performance Highlights Key Technical Data

Uploaded by

Duodo NguyenOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Acronal PRO 7600: Exemplary Applications Performance Highlights Key Technical Data

Uploaded by

Duodo NguyenCopyright:

Available Formats

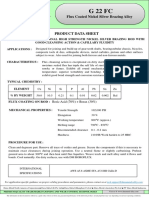

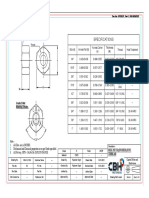

Styrene/acrylic dispersion for dip coatings

Acronal® PRO 7600

Performance highlights Key technical data Exemplary applications

Good adhesion on steel and galvanized Self crosslinking styrene-acrylic dispersion

Good corrosion protection Solids by weight: ~ 50 %

Controlled rheology at low shear rates Viscosity: 300–350 mPa∙s (25 °C)

Good acid and Cr-VI stability (coil) pH: 9–9.5

Intrinsic rheology for low shear applications Availability

MFT: ~ 22 °C

Rheology (= film thickness) of dip coatings can be Density 1.04 g/cm3 Samples & commercial

easily adjusted with BASF formulation additives quantities available

(see table)

Usage PRO 7600 Acronal Rheovis Rheovis Rheovis Rheovis Rheovis Rheovis Rheovis

Pro 7600 1337 1303 1331 1291 1332 1330 1256

Blank 1% 1% 1% 1% 1% 1% 1%

Light to medium duty (≤ 240 h SST) applications

Viscosity

(C2–C3) 1 s-1 4307 4782 7384 5922 19226 11449 3173 19181

Steel and galvanized parts and constructions Viscosity

10 s-1 914 1144 1608 1573 8324 1409 936 7252

Electricity pylons, metal roofs Viscosity

Suitable for thin layer applications (DFT 2–5 µm), 100 s-1 261 340 443 613 2582 411 342 1779

Viscosity

e.g. permanent coating, zinc lamellar, pretreatment 1000 s-1 99 125 147 253 329 150 143 262

etc. Viscosity of Acronal PRO 7600 with different rheology additves measured at different shear rates

Especially suited for dip-coatings with Rheometer. Viscosity at shear rate 1 s-1 is important for dip coatings

Red primer: Salt Spray Test Results

on Cold Rolled Steel after 240 h (80

microns dry film thickness)

1 26.03.2020

You might also like

- Viscolam PS 202 - en 2019Document1 pageViscolam PS 202 - en 2019Duodo NguyenNo ratings yet

- 1.9.1.2-75B - BondArc WireDocument6 pages1.9.1.2-75B - BondArc WireGiovanni Cervera FerriolNo ratings yet

- Enlistment Vendor ListDocument24 pagesEnlistment Vendor ListMahir PambharNo ratings yet

- ATA Heet: Marvac 250 VIM-VARDocument2 pagesATA Heet: Marvac 250 VIM-VARspibluNo ratings yet

- What Is Aluminium PCB Manufacturing ProcessDocument19 pagesWhat Is Aluminium PCB Manufacturing ProcessjackNo ratings yet

- CR Caterpillar NewDocument103 pagesCR Caterpillar NewSuratmanNo ratings yet

- Tafa Arc Spray Wire 1.9.1.2-01T - Aluminum Wire 01TDocument4 pagesTafa Arc Spray Wire 1.9.1.2-01T - Aluminum Wire 01TIkhsan LyNo ratings yet

- Flowcrete Asia System Data Sheet Flowflake GlowDocument2 pagesFlowcrete Asia System Data Sheet Flowflake GlowbidiecNo ratings yet

- Carboguard 890 PDSDocument5 pagesCarboguard 890 PDScrisNo ratings yet

- Carboguard 893: Selection & Specification DataDocument5 pagesCarboguard 893: Selection & Specification DataQuy RomNo ratings yet

- Carboguard 893 PDSDocument2 pagesCarboguard 893 PDSNguyễn Thị Châu TâyNo ratings yet

- 1.4462 SpecificationDocument2 pages1.4462 SpecificationSergeyNo ratings yet

- ARCAP - Grades and PropertiesDocument7 pagesARCAP - Grades and PropertiesEminent RishNo ratings yet

- Paint Henelit Henedur SFCDocument2 pagesPaint Henelit Henedur SFCsljiva11No ratings yet

- Carboguard 890 PDSDocument5 pagesCarboguard 890 PDSAchraf BoudayaNo ratings yet

- X65Cr13 C 0.58 - 0.70 CR 12.50 - 14.50 S Max. 0.015Document2 pagesX65Cr13 C 0.58 - 0.70 CR 12.50 - 14.50 S Max. 0.015Jim SmithNo ratings yet

- Black Knight 1000 BrochureDocument2 pagesBlack Knight 1000 BrochureAdamMitchellNo ratings yet

- Stainless Steel 1.4462 (2205) Sheet and Plate: Specifications Alloy DesignationsDocument3 pagesStainless Steel 1.4462 (2205) Sheet and Plate: Specifications Alloy DesignationsPaulNo ratings yet

- PS-SB-499 EngDocument2 pagesPS-SB-499 EngaylinaykanNo ratings yet

- Data MP35N Rev-2Document2 pagesData MP35N Rev-2Nishant MehtaNo ratings yet

- RT/duroid 6006/6010LM High Frequency Laminates: FeaturesDocument2 pagesRT/duroid 6006/6010LM High Frequency Laminates: FeaturesyyryNo ratings yet

- Bitumastic 300 MDocument2 pagesBitumastic 300 MANIBALLOPEZVEGA100% (1)

- Ceralag-01: Ceramic Lagging SheetingDocument2 pagesCeralag-01: Ceramic Lagging SheetingARUN KUMAR DASNo ratings yet

- Carbozinc 11: Selection & Specification Data Substrates & Surface PreparationDocument2 pagesCarbozinc 11: Selection & Specification Data Substrates & Surface PreparationAhmed ElbahrawyNo ratings yet

- Cu ZN 10Document1 pageCu ZN 10Sara RiddleNo ratings yet

- 1 Ceramic Fiber BoardsDocument2 pages1 Ceramic Fiber BoardsMahesh MishraNo ratings yet

- Carbon Steel Belt Biscuits Line Bakery OvenDocument1 pageCarbon Steel Belt Biscuits Line Bakery OvenLavender ShenNo ratings yet

- Sanitile 120 PDSDocument4 pagesSanitile 120 PDSDuongthithuydungNo ratings yet

- Flowshield LXP System Data Sheet (en-GB)Document2 pagesFlowshield LXP System Data Sheet (en-GB)nblinoNo ratings yet

- Section 2 - Nikko Welding ConsumablesDocument9 pagesSection 2 - Nikko Welding Consumablesangga franugrahaNo ratings yet

- Resource Guide: Section 4: Ni-ResistDocument8 pagesResource Guide: Section 4: Ni-ResistMiguel Angel EscalanteNo ratings yet

- Aalco Metals LTD Stainless Steel 14462 Sheet and Plate 102Document3 pagesAalco Metals LTD Stainless Steel 14462 Sheet and Plate 102Jessicalba LouNo ratings yet

- Stainless Steel Bar 431 Atlas 431: Colour Code: Signal RedDocument3 pagesStainless Steel Bar 431 Atlas 431: Colour Code: Signal RedNitin AggarwalNo ratings yet

- Nerocoat Epoxy Powders 6000 PDSDocument2 pagesNerocoat Epoxy Powders 6000 PDSarvind kumar yadavNo ratings yet

- Cu ZN 15Document2 pagesCu ZN 15wjjt6chgtmNo ratings yet

- Cuznpb2 LeadedDocument3 pagesCuznpb2 Leadedwjjt6chgtmNo ratings yet

- G 22 FC Product Data Sheet (With Specs)Document1 pageG 22 FC Product Data Sheet (With Specs)candraNo ratings yet

- CuNiSi AlloyDocument6 pagesCuNiSi AlloyJdjoNo ratings yet

- Delta Protekt KL120Document1 pageDelta Protekt KL120GavinNo ratings yet

- Urethane Coating 165 PWDocument2 pagesUrethane Coating 165 PWANIBALLOPEZVEGANo ratings yet

- 1.4028 enDocument2 pages1.4028 ensandeep acharNo ratings yet

- Carboguard 893 PDSDocument5 pagesCarboguard 893 PDSUtomoNo ratings yet

- Electrode Booklet F Web 100Document1 pageElectrode Booklet F Web 100satnamNo ratings yet

- Fast Clad HB Acrylic: Protective & Marine CoatingsDocument4 pagesFast Clad HB Acrylic: Protective & Marine CoatingsAna CabreraNo ratings yet

- Flowcrete Asia Mondéco Crystal May2020 TdsDocument2 pagesFlowcrete Asia Mondéco Crystal May2020 TdsQuoc AnNo ratings yet

- Specification Sheet: 2304: (UNS S32304)Document2 pagesSpecification Sheet: 2304: (UNS S32304)Deepak TdNo ratings yet

- High Tensile: Voestalpine High Performance Metals (Australia) Pty LTDDocument5 pagesHigh Tensile: Voestalpine High Performance Metals (Australia) Pty LTDSinan YıldızNo ratings yet

- Carboguard 690: Selection & Specification Data Selection & Specification DataDocument2 pagesCarboguard 690: Selection & Specification Data Selection & Specification DataImran AhmadNo ratings yet

- Carboguard 893 SG PDSDocument2 pagesCarboguard 893 SG PDSAhmed ElbahrawyNo ratings yet

- 1-2620 Low Voc Conformal CoatingDocument4 pages1-2620 Low Voc Conformal CoatingGreat StuffNo ratings yet

- Carboguard 893 PDSDocument5 pagesCarboguard 893 PDSTrịnh Minh KhoaNo ratings yet

- Data Sheet CuZn20Al2AsDocument1 pageData Sheet CuZn20Al2AsJean Carlos Reyna PascualNo ratings yet

- KN0300 - Sonia Brühl - FreeDocument21 pagesKN0300 - Sonia Brühl - FreesbruhlNo ratings yet

- RT-duroid 6006-6010LM Laminate Data Sheet PDFDocument2 pagesRT-duroid 6006-6010LM Laminate Data Sheet PDFClaudia FonsecaNo ratings yet

- BELZONA 1111 Product Specification SheetDocument2 pagesBELZONA 1111 Product Specification SheetMohamed NouzerNo ratings yet

- 718 Stangard Egf (NV)Document5 pages718 Stangard Egf (NV)Sandeep gangulyNo ratings yet

- Done - SSAB - Welding of StrenxDocument16 pagesDone - SSAB - Welding of StrenxMONo ratings yet

- Gb8417domex500mc PDFDocument2 pagesGb8417domex500mc PDFMario MereniNo ratings yet

- Domex 650 MC Hot Rolled, Extra High Strength, Cold Forming SteelDocument2 pagesDomex 650 MC Hot Rolled, Extra High Strength, Cold Forming SteelHugo RodriguezNo ratings yet

- Material Product Data Sheet Chromium Carbide - 20 % Nickel Chromium PowdersDocument4 pagesMaterial Product Data Sheet Chromium Carbide - 20 % Nickel Chromium PowdersJesus D. Gutierrez G.No ratings yet

- Atlas Grade Datasheet 410 Rev May 2008Document2 pagesAtlas Grade Datasheet 410 Rev May 2008Satendra ThakurNo ratings yet

- Loctite EA 3476: Technical Data SheetDocument4 pagesLoctite EA 3476: Technical Data SheetKarsa SambasNo ratings yet

- Dogal LAD High Strength Low Alloy Steels For Cold Forming: GeneralDocument2 pagesDogal LAD High Strength Low Alloy Steels For Cold Forming: Generalchristos032No ratings yet

- Viscopol-7788 en A4Document1 pageViscopol-7788 en A4Duodo NguyenNo ratings yet

- VISCOLAM - PS102 - TDS - 170123 - en 2019Document1 pageVISCOLAM - PS102 - TDS - 170123 - en 2019Duodo NguyenNo ratings yet

- PRIMAL™ AS-356 EmulsionDocument2 pagesPRIMAL™ AS-356 EmulsionLong An ĐỗNo ratings yet

- VISCOLAM 635 TDS 171027 enDocument2 pagesVISCOLAM 635 TDS 171027 enDuodo NguyenNo ratings yet

- Carbowet® DC01 - EvonikDocument2 pagesCarbowet® DC01 - EvonikDuodo NguyenNo ratings yet

- MOMENTIVE - Silquest A-187 - Adhesion Promoter TDSDocument6 pagesMOMENTIVE - Silquest A-187 - Adhesion Promoter TDSDuodo NguyenNo ratings yet

- Binders For Architectural Coatings: Dow Coating MaterialsDocument12 pagesBinders For Architectural Coatings: Dow Coating MaterialsDuodo NguyenNo ratings yet

- Dispex AA4140 - Dispex N40Document3 pagesDispex AA4140 - Dispex N40Duodo NguyenNo ratings yet

- 11da MFFT HDocument4 pages11da MFFT HDuodo NguyenNo ratings yet

- Lumiflon Fe4300: FEVE Waterborne Resin PolyolDocument2 pagesLumiflon Fe4300: FEVE Waterborne Resin PolyolDuodo NguyenNo ratings yet

- MTC PipeDocument1 pageMTC PipeMathavan ABMNo ratings yet

- BOQ - Kaveri IDEMI PDFDocument13 pagesBOQ - Kaveri IDEMI PDFAnjum AttarNo ratings yet

- Value Stream Mapping VSM A Key Tool For Execution of Lean PrinciplesDocument5 pagesValue Stream Mapping VSM A Key Tool For Execution of Lean PrinciplesJustformedia JustformediaNo ratings yet

- Epv Bro Pres 02Document20 pagesEpv Bro Pres 02Miguel CastilloNo ratings yet

- EagleBurgmann - Buraflon 5846 - ENDocument2 pagesEagleBurgmann - Buraflon 5846 - ENsf wNo ratings yet

- Curby Mini-TaperDocument2 pagesCurby Mini-TaperLeo IvaniševićNo ratings yet

- Datasheet FBLT054049 en USDocument1 pageDatasheet FBLT054049 en USSuplidora Industrial 6 SigmaNo ratings yet

- PDS Sikaflex SelfLevelingSealantDocument5 pagesPDS Sikaflex SelfLevelingSealantDerek LobedanNo ratings yet

- Xuper 646 XHDDocument2 pagesXuper 646 XHDJuan LondonoNo ratings yet

- MOLDDocument22 pagesMOLDyusufj721No ratings yet

- Hydration of Blended Cement With High-Volume Slag and Nano-Silica (26.08.2023)Document17 pagesHydration of Blended Cement With High-Volume Slag and Nano-Silica (26.08.2023)Velchuri SairamNo ratings yet

- 2 - 2 Fundamentals of CastingDocument172 pages2 - 2 Fundamentals of CastingColorgold BirlieNo ratings yet

- Rehovot Engineering ProductsDocument8 pagesRehovot Engineering ProductsU M NarayananNo ratings yet

- Grinding WheelDocument12 pagesGrinding WheelNaresh yadavNo ratings yet

- Bha Cartridge Pleated Filters Dust Collection BrochureDocument8 pagesBha Cartridge Pleated Filters Dust Collection Brochuremazouz.lmfNo ratings yet

- SHRH DMW FailuresDocument1 pageSHRH DMW FailuresNandaNo ratings yet

- A Case Study of A Sri Lankan ManufacturingDocument11 pagesA Case Study of A Sri Lankan ManufacturingAlex J. Tocto BustamanteNo ratings yet

- Company Introduction - CINIC - Nutshell - 2.2.2023 - PlasticsDocument20 pagesCompany Introduction - CINIC - Nutshell - 2.2.2023 - PlasticsMAURICIO MEJÍANo ratings yet

- Beveling PDFDocument29 pagesBeveling PDFTechnology SinghNo ratings yet

- Product-Sheet Filter NZB 03 2017Document2 pagesProduct-Sheet Filter NZB 03 2017Nduong NguyenNo ratings yet

- Company Profile ALC 250723Document26 pagesCompany Profile ALC 250723Lâm Quốc TrâmNo ratings yet

- Earthing - Soluti HureDocument32 pagesEarthing - Soluti HureChulpath MendraNo ratings yet

- MillingDocument76 pagesMillingAbduljebar SemuNo ratings yet

- 110372717Document44 pages110372717Alexis Rodrigo Tapia EstrellaNo ratings yet

- Ryton® PPS - Corrosion-Resistant-CoatingsDocument9 pagesRyton® PPS - Corrosion-Resistant-CoatingsAhmed FathyNo ratings yet

- Specifications: Hex Nuts (Inches) Unc ThreadDocument2 pagesSpecifications: Hex Nuts (Inches) Unc ThreadqualityNo ratings yet

- Effect of Hardening Conditions On Mechanical Properties of High Speed SteelsDocument9 pagesEffect of Hardening Conditions On Mechanical Properties of High Speed SteelsInisial DINo ratings yet