Professional Documents

Culture Documents

Goel TMT Physical Report-Signed

Uploaded by

sitaramap10 sathupallyOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Goel TMT Physical Report-Signed

Uploaded by

sitaramap10 sathupallyCopyright:

Available Formats

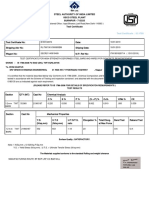

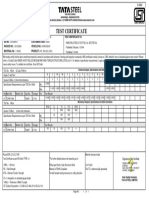

Test Report on Mechanical Properties of High Strength Deformed Steel Bar

TRF No :- TMT/20mm/20220611/004 Date of Report :- 13-06-2022

Report Ref No :- MCS-HYD/2022-23/Reports/Lab/Steel/20mm/20220613004

:- SRLIP-Package-10 Sathupally Trunts Earth Work, Excavation, Forming embankment and providing CC Lining

including construction of CM&CD works structure on of sathupally main canal from km 23.700 near cherukupally (V)

sathupally (M) in Khammam District to km 42.775 near Gandugulapally (V) Dammapeta (M) in Bhadradri Kothagudem

Name of Work District Bethupally branch canal from 0/0 to 1.740 in Gandugulapally (V) Dammapeta (M) and Dammapeta branch

canal from 0/0 to near Gandugulapally (V) to km 13.450 near Apparaopeta (V) of Dammapeta (M) in Bhadradri

Kothagudem District. Ramanthapur Pedda Cheruvu to Ramanthapur Chinna Cheruvu b) Ramanthapur Chinna Cheruvu

to Irrigation Channel in L.B Nagar Zone of GHMC Under Package V (E) of Strategic Nala Development Programme.

Agency :- M/S Prasad & Co. (Pw) LTD AVR. MAX (JV)

Material Received :- High Strength Deformed Steel Bar/Reinforcement Steel Bar Method of Test :- I.S.1608-2018 P-1

Sample Mark :- GOEL TMT Test Started :- 11-06-2022

Grade of Steel :- Fe 500 D Test Completed :- 11-06-2022

A) High Strength Deformed Steel Bar test Result.

Cross Sectional Area Proof Stress 0.2% / Yield Tensile Stress Bend/Re-Bend

S.NO Bar Dia (mm) Mass in Kg/m Elongation %

(mm2) Stress (Mpa) (Mpa) Stress

1 20.0 2.424 314.16 576.0 664.00 17.60 A

2 20.0 2.428 314.16 588.7 668.00 17.90 A

3 20.0 2.421 314.16 589.1 659.00 17.10 A

IS:1599-1985 RA

Method of Test IS: 1786:2008 RA-2013 IS: 1608-2018 P-1

2006

Bend/Rebend Stresses Type of Class A= Satisfaction, Type of Class B= Unsatisfaction

Requirement as per IS 1786-2008 RA 2013, (Amend 4, 2019)

Property Fe 415 Fe 415D Fe 500 Fe 500D Fe 550 Fe 550D Fe 600

0.2% Proof 415 415 500 500 550 550 600

Max.tensile Stress N/mm2,

Min/% more than actual Yield 485/10% 485/12% 545/8% 565/10% 585/6% 600/8% 660/6%

Stress

Min Elongation % 14.8 18 12 16 10 14.5 10

Bend Test:- There Shall not be any transverse crack/fracture in the bent portion.

Requirement as per IS 1786-2008 RA 2013, (Amend 4, 2019)

Diameter in mm 8 10 12 16 20 25 28 32

Mass per meter(kg) 0.395 0.617 0.888 1.580 2.470 3.850 4.830 6.310

Tolerances on Nominal -8% -6% -4%

**End of Report**

Note:-

1. The Results are given only for the samples submitted by the Client.

2. Manglam Consultancy Services is not responsible for any interpretation of test results.

3. Reports are not supposed to be used for publicity.

For Manglam Consultancy Services Hyderabad

Tested By Authorised Signatory

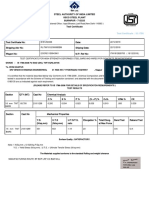

Test Report on Mechanical Properties of High Strength Deformed Steel Bar

TRF No :- TMT/16mm/20220611/003 Date of Report :- 13-06-2022

Report Ref No :- MCS-HYD/2022-23/Reports/Lab/Steel/16mm/20220613003

:- SRLIP-Package-10 Sathupally Trunts Earth Work, Excavation, Forming embankment and providing CC Lining

including construction of CM&CD works structure on of sathupally main canal from km 23.700 near cherukupally (V)

sathupally (M) in Khammam District to km 42.775 near Gandugulapally (V) Dammapeta (M) in Bhadradri Kothagudem

Name of Work District Bethupally branch canal from 0/0 to 1.740 in Gandugulapally (V) Dammapeta (M) and Dammapeta branch

canal from 0/0 to near Gandugulapally (V) to km 13.450 near Apparaopeta (V) of Dammapeta (M) in Bhadradri

Kothagudem District. Ramanthapur Pedda Cheruvu to Ramanthapur Chinna Cheruvu b) Ramanthapur Chinna Cheruvu

to Irrigation Channel in L.B Nagar Zone of GHMC Under Package V (E) of Strategic Nala Development Programme.

Agency :- M/S Prasad & Co. (Pw) LTD AVR. MAX (JV)

Material Received :- High Strength Deformed Steel Bar/Reinforcement Steel Bar Method of Test :- I.S.1608-2018 P-1

Sample Mark :- GOEL TMT Test Started :- 11-06-2022

Grade of Steel :- Fe 500 D Test Completed :- 11-06-2022

A) High Strength Deformed Steel Bar test Result.

Cross Sectional Area Proof Stress 0.2% / Yield Tensile Stress Bend/Re-Bend

S.NO Bar Dia (mm) Mass in Kg/m Elongation %

(mm2) Stress (Mpa) (Mpa) Stress

1 16.0 1.558 201.06 518.0 612.00 18.2 A

2 16.0 1.560 201.06 522.0 615.00 18.8 A

3 16.0 1.549 201.06 512.0 609.00 17.9 A

IS:1599-1985 RA

Method of Test IS: 1786:2008 RA-2013 IS: 1608-2018 P-1

2006

Bend/Rebend Stresses Type of Class A= Satisfaction, Type of Class B= Unsatisfaction

Requirement as per IS 1786-2008 RA 2013, (Amend 4, 2019)

Property Fe 415 Fe 415D Fe 500 Fe 500D Fe 550 Fe 550D Fe 600

0.2% Proof 415 415 500 500 550 550 600

Max.tensile Stress N/mm2,

Min/% more than actual Yield 485/10% 485/12% 545/8% 565/10% 585/6% 600/8% 660/6%

Stress

Min Elongation % 14.8 18 12 16 10 14.5 10

Bend Test:- There Shall not be any transverse crack/fracture in the bent portion.

Requirement as per IS 1786-2008 RA 2013, (Amend 4, 2019)

Diameter in mm 8 10 12 16 20 25 28 32

Mass per meter(kg) 0.395 0.617 0.888 1.580 2.470 3.850 4.830 6.310

Tolerances on Nominal -8% -6% -4%

**End of Report**

Note:-

1. The Results are given only for the samples submitted by the Client.

2. Manglam Consultancy Services is not responsible for any interpretation of test results.

3. Reports are not supposed to be used for publicity.

For Manglam Consultancy Services Hyderabad

Tested By Authorised Signatory

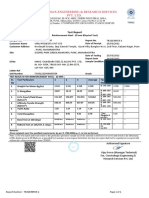

Test Report on Mechanical Properties of High Strength Deformed Steel Bar

TRF No :- TMT/12mm/20220611/002 Date of Report :- 13-06-2022

Report Ref No :- MCS-HYD/2022-23/Reports/Lab/Steel/12mm/20220613002

:- SRLIP-Package-10 Sathupally Trunts Earth Work, Excavation, Forming embankment and providing CC Lining

including construction of CM&CD works structure on of sathupally main canal from km 23.700 near cherukupally (V)

sathupally (M) in Khammam District to km 42.775 near Gandugulapally (V) Dammapeta (M) in Bhadradri

Name of Work Kothagudem District Bethupally branch canal from 0/0 to 1.740 in Gandugulapally (V) Dammapeta (M) and

Dammapeta branch canal from 0/0 to near Gandugulapally (V) to km 13.450 near Apparaopeta (V) of Dammapeta

(M) in Bhadradri Kothagudem District. Ramanthapur Pedda Cheruvu to Ramanthapur Chinna Cheruvu b)

Ramanthapur Chinna Cheruvu to Irrigation Channel in L.B Nagar Zone of GHMC Under Package V (E) of Strategic Nala

Agency :- M/S Prasad & Co. (Pw) LTD AVR. MAX (JV)

Material Received :- High Strength Deformed Steel Bar/Reinforcement Steel Bar Method of Test :- I.S.1608-2018 P-1

Sample Mark :- GOEL TMT Test Started :- 11-06-2022

Grade of Steel :- Fe 500 D Test Completed :- 11-06-2022

A) High Strength Deformed Steel Bar test Result.

Cross Sectional Area Proof Stress 0.2% / Yield Tensile Stress Bend/Re-Bend

S.NO Bar Dia (mm) Mass in Kg/m Elongation %

(mm2) Stress (Mpa) (Mpa) Stress

1 12.0 0.893 113.10 645.0 695.00 21.6 A

2 12.0 0.887 113.10 642.0 691.00 19.2 A

3 12.0 0.883 113.10 637.0 697.00 19.8 A

IS:1599-1985 RA

Method of Test IS: 1786:2008 RA-2013 IS: 1608-2018 P-1

2006

Bend/Rebend Stresses Type of Class A= Satisfaction, Type of Class B= Unsatisfaction

Requirement as per IS 1786-2008 RA 2013, (Amend 4, 2019)

Property Fe 415 Fe 415D Fe 500 Fe 500D Fe 550 Fe 550D Fe 600

0.2% Proof 415 415 500 500 550 550 600

Max.tensile Stress N/mm2,

Min/% more than actual 485/10% 485/12% 545/8% 565/10% 585/6% 600/8% 660/6%

Yield Stress

Min Elongation % 14.8 18 12 16 10 14.5 10

Bend Test:- There Shall not be any transverse crack/fracture in the bent portion.

Requirement as per IS 1786-2008 RA 2013, (Amend 4, 2019)

Diameter in mm 8 10 12 16 20 25 28 32

Mass per meter(kg) 0.395 0.617 0.888 1.580 2.470 3.850 4.830 6.310

Tolerances on Nominal -8% -6% -4%

**End of Report**

Note:-

1. The Results are given only for the samples submitted by the Client.

2. Manglam Consultancy Services is not responsible for any interpretation of test results.

3. Reports are not supposed to be used for publicity.

For Manglam Consultancy Services Hyderabad

Tested By Authorised Signatory

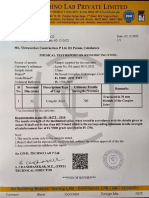

Test Report on Mechanical Properties of High Strength Deformed Steel Bar

TRF No :- TMT/10mm/20220611/001 Date of Report :- 13-06-2022

Report Ref No :- MCS-HYD/2022-23/Reports/Lab/Steel/10mm/20220613001

:- SRLIP-Package-10 Sathupally Trunts Earth Work, Excavation, Forming embankment and providing CC Lining

including construction of CM&CD works structure on of sathupally main canal from km 23.700 near cherukupally (V)

sathupally (M) in Khammam District to km 42.775 near Gandugulapally (V) Dammapeta (M) in Bhadradri

Name of Work Kothagudem District Bethupally branch canal from 0/0 to 1.740 in Gandugulapally (V) Dammapeta (M) and

Dammapeta branch canal from 0/0 to near Gandugulapally (V) to km 13.450 near Apparaopeta (V) of Dammapeta

(M) in Bhadradri Kothagudem District. Ramanthapur Pedda Cheruvu to Ramanthapur Chinna Cheruvu b)

Ramanthapur Chinna Cheruvu to Irrigation Channel in L.B Nagar Zone of GHMC Under Package V (E) of Strategic Nala

Agency :- M/S Prasad & Co. (Pw) LTD AVR. MAX (JV)

Material Received :- High Strength Deformed Steel Bar/Reinforcement Steel Bar Method of Test :- I.S.1608-2018 P-1

Sample Mark :- GOEL TMT Test Started :- 11-06-2022

Grade of Steel :- Fe 500 D Test Completed :- 11-06-2022

A) High Strength Deformed Steel Bar test Result.

Cross Sectional Area Proof Stress 0.2% / Yield Tensile Stress Bend/Re-Bend

S.NO Bar Dia (mm) Mass in Kg/m Elongation %

(mm2) Stress (Mpa) (Mpa) Stress

1 10.0 0.600 78.54 588.0 658.00 20.3 A

2 10.0 0.608 78.54 586.0 659.00 18.2 A

3 10.0 0.602 78.54 583.0 655.00 19.5 A

IS:1599-1985 RA

Method of Test IS: 1786:2008 RA-2013 IS: 1608-2018 P-1

2006

Bend/Rebend Stresses Type of Class A= Satisfaction, Type of Class B= Unsatisfaction

Requirement as per IS 1786-2008 RA 2013, (Amend 4, 2019)

Property Fe 415 Fe 415D Fe 500 Fe 500D Fe 550 Fe 550D Fe 600

0.2% Proof 415 415 500 500 550 550 600

Max.tensile Stress N/mm2,

Min/% more than actual 485/10% 485/12% 545/8% 565/10% 585/6% 600/8% 660/6%

Yield Stress

Min Elongation % 14.8 18 12 16 10 14.5 10

Bend Test:- There Shall not be any transverse crack/fracture in the bent portion.

Requirement as per IS 1786-2008 RA 2013, (Amend 4, 2019)

Diameter in mm 8 10 12 16 20 25 28 32

Mass per meter(kg) 0.395 0.617 0.888 1.580 2.470 3.850 4.830 6.310

Tolerances on Nominal -8% -6% -4%

**End of Report**

Note:-

1. The Results are given only for the samples submitted by the Client.

2. Manglam Consultancy Services is not responsible for any interpretation of test results.

3. Reports are not supposed to be used for publicity.

For Manglam Consultancy Services Hyderabad

Tested By Authorised Signatory

You might also like

- Test Certificate 12mmDocument1 pageTest Certificate 12mmSabyasachi Bangal67% (9)

- Test Certificate 16mmDocument1 pageTest Certificate 16mmSabyasachi Bangal67% (3)

- Bobcat T2556 Hydraulic Schematic PDFDocument3 pagesBobcat T2556 Hydraulic Schematic PDFAnonymous HxADrI1bNo ratings yet

- R.K Steel Udyog PVT - LTD: Test Certificate For High Strength Deformed Steel Bars and Wires For Concrete ReinforcementDocument2 pagesR.K Steel Udyog PVT - LTD: Test Certificate For High Strength Deformed Steel Bars and Wires For Concrete Reinforcementnanda kishopre100% (4)

- MTC Inv 053 PDFDocument1 pageMTC Inv 053 PDFBeshnu Garanaik100% (2)

- Dinner With FirendsDocument2 pagesDinner With FirendsDaniyal Shahzad0% (2)

- Shades e Q ChartDocument2 pagesShades e Q ChartMadelyn100% (1)

- Manga ListDocument4 pagesManga ListjspamNo ratings yet

- GSM Air InterfaceDocument40 pagesGSM Air InterfacePavalakkodi Bharathi100% (1)

- 21055-Acoustics India - 15nosDocument27 pages21055-Acoustics India - 15nosgowtham_venkat_4No ratings yet

- Constrologix Engineering & Research Services Pvt. LTD.: Test ReportDocument1 pageConstrologix Engineering & Research Services Pvt. LTD.: Test ReportPRASAD THOMBARENo ratings yet

- 16mm Sail Qrcode-1Document2 pages16mm Sail Qrcode-1Mohd imranNo ratings yet

- HR 3.50MM July 2019Document1 pageHR 3.50MM July 2019satrughana patraNo ratings yet

- TMT Fe-550D, 500DDocument9 pagesTMT Fe-550D, 500DRAJKUMAR CHATTERJEE. (RAJA.)No ratings yet

- 08-10-23 We MDPL GVNDRM 2nd Ra BillDocument220 pages08-10-23 We MDPL GVNDRM 2nd Ra BillLavanya vollalaNo ratings yet

- Comment - Design of 24 M Comp Girder-R5 FINAL PDFDocument60 pagesComment - Design of 24 M Comp Girder-R5 FINAL PDFNilay Gandhi100% (2)

- Rebar Coupler SpecificationDocument7 pagesRebar Coupler SpecificationÇïvílìåñ ÑâvîñNo ratings yet

- Page 2 of 6: Test Certificate No. 0000052877Document1 pagePage 2 of 6: Test Certificate No. 0000052877pranesh kadam100% (2)

- 12mm Diameter ReportsDocument2 pages12mm Diameter ReportsPRASAD THOMBARENo ratings yet

- TTR Doc - CRP Sas-Kbl PKG - r0Document2 pagesTTR Doc - CRP Sas-Kbl PKG - r0Anonymous EVFw59No ratings yet

- Data Sheets Me6222 - 2023Document16 pagesData Sheets Me6222 - 2023yagnikvaidya123No ratings yet

- LRPC Credentials - 1 PDFDocument102 pagesLRPC Credentials - 1 PDFSM AreaNo ratings yet

- WPQT SawDocument2 pagesWPQT Sawkiran144No ratings yet

- Page: 1/44 Date: 29-APR-2020Document44 pagesPage: 1/44 Date: 29-APR-2020Felipe De la cruzNo ratings yet

- Annexure-I For Gem Bid No:Gem/2021/B/1451378 Dated: 19-08-2021Document15 pagesAnnexure-I For Gem Bid No:Gem/2021/B/1451378 Dated: 19-08-2021Sravan DasariNo ratings yet

- 10 MM Test CertificateDocument1 page10 MM Test CertificatesimbamikeNo ratings yet

- Full Thread CatalogDocument5 pagesFull Thread CatalogZahin BasriNo ratings yet

- 10 MM AS0480104Document1 page10 MM AS0480104mamdouhNo ratings yet

- 074 - ANPAM EnggDocument1 page074 - ANPAM EnggvinuNo ratings yet

- G2206070002 0001 Test ReportDocument12 pagesG2206070002 0001 Test Reportrakesh kumarNo ratings yet

- JSW STEEL LTD Depot-Palwal, Ja: GALVANNEALED/18-19/0000981653Document1 pageJSW STEEL LTD Depot-Palwal, Ja: GALVANNEALED/18-19/0000981653asNo ratings yet

- DCL Test Report - Size 12.7 MM - 18-2-2020Document2 pagesDCL Test Report - Size 12.7 MM - 18-2-2020docpt76No ratings yet

- Request For Non-Destructive Test (NDT) : Jutasama Sdn. BHDDocument3 pagesRequest For Non-Destructive Test (NDT) : Jutasama Sdn. BHDMohdHuzairiRusliNo ratings yet

- Threaded Rod: Key Benefits - PlainDocument6 pagesThreaded Rod: Key Benefits - PlainGuTyNo ratings yet

- Test Results For Reinforcement Steel - 16 MM:: Constrologix Engineering & Research ServicesDocument2 pagesTest Results For Reinforcement Steel - 16 MM:: Constrologix Engineering & Research ServicesPRASAD THOMBARENo ratings yet

- International Trading Corporat: Hot Rolled Carbon Steel Sheet and Strip As Per Is: 1079 - 2017Document1 pageInternational Trading Corporat: Hot Rolled Carbon Steel Sheet and Strip As Per Is: 1079 - 2017SILAMBARASAN KNo ratings yet

- Master GI Corrugated Duct Sirim CertDocument5 pagesMaster GI Corrugated Duct Sirim CertZhen HaoNo ratings yet

- HS FSW01 00000088aec - CDocument5 pagesHS FSW01 00000088aec - CMarcoNo ratings yet

- 10MMDocument1 page10MMStructures ProductionNo ratings yet

- 4.0X1500. 23920 E250a DoDocument1 page4.0X1500. 23920 E250a Dosatyaprakashgond100% (1)

- Strip Seal Expansion JointDocument13 pagesStrip Seal Expansion JointsmithNo ratings yet

- 6 4029 - Print - 04 09 2015Document3 pages6 4029 - Print - 04 09 2015Shahzad AhmadNo ratings yet

- RLMM-list 15.10.2018Document3 pagesRLMM-list 15.10.2018Gohar Najeeb JillaniNo ratings yet

- Technical Specification (Medium Voltage) Aaa Covered Conductor & AccesoriesDocument36 pagesTechnical Specification (Medium Voltage) Aaa Covered Conductor & AccesoriesCabcon India100% (1)

- Ministry of New and Renewable Energy Government of India Wind Energy DivisionDocument4 pagesMinistry of New and Renewable Energy Government of India Wind Energy DivisiongamesaalertsNo ratings yet

- Hai Point JKR Requirement Channel and Batten 2020Document23 pagesHai Point JKR Requirement Channel and Batten 2020kimchewlim82No ratings yet

- IS 2062 E250A 25mm PlateDocument3 pagesIS 2062 E250A 25mm PlateKandula RajuNo ratings yet

- Banjo Beam - MTC 3.5 MM E 46Document1 pageBanjo Beam - MTC 3.5 MM E 46Rajhans PressingNo ratings yet

- Summary Sheet: AS ATTACHED OFFER LIST (QA/LVL/2300/01 & QA/LVL/2300/02)Document1 pageSummary Sheet: AS ATTACHED OFFER LIST (QA/LVL/2300/01 & QA/LVL/2300/02)GobinderSinghSidhuNo ratings yet

- DCL Test Report - Size 15.24 MM - 18-2-2020Document2 pagesDCL Test Report - Size 15.24 MM - 18-2-2020docpt76No ratings yet

- GortDocument4 pagesGortcharitha naiduNo ratings yet

- Bishweshwar Lal Steels: Hot Rolled Steel Strip For Welded Tubes and Pipes As Per Is: 10748 - 2004Document1 pageBishweshwar Lal Steels: Hot Rolled Steel Strip For Welded Tubes and Pipes As Per Is: 10748 - 2004ravigurajapuNo ratings yet

- Proposed WPS For API 5LDocument1 pageProposed WPS For API 5LMecon HyderabadNo ratings yet

- 6-Stephen Morrell Global Trends in Ore HardnessDocument25 pages6-Stephen Morrell Global Trends in Ore HardnessJUAN DIEGO FALCON CHURANo ratings yet

- Adobe ScanDocument4 pagesAdobe Scanroyal craftNo ratings yet

- Ralla AnanthapuramuDocument72 pagesRalla AnanthapuramuVannurSwamyNo ratings yet

- CAPTAIN250DITEINCOMPLETEAug 2020Document15 pagesCAPTAIN250DITEINCOMPLETEAug 2020billal toufik BendjimaNo ratings yet

- 26071-100-V20A-000-00007 - 004 - Piling Test (PDA, PIT, Static Load Test Dan VMT) Procedure by Third PartyDocument118 pages26071-100-V20A-000-00007 - 004 - Piling Test (PDA, PIT, Static Load Test Dan VMT) Procedure by Third Partycrystian NapitupuluNo ratings yet

- Taguchi MethodDocument6 pagesTaguchi Methodpankajdeekshith1No ratings yet

- 300 C SailDocument2 pages300 C Sailchandrabhushan kushwahaNo ratings yet

- KLJ Hdpe BK 9606 Arat AratDocument1 pageKLJ Hdpe BK 9606 Arat AratDinesh SinghNo ratings yet

- 7191329914-MEC24-01-CMY (Nom - Geom-CCCC) - SignedDocument5 pages7191329914-MEC24-01-CMY (Nom - Geom-CCCC) - SignedEsvimy Deliquena CauilanNo ratings yet

- Jindal Steel & Power Limited: Page 1 of 6Document1 pageJindal Steel & Power Limited: Page 1 of 6pranesh kadam100% (3)

- The Happy Mirror StoryDocument8 pagesThe Happy Mirror StoryEmmanuel RecodoNo ratings yet

- Sadik Hadzovic Diet and Workout RoutineDocument7 pagesSadik Hadzovic Diet and Workout Routineann saad100% (1)

- KDL 32 P 3550Document53 pagesKDL 32 P 3550Инж. Хранимир БешковNo ratings yet

- Vocabulary 7 Reading ComprehensionDocument1 pageVocabulary 7 Reading ComprehensionFreddy Benjamin Sepulveda TapiaNo ratings yet

- Why Collabration Take Place Between Mas and AirasiaDocument5 pagesWhy Collabration Take Place Between Mas and AirasiaTran Hung100% (1)

- Modern Electronic Communication 7th Edition by Beasley & Miller MCQDocument18 pagesModern Electronic Communication 7th Edition by Beasley & Miller MCQJulio Gabriel Aseron100% (1)

- Darmstadt: Ernst Thomas, Revised by Wilhelm SchlüterDocument4 pagesDarmstadt: Ernst Thomas, Revised by Wilhelm SchlüterYiorgos ChristofiNo ratings yet

- Long Live The Princess Quick Guide SPOILERSDocument3 pagesLong Live The Princess Quick Guide SPOILERSImam AndriantoNo ratings yet

- 00 WIKI - House CorrinoDocument4 pages00 WIKI - House CorrinoArturo CampilloNo ratings yet

- Omnivision OVB0B 200MP Smartphone Image Sensor Product Brief Via Revu PhilippinesDocument2 pagesOmnivision OVB0B 200MP Smartphone Image Sensor Product Brief Via Revu PhilippinesAlora Uy GuerreroNo ratings yet

- Philips SPD2400L1 Update To Y5H4 InformationDocument6 pagesPhilips SPD2400L1 Update To Y5H4 Informationtonyj327No ratings yet

- # Lecture III - Advanced Computer Networking - Sci-Tech With EstifDocument25 pages# Lecture III - Advanced Computer Networking - Sci-Tech With EstifESTIFANOSNo ratings yet

- Sea To Summit 2008 CatalogDocument34 pagesSea To Summit 2008 CatalogLinggawatiAditopoNo ratings yet

- April Free Chapter - Fifty Shades of Grey by E. L. JamesDocument22 pagesApril Free Chapter - Fifty Shades of Grey by E. L. JamesRandomHouseAU74% (47)

- FREEZAL LeafletDocument2 pagesFREEZAL LeafletPraistonNo ratings yet

- Weight Watchers Points Plus Burgers: Serving Size 1 Dipping Cup Unless Otherwise NotedDocument7 pagesWeight Watchers Points Plus Burgers: Serving Size 1 Dipping Cup Unless Otherwise NotedRaymond JensenNo ratings yet

- Audition Requirements Preparing Your Audition!: New Jersey All-State ChorusDocument5 pagesAudition Requirements Preparing Your Audition!: New Jersey All-State ChorusBrianNo ratings yet

- Omron Price List SMPS For Print 29.11.19Document16 pagesOmron Price List SMPS For Print 29.11.19Devendra singhNo ratings yet

- Pepsi BriefDocument2 pagesPepsi Briefamr369No ratings yet

- Es280 282 283 SH v18Document760 pagesEs280 282 283 SH v18Jorge Ares Guzman PaezNo ratings yet

- Nikon Tseries CloseupDocument5 pagesNikon Tseries Closeupdergi100% (1)

- GAMESLISTDocument39 pagesGAMESLISTAndrello Grezula PastaNo ratings yet

- Stage 3 Test Answer KeysDocument32 pagesStage 3 Test Answer KeysДарья ТретNo ratings yet

- Summative Test - Forms of The VerbDocument2 pagesSummative Test - Forms of The Verbcrisanto_oroceoNo ratings yet