Professional Documents

Culture Documents

Bindex E-190 Speciality Polymers: Technical Data Sheet

Uploaded by

fOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bindex E-190 Speciality Polymers: Technical Data Sheet

Uploaded by

fCopyright:

Available Formats

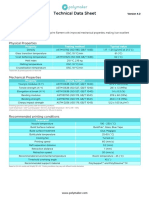

BindEX E-190 Speciality Polymers

TECHNICAL DATA SHEET

BINDEX E-190 is a maleic anhydride modified metallocene based polyethylene. With advanced anhydride

grafting technology, this grade is used to combine multilayer structures involving Nylon 6, Nylon 66, or EVOH for

gas barrier properties with variety of HDPE, LLDPE and LDPE grades for functions like, moisture barrier, sealability

etc.

Applications

• Maleic anhydride groups chemically react with amine groups of PA or hydroxyl groups of EVOH,

while polyethylene part adheres naturally with polyethylene on the other side, thus giving a

composite structure.

• Designed to use as a tie layer resin in conventional extrusion and co-extrusion equipments for making

multilayer tubes.

• Can be used in its pure form as well as in diluted form, depending on the inter-layer adhesion

required in the end-application. Recommended dilution is 25 – 50% by using similar MFI HDPE.

Key Properties

General Typical Value (SI) Test Method

MFI (190 °C/2.16 Kg) 1.3 g/10min ASTM D1238

Bonded Maleic Anhydride Medium ®

PLUSS method

Yellowness Index 3.0 ASTM E-313

Melting Temperature 114 °C DSC

Mechanical Typical Value (SI) Test Method

Tensile Strength @ Break 15 MPa ASTM D638/2010

Elongation @ Break 700 % ASTM D638/2010

Tensile Modulus 38 MPa ASTM D638/2010

Pluss Advanced Technologies Pvt. Ltd.

B-205, Tower B – Pioneer Urban Square, Sec 62, Gurugram-122101, Haryana, India

Telephone: +91 - 124 - 4309490/91/92

E-mail: info@pluss.co.in | Web: www.pluss.co.in

Page 1 of 2 Doc: 226, June 2021

TECHNICAL DATA SHEET

Hardness Typical Value (SI) Test Method

Durometer Hardness

Shore D 45 ASTM D2240/ISO868

Shore A 96 ASTM D2240

Storage and Handling Procedures

BindEX E-190 is mildly hygroscopic and should be stored in a dry, cool and well-ventilated area. It is supplied

in pre-dried moisture proof bags and thus no need to dry prior to processing. In case of open bags, it is

recommended that prior to processing, the requisite quantity of material to be used should be dried in a

hopper dryer or oven at 80-90 °C for about 2 hours for obtaining best results. Read and understand Safety

Data Sheet (SDS) for more detailed information on the safe handling and disposal of these speciality

polymers.

Processing Conditions

BindEX E-190 can be processed on most of the standard extrusion equipments designed to process

conventional polyolefins. Maximum processing temperature should not exceed 280 °C. At temperatures above

280 °C, these speciality polymers can evolve low concentrations of fumes. If overheated, more extensive

decomposition may occur due to exposure of overheated polymers to atmospheric oxygen. Adequate local

ventilation should be provided to remove the fumes from the work area.

Packaging

BindEX speciality polymers are supplied in pre-dried form in 25 Kg (55 lbs) PE lined, HD woven cloth-laminated

paper bags and 750 Kg (1650 lbs) FIBC’s. Depending upon customer’s requirement, the bags can be further

palletized for dispatch. They should be stored in cool and dry place.

The information given here is meant as a guide to determining suitability of our products for the stated applications. It is based on trials carried out by our

laboratories and data selected from literature and shall in no event be held to constitute or imply any warranty. The products are intended for use in industrial

applications. The users should test the materials before use and satisfy themselves with regard to contents and suitability in the desired application. Our formal

specifications define the limits of our commitment. Recommendation herein may not be construed as freedom to infringe/operate under any third party

patents. In the event of a proven claim, our liability is limited only to replacement of our material and in no case shall we be liable for special, incidental or

consequential damages arising out of usage of our material. This datasheet is subject to change without notice.

Page 2 of 2 Doc: 226, June 2021

You might also like

- Prepositions Below by in On To of Above at Between From/toDocument2 pagesPrepositions Below by in On To of Above at Between From/toVille VianNo ratings yet

- SOP No. 6Document22 pagesSOP No. 6Eli CohenNo ratings yet

- Municipality of Boliney: Republic of The Philippines Cordillera Administrative Region Province of AbraDocument7 pagesMunicipality of Boliney: Republic of The Philippines Cordillera Administrative Region Province of AbraErnest Aton100% (1)

- Wood Floor Cleaning Guide: What You Should Use To Clean Your FloorDocument2 pagesWood Floor Cleaning Guide: What You Should Use To Clean Your FloorfNo ratings yet

- Business Plan GROUP 10Document35 pagesBusiness Plan GROUP 10Sofia GarciaNo ratings yet

- Financial StatementDocument8 pagesFinancial StatementDarwin Dionisio ClementeNo ratings yet

- Strategic Management ModelsDocument4 pagesStrategic Management ModelsBarno NicholusNo ratings yet

- Iso 24023 2 2020Document9 pagesIso 24023 2 2020fNo ratings yet

- Astm D 1037 1999Document31 pagesAstm D 1037 1999Shubham SharmaNo ratings yet

- Bindex E-188 Speciality Polymer: Technical Data SheetDocument2 pagesBindex E-188 Speciality Polymer: Technical Data SheetfNo ratings yet

- TDS Pe 100 Ub5206h 01 PDFDocument2 pagesTDS Pe 100 Ub5206h 01 PDFOktaviandri SaputraNo ratings yet

- Product Data Sheet: Sumitomo Polyethylene LdpeDocument2 pagesProduct Data Sheet: Sumitomo Polyethylene LdpeMd Abdul SalamNo ratings yet

- TDS-PE-102-UB5502H (Provisional) 2019Document2 pagesTDS-PE-102-UB5502H (Provisional) 2019Oktaviandri SaputraNo ratings yet

- Si6008 TDS PDFDocument2 pagesSi6008 TDS PDFBelalang NgantukNo ratings yet

- TDS Pe 008 Up4806hDocument2 pagesTDS Pe 008 Up4806hariefNo ratings yet

- TDS Pe 200 SF5007Document2 pagesTDS Pe 200 SF5007Oktaviandri SaputraNo ratings yet

- TWO H Chem LTD.: Nova-P Nova-PDocument2 pagesTWO H Chem LTD.: Nova-P Nova-PKingsley BaptistaNo ratings yet

- TDS Pe 002 Uf1810t 03Document2 pagesTDS Pe 002 Uf1810t 03qc jrpNo ratings yet

- Technyl Star S 218 V30 BK 31NDocument3 pagesTechnyl Star S 218 V30 BK 31Nratz23695No ratings yet

- TDS PP 306 Hi10ho 03Document2 pagesTDS PP 306 Hi10ho 03indahNo ratings yet

- High Density Polyethylene Injection MoldingDocument2 pagesHigh Density Polyethylene Injection MoldingQuality teamNo ratings yet

- Cardia Biohybrid™ H-F PDFDocument2 pagesCardia Biohybrid™ H-F PDFXuân Giang NguyễnNo ratings yet

- Dow Kt10000ueDocument2 pagesDow Kt10000ueChu ChuNo ratings yet

- Titanvene ll0209sr Product Data SheetpdfDocument1 pageTitanvene ll0209sr Product Data SheetpdfHanry WRNo ratings yet

- Hdpe Me8000 (En)Document1 pageHdpe Me8000 (En)Judith Casstañeda AgurtoNo ratings yet

- Linear Low Density Polyethylene Injection MoldingDocument2 pagesLinear Low Density Polyethylene Injection MoldingakshayNo ratings yet

- 400 00030930en Engage 8003 TdsDocument4 pages400 00030930en Engage 8003 TdsManoharan SundaramNo ratings yet

- TDS Pe 100 Ub5206h 02 PDFDocument2 pagesTDS Pe 100 Ub5206h 02 PDFOktaviandri SaputraNo ratings yet

- TI FURADUR DBK 323 enDocument5 pagesTI FURADUR DBK 323 endris.elmouteaNo ratings yet

- H030SGDocument2 pagesH030SGLaxman AhirNo ratings yet

- 02 Bab IiDocument2 pages02 Bab IiariefNo ratings yet

- Dow KT 10000 UeDocument2 pagesDow KT 10000 UeLuca GuadagnoNo ratings yet

- Product Data Sheet: Typical PropertiesDocument2 pagesProduct Data Sheet: Typical PropertiesManufaktur Sinar JoyoboyoNo ratings yet

- SEMICOSIL 987 GR en 2021.09.17Document4 pagesSEMICOSIL 987 GR en 2021.09.17Carlos Enriquez ReyesNo ratings yet

- TDS J1020xa20Document2 pagesTDS J1020xa20akshayNo ratings yet

- Alkathene LDN248Document1 pageAlkathene LDN248Manoj SahuNo ratings yet

- RCE111NPDocument3 pagesRCE111NPdignityymartNo ratings yet

- TDS Pe 201 Sf5008eDocument2 pagesTDS Pe 201 Sf5008eOktaviandri SaputraNo ratings yet

- TDS Pe 003 Uf1810s1 03Document2 pagesTDS Pe 003 Uf1810s1 03qc jrpNo ratings yet

- Molykote D 321R - BrochureDocument2 pagesMolykote D 321R - Brochuretaufik perdanaNo ratings yet

- Product Datasheet Erkodur-Al: 1. Manufacturer InformationDocument2 pagesProduct Datasheet Erkodur-Al: 1. Manufacturer InformationALEGOZ ALEGOZNo ratings yet

- PP Trilene Hi10hoDocument2 pagesPP Trilene Hi10hoLaili AzkiyahNo ratings yet

- TDS Polidan TA HF V 1.0 June 2017Document3 pagesTDS Polidan TA HF V 1.0 June 2017valdecirnasatoNo ratings yet

- TDS HPR3518CB AstmDocument2 pagesTDS HPR3518CB AstmOsamah JoubsenNo ratings yet

- TDS SCGC PP P348S Rev Mar2022Document3 pagesTDS SCGC PP P348S Rev Mar2022y.s.6saputroNo ratings yet

- TDS Pe 010 Uf1820t 04Document2 pagesTDS Pe 010 Uf1820t 04Lenggana SukriaNo ratings yet

- CirRenew C14 LD2420DDocument3 pagesCirRenew C14 LD2420DJaime222No ratings yet

- TDS PP 305 HF10TQ 02Document2 pagesTDS PP 305 HF10TQ 02Lungkoneng HRDNo ratings yet

- TDS Emeraude Ldpe Lf2021e - V 2.3Document1 pageTDS Emeraude Ldpe Lf2021e - V 2.3Gabriela Lopez MunozNo ratings yet

- TDS Pe 001 Uf1810Document2 pagesTDS Pe 001 Uf1810asrilNo ratings yet

- Enersyn RC-S RangeDocument2 pagesEnersyn RC-S RangecarmaNo ratings yet

- High Density Polyethylene Grade Used in Injection Molding Melt Index: 62 Density: 0.942Document2 pagesHigh Density Polyethylene Grade Used in Injection Molding Melt Index: 62 Density: 0.942Phung LucNo ratings yet

- Alathon®: ApplicationsDocument2 pagesAlathon®: ApplicationsCarlos Revilla FloresNo ratings yet

- Luban DFDA-7047: Linear Low Density PolyethyleneDocument2 pagesLuban DFDA-7047: Linear Low Density PolyethyleneNazmul - Polymet SANo ratings yet

- Golden Power ATF DEX III TDSDocument1 pageGolden Power ATF DEX III TDSsimon.clove034No ratings yet

- Technical Data Sheet - ISO PE LYONDELLDocument3 pagesTechnical Data Sheet - ISO PE LYONDELLNur AzizahNo ratings yet

- Petronas Syntium 5000 CP 5w-30 70606e18eu 70606m12euDocument2 pagesPetronas Syntium 5000 CP 5w-30 70606e18eu 70606m12eusergsxrNo ratings yet

- Fluide at 42Document3 pagesFluide at 42Clodoaldo De Melo PereiraNo ratings yet

- TDS EU G-Energy X Hydro Bio EngDocument2 pagesTDS EU G-Energy X Hydro Bio EngАлексей ДэконNo ratings yet

- FK1828Document3 pagesFK1828dignityymartNo ratings yet

- 3 Property H7900 EngDocument1 page3 Property H7900 EngMohit MohataNo ratings yet

- Epofine 184-Finehard 907 - Acc 062Document4 pagesEpofine 184-Finehard 907 - Acc 062Karishma PrabhuNo ratings yet

- Lotte Titanvene HD5401GADocument2 pagesLotte Titanvene HD5401GAifah0% (1)

- Mdpe 3802BDocument1 pageMdpe 3802BIndrajeet DodlaNo ratings yet

- Luban DFDA-7047: Linear Low Density PolyethyleneDocument2 pagesLuban DFDA-7047: Linear Low Density PolyethyleneJasmine leNo ratings yet

- Sikafloor - 264 EngDocument5 pagesSikafloor - 264 Engbassem kooliNo ratings yet

- International Standard: Iteh Standard Preview (Standards - Iteh.ai)Document11 pagesInternational Standard: Iteh Standard Preview (Standards - Iteh.ai)Prosenjitroy RoyNo ratings yet

- Iso 16396 1 2015Document11 pagesIso 16396 1 2015fNo ratings yet

- Iso 11833 1 2019Document11 pagesIso 11833 1 2019fNo ratings yet

- Iso 11833 2 1998Document8 pagesIso 11833 2 1998fNo ratings yet

- Iso 1874 2 2006Document9 pagesIso 1874 2 2006fNo ratings yet

- Iso 16396 2 2017Document9 pagesIso 16396 2 2017fNo ratings yet

- Iso 24023 1 2020Document9 pagesIso 24023 1 2020fNo ratings yet

- PolyMax PLA TDS V4Document2 pagesPolyMax PLA TDS V4fNo ratings yet

- Graft Copolymers of Maleic Anhydride and Its Isostructural AnaloguesDocument63 pagesGraft Copolymers of Maleic Anhydride and Its Isostructural AnaloguesfNo ratings yet

- EN ISO 1874-2 (2006) (E) CodifiedDocument5 pagesEN ISO 1874-2 (2006) (E) CodifiedfNo ratings yet

- Wasif Service Export 2022-02-15T09 59 49.358ZDocument320 pagesWasif Service Export 2022-02-15T09 59 49.358ZfNo ratings yet

- Co-Extrusion of Wpcs With A Clear Cap Layer To Improve Color StabilityDocument14 pagesCo-Extrusion of Wpcs With A Clear Cap Layer To Improve Color StabilityfNo ratings yet

- The effect of inorganic fillers on the properties of wood plastic مهمDocument139 pagesThe effect of inorganic fillers on the properties of wood plastic مهمfNo ratings yet

- Iso 6453 1985Document8 pagesIso 6453 1985fNo ratings yet

- Bindex E-190 Speciality Polymers: Technical Data SheetDocument2 pagesBindex E-190 Speciality Polymers: Technical Data SheetfNo ratings yet

- Property Changes of Wood Fiber HDPE CompDocument4 pagesProperty Changes of Wood Fiber HDPE CompfNo ratings yet

- ASTM D3679 Rev 6 1 2017 ED 10 5 2019Document10 pagesASTM D3679 Rev 6 1 2017 ED 10 5 2019fNo ratings yet

- Ilnas-En Iso 21306-2:2019Document6 pagesIlnas-En Iso 21306-2:2019fNo ratings yet

- Shakoorifirstpaper-ThermoplasMat-EffectofDiepressure-Publishedwithaddress مهمDocument14 pagesShakoorifirstpaper-ThermoplasMat-EffectofDiepressure-Publishedwithaddress مهمfNo ratings yet

- Schirp 2015 Effectiveness Pigments WPCDocument2 pagesSchirp 2015 Effectiveness Pigments WPCfNo ratings yet

- public - version مهم جداDocument150 pagespublic - version مهم جداfNo ratings yet

- Iso 21306 2 2019Document9 pagesIso 21306 2 2019fNo ratings yet

- Vhi 160201-Quality Requirements WPC Deckings enDocument26 pagesVhi 160201-Quality Requirements WPC Deckings enfNo ratings yet

- Amir Toghyani A4 - Ei ArtikDocument98 pagesAmir Toghyani A4 - Ei ArtikfNo ratings yet

- Charpy and Izod Impact TestsDocument3 pagesCharpy and Izod Impact TestsfNo ratings yet

- Freqinv 3g3fv Ds 01oct2000Document20 pagesFreqinv 3g3fv Ds 01oct2000Mohd Abu AjajNo ratings yet

- Finaniial AsceptsDocument280 pagesFinaniial AsceptsKshipra PrakashNo ratings yet

- Common Base AmplifierDocument6 pagesCommon Base AmplifierMuhammad SohailNo ratings yet

- Auto Report LogDocument3 pagesAuto Report LogDaniel LermaNo ratings yet

- Incoterms 2010 PresentationDocument47 pagesIncoterms 2010 PresentationBiswajit DuttaNo ratings yet

- Math 1 6Document45 pagesMath 1 6Dhamar Hanania Ashari100% (1)

- Modal Case Data Form: GeneralDocument4 pagesModal Case Data Form: GeneralsovannchhoemNo ratings yet

- Ambient Lighting Vol 6 CompressedDocument156 pagesAmbient Lighting Vol 6 Compressedadvait_etcNo ratings yet

- Software Testing Notes Prepared by Mrs. R. Swetha M.E Unit I - Introduction at The End of This Unit, The Student Will Be Able ToDocument30 pagesSoftware Testing Notes Prepared by Mrs. R. Swetha M.E Unit I - Introduction at The End of This Unit, The Student Will Be Able ToKabilan NarashimhanNo ratings yet

- WWW - Manaresults.co - In: Internet of ThingsDocument3 pagesWWW - Manaresults.co - In: Internet of Thingsbabudurga700No ratings yet

- Charlemagne Command ListDocument69 pagesCharlemagne Command ListBoardkingZeroNo ratings yet

- List of Light Commercial LED CodesDocument8 pagesList of Light Commercial LED CodesRenan GonzalezNo ratings yet

- VRIODocument3 pagesVRIOJane Apple BulanadiNo ratings yet

- Self-Instructional Manual (SIM) For Self-Directed Learning (SDL)Document28 pagesSelf-Instructional Manual (SIM) For Self-Directed Learning (SDL)Monique Dianne Dela VegaNo ratings yet

- Enumerator ResumeDocument1 pageEnumerator Resumesaid mohamudNo ratings yet

- Modeling and Fuzzy Logic Control of A Quadrotor UAVDocument5 pagesModeling and Fuzzy Logic Control of A Quadrotor UAVAnonymous kw8Yrp0R5rNo ratings yet

- Manulife Health Flex Cancer Plus Benefit IllustrationDocument2 pagesManulife Health Flex Cancer Plus Benefit Illustrationroschi dayritNo ratings yet

- Computerized AccountingDocument14 pagesComputerized Accountinglayyah2013No ratings yet

- Civil NatureDocument3 pagesCivil NatureZ_Jahangeer100% (4)

- LISTA Nascar 2014Document42 pagesLISTA Nascar 2014osmarxsNo ratings yet

- Fammthya 000001Document87 pagesFammthya 000001Mohammad NorouzzadehNo ratings yet

- Nasoya FoodsDocument2 pagesNasoya Foodsanamta100% (1)

- Press Release - INTRODUCING THE NEW LAND ROVER DEFENDER PDFDocument6 pagesPress Release - INTRODUCING THE NEW LAND ROVER DEFENDER PDFJay ShahNo ratings yet

- Questionnaire: ON Measures For Employee Welfare in HCL InfosystemsDocument3 pagesQuestionnaire: ON Measures For Employee Welfare in HCL Infosystemsseelam manoj sai kumarNo ratings yet