Professional Documents

Culture Documents

ME 4131 Notes 1

Uploaded by

jaz squaredCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ME 4131 Notes 1

Uploaded by

jaz squaredCopyright:

Available Formats

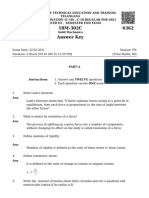

STRENGTH OF MATERIALS A-3

Simpleand Direct Stresses:

1. Tensile Stress-the force per unit area which is perpendicular to the surface that produces

stretching of a material by the application of pulling forces.

F

2. Compressive Stress- is the stress state when the material is compact.

3. Shearing Stress is a type of stress when a force applied produces a sliding failure of a

material along a plane that is parallel to the direction of the applied force.

S, F

4. Bearing Stress-the surface pressure acting on a machine member as a result of applied

load divided bearing area.

Sp F

LD

********************************

5. Torsional Stress - the shear stress on a transverse cross section resulting when one end

of a machine member is twisted in one direction.

Tc

S

J

16T (for solid circular shaft)

neutral axis

S = 6TD (for hollow circular shaft)

zp-D

MACHINE DESIGN REVIEWER by JAS TORDILLO

A-4

Stress-a compressive or tensile longitudinai stress deveioo

oped

6. Bending (Flexural )

of curvature induced by an external load.

machine member as a result

Me NA

where:

M moment

neutral axis(NNA)

C distance of farthest fiber from

cross sections

C h/2 for rectanguiar

=

is the diameter

=

d/2 for circular cross section where d

i= moment inertia about the neutral axis

of

I for rectangular section

12

Z section modulus

7. Strain, Elongation (or shortening)

Strain, E, - elongation expressed in percentage or unit elongation. Units of strain are in/in

mm/mm, and percent, or no units at all.

Strain, e =

stress

E

strain

y S=Le

Actual lerngth =

L+y

where:

y elongation or shortening (deformation)

L length

F =

force applied

A =

Cross-sectional area

S Stress

E Modulus of

Elasticity (Young's Modulus)

30,000,000 psi for steel (206,786 MPa)

10,000,000 psi for aluminium

For shear stress, the

constant of proportionality is the shear modulus, G.

Shear stress =G{0)

where: 6 =

angle

STRENGTH OF MATERIALS A-5

Total Strain Energy. The energy stored in a loaded member is equal to the work required to

deform the member.

U %Fy = FL

2AE

8. Thermal Elongation and Thermal Stress

AL y = kL (t -t)

AA = VA (t2 - ti)

L AL

AV BV(t2 - t)

Thermal Stress, S

t2

S E kE(ta-t:)

where:

Y elongation due to temperature change, m

k =coefficient of linear thermal expansion, m/m-°C

coefficient of area thermal expansion, 1/°C

=

B =coefficient of volumetric thermal expansion, 1/ C

t = initial temperature, "c

tz final temperature, "C

S = stress

Thermal Strain, Eth

Eth

L

9. Poisson's Ratio (u)

lateral strain

longitudial strain

vdiues of

Poisson's ratio range between 0.25 to 0.35 for most materials.

10. Shear Modulus

(Modulus of Elasticity in Shear, G)

G shear strest)

shear strainy)

G E

21+0)

You might also like

- Chapter3 LectureDocument48 pagesChapter3 LectureAlaaNo ratings yet

- MCC - Installation & Commisioning ManualDocument24 pagesMCC - Installation & Commisioning ManualViresh ShaunakNo ratings yet

- Section III: Load and Stress AnalysisDocument29 pagesSection III: Load and Stress Analysisrameshaarya99No ratings yet

- Diesel Power Plant - ComputationDocument19 pagesDiesel Power Plant - Computationjaz squared100% (3)

- MACHINE DESIGN 1 FORMULAS AND EXERCISESDocument18 pagesMACHINE DESIGN 1 FORMULAS AND EXERCISESX FLAMM0% (1)

- ME 528 REVIEW MACHINE DESIGN FORMULASDocument27 pagesME 528 REVIEW MACHINE DESIGN FORMULASNiño Gerard JabagatNo ratings yet

- B25D Mk 6.1 Parts ManualDocument678 pagesB25D Mk 6.1 Parts ManualRavinder SinghNo ratings yet

- Physical Quantum MechanicsDocument33 pagesPhysical Quantum MechanicsJerome ColicoNo ratings yet

- Baffle Selection PDFDocument7 pagesBaffle Selection PDFmaruthigabbita100% (3)

- 1vce014869t0201 PDFDocument39 pages1vce014869t0201 PDFkienNo ratings yet

- Design and Engineering Manual - DEM2Document13 pagesDesign and Engineering Manual - DEM2Vicks BTBNo ratings yet

- To RsionDocument16 pagesTo Rsionpriodeep chowdhuryNo ratings yet

- LightingDocument11 pagesLightingHafed BaccoucheNo ratings yet

- SRU Presentation For NewDocument47 pagesSRU Presentation For Newviettanct100% (3)

- Climate Change Act SummaryDocument19 pagesClimate Change Act SummaryNorlyn Joy InsigneNo ratings yet

- Strength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresFrom EverandStrength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresRating: 4 out of 5 stars4/5 (1)

- Design of Machine Elements NotesDocument483 pagesDesign of Machine Elements NotesHarsha VardhanNo ratings yet

- StressesDocument5 pagesStressesWendel EjeNo ratings yet

- Engineering Design CHAPTER 2design Against Static LoadDocument35 pagesEngineering Design CHAPTER 2design Against Static LoadvenkeekuNo ratings yet

- 1.introduction To Stresses & Strains PDFDocument48 pages1.introduction To Stresses & Strains PDFErNo ratings yet

- Chapter 2Document40 pagesChapter 2IntanLeeyanaNo ratings yet

- ANALYSIS OF SIMPLE STRESSESDocument58 pagesANALYSIS OF SIMPLE STRESSESHhchNo ratings yet

- Shear and Bending in Beams ProblemsDocument37 pagesShear and Bending in Beams ProblemsRobert DownieNo ratings yet

- Chapter1 PDFDocument50 pagesChapter1 PDFShueibNo ratings yet

- REGENT EDUCATION & RESEARCH FOUNDATIONDocument14 pagesREGENT EDUCATION & RESEARCH FOUNDATIONArghya ModakNo ratings yet

- Modulus of Rigidity of Rubber ExperimentDocument6 pagesModulus of Rigidity of Rubber ExperimentUsamaNo ratings yet

- Exp # 04Document8 pagesExp # 04Savaiz HannanNo ratings yet

- Mechanical Properties of MetalsDocument46 pagesMechanical Properties of Metalsภาคภูมิ เหมยากรNo ratings yet

- Members Subjected To BendingDocument5 pagesMembers Subjected To BendingRonald obasieNo ratings yet

- Stress: Engr. Estanislao M. Pialago Jr. PMEDocument16 pagesStress: Engr. Estanislao M. Pialago Jr. PMEBrianNo ratings yet

- REF1Document82 pagesREF1Vijay WadhwaNo ratings yet

- Ceg 221 - Mechanics of Materials IiDocument34 pagesCeg 221 - Mechanics of Materials IiMoshood Mubarak AyindeNo ratings yet

- chap 5 flexural and shear stresses ADocument67 pageschap 5 flexural and shear stresses Atesera addisNo ratings yet

- MECHANICS OF MATERIALS REVIEWDocument23 pagesMECHANICS OF MATERIALS REVIEWlowCL100% (1)

- Machine Design I Learning Module I: Stress Analysis: Authored By: Engr. Ronnie Tavares Rat/8/17/2013/8:55 PMDocument32 pagesMachine Design I Learning Module I: Stress Analysis: Authored By: Engr. Ronnie Tavares Rat/8/17/2013/8:55 PMOtil SeravatNo ratings yet

- Chapter One S.MDocument46 pagesChapter One S.MKebede HaileNo ratings yet

- Strength of Materials 2022 by S K Mondal 8 MB-edited PDFDocument338 pagesStrength of Materials 2022 by S K Mondal 8 MB-edited PDFRajesh sahaNo ratings yet

- Beam TheoryDocument7 pagesBeam TheoryserkanNo ratings yet

- Emf AssignmentDocument27 pagesEmf AssignmentBhaskar KumarNo ratings yet

- Machine Design-Lecture Strength of Materials Simple, Combined and Variable StressesDocument41 pagesMachine Design-Lecture Strength of Materials Simple, Combined and Variable StressesXyrilCualaNo ratings yet

- Ekeeda - Civil Engineering - Strength of MaterialsDocument14 pagesEkeeda - Civil Engineering - Strength of MaterialsekeedaNo ratings yet

- Strength of Materials MarksDocument28 pagesStrength of Materials Markslogeshboy007No ratings yet

- 10.concepts of Force-Stress and Deformation-StrainDocument25 pages10.concepts of Force-Stress and Deformation-StrainPompy JoeNo ratings yet

- 232 Chap 1Document7 pages232 Chap 1Harry WellingtoneNo ratings yet

- Experiment # 8: Modulus of ElasticityDocument6 pagesExperiment # 8: Modulus of ElasticityUsamaNo ratings yet

- SOMDocument431 pagesSOMPradeepvenugopalNo ratings yet

- Experiment # 7: Modulus of ElasticityDocument6 pagesExperiment # 7: Modulus of ElasticityUsamaNo ratings yet

- Torsion Lab Report: Determining Shear ModulusDocument5 pagesTorsion Lab Report: Determining Shear ModulusNourTarekHassenNo ratings yet

- Machine Design (Term Paper)Document7 pagesMachine Design (Term Paper)Sajawal KhanNo ratings yet

- Department of Mechanical Engineering Mechanic Division Spec. Laboratory - Torsion Lab. ReportDocument5 pagesDepartment of Mechanical Engineering Mechanic Division Spec. Laboratory - Torsion Lab. ReportBhanuka SamarakoonNo ratings yet

- Unit 3: Longitudinal Direct Bending Stresses in Beams: Eng. Strength of Materials Iii (Mst31A)Document31 pagesUnit 3: Longitudinal Direct Bending Stresses in Beams: Eng. Strength of Materials Iii (Mst31A)Tony NgoneloNo ratings yet

- Simple Stress Stress - Is Defined As The Internal Resistance of A Material To The Action of ExternalDocument43 pagesSimple Stress Stress - Is Defined As The Internal Resistance of A Material To The Action of ExternalalvinNo ratings yet

- MD1 Topic 1 Simple StressesDocument8 pagesMD1 Topic 1 Simple StressesIvan Jeremy AbilaNo ratings yet

- 10.concepts of Force-Stress and Deformation-StrainDocument25 pages10.concepts of Force-Stress and Deformation-StrainaderancNo ratings yet

- Internal II Question Bank SOMDocument7 pagesInternal II Question Bank SOMsathyadallyNo ratings yet

- The Torsion FormulaDocument12 pagesThe Torsion FormulaRonaldoNo ratings yet

- Strength of Materials 2015 by S K MondalDocument473 pagesStrength of Materials 2015 by S K MondalNitik KumarNo ratings yet

- Physics NotesDocument18 pagesPhysics Notesthavaselvan50% (2)

- 18M-302C 6362 Answer KeyDocument26 pages18M-302C 6362 Answer KeyharicoolestNo ratings yet

- Strain Energy Explained: Formulas and Beam CalculationsDocument6 pagesStrain Energy Explained: Formulas and Beam CalculationsNguyen NgaNo ratings yet

- 9 ChapterDocument37 pages9 ChapterSwizzy SpeedsterNo ratings yet

- Strength of Materials 2018 by S K MondalDocument482 pagesStrength of Materials 2018 by S K MondalSnake BiteNo ratings yet

- Bending 1Document20 pagesBending 1Hossam SallamNo ratings yet

- Stress Analysis in Elastic Bending Beams and Thick Hollow CylindersDocument6 pagesStress Analysis in Elastic Bending Beams and Thick Hollow Cylindersمحمد فطري فيك نظامNo ratings yet

- Chapter 02 Mechanics of MaterialsDocument50 pagesChapter 02 Mechanics of Materialspanave3104No ratings yet

- Formula Sheet Mechanics MaterialsDocument4 pagesFormula Sheet Mechanics MaterialsJames BuserNo ratings yet

- Energy MethodDocument44 pagesEnergy MethodZulfadhli ZainudinNo ratings yet

- Co GenerationDocument16 pagesCo Generationjaz squaredNo ratings yet

- DIESEL PPDocument62 pagesDIESEL PPjaz squaredNo ratings yet

- ME 4121 Act 1Document1 pageME 4121 Act 1jaz squaredNo ratings yet

- Diesel CycleDocument1 pageDiesel Cyclejaz squaredNo ratings yet

- Manufacturing Tolerances ExplainedDocument2 pagesManufacturing Tolerances Explainedjaz squaredNo ratings yet

- ME 4131 Notes 6Document4 pagesME 4131 Notes 6jaz squaredNo ratings yet

- Supplementary Notes On Variable LoadDocument3 pagesSupplementary Notes On Variable Loadjaz squaredNo ratings yet

- ME 4131 Notes 2Document6 pagesME 4131 Notes 2jaz squaredNo ratings yet

- ME 4131 Notes 3Document2 pagesME 4131 Notes 3jaz squaredNo ratings yet

- Springs: When Long Dimension Is Parallel To AxisDocument6 pagesSprings: When Long Dimension Is Parallel To AxisLister NambatacNo ratings yet

- VolDocument246 pagesVolapi-3698996No ratings yet

- Statement 1 Is Not Correct: Article 161 of The Constitution of India DescribesDocument13 pagesStatement 1 Is Not Correct: Article 161 of The Constitution of India Describesamol maliNo ratings yet

- Basic Mechanical EngineeringDocument13 pagesBasic Mechanical EngineeringJaysun Lanario PacrisNo ratings yet

- MAPÚA UNIVERSITY WRITTEN REPORT ON PNEUMATICSDocument14 pagesMAPÚA UNIVERSITY WRITTEN REPORT ON PNEUMATICSAndreNo ratings yet

- York Manual - YOCA - YOHA - ENDocument6 pagesYork Manual - YOCA - YOHA - ENPonto de Presença da RNP no PiauíNo ratings yet

- Method of Statement For Hydrostatic Test: DocumentDocument3 pagesMethod of Statement For Hydrostatic Test: DocumentIlyas RunNo ratings yet

- Gas Insulated TransformerDocument12 pagesGas Insulated Transformermithun1105No ratings yet

- System4700geneobrochure 4700700 RehauDocument16 pagesSystem4700geneobrochure 4700700 RehauraduteopNo ratings yet

- Stabilized Earth Fault Current Relay Settings GuideDocument20 pagesStabilized Earth Fault Current Relay Settings GuideRaj KrishNo ratings yet

- HAMMAD ENGINEERING COMPANY PresentationDocument11 pagesHAMMAD ENGINEERING COMPANY Presentationrehansadiq1No ratings yet

- Flat Roof - WikipediaDocument6 pagesFlat Roof - WikipediaIeeeChannaNo ratings yet

- CACRE Manuscript 23112016Document230 pagesCACRE Manuscript 23112016Michele FortunatoNo ratings yet

- 2015-05-28 - Major Purchase Order - PDRP - Apr-2015Document2 pages2015-05-28 - Major Purchase Order - PDRP - Apr-2015Hytech Pvt. Ltd.No ratings yet

- Unit-Iii Electromagnetic Waves - NotesDocument13 pagesUnit-Iii Electromagnetic Waves - NotesAnusha KovuruNo ratings yet

- 05diffsep07 PDFDocument38 pages05diffsep07 PDFNaomi Lizzy FluegelNo ratings yet

- BW213DH-4, BW213PDH-4: Single Drum Vibratory RollerDocument4 pagesBW213DH-4, BW213PDH-4: Single Drum Vibratory RollerAnh NguyenNo ratings yet

- 5 Subsea ArchitectureDocument39 pages5 Subsea Architectureahmezo100% (1)

- Question Bank FOR Je-Ii SelectionDocument59 pagesQuestion Bank FOR Je-Ii SelectionPankaj DhandeNo ratings yet

- Unit 8: Title: Cylinder Block and Cylinder Head General ObjectiveDocument15 pagesUnit 8: Title: Cylinder Block and Cylinder Head General ObjectiveAdid PunyaNo ratings yet

- En14511 4 2004Document14 pagesEn14511 4 2004pavlosmicNo ratings yet