Professional Documents

Culture Documents

Dpgs43hp.1 Switch Presion Gauge

Uploaded by

Q Llanos HenryCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Dpgs43hp.1 Switch Presion Gauge

Uploaded by

Q Llanos HenryCopyright:

Available Formats

Pressure

Differential pressure gauge with switch contacts

For the process industry

Models DPGS43HP.1x0, high overload safety up to 40, 100, 250 or 400 bar

WIKA data sheet PV 27.13

for further approvals

see page 9

Applications

■ Control and regulation of processes

■ Monitoring of plants and switching of circuits

■ For measuring locations with a high differential pressure

overload and/or high working pressures (static pressures),

also in aggressive environments

■ Easy-to-read, analogue on-site display needing no exter-

nal power

■ Pump monitoring and control, filter monitoring, level

measurement on closed vessels

Special features

■ Differential pressure measuring ranges from 0 … 60 mbar

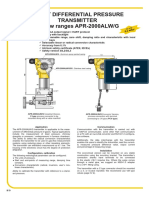

■ High working pressure (static pressure) and high overload Differential pressure gauge model DPGS43HP.100 with

safety, selectable up to 40, 100, 250 or 400 bar switch contact model 821.21

■ Measuring cell liquid dampening against rapid pressure

changes

■ Instruments with inductive contacts for use in hazardous

areas

■ Instruments with switch contact for PLC applications

Description

Wherever the process pressure has to be indicated locally Switch contacts consisting of several contacts can also be

and, at the same time, circuits need to be switched, the set to a single set point. Contact actuation is made when the

model DPGS43HP.1x0 switchGAUGE finds its use. actual value pointer travels beyond or below the desired set

point.

Switch contacts (electrical alarm contacts) make or break

circuits dependent upon the pointer position of the indicating The pressure gauge is manufactured in accordance with

measuring instruments. The switch contacts are adjustable DIN 16085 and fulfils all requirements of the relevant

over the full extent of the scale range (see DIN 16085), and standards (EN 837-3) and regulations for the on-site display

are mounted predominantly below the dial, though also of the working pressure of pressure vessels.

partly on top of the dial. The instrument pointer (actual value As switch contacts, magnetic snap-action contacts, reed

pointer) moves freely across the entire scale range, indepen- switches, inductive contacts and electronic contacts are

dent of the setting. available. Inductive contacts can be used in hazardous areas.

The set pointer can be adjusted using a removable adjust- For triggering programmable logic controllers (PLC), electro-

ment key in the window. nic contacts and reed switches can be used.

WIKA data sheet PV 27.13 ∙ 06/2021 Page 1 of 12

Data sheets showing similar products:

Diaphragm pressure gauge with switch contacts, model PGS43.100, PGS43.160; see data sheet PV 24.03

Specifications

Models DPGS43HP.100 and DPGS43HP.160

Version Highest overload safety either side, pressure ratings PN 40, 100, 250 or 400, system fill fluid of the

measuring cell acts as the dampening of the display.

Overload resistance per EN 837-3.

Nominal size in mm ■ 100

■ 160

Accuracy class 1.6

Option:

1.0 on request, (Monel version: 2.5)

Scale ranges Instruments with PN 40 and 100:

■ 0 … 60 mbar to 0 … 160 mbar (measuring cell □ 140)

■ 0 … 0.25 bar to 0 … 40 bar (measuring cell □ 82)

Instruments with PN 250:

■ 0 … 60 mbar to 0 … 250 mbar (measuring cell □ 140)

■ 0 … 0.4 bar to 0 … 40 bar (measuring cell □ 82)

Instruments with PN 400:

0 … 0.4 bar to 0 … 40 bar (measuring cell □ 86)

Dimensions of measuring cell from page 11

other units (e.g. psi, kPa) available

or all other equivalent vacuum or combined pressure and vacuum ranges

Scale Single scale

Option:

■ Dual scale

■ Scale layout (e.g. linear pressure or square root incrementation)

Zero point setting By means of adjustment appliance

Pressure limitation

Steady Full scale value

Fluctuating 0.9 x full scale value

Observe the recommendations for the use of mechanical pressure measuring systems in ac-

cordance with EN 837-2

Overpressure safety and max. Either side max. 40, 100, 250 or 400 bar

working pressure (static pressure)

Connection location Lower mount (radial)

Option:

■ Back mount

■ Connection at 12 o‘clock

Process connection ■ G ½ B female

■ G ½ B male

■ ½ NPT male

■ Differential process connection per EN 61518

Other process connections via female or male threads on request

Permissible temperature 1)

Medium -20 ... +100 °C

Option:

Medium temperature > 100 °C on request

Ambient -20 ... +60 °C

Option:

Ambient temperature -40 ... +60 °C (silicone oil filling)

Temperature effect When the temperature of the measuring system deviates from the reference temperature (+20 °C):

max. ±0.5 %/10 K of full scale value

Case filling Without

Option:

With case filling

1) For hazardous areas, the permissible temperature of the contact model 831 will exclusively apply (see page 6). These must not be exceeded at the instrument either (for details see

operating instructions). If necessary, measures for cooling (e.g. syphon, instrumentation valve, etc.) have to be taken.

WIKA data sheet PV 27.13 ∙ 06/2021 Page 2 of 12

Models DPGS43HP.100 and DPGS43HP.160

Venting of the media chambers ■ Instruments with PN 40 and 100: For scale ranges ≤ 0.16 bar

(option for scale ranges ≥ 0.25 bar)

■ Instruments with PN 250 and 400: Standard for scale ranges ≤ 0.25 bar

(option for scales ranges ≥ 0.4 bar)

Option:

Venting of the media chambers for scale ranges ≥ 0.25 bar or ≥ 0.4 bar

System fill fluid of measuring cell Silicone oil

Option:

Measuring cell filling with special medium, e.g. for use in oxygen applications

Others on request

Wetted materials

Measuring flanges with process Stainless steel 316L

connection

Pressure elements ■ ≤ 0.25 bar: Stainless steel 1.4571

■ > 0.25 bar: NiCr alloy (Inconel)

Measuring cell Chrome steel

Venting of the media chambers Stainless steel 316L

Sealings FPM/FKM

Non-wetted materials

Flange connecting screws ■ PN 40 / 100: Stainless steel

■ PN 250 / 400: Steel, corrosion-protected

Case, movement, bayonet ring Stainless steel

Dial Aluminium, white, black lettering

Pointer Aluminium, black

Window Laminated safety glass

Ingress protection per IP54 1 )

IEC/EN 60529 Option:

IP65 with liquid filling

Installation According to affixed symbols: ⊕ high pressure, ⊖ low pressure

Mounting ■ Rigid measuring lines

■ Drilled mounting holes at the back of the measuring cell

Option:

■ Panel mounting flange

■ Instrument mounting bracket for wall or pipe mounting

Electrical connection Cable socket PA 6, black

Per VDE 0110 insulation group C/250 V

Cable gland M20 x 1.5

Strain relief

6 screw terminals + PE for conductor cross-section 2.5 mm²

For dimensions see page 10

others on request

1) Ingress protection IP54 with safety version and lower back mount.

Other versions

Wetted parts made of special material (Monel, PTFE lining)

WIKA data sheet PV 27.13 ∙ 06/2021 Page 3 of 12

Switch contacts

Magnetic snap-action contact model 821 Reed switch model 851

■ No control unit and no supply voltage required ■ No control unit and no supply voltage required

■ Direct switching up to 250 V, 1 A ■ Direct switching up to 250 V, 1 A

■ Up to 4 switch contacts per measuring instrument ■ For direct triggering of a programmable logic controller

(PLC)

Inductive contact model 831 ■ Free from wear as without contact

■ Suitable for use in hazardous areas with corresponding ■ NS 100: Up to two change-over contacts per measuring

control unit (model 904.xx) instrument;

■ Long service life due to non-contact sensor NS 160: Up to one change-over contact per measuring

■ Low influence on the indication accuracy instrument (switching voltages AC < 50 V and DC < 75 V,

■ Fail-safe switching at high switching frequency switch contact not adjustable from outside)

■ Insensitive to corrosion

■ Also available in safety version Switching function

■ Up to 3 switch contacts per measuring instrument The switching function of the switch is indicated by index 1,

2 or 3

Electronic contact model 830 E

■ For direct triggering of a programmable logic controller Model 8xx.1: Normally open (clockwise pointer motion)

(PLC)

Model 8xx.2: Normally closed (clockwise pointer motion)

■ 2-wire system (option: 3-wire system)

■ Long service life due to non-contact sensor Models 821.3 Change-over; one contact breaks and one

■ Low influence on the indication accuracy and 851.3: contact makes simultaneously when pointer

■ Fail-safe switching at high switching frequency reaches set point

■ Insensitive to corrosion

■ Up to 3 switch contacts per measuring instrument For further information on switch contacts, see data sheet

AC 08.01

Other versions

■ Contact model 821 with separate circuits

■ Contact model 821 as change-over contact (break or

make simultaneously at the set point)

■ Contact model 821 with cable break monitoring (parallel

resistance 47 kΩ and 100 kΩ)

■ Contacts fixed, without contact adjustment lock

■ Contact adjustment lock leaded

■ Contact adjustment key fixed

WIKA data sheet PV 27.13 ∙ 06/2021 Page 4 of 12

Specifications for instruments with magnetic snap-action contact model 821

Measuring span Nominal size Max. number of con- Switching current range I

tacts

≤ 60 mbar 100, 160 2 0.02 ... 0.3 A

> 100 mbar 100, 160 4 0.02 ... 0.3 A

The recommended setting range of the contacts is 25 ... 75 % of the scale (0 ... 100 % on request).

Contact material (standard): Silver-nickel, gold-plated

Setting the contacts

The recommended minimum clearance between 2 contacts is 20 % of the measuring span.

The switch hysteresis is 2 ... 5 % (typical).

Characteristics Unfilled instruments Filled instruments

Resistive load Resistive load

Rated operating voltage Ueff ≤ 250 V ≤ 250 V

Rated operating current

Switch-on current ≤ 0.5 A ≤ 0.5 A

Switch-off current ≤ 0.5 A ≤ 0.5 A

Continuous current ≤ 0.3 A ≤ 0.3 A

Switching power ≤ 30 W / ≤ 50 VA ≤ 20 W / ≤ 20 VA

Recommended contact load with resistive and inductive loads

Operating voltage Unfilled instruments Filled instruments

Resistive load Inductive load Resistive load Inductive load

Direct Alter- cos ϕ > 0.7 Direct Alter- cos ϕ > 0.7

current nating current nating

current current

DC 220 V / AC 230 V 100 mA 120 mA 65 mA 65 mA 90 mA 40 mA

DC 110 V / AC 110 V 200 mA 240 mA 130 mA 130 mA 180 mA 85 mA

DC 48 V / AC 48 V 300 mA 450 mA 200 mA 190 mA 330 mA 130 mA

DC 24 V / AC 24 V 400 mA 600 mA 250 mA 250 mA 450 mA 150 mA

WIKA data sheet PV 27.13 ∙ 06/2021 Page 5 of 12

Specifications for instruments with inductive contact model 831

Measuring span Nominal size Max. number of contacts

≤ 60 mbar 100, 160 2

> 100 mbar 100, 160 3

The recommended setting range of the contacts is 10 ... 90 % of the scale (0 ... 100 % on request).

Setting of contacts to identical set point

Up to 2 contacts can be set to an identical set point. For a version with 3 contacts this is not possible. The left (no. 1) or right

(no. 3) contact may not be set to the same set point as the other 2 contacts. The required displacement is approx. 30°, optio-

nally to the right or to the left.

Available contact versions

■ 831-N

■ 831-SN, safety version 1)

■ 831-S1N, safety version 1), inverted signal

1) only operate with a corresponding isolating amplifier (model 904.3x)

Permissible temperature ranges

T6 T5 ... T1 T135°C

-20 ... +60 °C -20 ... +70 °C -20 ... +70 °C

For further information on hazardous areas, see operating instructions.

Associated isolating amplifiers and control units

Model Version Ex version

904.28 KFA6 - SR2 - Ex1.W 1 contact yes

904.29 KFA6 - SR2 - Ex2.W 2 contacts yes

904.30 KHA6 - SH - Ex1 1 contact yes - safety equipment

904.33 KFD2 - SH - Ex1 1 contact yes - safety equipment

904.25 MSR 010-I 1 contact no

904.26 MSR 020-I 2 contacts no

904.27 MSR 011-I Two-point control no

WIKA data sheet PV 27.13 ∙ 06/2021 Page 6 of 12

Specifications for instruments with electronic contact model 830 E

Measuring span Nominal size Max. number of contacts

≤ 60 mbar 100, 160 2

> 100 mbar 100, 160 3

The recommended setting range of the contacts is 10 ... 90 % of the scale (0 ... 100 % on request).

Setting of contacts to identical set point

Up to 2 contacts can be set to an identical set point. For a version with 3 contacts this is not possible. The left (no. 1) or right

(no. 3) contact may not be set to the same set point as the other 2 contacts. The required displacement is approx. 30°, optio-

nally to the right or to the left.

Characteristics

Contact version Normally open, normally closed

Type of output PNP transistor

Operating voltage DC 10 ... 30 V

Residual ripple max. 10 %

No-load current ≤ 10 mA

Switching current ≤ 100 mA

Residual current ≤ 100 µA

Voltage drop (with Imax.) ≤ 0.7 V

Reverse polarity protection Conditional UB (the switched output 3 or 4 must never be set directly to minus)

Anti-inductive protection 1 kV, 0.1 ms, 1 kΩ

Oscillator frequency approx. 1,000 kHz

EMC per EN 60947-5-2

WIKA data sheet PV 27.13 ∙ 06/2021 Page 7 of 12

Specifications for instruments with reed switch model 851

Measuring span Nominal size Max. number of contacts

≥ 60 mbar 100, 160 2

Switching power Pmax 60 W / 60 VA

Switching current 1A

Characteristics

Contact version Change-over contact

Type of contact Bistable

Max. switching voltage AC/DC 250 V

Min. switching voltage Not required

Switching current AC/DC 1 A

Min. switching current Not required

Transport current AC/DC 2 A

cos ϕ 1

Switching power 60 W/ VA

Contact resistance (static) 100 mΩ

Insulation resistance 109 Ω

Breakdown voltage DC 1,000 V

Switching time incl. contact chatter 4.5 ms

Contact material Rhodium

Switch hysteresis 3 ... 5 %

■ The limit values presented here must not be exceeded.

■ When using two contacts, these cannot be set to the same point. Depending on the switching function, a minimum

clearance of 15 ... 30° is required.

■ The setting range of the contacts is 10 ... 90 % of the scale.

■ The switching function can be set in manufacturing such that the reed contact will actuate exactly at the required switch

point. For this, we need the switching direction to be specified on order.

WIKA data sheet PV 27.13 ∙ 06/2021 Page 8 of 12

Approvals

Logo Description Country

EU declaration of conformity European Union

■ EMC directive

■ Low voltage directive

■ RoHS directive

■ ATEX directive (directive) ¹⁾

Hazardous areas

- Ex ia Gas [II 2G Ex ia IIC T6/T5/T4 Gb]

Dust [II 2D Ex ia IIIB T135°C Db]

IECEx (option) 1) International

Hazardous areas

- Ex ia Gas [Ex ia IIC T6/T5/T4 Gb]

Dust [Ex ia IIIB T135°C Db]

EAC (option) Eurasian Economic Com-

■ EMC directive munity

■ Low voltage directive

■ Hazardous areas 1)

GOST (option) Russia

Metrology, measurement technology

- MTSCHS (option) Kazakhstan

Permission for commissioning

Ex Ukraine (option) 1) Ukraine

Hazardous areas

NEPSI (option) 1) China

Hazardous areas

- CRN Canada

Safety (e.g. electr. safety, overpressure, ...)

1) Only for instruments with model 831 and not for instruments with PTFE lining

Certificates (option)

■ 2.2 test report per EN 10204 (e.g. state-of-the-art

manufacturing, indication accuracy)

■ 3.1 inspection certificate per EN 10204 (e.g. indication

accuracy)

Approvals and certificates, see website

Accessories

■ Instrument mounting bracket for wall or pipe mounting

■ Panel mounting flange, polished stainless steel

■ Instrument mounting bracket for wall or pipe mounting,

lacquered steel or stainless steel

■ Sealings (model 910.17, see data sheet AC 09.08)

■ Valves (models IV3x/IV5x, see data sheet AC 09.23)

■ Diaphragm seal

WIKA data sheet PV 27.13 ∙ 06/2021 Page 9 of 12

Dimensions in mm

Cable socket

Contact models: 821 and 851 Contact models: 831 and 830 E

14336089.01

Only use cable with a Only use cable with a

diameter of 5 ... 10 mm diameter of 7 ... 13 mm

49.5

68

M20x1,5

M20x1,5

WIKA data sheet PV 27.13 ∙ 06/2021 Page 10 of 12

Dimensions in mm

switchGAUGE model DPGS43HP.100 with switch contact model 821, 831 or 830 E

removable adjustment

key

For cable socket

dimensions see

page 10

Scale range ≤ 0.25 bar: p = 140 mm, h = 86 mm

> 0.25 bar: p = 82 mm, h = 64 mm

Type of contact Dimensions in mm

X Y

Single or double contact 97 55

Double (change-over) contact 122 80

Triple contact 105 63

Quadruple contact 122 80

switchGAUGE model DPGS43HP.160 with switch contact model 821, 831 or 830 E

removable adjustment

key

For cable

socket di-

mensions see

page 10

Scale range ≤ 0.25 bar: p = 140 mm, h = 86 mm

> 0.25 bar: p = 82 mm, h = 64 mm

Type of contact Dimensions in mm

X

Single or double contact 102

Double (change-over) contact 116

Triple contact 102

Quadruple contact 116

WIKA data sheet PV 27.13 ∙ 06/2021 Page 11 of 12

switchGAUGE model DPGS43HP.100 with switch contact model 851.3 or 851.33

14022318.01

removable adjustment

key

For cable

socket di-

mensions see

page 10

Scale range ≤ 0.25 bar: p = 140 mm, h = 86 mm

> 0.25 bar: p = 82 mm, h = 64 mm

switchGAUGE model DPGS43HP.160 with switch contact model 851.3

14022276.01

For cable

socket di-

mensions see

page 10

Scale range ≤ 0.25 bar: p = 140 mm, h = 86 mm

> 0.25 bar: p = 82 mm, h = 64 mm

Ordering information

Model / Nominal size / Type of contact / Contact version / Scale range / Scale version (linear pressure or square root incremen-

tation) / Max. working pressure (static pressure) / Process connection / Connection location / Options

© 08/2010 WIKA Alexander Wiegand SE & Co. KG, all rights reserved.

The specifications given in this document represent the state of engineering at the time of publishing.

We reserve the right to make modifications to the specifications and materials.

06/2021 EN

WIKA data sheet PV 27.13 ∙ 06/2021 Page 12 of 12

WIKA Alexander Wiegand SE & Co. KG

Alexander-Wiegand-Straße 30

63911 Klingenberg/Germany

Tel. +49 9372 132-0

Fax +49 9372 132-406

info@wika.de

www.wika.de

You might also like

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- BaylorDocument140 pagesBaylorjairoleonx542691% (11)

- 876-32 Model SDA Direct-Dial Pilot.Document11 pages876-32 Model SDA Direct-Dial Pilot.Naveed AliNo ratings yet

- Lrs Resistencia Liquid StarterDocument45 pagesLrs Resistencia Liquid StarterQ Llanos HenryNo ratings yet

- Cpi - Cpi1004 Cmp200 Brochure e FNL CRPDDocument4 pagesCpi - Cpi1004 Cmp200 Brochure e FNL CRPDRaulNo ratings yet

- 通用电气GE Optima CT520Pro 全身用X射线计算机体层摄影装置7f0Document22 pages通用电气GE Optima CT520Pro 全身用X射线计算机体层摄影装置7f0service iyadMedicalNo ratings yet

- Manual Servos FanucDocument658 pagesManual Servos FanucGerman Lag100% (1)

- Dpi - 603 - Druck-Portable Pressure Calibrator ManualDocument4 pagesDpi - 603 - Druck-Portable Pressure Calibrator ManualMusrizal MarwanNo ratings yet

- Manometro WikaDocument8 pagesManometro WikaAntonio ZekyNo ratings yet

- Attachment#2 - Example of Bourdon Tube Pressure Gauge With Switch Contacts PDFDocument17 pagesAttachment#2 - Example of Bourdon Tube Pressure Gauge With Switch Contacts PDFIbrahim Ben AmeurNo ratings yet

- DS PV1502 en Co 8052Document6 pagesDS PV1502 en Co 8052SERDINA FFNo ratings yet

- Differential Pressure Gauge Model 712.15.160, Copper Alloy Model 732.15.160, Stainless Steel VersionDocument11 pagesDifferential Pressure Gauge Model 712.15.160, Copper Alloy Model 732.15.160, Stainless Steel VersionNayan DudhatraNo ratings yet

- Wika Pgt23.1001 DatasheetDocument5 pagesWika Pgt23.1001 DatasheetongquangthaiNo ratings yet

- DATA SHEET Bourdon Tube Pressure Gauge With Switch ContactsDocument12 pagesDATA SHEET Bourdon Tube Pressure Gauge With Switch ContactsMirwan MukminNo ratings yet

- WikaDocument10 pagesWikasolensa mantenimientoNo ratings yet

- Differential Pressure Gauges Cryo Gauge Model 712.15: ApplicationsDocument8 pagesDifferential Pressure Gauges Cryo Gauge Model 712.15: ApplicationsdhaktodesatyajitNo ratings yet

- Gas-Actuated Thermometer With Switch Contacts Model 73, Stainless Steel VersionDocument12 pagesGas-Actuated Thermometer With Switch Contacts Model 73, Stainless Steel VersionchauNo ratings yet

- DS8792 Standard EU enDocument17 pagesDS8792 Standard EU enItss Mee HadiNo ratings yet

- Dpi 603 DatasheetDocument2 pagesDpi 603 DatasheetFabiano PalaveriNo ratings yet

- DPI610 615LP (16jan02)Document4 pagesDPI610 615LP (16jan02)bertan dağıstanlıNo ratings yet

- Astm Compression Tester Accessories: ADR Advanced Digital ReadoutDocument7 pagesAstm Compression Tester Accessories: ADR Advanced Digital ReadoutJorge SanchezNo ratings yet

- Haefely 2999x Ds 1604 SpecDocument4 pagesHaefely 2999x Ds 1604 SpecKhoilnNo ratings yet

- Field Devices - Controllers: Log oDocument12 pagesField Devices - Controllers: Log oisctomaslopezNo ratings yet

- HONEYWELL Transmisor Presion DifDocument2 pagesHONEYWELL Transmisor Presion DifAriel BNo ratings yet

- Dp303 Wet Wet Differential Pressure SensorDocument2 pagesDp303 Wet Wet Differential Pressure SensorJhors RojasNo ratings yet

- SwitzerDocument4 pagesSwitzerJove MultisystemsNo ratings yet

- SCX Series: Precision Compensated Pressure SensorsDocument10 pagesSCX Series: Precision Compensated Pressure SensorsJoel PalzaNo ratings yet

- SS CP 2181 UsDocument12 pagesSS CP 2181 Usmohammed goudaNo ratings yet

- 3 En230 B R4VPDocument11 pages3 En230 B R4VPAlessandro OliveiraNo ratings yet

- Digital transmitters with remote seals for pressure and levelDocument22 pagesDigital transmitters with remote seals for pressure and levelHectorNo ratings yet

- Chapter 1 (M) : Calibration of Pressure Indicating DevicesDocument1 pageChapter 1 (M) : Calibration of Pressure Indicating DevicesNAVEEN CHANDRA KCNo ratings yet

- FREJA546 - DS - EN Megger继保仪Document12 pagesFREJA546 - DS - EN Megger继保仪wubinhappydayNo ratings yet

- Transmisor de PressaoDocument4 pagesTransmisor de PressaoSergio KühlNo ratings yet

- Catalogo de SensoresDocument10 pagesCatalogo de SensoresjorgecasaliniNo ratings yet

- Features: Level Measurements Hydraulic Systems Oil Core TestingDocument4 pagesFeatures: Level Measurements Hydraulic Systems Oil Core TestingputrastevanofyNo ratings yet

- MS12 Digital Pressure Switch / Transmitter: ApplicationDocument4 pagesMS12 Digital Pressure Switch / Transmitter: ApplicationOchoa Para La BandaNo ratings yet

- TAPCON230Document6 pagesTAPCON230Rafat ThongNo ratings yet

- DT 14 XXDocument2 pagesDT 14 XXDarNo ratings yet

- 48-135.10 Digital E3 Modulevel Liquid Level Displacer TransmitterDocument12 pages48-135.10 Digital E3 Modulevel Liquid Level Displacer TransmitterArif DarmawanNo ratings yet

- Multi Function TesterDocument8 pagesMulti Function TesterAlphatech1No ratings yet

- 12659358631051Document4 pages12659358631051KamillAL-akhrasNo ratings yet

- Ceramic Pressure Transmitter with 4-20mA Output for 0-10bar (PT10R-1001-I2-H1143/XDocument3 pagesCeramic Pressure Transmitter with 4-20mA Output for 0-10bar (PT10R-1001-I2-H1143/XSilvio MeloNo ratings yet

- PDR1000. - 2019 NDocument4 pagesPDR1000. - 2019 Nalief setiawanNo ratings yet

- Automatic 12 KV Insulation Test System (C, Tan, PF) 2816/5284Document4 pagesAutomatic 12 KV Insulation Test System (C, Tan, PF) 2816/5284pstevandNo ratings yet

- Duct Mount Pressure TransmitterDocument2 pagesDuct Mount Pressure TransmitterShadab khanNo ratings yet

- Install Digital Pressure GaugeDocument15 pagesInstall Digital Pressure GaugeClever Negrete NovaNo ratings yet

- Digital/Bar-Graph Pressure Gauge Installation Instructions DPS-1591DP FORM DPS1591 II 7-02Document15 pagesDigital/Bar-Graph Pressure Gauge Installation Instructions DPS-1591DP FORM DPS1591 II 7-02Clever Negrete NovaNo ratings yet

- Voltage Monitoring Types SWDocument12 pagesVoltage Monitoring Types SWMardian Syah BejjoNo ratings yet

- Catalog Megger Mto210Document2 pagesCatalog Megger Mto210leha_pc3No ratings yet

- Lindab Manual Leakage TesterDocument24 pagesLindab Manual Leakage TesterleonelNo ratings yet

- Ge Dpi PR CalibratorDocument8 pagesGe Dpi PR CalibratorTp PtNo ratings yet

- Apr 2000galwDocument3 pagesApr 2000galwANGEL FLORESNo ratings yet

- Honeywell Sensing Heavy Duty Pressure Px2 Series Datasheet 50069942 I enDocument10 pagesHoneywell Sensing Heavy Duty Pressure Px2 Series Datasheet 50069942 I enDen CakraNo ratings yet

- Barografo FoxboreDocument16 pagesBarografo FoxboreojrfgmrfNo ratings yet

- Ficha Tecnica Ps510-600-01-Li2upn8-H1141Document3 pagesFicha Tecnica Ps510-600-01-Li2upn8-H1141Gustavo EgasNo ratings yet

- PX Series: Process ControllerDocument30 pagesPX Series: Process ControllerSerhiiNo ratings yet

- 00 - Valvula Prop - DREB6XDocument12 pages00 - Valvula Prop - DREB6XRonald MonteiroNo ratings yet

- Ficha Tecnica Transmisor de Presión Turck Pt3000psig-2003-I2-H1143Document4 pagesFicha Tecnica Transmisor de Presión Turck Pt3000psig-2003-I2-H1143Gustavo EgasNo ratings yet

- SITRANS P Pressure Transmitters for Demanding ApplicationsDocument30 pagesSITRANS P Pressure Transmitters for Demanding ApplicationsMacakafkaNo ratings yet

- EN 05038 en NaDocument2 pagesEN 05038 en NaFernando Tellez CordovaNo ratings yet

- Ask 800Document10 pagesAsk 800eletrica.smeNo ratings yet

- Fully Automated Three Phase 250V Transformer Turns Ratio MeterDocument6 pagesFully Automated Three Phase 250V Transformer Turns Ratio Meterpeppeto373137No ratings yet

- VEGAMET 862 Controller Spec SheetDocument2 pagesVEGAMET 862 Controller Spec SheetNithiananthan ArunasalamNo ratings yet

- Patron Trab PresionDocument5 pagesPatron Trab PresionSilvia Del RioNo ratings yet

- Icot 5000 PosicionadorDocument39 pagesIcot 5000 PosicionadorLuis Humberto Ruiz BetanzosNo ratings yet

- Kinetrol Rotary Actuator USADocument68 pagesKinetrol Rotary Actuator USAprasasti prasastiNo ratings yet

- Pvs Product BulletinDocument26 pagesPvs Product BulletinQ Llanos HenryNo ratings yet

- SIPART PS2, PS2 PA Electropneumatic Positioner For Linear and Rotary Actuators ManualDocument142 pagesSIPART PS2, PS2 PA Electropneumatic Positioner For Linear and Rotary Actuators Manualautoexpo1No ratings yet

- XMT868i Service Manual PDFDocument78 pagesXMT868i Service Manual PDFjairo mahechaNo ratings yet

- Assembly Features: Removable Terminal GreenDocument3 pagesAssembly Features: Removable Terminal GreenQ Llanos HenryNo ratings yet

- Kalibrasi Ramsey Metal DetectorDocument89 pagesKalibrasi Ramsey Metal DetectorDwiky Adhi Putra HanKhangNo ratings yet

- Vca VCN VCG - Usa - 01 12 PDFDocument16 pagesVca VCN VCG - Usa - 01 12 PDFProc. RembangNo ratings yet

- Webds109 12 Act-DaDocument2 pagesWebds109 12 Act-DaQ Llanos HenryNo ratings yet

- Ka01163pen 0216Document40 pagesKa01163pen 0216Q Llanos HenryNo ratings yet

- TD Sar2 1ph enDocument4 pagesTD Sar2 1ph enQ Llanos HenryNo ratings yet

- Flödesmätare VCA - 02 - FC - Kracht - EngDocument2 pagesFlödesmätare VCA - 02 - FC - Kracht - EngMiguel Angel RodriguezNo ratings yet

- BES M30ML-PSC10A-S04G-W Bes02Km: Inductive SensorDocument1 pageBES M30ML-PSC10A-S04G-W Bes02Km: Inductive SensorQ Llanos HenryNo ratings yet

- Logix 3800MD Positioner Manual IOMDocument100 pagesLogix 3800MD Positioner Manual IOMMatheus SilvaNo ratings yet

- Ramsey Mercury Free Tilt Sensor 8054.0514 CODocument4 pagesRamsey Mercury Free Tilt Sensor 8054.0514 COlf123No ratings yet

- UF D5500 Caudalimetro Clamp On Fijo Aguas Sucias Micronics FOLLETODocument4 pagesUF D5500 Caudalimetro Clamp On Fijo Aguas Sucias Micronics FOLLETOQ Llanos HenryNo ratings yet

- Kalibrasi Ramsey Metal DetectorDocument89 pagesKalibrasi Ramsey Metal DetectorDwiky Adhi Putra HanKhangNo ratings yet

- Ti00363fen - 1514 AaaDocument48 pagesTi00363fen - 1514 AaaQ Llanos HenryNo ratings yet

- Ceraphant T PTC31, PTP31, PTP35: Technical InformationDocument32 pagesCeraphant T PTC31, PTP31, PTP35: Technical InformationAmit AGRAWALNo ratings yet

- 1 2 3 4 5 6 7 8 9 10 11 12 13 Simatic S7-300 Automation System, Hardware and Installation: CPU 312IFM - 318-2 DPDocument238 pages1 2 3 4 5 6 7 8 9 10 11 12 13 Simatic S7-300 Automation System, Hardware and Installation: CPU 312IFM - 318-2 DPmuhammad arif100% (1)

- SS - 265DS en 06 12 - 2010Document24 pagesSS - 265DS en 06 12 - 2010Q Llanos HenryNo ratings yet

- Tfs User's Guide Mfts Rec4274c - enDocument50 pagesTfs User's Guide Mfts Rec4274c - enAngel Francisco NavarroNo ratings yet

- Ti01130pen 0618Document48 pagesTi01130pen 0618Q Llanos HenryNo ratings yet

- TD Sar2 3ph enDocument4 pagesTD Sar2 3ph enQ Llanos HenryNo ratings yet

- Sensor Inductivo 871tm Allen BraylenDocument2 pagesSensor Inductivo 871tm Allen BraylenQ Llanos HenryNo ratings yet

- Manual PROFIBUS Repeater OZD Profi 12MDocument40 pagesManual PROFIBUS Repeater OZD Profi 12MpatrickNo ratings yet

- Ramsey Mercury Free Tilt Sensor 8054.0514 CODocument4 pagesRamsey Mercury Free Tilt Sensor 8054.0514 COlf123No ratings yet

- Sitrans Wm100 SwitchDocument22 pagesSitrans Wm100 SwitchQ Llanos HenryNo ratings yet

- Range: Keeping The World FlowingDocument52 pagesRange: Keeping The World FlowingArgaardNo ratings yet

- DC Servo Motor - MalDocument6 pagesDC Servo Motor - Malapi-19787379100% (1)

- ECP Safe-T-Pull Remote (2019)Document2 pagesECP Safe-T-Pull Remote (2019)Guang ChenzNo ratings yet

- MasterLogic50 ManualDocument510 pagesMasterLogic50 ManualAriel Gallardo0% (1)

- STK0825F 1Document8 pagesSTK0825F 1Námaste AbaddonNo ratings yet

- Additional Work of L.P.ODocument13 pagesAdditional Work of L.P.Oscribd_lostandfoundNo ratings yet

- EXTA4Document39 pagesEXTA4Regis RomaryNo ratings yet

- LDC6 400 L16Document2 pagesLDC6 400 L16npNo ratings yet

- System House Electrical Panel SolutionsDocument17 pagesSystem House Electrical Panel SolutionsrkinspiresNo ratings yet

- Pulse ModulationDocument32 pagesPulse ModulationZelalem BirhanuNo ratings yet

- NV200 Manual Set - Section 2Document13 pagesNV200 Manual Set - Section 2wodrNo ratings yet

- Keyes - Infrared Receiver and Transmitter ModuleDocument9 pagesKeyes - Infrared Receiver and Transmitter ModulePedro MorrisNo ratings yet

- Lab No. # 11 Transient Response Analysis of Series RC CircuitDocument6 pagesLab No. # 11 Transient Response Analysis of Series RC CircuitWaqas AmeenNo ratings yet

- 33kV CT Test ReportDocument2 pages33kV CT Test Reportzahidul IslamNo ratings yet

- Small Signal Transistors TO-39 CaseDocument1 pageSmall Signal Transistors TO-39 CasePetr ggaNo ratings yet

- Activity-Lab-2-The DC Shunt Generator and MotorDocument14 pagesActivity-Lab-2-The DC Shunt Generator and MotorDiether PaderoNo ratings yet

- Testing&Testabilty Course PlanDocument5 pagesTesting&Testabilty Course PlanLava Kumar BNo ratings yet

- Stepping Motor EncoderDocument32 pagesStepping Motor EncoderAsistencia Técnica JLFNo ratings yet

- Datasheet 80010826Document8 pagesDatasheet 80010826slavunNo ratings yet

- MQ5 Moulded Case Circuit Breakers: Dual Power Automatic Transfer SwitchDocument4 pagesMQ5 Moulded Case Circuit Breakers: Dual Power Automatic Transfer SwitchAlex VegasNo ratings yet

- Tinkering PPT Wind GeneratorDocument10 pagesTinkering PPT Wind Generatormr copy xeroxNo ratings yet

- Bushing Conductor TypesDocument2 pagesBushing Conductor TypesSandeep BNo ratings yet

- MY Mini ProjectDocument9 pagesMY Mini ProjectPravin SalunkheNo ratings yet

- Chapter23 Electric Potential Part1 Part2Document7 pagesChapter23 Electric Potential Part1 Part2Barış ÖzdemirNo ratings yet

- Service Manual: AV-2106BE, AV-21B16, AV-21BMG6B, AV-21BMG6Document114 pagesService Manual: AV-2106BE, AV-21B16, AV-21BMG6B, AV-21BMG6Victor SampaNo ratings yet

- Tutorial 1 ITT400 CS2302A Group 4Document10 pagesTutorial 1 ITT400 CS2302A Group 4fatin farhanahNo ratings yet