Professional Documents

Culture Documents

Theories of Failure in Strength of Materials: Maximum Principal Stress Theory

Uploaded by

Etamus 1006Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Theories of Failure in Strength of Materials: Maximum Principal Stress Theory

Uploaded by

Etamus 1006Copyright:

Available Formats

We were discussing

Slope and deflection of beam, Rankine’s formula for columns, bending

stress in beam and different types of load acting on beam in our previous post.

Today we will understand here the theories of failure, in strength of material, with the help of

this post.

As we know very well that when a body or component or material will be subjected with an

external load, there will be developed stresses and strains in the body or component.

As per hook’s law, stress will be directionally proportional to the strain within the elastic limit or

we can say in simple words that if an external force is applied over the object, there will be some

deformation or changes in the shape and size of the object. Body will secure its original shape

and size after removal of external force.

Within the elastic limit, there will be no permanent deformation in the body i.e. deformation will

be disappeared after removal of load.

If external load is applied beyond the elastic limit, there will be a permanent deformation in the

body i.e. deformation will not be disappeared after removal of load. Component or material or

body will be said to be failed, if there will be developed permanent deformation in the body due

to external applied load.

Theories of failure help us in order to calculate the safe size and dimensions of a machine

component when it will be subjected with combined stresses developed due to various loads

acting on it during its functionality.

There are following theories as listed here for explaining the causes of failure of a component or

body subjected with external loads.

The maximum principal stress theory

The maximum principal strain theory

The maximum shear stress theory

The maximum strain energy theory

The maximum shear strain energy theory

We will first understand here the maximum principal stress theory

According to the theory of maximum principal stress, “The failure of a material or component

will occur when the maximum value of principle stress developed in the body exceeds the

limiting value of stress”.

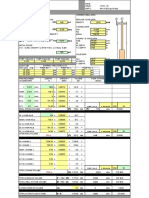

Let us explain the maximum principal stress theory by considering here one component which is

subjected with an external load and we have drawn here the stress-strain curve as displayed in

following figure.

Point A – It is proportionality limit; up to this point hooks law will be followed.

Point B – Elastic limit, up to this point the deformation will be elastic.

Point C – Lower yield stress.

Point D – Ultimate stress, it is the maximum value of stress in stress – strain diagram.

Point E- It is the fracture point, up to this point the material will have only elastic & plastic

deformation ,but at this point fracture or rupture take place.

If maximum value of principal stress developed in the body exceeds the point D, failure will take

place.

Therefore in order to avoid the condition of failure of the component, maximum value of

principal stress developed in the body must be below than the failure stress i.e. ultimate stress or

yield stress.

Condition of failure

Maximum value of principal stress developed in the body > Failure stress

σ1 > σy or σul

Condition for safe design

Maximum value of principal stress developed in the body ≤ Permissible stress or allowable stress

Permissible stress is basically defined as the ratio of failure stress i.e. ultimate stress or yield

stress to the factor of safety.

Permissible stress = Ultimate stress or yield stress / F.O.S

Important points in maximum principal stress theory

Maximum principal stress theory is also termed as Rankine’s theory

Maximum principal stress theory is quite suitable for securing the safe design of machine

component made of brittle(Acrylic) material as brittle materials are weak with respect to tension.

Maximum principal stress theory is not suitable for securing the safe design of machine

component made of ductile(Steel) material as shear failure may take place.

Maximum principal stress theory may be suitable for securing the safe design of machine

component made of ductile material under following three situations.

1. Uniaxial state of stress

2. Biaxial state of stress when principal stresses are like in nature

3. Under hydrostatic stress

Do you have suggestions? Please write in comment box.

We will now discuss the maximum principal strain theory, in the category of strength of

material, in our next post.

You might also like

- Stress-Strain Analysis of Axially Loaded MembersDocument22 pagesStress-Strain Analysis of Axially Loaded MembersMark MarkNo ratings yet

- Stresses in Pressure Vessel Design: Maximum Principal Stress TheoryDocument11 pagesStresses in Pressure Vessel Design: Maximum Principal Stress TheorybahmanNo ratings yet

- Lesson 1 and 2-1 PDFDocument22 pagesLesson 1 and 2-1 PDFDenver NieverasNo ratings yet

- My CEG Lab Report (1) (AutoRecovered)Document63 pagesMy CEG Lab Report (1) (AutoRecovered)akinyemi.favour.isaacNo ratings yet

- Relationship between Stress and Strain CurveDocument2 pagesRelationship between Stress and Strain Curvebabe100% (4)

- Relationship between Stress and Strain CurveDocument2 pagesRelationship between Stress and Strain CurvebabeNo ratings yet

- LESSON 4. Stresses On StructuresDocument5 pagesLESSON 4. Stresses On StructuresAdarsh bhatNo ratings yet

- What Is The Stress Strain CurveDocument5 pagesWhat Is The Stress Strain CurveEASHWAR PRODUCTIVENo ratings yet

- Theories of Elastic FailureDocument15 pagesTheories of Elastic FailurejaishowNo ratings yet

- Module 2Document59 pagesModule 2STEPHEN VILLARUZNo ratings yet

- Stresses in Machine MemberDocument18 pagesStresses in Machine MemberK ULAGANATHANNo ratings yet

- Stresses in Machine ElementsDocument18 pagesStresses in Machine ElementsthirumalaikumaranNo ratings yet

- Strength of Materials Lecture NotesDocument272 pagesStrength of Materials Lecture NotesbookdigitNo ratings yet

- Lecture On Mechanics of Materials PDFDocument14 pagesLecture On Mechanics of Materials PDFCliffordJamesSabiganNo ratings yet

- Module 6-Load and Stress AnalysisDocument39 pagesModule 6-Load and Stress AnalysisCamille ManlapigNo ratings yet

- Concept of Stresses and StrainDocument30 pagesConcept of Stresses and StrainAshenafi KenaNo ratings yet

- Machine Element and Design IDocument34 pagesMachine Element and Design IEmmanuel MatutuNo ratings yet

- Assignment Stress Strain DiagramDocument26 pagesAssignment Stress Strain DiagramShivani MedhekarNo ratings yet

- TOP 20+ Strength of Materials Interview QuestionsDocument10 pagesTOP 20+ Strength of Materials Interview QuestionsAkash SharmaNo ratings yet

- Lec 13Document15 pagesLec 13Janaki RamanNo ratings yet

- 18eng25: Building Structures-IiDocument61 pages18eng25: Building Structures-IideekshaNo ratings yet

- Stress Strain RealtionshipDocument35 pagesStress Strain RealtionshipKhalid YousafNo ratings yet

- Strength of Materials Basics and Equations - Mechanics of Materials - Engineers EdgeDocument6 pagesStrength of Materials Basics and Equations - Mechanics of Materials - Engineers EdgeansarNo ratings yet

- Stress Strain CurveDocument12 pagesStress Strain CurveGlerommie CastroNo ratings yet

- Report (MEC214)Document8 pagesReport (MEC214)عبدالله عبيدNo ratings yet

- HOOKE'S LAW & MATERIAL PROPERTIESDocument19 pagesHOOKE'S LAW & MATERIAL PROPERTIESSary LimNo ratings yet

- Debre-Markos University Mechanical Engineering Stress ChapterDocument25 pagesDebre-Markos University Mechanical Engineering Stress Chapterbiruk geseseNo ratings yet

- Stress, Strain and ElasticityDocument5 pagesStress, Strain and ElasticitychowhkNo ratings yet

- Scriet (Agriculture Depatment), Ccsu Meerut Machine Design (Unit 4 Lecture 5)Document7 pagesScriet (Agriculture Depatment), Ccsu Meerut Machine Design (Unit 4 Lecture 5)Vivek MishraNo ratings yet

- Theories of Elastic FailureDocument6 pagesTheories of Elastic FailurePrithvi ChilukuriNo ratings yet

- Material Properties ReportDocument8 pagesMaterial Properties ReportazizsaafanNo ratings yet

- Young's modulus, stress-strain diagrams, and other mechanical propertiesDocument14 pagesYoung's modulus, stress-strain diagrams, and other mechanical propertiesJitendra GangwarNo ratings yet

- Theories of FailureDocument3 pagesTheories of FailureLook-n De SousaNo ratings yet

- Theories of Mechanical FailureDocument11 pagesTheories of Mechanical FailureRavi PalaskarNo ratings yet

- Mechanics of MaterialsDocument43 pagesMechanics of Materialsmtalhasyed100% (3)

- 9.theories of Elastic FailureDocument6 pages9.theories of Elastic FailureRohit KumarNo ratings yet

- Failure TheoriesDocument6 pagesFailure TheoriesNobleSharmaNo ratings yet

- Plastic Analysis of StructuresDocument26 pagesPlastic Analysis of Structuresomar sayedNo ratings yet

- Stress and Strain: Elastic ModulusDocument10 pagesStress and Strain: Elastic Moduluslaura sageNo ratings yet

- Theories of Failure: Machine Design StructuralDocument3 pagesTheories of Failure: Machine Design Structuralamarkiran vinayakNo ratings yet

- Design For Static StrengthDocument39 pagesDesign For Static StrengthNeya SebastianNo ratings yet

- Mechanics of Structures-1Document13 pagesMechanics of Structures-1ErvinNo ratings yet

- Stress-Strain DiagramDocument10 pagesStress-Strain DiagramSalman KhanNo ratings yet

- LectureDocument50 pagesLectureIsmailNo ratings yet

- STRESSES ON STRUCTURES: TYPES, CALCULATIONS & DESIGN METHODSDocument5 pagesSTRESSES ON STRUCTURES: TYPES, CALCULATIONS & DESIGN METHODSBweks LeBron MVPNo ratings yet

- Stress Strain CurveDocument7 pagesStress Strain Curvekihal zohirNo ratings yet

- LectureDocument19 pagesLectureIsmailNo ratings yet

- Unit-5-Lecture-21 On Mechanical EngineeringDocument20 pagesUnit-5-Lecture-21 On Mechanical EngineeringDeepakNo ratings yet

- 1.DEFINE: A) Linear Static AnalysisDocument9 pages1.DEFINE: A) Linear Static Analysissyaqirah shahriNo ratings yet

- Motivation and Goal Setting for SuccessDocument23 pagesMotivation and Goal Setting for Successbiruk geseseNo ratings yet

- Plastic Analysis PresnetationDocument123 pagesPlastic Analysis PresnetationMisganaw YeshiwasNo ratings yet

- Rheological Properties (Terminology)Document18 pagesRheological Properties (Terminology)adNo ratings yet

- Mechanical Properties of MaterialsDocument17 pagesMechanical Properties of MaterialsJackie wanNo ratings yet

- Solid Mechanics Short Questions and AnswersDocument61 pagesSolid Mechanics Short Questions and Answerssampathsiddam77% (31)

- Ductile vs brittle material behavior under static and variable loadingDocument7 pagesDuctile vs brittle material behavior under static and variable loadingNishaThakuriNo ratings yet

- Theory of Elastisity, Stability and Dynamics of Structures Common ProblemsFrom EverandTheory of Elastisity, Stability and Dynamics of Structures Common ProblemsNo ratings yet

- Stability of Discrete Non-conservative SystemsFrom EverandStability of Discrete Non-conservative SystemsRating: 1 out of 5 stars1/5 (1)

- Ryobi Power Tool Catalogue 2017Document31 pagesRyobi Power Tool Catalogue 2017Etamus 1006No ratings yet

- NP330 NP332UserManual enDocument23 pagesNP330 NP332UserManual enEtamus 1006No ratings yet

- Acrylic StandardsDocument1 pageAcrylic StandardsEtamus 1006No ratings yet

- Supaee NggnoenDocument2 pagesSupaee NggnoenEtamus 1006No ratings yet

- Halot One PlusDocument25 pagesHalot One PlusEtamus 1006No ratings yet

- Hilti Catalogue 2020 6-Chemical Anchor - Final LRNCDocument46 pagesHilti Catalogue 2020 6-Chemical Anchor - Final LRNCEtamus 1006No ratings yet

- DriveWorksProAdvanced V18Document126 pagesDriveWorksProAdvanced V18Etamus 1006No ratings yet

- Essentials Training Reference Quick Reference GuideDocument2 pagesEssentials Training Reference Quick Reference GuideEtamus 1006No ratings yet

- Mass-Transfer Diffusion Coefficients in Binary Systems: AppendixDocument3 pagesMass-Transfer Diffusion Coefficients in Binary Systems: AppendixAnisaNo ratings yet

- Underground Works: Projek Mass Rapid Transit Laluan 2: Sg. Buloh - Serdang - PutrajayaDocument21 pagesUnderground Works: Projek Mass Rapid Transit Laluan 2: Sg. Buloh - Serdang - PutrajayaMohd FadliNo ratings yet

- Electricity Distribution Systems ExplainedDocument2 pagesElectricity Distribution Systems ExplainedMichael SharpeNo ratings yet

- Pollution Monitoring Using Sensors and Wireless Sensor Networks: A SurveyDocument6 pagesPollution Monitoring Using Sensors and Wireless Sensor Networks: A SurveyInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Physics I Problems PDFDocument1 pagePhysics I Problems PDFBOSS BOSSNo ratings yet

- Workbook Answers Chapter 5 Asal PhysicsDocument2 pagesWorkbook Answers Chapter 5 Asal PhysicsSaw Lip Xuan JeffNo ratings yet

- Gate - 2006 PDFDocument13 pagesGate - 2006 PDFRBNo ratings yet

- Motor Vibration AnalysisDocument61 pagesMotor Vibration Analysiskiki kamuiNo ratings yet

- Joola Rubber ComparisonDocument1 pageJoola Rubber ComparisonAmherst100% (1)

- Gasification For Practical ApplicationsDocument352 pagesGasification For Practical ApplicationsOthmane DrissiNo ratings yet

- Thermodynamics IntroductionDocument27 pagesThermodynamics IntroductionLeslie Owusu MensahNo ratings yet

- (AMW0001) Biasing LDMOS FETs For Linear OperationDocument3 pages(AMW0001) Biasing LDMOS FETs For Linear OperationThanhha NguyenNo ratings yet

- Shindengen: Super Fast Recovery RectifiersDocument7 pagesShindengen: Super Fast Recovery RectifiersJose Carlos SoaresNo ratings yet

- Abiotic and Biotic Factors DFDocument2 pagesAbiotic and Biotic Factors DFMushfique HussainNo ratings yet

- Aseptic Spray Dryers: An Effective Method For Sterile Solid Drug ManufactureDocument4 pagesAseptic Spray Dryers: An Effective Method For Sterile Solid Drug ManufactureJacob DonoghueNo ratings yet

- Type P8n, PQ8n, PN8n: Auxiliary RelayDocument7 pagesType P8n, PQ8n, PN8n: Auxiliary RelayDinesh ThevanNo ratings yet

- 1945-1946 350cc Model CODocument52 pages1945-1946 350cc Model COroyceNo ratings yet

- Brochure - Porcelain Ventilated FaçadeDocument100 pagesBrochure - Porcelain Ventilated Façadebatteekh100% (1)

- IS 40 Power FactorDocument2 pagesIS 40 Power Factortekeba lakeNo ratings yet

- VFT Simulink Model Studies Power TransferDocument5 pagesVFT Simulink Model Studies Power TransferJawad IqbalNo ratings yet

- Rate of Reaction 2Document23 pagesRate of Reaction 2brydonsantosNo ratings yet

- Bosch Dishwasher SMU50M05AU User ManualDocument38 pagesBosch Dishwasher SMU50M05AU User Manualgedaso100% (1)

- Engine Performance Data at 1800 RPM: X3.3 1 Cummins India Limited S3.8Document4 pagesEngine Performance Data at 1800 RPM: X3.3 1 Cummins India Limited S3.8Rasheed SiddiquiNo ratings yet

- Speed Control of Induction Motor Using Triac: Prachi M. Palpankar, Sanraj Harle, Tushar Karade, Suraj LekurwaleDocument3 pagesSpeed Control of Induction Motor Using Triac: Prachi M. Palpankar, Sanraj Harle, Tushar Karade, Suraj LekurwaleChandan SharmaNo ratings yet

- Internal Rotary Inspection System (IRIS) Tubular TestingDocument3 pagesInternal Rotary Inspection System (IRIS) Tubular Testingநந்த குமார் சம்பத் நாகராஜன்100% (1)

- Isolation ValvesDocument10 pagesIsolation ValvesnotiadraNo ratings yet

- ( (C) - CURR. DENSITY) X SHOE T.V.D. X 0.052 X 3.281Document5 pages( (C) - CURR. DENSITY) X SHOE T.V.D. X 0.052 X 3.281Nitin GandhareNo ratings yet

- International Standard: Electric Vehicle Wireless Power Transfer (WPT) Systems - Part 1: General RequirementsDocument11 pagesInternational Standard: Electric Vehicle Wireless Power Transfer (WPT) Systems - Part 1: General RequirementsАндрейNo ratings yet

- AUTOMOTIVE PASSENGER VEHICLES LUBRICANTS (English)Document24 pagesAUTOMOTIVE PASSENGER VEHICLES LUBRICANTS (English)darionestoroskiNo ratings yet

- Soundbite: Amir Abolfathi, Sonitus Medical One of The Top Inventions of 2010 in Popular Science MagazineDocument5 pagesSoundbite: Amir Abolfathi, Sonitus Medical One of The Top Inventions of 2010 in Popular Science MagazineMatthew CuaNo ratings yet