Professional Documents

Culture Documents

SiO2 - MOLYBDOSILICIC ACID AND REDOX TITRATION OF MOLYBDENUM (III)

Uploaded by

Oscar BenimanaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SiO2 - MOLYBDOSILICIC ACID AND REDOX TITRATION OF MOLYBDENUM (III)

Uploaded by

Oscar BenimanaCopyright:

Available Formats

652 SHORTCOMMUNICATIONS

REFERENCES

5. A. Saito and S.’Himeno, Nippon Kagaku Kaishi, 1974,

1. H. Dahms, J. Electroanal. Chem., 1964, 8, 5. 2340.

2. G. C. Barker and J. A. Bolzan, Z. Anal. Chem., 1965, 6. I. M. Kolthoff and S. E. Khalafalla, Reo. Polarogr.,

216, 15. 1963, 11, 11.

3. W. H. Reinmuth and K. Balasubramanian, J. Elec- 7. F. Stmad, Collection Czech. Chem. Commun., 1939, 11,

troanal. Chem., 1972, 38, 79. 391.

4. R. Guidelli, ibid., 1968, 18, 5.

Talanto, Vol. 24, pp. 652654. Pergamon Press, 1977. Printed in Great Bntain

DETERMINATION OF SILICA IN SILICATES BY FORMATION OF

1ZMOLYBDOSILICIC ACID AND REDOX TITRATION OF MOLYBDENUM(II1)

0. A. OHLWEILER and J. 0. MEDITSCH

Instituto de Quimica, Universidade Federal, Porto Alegre, Brasil

(Received 17 January 1977. Accepted 16 April 1977)

Summary-An indirect titrimetric method for the determination of silica in silicates is described. A

boron trioxide-lithium carbonate (1O:l) mixture is used as flux and the melt is dissolved in an acidic

molybdate solution to form 12-molybdosilicic acid. The yellow complex is extracted with methyl isobu-

tyl ketone (MIBK) and, after removal of the co-extracted molybdate reagent, is decomposed with

alkali. The resultant aqueous phase is acidified and passed through a Jones reductor to convert the

molybdenum(V1) into molybdenum(III), which is then titrated with potassium permanganate. The

method has high precision and accuracy. Phosphorus, titanium, zirconium and vanadium, in amounts

that may occur in silicate rocks, do not interfere; at least 5% P,O,, 5% TiO,, 2% ZrO, and 0.5%

V,O, are permissible. Fluorine (at least 2%) can also be tolerated when lithium metaborate is used

as flux.

Indirect amplification methods have been published for the Procedure

determination of silicon by atomic-absorption spectro- Transfer 0.100&0.1500 g of the finely powdered sample

metry of the twelve molybdenum atoms associated with (<200 mesh), containing 5&70mg of silica, to a 30-ml

each silicon atom in 12-molybdosilicic acid, after its selec- platinum crucible. Add l.OOg of boron trioxide and O.lOg

tive extraction into an organic solvent.‘-4 of lithium carbonate and mix intimately with a short glass

This paper describes an indirect titrimetric method for rod with rounded ends. Heat carefully with a small flame

the determination of silica in silicates, by formation of until any water is completely expelled, then cover the cru-

IZmolybdosilicic acid, its selective extraction with methyl cible and heat with a strong flame (ca. 1000”). After fusion

isobutyl ketone (MIBK), washing of the organic extract for 30 mitt, allow the crucible to cool to room temperature.

with dilute hydrochloric acid to remove excess of molyb- Weigh out 8.Og of sodium molybdate,

date, decomposition of the lbmolybdosilicic acid with Na,Mo0,.2H,O, transfer to a lOOO-ml beaker and dis-

dilute ammonia solution and transfer of the molybdenum solve in about 700 ml of distilled water. Add, with stirring,

to the alkaline aqueous phase, acidification with sulphuric 6.0mI of concentrated hydrochloric acid and then place

acid, reduction to molybdenum(II1) in a Jones reductor, the crucible in the solution contained in the beaker. Rinse

then titration with potassium permanganate. A similar pro- the cover of the crucible into the beaker with distilled

cedure has been used by Kirkbright et al. for the deter- water. Put the beaker in the cavitation bath of the ultra-

mination of phosphorus.5 sonic generator until the cake becomes detached from

the crucible (ca. 1 mm). Then stir magnetically (Teflon-

EXPERIMENTAL coated stirrer bar) until the melt dissolves (about 20 min)

forming a yellow molybdosilicic acid solution. Remove and

Reagents

rinse the crucible with distilled water. Transfer the yellow

Iron(III) phosphate solution. Prepare 1 litre of solution solution to a lOOO-ml volumetric flask and dilute to

containing 48.5 g of NH,Fe(SO,), ‘12Hz0, 40 ml of 85% volume with distilled water.

phosphoric acid and 50 ml of concentrated sulphuric acid. Transfer a 50-ml aliquot to a 250-ml separating-funnel

and add 16.0 ml of concentrated hydrochloric acid to make

Apparatus the solution about 3M in HCl. Then add 75 ml of MIBK

Ultrasonic generator. Operating frequency, 20 kHz; cavi- and shake for 5 min. Allow adequate time for the layers

tation bath, 16cm diameter, 1Ocm height; power density to separate and transfer the aqueous phase (containing

in the cavitation bath, 2 W/cm2. most of the molybdate excess and any unextracted

Jones reductor. Prepare and store conventionally.6 If the 1Zmolybdosilicic acid) to a second 250-ml separating fun-

reductor has been standing idle, pass 1OOml of sulphuric nel, retaining the organic phase in the first one. Rinse the

acid (1 + 19) through it and then a little cold water. organic phase with a 2-3 ml of water. Add 50 ml of MIBK

SHORT CQMMUNlCATIONS 653

to the second separating-funnel, shake for 5 min and dis- city and effectiveness in silicate decomposition as shown

card the aqueous phase. in previous studies. ‘-’ The dissolution of the cake in an

Add 25 ml of 1M hydrochloric acid to each of the separ- acidic molybdate solution ensures the complete depolymer-

ating-funnels, shake both for 30sec and allow the layers ization of silica and the formation of the 1Zmolybdosilicic

to separate. Take the first funnel, discard the aqueous acid. In the dissolution step, sufficient hydrochloric acid

phase, and rinse the funnel tip with distilled water (do is added to lower the pH to 1.3. The correct amount of

this after all transfers of aqueous phases). Transfer the acid was empirically determined, as the presence of molyb-

aqueous phase from the second funnel to the fist. Shake date alters the pH of the solution. The complete formation

the first funnel for 30 set and then discard the aqueous of the yellow molybdosilicate complex is obtained by the

phase. Shake the organic phase in the second funnel with presence of a relatively high excess of molybdate reagent.

25 ml of IM hydrochloric acid for 30 set and transfer the An aliquot for analysis should contain no more than

aqueous phase to the first funnel. Shake this for 3Osec, 3.5 mg of SiO,; otherwise the extraction of 12-molybdo-

allow the layers to separate, and discard the aqueous silicic acid with the organic solvent is hindered.

phase. Transfer the organic phase from the second funnel Extraction of 1Zmolybdosilicic acid with MIBK was

to the first. Add 30ml of 1W ammonia solution to the used to permit the separation of other molybdoheteropoly

funnel and shake for 30 sec. Drain the aqueous phase into acids eventually present and also the subsequent removal

a IOO-ml beaker. Add another 30 ml of 1M ammonium of the co-extracted molybdate. The extractability of molyb-

hydroxide, shake for 30 set, drain the aqueous phase into doheteropoly acids in MIBK was studied recently.iO

the beaker and rinse the funnel with distilled water into Molybdosilicic acid has a maximum distribution ratio of

the beaker. approximately 720 from 0.084.0&f hydrochloric acid and

Add 6 ml of concentrated sulphuric acid to the solution thus can be quantitatively extracted over this range.

containing the molybdenum. Transfer 35 ml of iron(II1) 12-Molybdosilicic acid can be selectively extracted in the

phosphate solution to the receiver of the Jones reductor, presence of molybdophosphoric and molybdoarsenic acids

and then enough water so that the tip of the reductor at an acidity >2.5M hydrochloric acid. Three washings

dips well beneath the surface of the solution. Draw the are needed to remove the excess of molybdate from the

cold solution of molybdenum through the reductor. Wash extract.

the beaker and reductor successively with 50 ml of sul- The method was tested with analysed samples (Table

phuric acid (1 + 19) and then transfer the two 5Gml ali- 1). The relative errors are less than 0.1%. The six results

quots of distilled water. Titrate the solution in the receiver for the soda feldspar gave a standard deviation of 0.02,%.

with 0.05N potassium permanganate. Synthetic samples were prepared with a soda feldspar

Make a blank deter~nation, passing successively containing 65.49% of SiOz, to which amounts of the fol-

through the reductor 150ml of sulphuric acid (1 + 19) and lowing potentially interfering elements were added: phos-

100 ml of distilled water. phorus, arsenic, titanium, zirconium, vanadium, niobium,

tantalum and fluorine. Particular attention was given to

RESJJXS AND DISCUSSION

phosphorus, titanium, and zirconium because small

mounts of these elements may occur in silicate minerals

The attack on the sample and the preparation of the and rocks, and they might be expected to interfere with

solution must ensure the conversion of all silica into the the method by virtue of their tendency to hydrolyse or

monomeric silicic acid in order to form 1Zmolybdosilicic form the heteropoly acids.“-i4.

acid. A fusion technique employing a boron trioxidolith- The results obtained with synthetic samples (Table 2)

ium carbonate (10: 1) flux was chosen for its speed, simpli- indicate that phosphorus, titanium, zirconium and vana-

Table 1. Results obtained in the determination of silica in silicate standard samples

SiO, found, Relative

Sample Composition, % % error, y0

Soda feldspar SiOa, 68.66; Al,O,, 19.06; 68.62 - 0.06

(U.S.N.B.S., No. 99) Fe,O,, 0.067; MgO, 0.053; 68.60 -0.09

CaO, 0.36; Na,O, 10.73; 68.62 -0.06

K,O, 0.41; TiO,, 0.017; 68.64 - 0.03

P,Os, 0.142; MnO, <O.OOl; 68.60 0.00

BaO, 0.01 68.66 - 0.09

Plastic clay SiO,, 59.11; Al,O,, 25.54; 59.07 -0.07

(U.S.N.B.S., No. 98) Fe,O,, 2.05; TiO,, 1.43;

ZrO,, 0.041; P,O,, 0.08;

V,Os, 0.025; Cr,O,, 0.021;

CaO, 0.21; MgO, 0.72; K,O,

3.17; Na,O, 0.28; SO,, 0.07;

MnO, 0.005; CuO, 0.009

Flint clay SiO*, 42.87; Al,O,, 38.77; 42.83 -0.09

(U.S.N.B.S., No. 97) Fe,Os, 0.98; TiOa, 2.38;

ZrO,, 0.25; P,O,, 0.08; V,O,,

0.040; Cr,O,, 0.079; CaO,

0.10; MgO, 0.26; K,O, 0.54;

NarO, 0.33; SOa, 0.042; MnO,

0.002: cue, o&O3

Burst refractory Si02,. 54.69; A&O,, 37.67 ; 54.64 -0.09

(U.S.N.B.S., No. 76) FeaO,, 2.38; TiO,, 2.21;

ZrO,, 0.07; MgO, 0.58; CaO,

0.27; K,O, 1.37; Na,O, 0.38;

P,O,, 0.069; v,o,, 0.021

654 SHORT COMMUNICATIONS

Table 2. Results obtained in the determination of silica in synthetic mixtures

prepared with a soda feldspar containing 65.49% of SiO,

Additions SiOz found, % Relative error, %

2% TiO, 65.43 -0.09

5% TiOZ 65.42 -0.11

5% P205 65.46 -0.05

2% P,O, + 5% TiO, 65.41 -0.03

5% P,Os + 5% TiOz 65.46 -0.05

5% P,O, + 5 TiOz + 1% ZrO, 65.46 -0.05

5% P,O, + 5 Ti02 + 2% ZrO, 65.41 -0.12

0.5% v,os 65.41 -0.12

1.0% v,05 65.32 -0.26

5% As,05 65.43 -0.09

2% Nb,O, 64.34 - 1.79

2% Ta,O, 65.01 -0.61

2% F (fusion with B,O,-Li,CO, 1O:l) 64.34 - 1.76

2% F (fusion with LiB02) 65.44 -0.08

dium, in amounts that usually occur in silicate rocks, do 2. G. F. Kirkbright, A. M. Smith and T. S. West, Analyst,

not interfere: at least 5% P20s, 5% TiO,, 2% ZrO, and 1967, 92, 411.

0.5% Vz05 are permissible. (The presence of 5% As,O, 3. W. S. Zaugg and R. Knox, Anal. Chem., 1966,38, 1759.

is also admitted.) Niobium and tantalum interfere. The 4. T. Kumamaru, Y. Otani and Y. Yamamoto, Bul[.

presence of fluorine yields low results when the sample Chem. Sot. Japan, 1967, 40, 427.

is fused with boron trioxide-lithium carbonate (10: 1) mix- 5. G. F. Kirkbright, A. M. Smith and T. S. West, Analyst,

ture, because some silicon is lost while fluorine volatilizes; 1968, 93, 224.

but good results are obtained by using a lithium metabor- 6. A. S. T. M., 1960 Book of A.S.T.M. Methods for Chemi-

ate flux to decompose the sample. cal Analysis of Metals, Philadelphia, 1960.

The association of twelve molybdenum atoms with each 7. 0. A. Ohlweiler, J. 0. Meditsch, C. L. P. da Silveira

atom of silicon in l-2-molybdosilicic acid and the reduction and S. Silva, Anal. Chim. Acta, 1972, 61, 57.

of the molybdenum(V1) to molybdenum(II1) before titra- 8. 0. A. Ohlweiler, J. 0. Meditsch, S. Silva and J. A.

tion of the latter with standard potassium permanganate Oderich, ibid., 1974, 69, 224.

gives an amplification factor of 36. Ordinarily, an amplifi- 9.. 0. A. Ohlweiler, J. 0. Meditsch and C. M. S. Piatnicki,

cation method is not used for the determination of major ibid., 1976, 84, 431.

constituents, but in this instance it allows the use of a 10. S. J. Simon and D. F. Boltz, Awl. Chem., 1975, 47,

small aliquot and, hence, the separation of interferents by 1758.

extraction of 12-molybdosilicic acid under selective condi- 11. G. F. Kirkbright, A. M. Smith and T. S. West, Analyst,

tions. The complete analysis can be performed in less than 1968, 93, 292.

4 hr. 12. G. F. Kirkbright, A. M. Smith, T. S. West and R.

REFERENCES

Wood, ibid., 1969, 94, 754.

13. H. N. Johnson, G. F. Kirkbright and T. S. West, ibid.,

1. T. R. Hurford, and D. F. Boltz, Anal. Chem., 1968, 1972, 97, 696.

40, 379. 14. Y. F. Shkaravskii, Russ. J. Inorg. Chem., 1963,8, 1339.

You might also like

- The Chemistry of Fertilisers and Manure - Including Information on the Chemical Constituents and Types of Fertilisers and ManuresFrom EverandThe Chemistry of Fertilisers and Manure - Including Information on the Chemical Constituents and Types of Fertilisers and ManuresRating: 5 out of 5 stars5/5 (1)

- Silica, Calorimetric, Molybd'ate Blue: 1. ApplicationDocument2 pagesSilica, Calorimetric, Molybd'ate Blue: 1. ApplicationLượng Nguyễn VănNo ratings yet

- Methods Chemical Analysis of Steels: ThirdDocument6 pagesMethods Chemical Analysis of Steels: ThirdferozNo ratings yet

- Alexander 1953Document3 pagesAlexander 1953brouuorbNo ratings yet

- MECHANISM OF H2S FORMATION FROM THIOSULFATEDocument8 pagesMECHANISM OF H2S FORMATION FROM THIOSULFATEredof markzNo ratings yet

- Ap Unit7 Worksheet AnswersDocument5 pagesAp Unit7 Worksheet Answersburcak gecNo ratings yet

- Iron Content in FoodsDocument5 pagesIron Content in FoodsPatrick Quiroz MorenoNo ratings yet

- Aoac 962.02 P2o5Document1 pageAoac 962.02 P2o5akloioNo ratings yet

- Atq Experiment 8 Chem 261 PDF FreeDocument7 pagesAtq Experiment 8 Chem 261 PDF FreeAliNo ratings yet

- Expt 1 To 4 Lab ReportDocument4 pagesExpt 1 To 4 Lab ReportEyvette GoNo ratings yet

- Arsenic + AntimonyDocument3 pagesArsenic + AntimonyTyroneNo ratings yet

- A Method For The Determination of 2-Imidazoline Residues in Food CropsDocument3 pagesA Method For The Determination of 2-Imidazoline Residues in Food CropsbudiwatesNo ratings yet

- Isolation and Characterization of Starch by Abarca - 2017 USTDocument5 pagesIsolation and Characterization of Starch by Abarca - 2017 USTWynlor AbarcaNo ratings yet

- Ciclo CuDocument7 pagesCiclo CuMaribel HolguinNo ratings yet

- Purification of Food-Grade Magnesium Chloride: 2 ExperimentalDocument4 pagesPurification of Food-Grade Magnesium Chloride: 2 ExperimentalLin MachacaNo ratings yet

- 1a11. IS 228 - Part - 11 - 1990Document6 pages1a11. IS 228 - Part - 11 - 1990hhr2412No ratings yet

- J. Biol. Chem.-1948-Barker-715-24Document11 pagesJ. Biol. Chem.-1948-Barker-715-24Rudy QuismorioNo ratings yet

- Ana Sci 5 85Document4 pagesAna Sci 5 85Taulant SheqerxhiuNo ratings yet

- JP17 01039Document2 pagesJP17 01039Sidahmed SiDo BouchenakNo ratings yet

- Andayani, Bagyo - 2011 - Tio 2 Beads For Photocatalytic Degradation of Humic Acid in Peat WaterDocument5 pagesAndayani, Bagyo - 2011 - Tio 2 Beads For Photocatalytic Degradation of Humic Acid in Peat WaterBFCNo ratings yet

- Separation of Antimony (Ii1) With Iodide andDocument8 pagesSeparation of Antimony (Ii1) With Iodide andWi FuentesNo ratings yet

- Precipitation of Molybdenum (V) As The Hydroxide AND Its Separation From RheniumDocument3 pagesPrecipitation of Molybdenum (V) As The Hydroxide AND Its Separation From RheniumBrent WoottonNo ratings yet

- Physical ChemistryDocument20 pagesPhysical ChemistryMarielley100% (6)

- A Rapid and Precise Method For Determining Sulfate in Seawater, Estuarine Waters, and Sediment Pore Waters'Document4 pagesA Rapid and Precise Method For Determining Sulfate in Seawater, Estuarine Waters, and Sediment Pore Waters'takkar1392No ratings yet

- Hydrolysis of Methyl Salicylate ExpDocument7 pagesHydrolysis of Methyl Salicylate ExpPradeep100% (1)

- AistDocument5 pagesAistKyla CarbonelNo ratings yet

- Synthesis of 1-Bromobutane via Alcohol HalogenationDocument10 pagesSynthesis of 1-Bromobutane via Alcohol HalogenationAmy GardnerNo ratings yet

- FL SopDocument45 pagesFL SopSara JohnsonNo ratings yet

- DownloadFile 3500 ZNDocument2 pagesDownloadFile 3500 ZNPenelope MeloNo ratings yet

- Lab Report-Elle Necole QuimadaDocument5 pagesLab Report-Elle Necole QuimadaElleNo ratings yet

- To Determine Copper Content in A CoinDocument15 pagesTo Determine Copper Content in A CoinagarwalvanshikaNo ratings yet

- Limnology Oceanography - September 1969 - Sol Rzano - Determination of Ammonia in Natural Waters by TheDocument3 pagesLimnology Oceanography - September 1969 - Sol Rzano - Determination of Ammonia in Natural Waters by TheOmar Miguel Peña SánchezNo ratings yet

- TalcDocument2 pagesTalcJoão AndréNo ratings yet

- Nitrate & NitriteDocument7 pagesNitrate & NitriteSteven LapidgeNo ratings yet

- Hill Reaction Measured SpectrophotometricallyDocument5 pagesHill Reaction Measured SpectrophotometricallyMagnus JordanNo ratings yet

- Determination of Small Amounts of Water in Organic Solvents by Spectrophotometric AnalysisDocument13 pagesDetermination of Small Amounts of Water in Organic Solvents by Spectrophotometric AnalysisLUIS XVNo ratings yet

- Preparation and Characterization of Monoclinic Sulfur Nanoparticles by Water-In-Oil Microemulsions TechniqueDocument4 pagesPreparation and Characterization of Monoclinic Sulfur Nanoparticles by Water-In-Oil Microemulsions TechniqueHamidreza AbriNo ratings yet

- Rate of Reaction LabDocument6 pagesRate of Reaction LabcurtisNo ratings yet

- Iodimetric Titration of Vitamin C: ReagentsDocument2 pagesIodimetric Titration of Vitamin C: ReagentsEbenezer EffisahNo ratings yet

- SulfatosDocument7 pagesSulfatosJohan andres Morales carvajalNo ratings yet

- Experiment 2 Waste Water Sampling and Characterization - Coagulation and Water HardnessDocument17 pagesExperiment 2 Waste Water Sampling and Characterization - Coagulation and Water HardnessSanjeev NehruNo ratings yet

- AOAC 960.05-MolybdenumDocument1 pageAOAC 960.05-MolybdenumYến PhiNo ratings yet

- American Society of Limnology and OceanographyDocument6 pagesAmerican Society of Limnology and OceanographyDominique LefevreNo ratings yet

- Complex SaltDocument8 pagesComplex Saltmipa amarNo ratings yet

- Aoac 906.03 PDFDocument2 pagesAoac 906.03 PDFAngie Cerinza AcostaNo ratings yet

- Determination of Dissolved OxygenDocument2 pagesDetermination of Dissolved OxygenMartk MartinezNo ratings yet

- Lab Manual Yr 3 InorganicDocument33 pagesLab Manual Yr 3 InorganicOmSilence2651No ratings yet

- The Effect of LIGNOSULFONATE en The Flotability of TalcDocument9 pagesThe Effect of LIGNOSULFONATE en The Flotability of TalcjvchiqueNo ratings yet

- Atq Experiment 8 Chem 26.1Document7 pagesAtq Experiment 8 Chem 26.1Rei Diaz Apalla100% (1)

- Removal of Copper (Ii) From Synthetic Waste Water Using BioremediationDocument35 pagesRemoval of Copper (Ii) From Synthetic Waste Water Using BioremediationShitanshu JainNo ratings yet

- H'Licrochemlcal Journal 15Document13 pagesH'Licrochemlcal Journal 15rezacvNo ratings yet

- Experiment No 1: Turbidity of WaterDocument2 pagesExperiment No 1: Turbidity of Waterramarao pagadalaNo ratings yet

- Synthesis, characterization and ligand exchange equilibria of potassium tris(oxalato)ferrate(IIIDocument8 pagesSynthesis, characterization and ligand exchange equilibria of potassium tris(oxalato)ferrate(IIIFaris Amzar SuhaimiNo ratings yet

- Experiment 1 Coagulation and FlocculationDocument6 pagesExperiment 1 Coagulation and Flocculationshahrolhazrien67% (6)

- Novel polymers for thiocyanate ion separationDocument7 pagesNovel polymers for thiocyanate ion separationAnonymous WkbmWCa8MNo ratings yet

- Kj2050 Lab 3 PointsDocument12 pagesKj2050 Lab 3 PointsJJ7788No ratings yet

- Study On The Precipitation of Magnesium Hydroxide From BrineDocument7 pagesStudy On The Precipitation of Magnesium Hydroxide From BrineJoel Jose Quisberth RodriguezNo ratings yet

- Dissolved oxygen estimation by redox titrationDocument2 pagesDissolved oxygen estimation by redox titrationSuet Wan GohNo ratings yet

- Kinetics of ChalcopyriteDocument6 pagesKinetics of ChalcopyriteMarcelo Sebastian HerreraNo ratings yet

- Approval Sheet: Mutmainnah Umar Rahmatia ID. 1513440003 ID. 1613040013Document15 pagesApproval Sheet: Mutmainnah Umar Rahmatia ID. 1513440003 ID. 1613040013rulmadhaniNo ratings yet

- KABANGU - Separation of NB & Ta From Mozambian TantaliteDocument5 pagesKABANGU - Separation of NB & Ta From Mozambian TantaliteOscar BenimanaNo ratings yet

- Determination of Niobium Using Volumetric TitrationDocument6 pagesDetermination of Niobium Using Volumetric TitrationOscar BenimanaNo ratings yet

- Liquid-liquid extraction of Ta and Nb using octanolDocument9 pagesLiquid-liquid extraction of Ta and Nb using octanolOscar BenimanaNo ratings yet

- Niobium: From Ore to Sophisticated Electronic ProductsDocument21 pagesNiobium: From Ore to Sophisticated Electronic ProductsOscar BenimanaNo ratings yet

- ANDERSSON - Tantalum & Tantalum CompoundsDocument15 pagesANDERSSON - Tantalum & Tantalum CompoundsOscar Benimana100% (1)

- SiO2 - Chemical Analysis of White Silica Sand by HClO4 - HFDocument6 pagesSiO2 - Chemical Analysis of White Silica Sand by HClO4 - HFOscar BenimanaNo ratings yet

- SiO2 - Rapid Analysis of Silicate RocksDocument47 pagesSiO2 - Rapid Analysis of Silicate RocksOscar BenimanaNo ratings yet

- SiO2 - Chemical Analysis by H2SO4 - HFDocument32 pagesSiO2 - Chemical Analysis by H2SO4 - HFOscar BenimanaNo ratings yet

- ISO-439-2020 For Silica Content With Fuming HClO4 AcidDocument9 pagesISO-439-2020 For Silica Content With Fuming HClO4 AcidOscar BenimanaNo ratings yet

- Technical Datasheet: Ec60 EasyconnectDocument10 pagesTechnical Datasheet: Ec60 EasyconnectDarlyn BayonaNo ratings yet

- Module 1 5 PHYSCI PDFDocument17 pagesModule 1 5 PHYSCI PDFRemar Jhon PaineNo ratings yet

- Clark 2016Document21 pagesClark 2016rafaelpulidoNo ratings yet

- Solved by Smart Exam Resources: Cambridge International General Certificate of Secondary EducationDocument16 pagesSolved by Smart Exam Resources: Cambridge International General Certificate of Secondary EducationHidayah TeacherNo ratings yet

- Presentation On Rayleighs Method of Dimensional AnalysisDocument13 pagesPresentation On Rayleighs Method of Dimensional Analysisabubakari meregulwaNo ratings yet

- Macropoxy 646 SEDocument4 pagesMacropoxy 646 SESleyda MunozNo ratings yet

- BiOBrCISO Crystal Structure and Peak ListDocument4 pagesBiOBrCISO Crystal Structure and Peak Listkẻ khờ khạoNo ratings yet

- 58 CitaDocument6 pages58 CitaKaren Alejandra López CastañosNo ratings yet

- Past Board Exam Problems in ChemistryDocument92 pagesPast Board Exam Problems in ChemistryJennifer L. MadronioNo ratings yet

- Chapter#1: Choose The Best AnswerDocument2 pagesChapter#1: Choose The Best AnswerMohammad AshfaqNo ratings yet

- Lect 17Document8 pagesLect 17JK JKNo ratings yet

- Deep Illustration For Loss of Circulation While DrillingDocument17 pagesDeep Illustration For Loss of Circulation While DrillingfuatNo ratings yet

- MSDS ChapsDocument1 pageMSDS ChapsPeterNo ratings yet

- Breakup of Questions:: Pesco Model Paper For Alm Test 2021 Total Mcqs 40 Total Marks 40 Time 80 MinsDocument5 pagesBreakup of Questions:: Pesco Model Paper For Alm Test 2021 Total Mcqs 40 Total Marks 40 Time 80 MinsFuzail ShoaibNo ratings yet

- TD Istra-40 enDocument2 pagesTD Istra-40 enAsmir SofticNo ratings yet

- CHEMISTRy Kcet 2022 Answer KeyDocument8 pagesCHEMISTRy Kcet 2022 Answer KeyAmoghaNo ratings yet

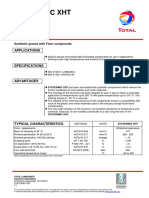

- TDS - Total - Statermic XHT - HNN - 201412 - enDocument1 pageTDS - Total - Statermic XHT - HNN - 201412 - enNibaldo KamelNo ratings yet

- 88848003EN Manual 884 Professional VADocument198 pages88848003EN Manual 884 Professional VAPedroNo ratings yet

- Stoichiometry Worksheet SolutionsDocument2 pagesStoichiometry Worksheet SolutionsQwert LimNo ratings yet

- Identification of Synthetic Cannabinoids in Seized SamplesDocument6 pagesIdentification of Synthetic Cannabinoids in Seized Samples049 VIMAL CHANDERNo ratings yet

- Chemistry 14ADocument11 pagesChemistry 14AJong.Gun.KimNo ratings yet

- Quaternary Ammonium CationDocument60 pagesQuaternary Ammonium Cationkhalid mehmoodNo ratings yet

- Loose Nanofiltration-Based Electrodialysis For Highly Efficient Textile WastewaterDocument34 pagesLoose Nanofiltration-Based Electrodialysis For Highly Efficient Textile Wastewatersowmya SNo ratings yet

- Balston Replacement ElementsDocument2 pagesBalston Replacement ElementsjudarangocaNo ratings yet

- Week4 MoleDocument3 pagesWeek4 MoleGerma ComandaNo ratings yet

- Bonding Agents & Adhesive MortarDocument2 pagesBonding Agents & Adhesive MortarNAYA95100% (1)

- Lab Report Spectrophotometric and Potentiometric Determination The PH of An Unknown BufferDocument7 pagesLab Report Spectrophotometric and Potentiometric Determination The PH of An Unknown BufferMatthew GarnerNo ratings yet

- Mercury: Cold Vapor Mercury Concentration Method Method 10065 0.1 To 2.5 G/L HGDocument12 pagesMercury: Cold Vapor Mercury Concentration Method Method 10065 0.1 To 2.5 G/L HGvignesh3772No ratings yet

- PVC LS100 by LGDocument1 pagePVC LS100 by LGabhaygupta1No ratings yet

- Yr 12 Chemistry Holiday HomeworkDocument8 pagesYr 12 Chemistry Holiday HomeworkEsam ELNOAMANYNo ratings yet