Professional Documents

Culture Documents

Example IQ OQ For Factory Acceptance Tests

Uploaded by

Meng PamplonaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Example IQ OQ For Factory Acceptance Tests

Uploaded by

Meng PamplonaCopyright:

Available Formats

Logo <insert project name>

FAT

Factory acceptance

test

Project name <insert project name>

Project number <insert project number>

Template document prepared by Sensum. Visit us at Page: 1 of 22

www.sensum.eu. Contact us to get MS Word document

without the footer.

Logo <insert project name> <insert project number>

Contents

Contents .................................................................................................................................................. 2

1. Document history ............................................................................................................................ 3

1.1. Glossary ....................................................................................................................................... 4

1.2. Qualification team identification ................................................................................................... 5

2. Introduction ..................................................................................................................................... 7

2.1. Scope ........................................................................................................................................... 7

2.2. Test instruction ............................................................................................................................. 7

3. Installation qualification tests .......................................................................................................... 8

3.1. Documentation verification ........................................................................................................... 9

3.2. Safety devices ............................................................................................................................ 10

3.3. Media supply .............................................................................................................................. 11

3.4. Software ..................................................................................................................................... 12

3.5. Material and roughness checks ................................................................................................. 12

3.6. Additional checks ....................................................................................................................... 13

3.7. Comments for Installation qualification tests.............................................................................. 14

4. Operation qualification tests ......................................................................................................... 16

4.1. Safety functions .......................................................................................................................... 17

4.2. Modes of operation .................................................................................................................... 18

4.3. Production requirement .............................................................................................................. 18

4.4. Alarms ........................................................................................................................................ 19

4.5. Additional operations and functions checks ............................................................................... 20

4.6. Comments for Operation qualification tests ............................................................................... 21

5. List of appendices ......................................................................................................................... 22

5.1. Appendix 1 – Equipment list ...................................................................................................... 22

5.2. Appendix 2 – Test material list ................................................................................................... 22

5.3. Appendix 3 – Attachment list ..................................................................................................... 22

5.4. Appendix 4 – Deficiency list ....................................................................................................... 22

Template document prepared by Sensum. Visit us at Page: 2 of 22

www.sensum.eu. Contact us to get MS Word document

without the footer.

Logo <insert project name> <insert project number>

1. Document history

Revision Date Compilation Changes

1.0.0 18.Apr.2017 John Doe First version

Template document prepared by Sensum. Visit us at Page: 3 of 22

www.sensum.eu. Contact us to get MS Word document

without the footer.

Logo <insert project name> <insert project number>

1.1. Glossary

CPL Change part list

EBR Electronic Batch Record

EC European conformity declaration

FAT Factory acceptance test

FS Functional specification

FSC Function specification and configuration document

GUI Graphical User Interface

HDS Hardware design specification

HMI Human-machine interface

IQ Installation qualification

MPO Maintenance Plan Overview

OQ Operational qualification

PCP Parts in contact with product

Recipe Inspection setting

SAT Site acceptance test

SDS Software design specification

SVS Software version specification

URS User requirement specification

WPL Wear part list

Template document prepared by Sensum. Visit us at Page: 4 of 22

www.sensum.eu. Contact us to get MS Word document

without the footer.

Logo <insert project name> <insert project number>

1.2. Qualification team identification

List of people involved in qualification session execution

1 Print name: Signature:

Company: Initials:

Function: Role: Executioner Witness

2 Print name: Signature:

Company: Initials:

Function: Role: Executioner Witness

3 Print name: Signature:

Company: Initials:

Function: Role: Executioner Witness

4 Print name: Signature:

Company: Initials:

Function: Role: Executioner Witness

5 Print name: Signature:

Company: Initials:

Function: Role: Executioner Witness

6 Print name: Signature:

Company: Initials:

Function: Role: Executioner Witness

Template document prepared by Sensum. Visit us at Page: 5 of 22

www.sensum.eu. Contact us to get MS Word document

without the footer.

Logo <insert project name> <insert project number>

7 Print name: Signature:

Company: Initials:

Function: Role: Executioner Witness

8 Print name: Signature:

Company: Initials:

Function: Role: Executioner Witness

9 Print name: Signature:

Company: Initials:

Function: Role: Executioner Witness

10 Print name: Signature:

Company: Initials:

Function: Role: Executioner Witness

11 Print name: Signature:

Company: Initials:

Function: Role: Executioner Witness

12 Print name: Signature:

Company: Initials:

Function: Role: Executioner Witness

Template document prepared by Sensum. Visit us at Page: 6 of 22

www.sensum.eu. Contact us to get MS Word document

without the footer.

Logo <insert project name> <insert project number>

2. Introduction

2.1. Scope

This document includes acceptance tests to check critical devices and functions of the machine. The

acceptance tests are to assure that:

The equipment is built in accordance with engineering and vendor specifications.

The equipment operates in compliance with the functional description.

The documentation complies to the “as-built” status.

2.2. Test instruction

1. Before starting ensure all required documents for verification are available.

2. If tests require verification of documents: this must be marked on the approved document and

this marked document must be attached to the completed test protocol.

3. Execution of the test must be witnessed by Customer’s representative.

4. Executioner and witness signs at completion of each test section.

5. Record any deficiency found in the Deficiency list.

Template document prepared by Sensum. Visit us at Page: 7 of 22

www.sensum.eu. Contact us to get MS Word document

without the footer.

Logo <insert project name> <insert project number>

3. Installation qualification tests

The Installation qualification tests are grouped in the following chapters:

Chapter tag Chapter title

IQ T1 Documentation verification

IQ T2 Safety devices

IQ T3 Media supply

IQ T4 Software

IQ T5 Material and roughness checks

IQ T6 Additional checks

Template document prepared by Sensum. Visit us at Page: 8 of 22

www.sensum.eu. Contact us to get MS Word document

without the footer.

Logo <insert project name> <insert project number>

3.1. Documentation verification

Test Test name / Test description Acceptance criteria / Expected test Actual result Pass/Fail Executed /

# result deficiency # Verified by

(Initials, date)

IQ Equipment drawings verification Drawings must match with the Tick the relevant box. If one or more results Executed:

are “No” then enter

T1.1 equipment.

deficiency

This test is performed to verify if number(s): Test # -

equipment drawings and equipment Drawing dimensions should be within ± Deficiency #.

dimensions are accurate. 3% of the measurement taken.

Verified:

Yes No

Layout diagram Attachment #:

_________________________

Template document prepared by Sensum. Visit us at www.sensum.eu. Contact us to get MS Page: 9 of 22

Word document without the footer.

Logo <insert project name> <insert project number>

3.2. Safety devices

Test Test name / Test description Acceptance criteria / Expected test Actual result Pass/Fail Executed /

# result deficiency # Witnessed by

(Initials, date)

IQ Safety devices check Tick the relevant box. If one or more results Executed:

are “No” then enter

T2.1

deficiency

Check the presence of safety devices. number(s): Test # -

Deficiency #.

Take Technical specification of safety

devices and check the presence of Witnessed:

safety devices listed in the document.

Safety devices are present.

Mark with green if components are

present and with red if components are

not present.

Yes No

Attach the signed document.

Template document prepared by Sensum. Visit us at www.sensum.eu. Contact us to get MS Page: 10 of 22

Word document without the footer.

Logo <insert project name> <insert project number>

3.3. Media supply

Test Test name / Test description Acceptance criteria / Expected test Actual result Pass/Fail Executed /

# result deficiency # Witnessed by

(Initials, date)

IQ Compressed air Compressed air supply value is in the Tick the relevant box. If one or more results Executed:

are “No” then enter

T3.1 specified range. deficiency

The compressed air supply is checked. number(s): Test # -

Deficiency #.

Witnessed:

Compressed air supply value is

in specified range.

Compressed air supply value is p= ________bar

p= 6 – 10 bar

Yes No

Template document prepared by Sensum. Visit us at www.sensum.eu. Contact us to get MS Page: 11 of 22

Word document without the footer.

Logo <insert project name> <insert project number>

3.4. Software

3.5. Material and roughness checks

Test Test name / Test description Acceptance criteria / Expected test Actual result Pass/Fail Executed /

# result deficiency # Witnessed by

(Initials, date)

IQ Parts in contact with products Tick the relevant box. If one or more results Executed:

are “No” then enter

T5.1

deficiency

The surface roughness for parts in number(s): Test # -

contact with products must allow Deficiency #.

cleanability. A surface roughness for

metallic parts of Ra<0.8 is required. Witnessed:

Synthetic materials in contact with

product must be GMP compliant and

resistant to all other materials used

(media, cleaning agents and Yes No

disinfectants). PCP document lists metallic parts with

certificates.

Take PCP document and check if Attachment #:

metalic are listed and certificates are

attached.

_________________________

Template document prepared by Sensum. Visit us at www.sensum.eu. Contact us to get MS Page: 12 of 22

Word document without the footer.

Logo <insert project name> <insert project number>

3.6. Additional checks

Test Test name / Test description Acceptance criteria / Expected test Actual result Pass/Fail Executed /

# result deficiency # Witnessed by

(Initials, date)

IQ Check the of scales for Tick the relevant box. If one or more Executed:

results are “No”

T6.1 reproducibility of settings

then enter

deficiency

Visually check the presence of scales number(s): Test #

for mechanical parameters described - Deficiency #.

in User list of parameters. Verified:

Visual check: scales are provided for

all mechanical parameters. Yes No

Template document prepared by Sensum. Visit us at www.sensum.eu. Contact us to get MS Page: 13 of 22

Word document without the footer.

Logo <insert project name> <insert project number>

3.7. Comments for Installation qualification tests

Comments for Installation qualification tests

Signature for comments

Executed: Name: Signature: Date:

Witnessed: Name: Signature: Date:

Template document prepared by Sensum. Visit us at www.sensum.eu. Contact us to get MS Page: 14 of 22

Word document without the footer.

Logo <insert project name> <insert project number>

Template document prepared by Sensum. Visit us at www.sensum.eu. Contact us to get MS Page: 15 of 22

Word document without the footer.

Logo <insert project name> <insert project number>

4. Operation qualification tests

The Operation qualification tests are grouped in the following chapters:

Chapter tag Chapter Title

OQ T1 Safety functions

OQ T2 Modes of operation

OQ T3 Production requirement

OQ T4 Alarms

OQ T5 Additional operations and functions checks

Template document prepared by Sensum. Visit us at Page: 16 of 22

www.sensum.eu. Contact us to get MS Word document

without the footer.

Logo <insert project name> <insert project number>

4.1. Safety functions

Test # Test name / Test description

OQ Safety at system failure & Main switch check

T1.1 In case of power loss, the system must be protected in the following priority and the likelihood of

damage must be minimized:

People and Environment

Equipment

Product

This test is done by switching off the machine.

Test procedure

Tick if

Step # Step description

done

1. Start the machine in operation mode.

2. Switch off the machine by switching turning off the main switch.

Switch on the machine by turning the main power switch to ON. Machine

3.

starts-up.

Acceptance criteria Actual result

1. Machine completely stops after switching off the main switch.

Yes No

2. Machine starts-up after turning main power switch to ON but does

not start to inspect automatically. Yes No

Pass/Fail deficiency #

Pass Fail, deficiency #: __________________________

Executed by (Initials, date) Witnessed by (Initials, date)

Template document prepared by Sensum. Visit us at Page: 17 of 22

www.sensum.eu. Contact us to get MS Word document

without the footer.

Logo <insert project name> <insert project number>

4.2. Modes of operation

4.3. Production requirement

Test # Test name / Test description

OQ Machine speed

T3.1 Machine output > 120 units / minute

Test procedure

Tick if

Step # Step description

done

Test set-up:

Write down the product name used for this test:

_________________________________________

1. Recipe used: _________________________________________

Set the machine as described in the recipe.

Fill the input container with approximately 2000 pieces of test product.

2. Set speed parameter to maximum value: ___________

3. Start the machine in operation mode.

4. Wait for the machine to achieve maximum speed.

5. Make print screen from GUI, where speed is displayed.

Print the print screen, sign and attach it to the document:

6.

Attachment #: ___________

Restore the parameter(s) to original value:

7.

Speed parameter

Acceptance criteria Actual result

Inspection speed of test product is more than 120 units /

minute Yes No

Pass/Fail deficiency #

Pass Fail, deficiency #: __________________________

Executed by (Initials, date) Witnessed by (Initials, date)

Template document prepared by Sensum. Visit us at Page: 18 of 22

www.sensum.eu. Contact us to get MS Word document

without the footer.

Logo <insert project name> <insert project number>

4.4. Alarms

Test # Test name / Test description

OQ Alarm #001 test

T4.1 Vacuum system failure detected!

Test procedure

Tick if

Step # Step description

done

Test set-up:

Remove test product from the machine.

1.

Recipe used: _________________________________________

Set the machine for test as described in loaded setting description.

2. Run the machine in operation mode.

3. Simulate vacuum pump failure by turning off vacuum pump main switch.

In case of vacuum system failure, machine stops and the Alarm #001 is

4.

displayed.

5. Confirm the alarm.

6. Switch on vacuum pump main switch.

7. Vacuum pump starts.

Acceptance criteria Actual result

In case of vacuum system failure, machine stops and the Alarm

#001 is displayed. Yes No

Pass/Fail deficiency #

Pass Fail, deficiency #: __________________________

Executed by (Initials, date) Witnessed by (Initials, date)

Template document prepared by Sensum. Visit us at Page: 19 of 22

www.sensum.eu. Contact us to get MS Word document

without the footer.

Logo <insert project name> <insert project number>

4.5. Additional operations and functions checks

Test # Test name / Test description

OQ

T5.1

Test procedure

Tick if

Step # Step description

done

1.

2.

Actual result

Yes No

Yes No

Pass/Fail deficiency #

Pass Fail, deficiency #: __________________________

Executed by (Initials, date) Witnessed by (Initials, date)

Template document prepared by Sensum. Visit us at Page: 20 of 22

www.sensum.eu. Contact us to get MS Word document

without the footer.

Logo <insert project name> <insert project number>

4.6. Comments for Operation qualification tests

Comments

Signature for comments

Executed: Name: Signature: Date:

Witnessed: Name: Signature: Date:

Template document prepared by Sensum. Visit us at Page: 21 of 22

www.sensum.eu. Contact us to get MS Word document

without the footer.

Logo <insert project name> <insert project number>

5. List of appendices

5.1. Appendix 1 – Equipment list

5.2. Appendix 2 – Test material list

5.3. Appendix 3 – Attachment list

5.4. Appendix 4 – Deficiency list

Template document prepared by Sensum. Visit us at Page: 22 of 22

www.sensum.eu. Contact us to get MS Word document

without the footer.

You might also like

- Learn AI-assisted Python Programming: With GitHub Copilot and ChatGPTFrom EverandLearn AI-assisted Python Programming: With GitHub Copilot and ChatGPTNo ratings yet

- Forensic Report TemplateDocument4 pagesForensic Report TemplatePranjal BagrechaNo ratings yet

- TBT FormDocument8 pagesTBT Formamit sharmaNo ratings yet

- Sample Internal Audit FormDocument2 pagesSample Internal Audit Formbiniyam markosNo ratings yet

- A Practical Guide To Open Source Software Licensing by Heather MeekerDocument361 pagesA Practical Guide To Open Source Software Licensing by Heather MeekerArthur BuchholzNo ratings yet

- RD050 Business Requirements ScenariosDocument7 pagesRD050 Business Requirements ScenariosVK SHARMANo ratings yet

- Python Programming Reference Guide: A Comprehensive Guide for Beginners to Master the Basics of Python Programming Language with Practical Coding & Learning TipsFrom EverandPython Programming Reference Guide: A Comprehensive Guide for Beginners to Master the Basics of Python Programming Language with Practical Coding & Learning TipsNo ratings yet

- SAP10120project Creation From Template User ManualDocument18 pagesSAP10120project Creation From Template User ManualTop NgôNo ratings yet

- Jdemo Lightweight Exploratory Developer Testing: Ilja PreußDocument26 pagesJdemo Lightweight Exploratory Developer Testing: Ilja PreußRaiTejaniNo ratings yet

- Manual TestingDocument21 pagesManual TestingRintu DasNo ratings yet

- Cs 112 Fcs Lab Manual 1Document40 pagesCs 112 Fcs Lab Manual 1oriental confessionNo ratings yet

- Windows Logo Icon Guidelines 0215Document8 pagesWindows Logo Icon Guidelines 0215HN DsgNo ratings yet

- Procurement Contract3 - PO Integration HRZ19CD03Document8 pagesProcurement Contract3 - PO Integration HRZ19CD03adnanakdrNo ratings yet

- Application Document: Multi-Organization SetupDocument42 pagesApplication Document: Multi-Organization Setupjaggu011No ratings yet

- SAP1133 Project Creation User ManualDocument20 pagesSAP1133 Project Creation User ManualTop NgôNo ratings yet

- Software Testing.cDocument31 pagesSoftware Testing.co.moulika maniNo ratings yet

- Access Preview: Digital Signatures For PDF DocumentsDocument94 pagesAccess Preview: Digital Signatures For PDF DocumentsSanjeev Kumar ChoudharyNo ratings yet

- Digital Signatures 20130304Document152 pagesDigital Signatures 20130304Diana CarolinaNo ratings yet

- Manual TestingDocument21 pagesManual Testingo.moulika mani40% (5)

- The Machinery Team: 1 Getting StartedDocument47 pagesThe Machinery Team: 1 Getting StartedSamoni SylviaNo ratings yet

- InterviewDocument4 pagesInterviewKannu SharmaNo ratings yet

- CMCC CPT281 PenTesting Lab5Document3 pagesCMCC CPT281 PenTesting Lab5Aisha AhmedNo ratings yet

- Introduction To PythonDocument20 pagesIntroduction To PythonBishnu Charan PanigrahiNo ratings yet

- DTW Experiment ListDocument1 pageDTW Experiment ListRahul Ratna KokkiligaddaNo ratings yet

- Ict2205 - Technical Writing: Rajarata University of Sri LankaDocument22 pagesIct2205 - Technical Writing: Rajarata University of Sri Lankanjhrfh comNo ratings yet

- Lab1 - Introduction To PythonDocument15 pagesLab1 - Introduction To Pythonlolo fikriNo ratings yet

- Date of Application:: Take Note Indicate The Currency You Are Using"Document2 pagesDate of Application:: Take Note Indicate The Currency You Are Using"ludovicNo ratings yet

- Project ReportDocument16 pagesProject ReportBeena TyagiNo ratings yet

- BR030 Business Requirements Mapping FormDocument10 pagesBR030 Business Requirements Mapping FormJulio FerrazNo ratings yet

- Is Your Windows License Legal - Should You Even Care - ZDNETDocument13 pagesIs Your Windows License Legal - Should You Even Care - ZDNETAlan WeissNo ratings yet

- HCI Project Final Report Group 15Document74 pagesHCI Project Final Report Group 15Raj Chauhan BhaveshkumarNo ratings yet

- Welcome Register ProcedureDocument3 pagesWelcome Register ProcedureVep SolutionsNo ratings yet

- Memo Basics .NET and Office 2003Document14 pagesMemo Basics .NET and Office 2003WekkelNo ratings yet

- DEF CON Safe Mode - Peleg Hadar - A Decade After Stuxnet's Printer Vulnerability Printing Is Still The Stairway To Heaven WPDocument21 pagesDEF CON Safe Mode - Peleg Hadar - A Decade After Stuxnet's Printer Vulnerability Printing Is Still The Stairway To Heaven WPasdfNo ratings yet

- Introduction To Visual BasicDocument40 pagesIntroduction To Visual BasicdNo ratings yet

- Visual Basic IntroDocument33 pagesVisual Basic IntrobbbarolomeNo ratings yet

- Penny 1Document5 pagesPenny 1penny sekeletiNo ratings yet

- PythonDocument124 pagesPythonatulvishwakarmaNo ratings yet

- Business PlanDocument10 pagesBusiness PlanRickhy ArthaNo ratings yet

- Python Course - I Getting Started With Python PDFDocument13 pagesPython Course - I Getting Started With Python PDFSwapnilSauravNo ratings yet

- CMP Lab ReportDocument9 pagesCMP Lab ReportAnisul KarimNo ratings yet

- Starting Page - MergedDocument31 pagesStarting Page - MergedNshjdibNo ratings yet

- Controls and Code Controls and Code: Chapter One Chapter OneDocument42 pagesControls and Code Controls and Code: Chapter One Chapter OneTiisetso MakgakgaNo ratings yet

- IPC ESB UAT ScriptDocument151 pagesIPC ESB UAT ScriptK SNo ratings yet

- Project Costing Training Manual - CompletedDocument87 pagesProject Costing Training Manual - Completednagabhushanam KajaNo ratings yet

- Lab Experiment #01 - System Event LogsDocument3 pagesLab Experiment #01 - System Event LogsDivy PathakNo ratings yet

- Topic: Computing: Unit - IDocument18 pagesTopic: Computing: Unit - IRavindranathNo ratings yet

- English Transcription SamplesDocument6 pagesEnglish Transcription SampleshchaghomiNo ratings yet

- Discord Bot With PythonDocument12 pagesDiscord Bot With PythonLekhaj GNo ratings yet

- 3 Flushing of Chilled Water PipingDocument10 pages3 Flushing of Chilled Water PipingBader ShrbajiNo ratings yet

- Complete VBDocument159 pagesComplete VBpraveen1510No ratings yet

- Best Free Online Booter: Click Here To DownloadDocument2 pagesBest Free Online Booter: Click Here To DownloadMuhammad S. RaniYahNo ratings yet

- ReseDocument7 pagesReseemumono8612No ratings yet

- Example FiltersDocument2 pagesExample FiltersMarcosNo ratings yet

- Chapter 1 Homework SolutionsDocument5 pagesChapter 1 Homework Solutionshbomber20No ratings yet

- It Is To Launch.: CompanyDocument9 pagesIt Is To Launch.: CompanyMemo OrtízNo ratings yet

- Torque Calculation of Various Grade BoltsDocument2 pagesTorque Calculation of Various Grade BoltsMeng PamplonaNo ratings yet

- ITP For Non-Fire Resistant CI CableDocument1 pageITP For Non-Fire Resistant CI CableMeng PamplonaNo ratings yet

- ITP For Profibus CABLE (YJ72759)Document1 pageITP For Profibus CABLE (YJ72759)Meng PamplonaNo ratings yet

- 4.FAT - MoM TemplateDocument5 pages4.FAT - MoM TemplateMeng PamplonaNo ratings yet

- BioAir EcoFilter BrochureDocument4 pagesBioAir EcoFilter BrochureMeng PamplonaNo ratings yet

- BIOFILTER - Specification 441000Document14 pagesBIOFILTER - Specification 441000Meng PamplonaNo ratings yet

- 2022-06-29 Method Statement of Construction of Odor Control System Rev. ADocument71 pages2022-06-29 Method Statement of Construction of Odor Control System Rev. AMeng PamplonaNo ratings yet

- Transformer VaultDocument7 pagesTransformer VaultMia Monica Fojas LoyolaNo ratings yet

- LEED V4 Core and Shell: Documentation ChecklistDocument1 pageLEED V4 Core and Shell: Documentation ChecklistMeng PamplonaNo ratings yet

- 10.chiller Case Studies-2Document83 pages10.chiller Case Studies-2Meng PamplonaNo ratings yet

- The Revised Philippine Mechanical Engineering CodeDocument3 pagesThe Revised Philippine Mechanical Engineering CodeGeofrey Sy Baje7% (14)

- Assignment 5 MRP PDFDocument7 pagesAssignment 5 MRP PDFNegashNo ratings yet

- Us Presidential Vocabulary - IpynbDocument40 pagesUs Presidential Vocabulary - Ipynbbahadursoma3No ratings yet

- Mini210s Manual 20120531Document233 pagesMini210s Manual 20120531cor01No ratings yet

- Electromagnetic Compatibility PDFDocument10 pagesElectromagnetic Compatibility PDFRedouane NaceriNo ratings yet

- Network Design CookbookDocument412 pagesNetwork Design Cookbookanon_73609093763% (8)

- Applied Information Processing Systems 2022Document588 pagesApplied Information Processing Systems 2022Med KH100% (1)

- Pre Test - CC 201 - Introduction To Computing PDFDocument2 pagesPre Test - CC 201 - Introduction To Computing PDFangel grace layaoNo ratings yet

- IT8711-FOSS and Cloud Computing Lab Manual ValliammaiDocument128 pagesIT8711-FOSS and Cloud Computing Lab Manual ValliammaihariniNo ratings yet

- Safety Manual (B-80687EN 10)Document35 pagesSafety Manual (B-80687EN 10)Jander Luiz TomaziNo ratings yet

- Motor Terminology and Electrical Performance CharacteristicsDocument37 pagesMotor Terminology and Electrical Performance CharacteristicsErick Yael Alcantar MaresNo ratings yet

- Chapter 3Document74 pagesChapter 3Berhane KifleNo ratings yet

- Library - Management - Project Report by Vaishali & Sukhwinder Kaur BCA (3rd Yr.)Document64 pagesLibrary - Management - Project Report by Vaishali & Sukhwinder Kaur BCA (3rd Yr.)Naveen SharmaNo ratings yet

- BC 547Document1 pageBC 547AnviNo ratings yet

- VeriFast LVDT FAQDocument2 pagesVeriFast LVDT FAQGerardoNo ratings yet

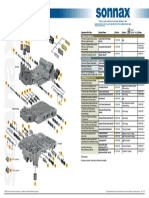

- Aisin AW TF-81SC: Click On Part Numbers For Product Details or VisitDocument1 pageAisin AW TF-81SC: Click On Part Numbers For Product Details or Visittejonmx100% (1)

- Rate Monotonic Scheduling: Group - 12Document19 pagesRate Monotonic Scheduling: Group - 12Brajmohan kr SinghNo ratings yet

- Process Selection and Facility LayoutDocument59 pagesProcess Selection and Facility LayoutKhietNo ratings yet

- UNIX PermissionsDocument4 pagesUNIX PermissionsIngiaNo ratings yet

- The Osint Cyber War 2021-02-22Document26 pagesThe Osint Cyber War 2021-02-22Carlos Alberto Mendes BetinhoNo ratings yet

- Future MuseumDocument12 pagesFuture MuseumPatriciaNo ratings yet

- IC Scrum Project Management Gantt Chart Template 10578 Excel 2000 2004Document6 pagesIC Scrum Project Management Gantt Chart Template 10578 Excel 2000 2004Paulo MendesNo ratings yet

- UKOOA Telecoms GuidelinesDocument35 pagesUKOOA Telecoms GuidelinesmaarutzNo ratings yet

- Evolution of NetworksDocument21 pagesEvolution of NetworksScribd Dot ComNo ratings yet

- Pangasinan State University Urdaneta Campus Urdaneta CityDocument11 pagesPangasinan State University Urdaneta Campus Urdaneta CityNephtali Pinos-anNo ratings yet

- Scenario - Based - Que - DbmsDocument8 pagesScenario - Based - Que - DbmsPrachi P100% (1)

- BAJA RULES 2020 Rev B 2020-01-26Document129 pagesBAJA RULES 2020 Rev B 2020-01-26baja100% (2)

- Colortrac S4e Service Manual-2Document66 pagesColortrac S4e Service Manual-2hany_elbanna2000100% (1)

- VIOFO A119 ManualeditedenlargedDocument1 pageVIOFO A119 Manualeditedenlargedhi.i.am noneNo ratings yet

- Help CenterDocument4 pagesHelp CenterShivali VermaNo ratings yet

- HW - Disk Storage 5 NewDocument2 pagesHW - Disk Storage 5 Newkingsbross72No ratings yet