Professional Documents

Culture Documents

Ac 3

Uploaded by

jamcaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ac 3

Uploaded by

jamcaCopyright:

Available Formats

3R-134a Refrigerant KM811227 06/00

KENWORTH HVAC SYSTEMS

Section

R-134a Refrigerant

3A Background

3B Differences Between R-12 and R134a Systems

3C Containers

3D Markings

3E Contamination

(06/00) KM811227 3-1

3

KENWORTH HVAC SYSTEMS

R-134a Refrigerant 3

Section 3A Background

Over the last ten years, scientists have noticed that the earth's ozone

layer is disappearing. Ozone is an oxygen molecule with three oxygen

atoms (O3), instead of the usual two atoms (O2). The ozone layer is part

of the earth's atmosphere between 10-20 miles from the earth's surface.

The ozone molecules in that part of the atmosphere absorb part of the

ultra-violet light from the sun. Too much ultra-violet light can cause skin

cancer and blindness. Scientists believe that the chlorine in CFC

(Cloro-Fluro-Carbon) chemicals, like R-12 refrigerant, is destroying the

ozone layer by chemically breaking up the O3 ozone molecules into O2

oxygen molecules.

In 1991 The Clean Air Act and other regulations came into effect. This law

phases out the manufacture of CFC chemicals. That means we will not be

able to buy new R-12 refrigerant and the supply of old R-12 will gradually

run out. Engineers have redesigned our truck air conditioning systems

using a new refrigerant called R-134a. The R-134a parts do the same

things as on R-12 systems, they have the same names and they look sim-

ilar.

All new Kenworths are built with R-134a systems. Eventually the old R-12

systems will disappear as the trucks are retired, or their air conditioning

systems are retrofitted with R-134a systems. During the time when we'll

be seeing both systems it will be extremely important not to mix parts or

refrigerants.

Section 3B Differences Between R-12 and R134a Systems

R-134a air conditioning systems are replacing R-12 air conditioning sys-

tems in our Kenworths. As the air conditioning systems for each model

are re-engineered, we will be seeing fewer and fewer R-12 systems in our

shops. During the several years where there are both types of air condi-

tioning systems on the road, we will have to be able to tell the difference

between the two types of systems. This is important for three reasons:

• Mixing R-12 and R-134a will create a new refrigerant that will not

work in the system designed for Kenworth.

• Allowing the R-12 mineral oil lubricant to contaminate a R-134a sys-

tem can create system damage.

• The parts of each air conditioning system are engineered for a spe-

cific refrigerant and they generally cannot be exchanged.

The only general exceptions for part exchange are using R-134a hoses

and o-rings in an R-12 system. Some newer receiver/dryers and expan-

sion valves have been engineered for both systems and are marked

clearly for use on both types of systems. R-134a expansion valves can be

3-2 KM811227 (06/00)

KENWORTH HVAC SYSTEMS

R-134a Refrigerant 3

used on R-12 systems, but R-12 expansion valves cannot be used on

R-134a systems. Still, it is strongly recommended that components

designed for specific refrigerants be only used in those systems.

The Differences in the Truck

Between R-12 and R-134a

Systems

Label The refrigerant identification label on the radiator is the best place to find

out if the air conditioning is a R-12 or R-134a system. See Figure 3-1. The

exact location of the label may vary with the model.

Figure 3-1 Refrigerant Identification Label

(06/00) KM811227 3-3

KENWORTH HVAC SYSTEMS

R-134a Refrigerant 3

R-134a Truck

Compressor

The lubricant used

in the R-134a com-

pressor will be

printed on the com-

The R-134a com- pressor nameplate.

pressor usually will R-134a systems will

have a sky blue list a PAG or POE

plastic tag on the lubricant. Currently,

suction port. Kenworth trucks use

both PAG and POE

lubricants.

Figure 3-2 Compressor Identification Tag

R-134a Truck There will be a different sized fitting on the service ports. R-12 service

Service Ports valve fittings will not fit on an R-134a system, and R-134a service valve

fittings will not fit on an R-12 system.

HIGH SIDE SERVICE PORT

LOW SIDE SERVICE PORT

Figure 3-3 Low Side and High Side Service Ports

3-4 KM811227 (06/00)

KENWORTH HVAC SYSTEMS

R-134a Refrigerant 3

R-134a Truck R-134a hoses will have a SAE J2064 stamped on them. Some R-12

Hoses trucks may be using R-134a hoses, so rely on more information to make a

decision.

A special liner inside the hose prevents the R-134a from escaping

through the hose.

R-134a HOSE

R-12 HOSE

Figure 3-4 R-134a and R-12 Hoses

R-134a Truck Buna and some black neoprene o-rings will react with the PAG and POE

O-Ring lubricants. Using them will quickly lead to a major leak.

Kenworth HNBR o-rings (tinted green) are specifically made for use with

Kenworth R-134a systems. Always use the HNBR o-rings. They may not

always be green in color.

In the real world there are a number of other o-rings that you may find in

equipment that are compatible with R-134a including:

• HNBR Light Blue: Ford

• H4C Black with a yellow dot (that rubs off): John Deere

• HNBR Orange emerlon coating: Caterpillar

Differences in the Shop • There is R-134, R-134a and R-134A. They are all different refriger-

Between R-12 and R-134a ants. Our Kenworth systems use R-134a. Do not confuse it with

R-134 or R-134A.

Systems

• R-134a will generally come in larger containers than R-12. When you

order R-134a, make sure you ask for the container for mobile or

vehicle use. R-134A for commercial or stationary HVAC systems will

have a different size fitting on the container than your charging sta-

tion.

• Kenworth R-134a systems take less refrigerant than the Kenworth

R-12 systems take. Always charge by weight because overcharging a

R-134a system will effect the performance.

(06/00) KM811227 3-5

KENWORTH HVAC SYSTEMS

R-134a Refrigerant 3

• The Refrigerant system is also sensitive to over-filling the oil reservoir

in the compressor. Excess oil will circulate through the system. Extra

oil in the system forms barriers in the condenser and evaporator that

interfere with heat exchange. Do not over-fill the oil reservoir in the

compressor.

• The lubricant will come in smaller cans and bottles. The lubricant

must be stored in a light-proof, sealed container. Do not re-use lubri-

cant. Fresh lubricant is a light yellow. If your lubricant turns brown or

black, dispose of it.

• R-134a molecules are much smaller than R-12 molecules. Hoses

need special barriers to prevent the R-134a from escaping through

the hose material. Always use factory made “barrier” hoses assem-

bled. Dirt in fittings may cause o-rings to distort enough to allow the

R-134a to escape. Keep service hose fittings clean and prevent

dirt and grease from getting on o-rings and fittings.

• You must use HNBR o-rings with R-134a systems. Many types of

black neoprene or rubber o-rings will quickly fail. Although there are a

number of black HNBR o-rings on the market, always be sure by

using green o-rings.

• Always lubricate the o-rings with a little mineral oil before install-

ing. If the o-rings are not lubricated they will distort, cut or tear when

you tighten the fitting.

• The distance the condenser is set from the radiator and after cooler is

a critical measurement set at the factory that effects the heat

exchange capability of the condenser. Always check condensers

for blockage when inspecting a truck.

• The receiver/dryer fittings on our R-134a Kenworths are reversed

fr o m t h e fit ti ng s o n R - 1 2 tr uck s. Alw ays u se th e correct

receiver/dryer for R-134a systems. Always check that the flow

direction is correct when you install the receiver/dryer.

• Do not discharge R-134a into the air. It must be recovered just like

R-12.

• Do not mix R-134a and R-12 service equipment. You must use

separate gauge sets, recovery stations and charging stations. The

only exception is a stand-alone vacuum pump that may be modified

for R-134a fittings.

• Make sure your leak detector will work with R-134a. Some leak

detectors will only find CFC materials (like R-12) and will not detect

HFC materials (like R-134a).

3-6 KM811227 (06/00)

KENWORTH HVAC SYSTEMS

R-134a Refrigerant 3

Section 3C Containers

Storing Refrigerant R-134a will come from the manufacturer in sky-blue colored tanks. The fit-

ting sizes will be different from R-12 containers, so it will be difficult to

confuse the two refrigerants.

When ordering R-134a make sure you order R-134a (little “a”) for auto-

motive or transportation use. The fittings on R-134a tanks for stationary

use are a different size than tanks for automotive use.

There are different refrigerants with similar names. There is also R-134

(with no letter) and R-134A (with a big A). These are different refrigerants.

They are not interchangeable.

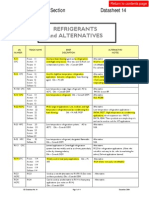

Section 3D Markings

Table 3-1 Refrigerant Markings

CONTAINER CHEMICAL

REFRIGERANT

COLOR SYMBOL

R-134a Sky Blue CH2FCF3

R-12 White CCI2F2

R-11 Orange CCL3F

R-22 Pale Green CHCIF2

R-502 Light Purple Mixture of R-22 and

R115

Containers with used R-134a that has not been recycled should be

clearly marked: DIRTY REFRIGERANT DO NOT USE WITHOUT RECY-

CLING or CONTAMINATED REFRIGERANT. Used R-134a containers

must be completely evacuated before disposal.

(06/00) KM811227 3-7

KENWORTH HVAC SYSTEMS

R-134a Refrigerant 3

Storage Tips

Table 3-2 Storage Tips

ALWAYS NEVER

Always use DOT or UL approved Never attempt to re-use shipping

containers. containers.

Always store containers where they Never drop a tank, damage a fitting or

are safe from damage. puncture the tank.

Always store R-134a in a stable Never store R-134a tanks in direct

environment with temperatures below sunlight or next to a heat source.

125°F.

Always evacuate empty storage Never place R-134a in a tank with an

cylinders before re-filling. unknown refrigerant.

Always fill a container by weight Never fill a container to more than

80% of its rated weight.

Always mark recovery tanks as Never recharge a truck’s system with

contaminated until they have been refrigerant from an unmarked tank.

recycled.

Never use a fitting adapter to place

R-134a in an R-12 tank or R-12 in a

R-134a tank.

Never mix R-134a and R-12.

Section 3E Contamination

The Unmarked If you find an unmarked R-134a tank, always assume it is contaminated.

Tank You can test for contamination by a temperature/pressure test. You will be

using the fact that every pure gas has a specific pressure at a specific

temperature. The pressure for R-134a at specific temperatures is a known

quantity. A contaminated tank of R-134a will have air and other gasses

that will not condense in it, so the pressure will be quite different from a

tank of pure R-134a.

To Check an • Let the tank sit at a constant temperature, above 65°F for 12 hours.

Unknown Tank

• Keep the tank away from direct sunlight or other heat source.

• Hook up an accurate gauge to the tank or use the low side gauge on

a manifold gauge set.

• Measure the ambient temperature next to the tank (within 3-4 inches).

• Read the pressure on the gauge.

• Find the ambient temperature measurement in Table 2-13, “Maximum

Pressures for Uncontaminated R-134a” on page 2-8.

3-8 KM811227 (06/00)

KENWORTH HVAC SYSTEMS

R-134a Refrigerant 3

• If the pressure you measured is higher than the one in the table for

the temperature, purge the air from the tank.

• Purge the tank by bleeding enough air from the top of the tank until

the pressure drops below the pressure listed in the table.

• Let the tank sit at a stable temperature for another 12 hours and

repeat the measurement.

• If the pressure is still above the table pressure for that temperature,

the tank is contaminated with air and should be recycled.

Maximum See Table 2-13, “Maximum Pressures for Uncontaminated R-134a” on

Pressues for page 2-8.

Uncontaminated

R-134a

(06/00) KM811227 3-9

KENWORTH HVAC SYSTEMS

R-134a Refrigerant 3

3-10 KM811227 (06/00)

You might also like

- WiringDocument147 pagesWiringNilson BarbosaNo ratings yet

- Tecumseh Guidelines For Utilization of R134aDocument7 pagesTecumseh Guidelines For Utilization of R134aAnibal RiosNo ratings yet

- Technical Digest: Hfcs HcfcsDocument20 pagesTechnical Digest: Hfcs HcfcsChevy CheNo ratings yet

- Forane Refrigerants PropertiesDocument20 pagesForane Refrigerants PropertiespetrcNo ratings yet

- Chapter 14 Refrigerants Refrigerant SelectionDocument10 pagesChapter 14 Refrigerants Refrigerant SelectionkuanyiNo ratings yet

- R134a PDFDocument6 pagesR134a PDFDaniel FernandezNo ratings yet

- Types of Refrigerant Gas PresentationDocument9 pagesTypes of Refrigerant Gas PresentationTAIMOOR HUDANo ratings yet

- Exploring The Differences Between R-410A and R-22Document4 pagesExploring The Differences Between R-410A and R-22aungwinnaingNo ratings yet

- Air Conditioning Tools: Recovery, Recycling, and Recharging Systems 2-1 Miscellaneous 2-12Document22 pagesAir Conditioning Tools: Recovery, Recycling, and Recharging Systems 2-1 Miscellaneous 2-12jhonNo ratings yet

- Gas R1234yfDocument7 pagesGas R1234yfAnonymous XPQKHSNo ratings yet

- Refrigerants Tables and Charts SIDocument14 pagesRefrigerants Tables and Charts SIJasmine Tuason33% (3)

- Effect of Engine Speed On The Performance of Automotive Air Conditioning System Using R134a and R152a As RefrigerantsDocument12 pagesEffect of Engine Speed On The Performance of Automotive Air Conditioning System Using R134a and R152a As RefrigerantsAamir ArainNo ratings yet

- The Difference Between R22 and R410A Refrigerant - AND ServicesDocument3 pagesThe Difference Between R22 and R410A Refrigerant - AND ServicesHumayun BaigNo ratings yet

- 4055 Refrigerants PDFDocument6 pages4055 Refrigerants PDFVinit JoryNo ratings yet

- Refrigerantes Cartas y TablasDocument196 pagesRefrigerantes Cartas y TablasNatali Paris PerviaNo ratings yet

- Refrigerantes Cartas y Tablas PDFDocument196 pagesRefrigerantes Cartas y Tablas PDFDebb Rs100% (2)

- P-H ChartsDocument75 pagesP-H ChartsmanigandanNo ratings yet

- WS Manual 1999 F-Super Duty S4 4 - Section 4, Group 12-19 - ElectricalDocument480 pagesWS Manual 1999 F-Super Duty S4 4 - Section 4, Group 12-19 - ElectricalJamison RobertsNo ratings yet

- Operating Manual: RobinairDocument21 pagesOperating Manual: RobinairGeorge Anderzon Victoriano RengifoNo ratings yet

- Production of R-134a: BackgroundDocument12 pagesProduction of R-134a: Backgroundmoh1234bukNo ratings yet

- Irreversibility Analysis of Two and Three Stage Vapour Compression Refrigeration Systems With Multi Evaporators and Flash-Intercooler UsingDocument8 pagesIrreversibility Analysis of Two and Three Stage Vapour Compression Refrigeration Systems With Multi Evaporators and Flash-Intercooler UsingIjrei JournalNo ratings yet

- 02 Air Conditioning ToolsDocument22 pages02 Air Conditioning ToolsTony Wilden Angelo PeñaNo ratings yet

- Retrofit SandenDocument5 pagesRetrofit SandenHenry LopezNo ratings yet

- Refrigerant Changeover Guidelines: Leading The Industry With Environmentally Responsible Refrigerant SolutionsDocument7 pagesRefrigerant Changeover Guidelines: Leading The Industry With Environmentally Responsible Refrigerant SolutionsMasoud KarimiNo ratings yet

- Gas R134a Replament To AutomotiveDocument6 pagesGas R134a Replament To AutomotiveSyamsul IrmaNo ratings yet

- Common RefrigerantDocument3 pagesCommon Refrigerantkibira316No ratings yet

- 2010 Cat PG 081Document1 page2010 Cat PG 081silvia64600No ratings yet

- Control of Moisture and Other Contaminants in Refrigerant SystemsDocument11 pagesControl of Moisture and Other Contaminants in Refrigerant SystemsCristhianPLNo ratings yet

- Copeland LubricantsDocument2 pagesCopeland LubricantsDanLorenaNo ratings yet

- MEBS6006 Part 2 Lecture 5Document46 pagesMEBS6006 Part 2 Lecture 5AbhijitNo ratings yet

- Air Conditioning System PDFDocument73 pagesAir Conditioning System PDFThếSơnNguyễnNo ratings yet

- Rtaa-Iom-4a Iom 70-125Document156 pagesRtaa-Iom-4a Iom 70-125emersonnakatoNo ratings yet

- Desirable Properties of A Refrigerant: RefrigerantsDocument12 pagesDesirable Properties of A Refrigerant: RefrigerantsPraveen AbisakeNo ratings yet

- Seminar For Refrigerant Identifier-User: Model: Neutronics Ultima ID-HVAC By:Cooltech Solution SDN BHDDocument63 pagesSeminar For Refrigerant Identifier-User: Model: Neutronics Ultima ID-HVAC By:Cooltech Solution SDN BHDMuhamad FadliNo ratings yet

- Freon 134a: Product InformationDocument6 pagesFreon 134a: Product Informationion sudituNo ratings yet

- RTAA-IOM-4A First HalfDocument75 pagesRTAA-IOM-4A First Halfmgs nurmansyahNo ratings yet

- Refrigerant Changeover GuidelinesDocument7 pagesRefrigerant Changeover GuidelinesPanji SegaraNo ratings yet

- Day 2 Session VI - 03 K. Jayakumar - EmersonDocument16 pagesDay 2 Session VI - 03 K. Jayakumar - EmersonMeghan WoodsNo ratings yet

- Refrigeration Cycles Real Vapor Compression CycleDocument9 pagesRefrigeration Cycles Real Vapor Compression CyclePaul RodgersNo ratings yet

- Refrigeration Cycles Real Vapor Compression CycleDocument9 pagesRefrigeration Cycles Real Vapor Compression CyclePaul RodgersNo ratings yet

- Pollution Prevention Goals: - Minimize Refrigerant Vented To The Atmosphere, and - Use Effective Alternatives To R-12Document9 pagesPollution Prevention Goals: - Minimize Refrigerant Vented To The Atmosphere, and - Use Effective Alternatives To R-12Hari IndhartoNo ratings yet

- Copeland Semi-Hermetic Compressor GatalogueDocument70 pagesCopeland Semi-Hermetic Compressor GatalogueMoon Choon-GeunNo ratings yet

- AC RefrigerantsDocument3 pagesAC Refrigerantsrohit1980No ratings yet

- Comparative Experimental Study of An Open Piston Compressor Working With R1234, R134, R290Document8 pagesComparative Experimental Study of An Open Piston Compressor Working With R1234, R134, R290Giorgio Intenz DangerNo ratings yet

- Refrigerant Changeover Guidelines CFC-12 To R-401ADocument7 pagesRefrigerant Changeover Guidelines CFC-12 To R-401AMaria DazaNo ratings yet

- Air Conditioning Systems With R 134a: Service TrainingDocument28 pagesAir Conditioning Systems With R 134a: Service TrainingAek Zaiaek100% (2)

- Technical Bulletin #R-100 Refrigerant: R410a vs. R407cDocument1 pageTechnical Bulletin #R-100 Refrigerant: R410a vs. R407cmunggangNo ratings yet

- Sealed System Service ManualDocument30 pagesSealed System Service ManualBarry BurkanNo ratings yet

- 02 Air Conditioning ToolsDocument23 pages02 Air Conditioning ToolsJose MNo ratings yet

- B U L L E T I N: Application EngineeringDocument4 pagesB U L L E T I N: Application EngineeringMaria DazaNo ratings yet

- Robinair 34800 2K Operation ManualDocument32 pagesRobinair 34800 2K Operation Manualhiperf2007100% (2)

- Refrigerants and Alternatives: Service Engineers' Section Datasheet 14Document4 pagesRefrigerants and Alternatives: Service Engineers' Section Datasheet 14rituneshmNo ratings yet

- Qdoc - Tips - Refrigerants Tables and Charts SiDocument14 pagesQdoc - Tips - Refrigerants Tables and Charts Simohammed sallemNo ratings yet

- Danfoss Ammonia RefrigerationDocument31 pagesDanfoss Ammonia RefrigerationMahmoud AbubakrNo ratings yet

- Robinair 34800 Operation ManualDocument32 pagesRobinair 34800 Operation ManualΠαναγιωτης ΑποστολοπουλοςNo ratings yet

- Ammonia or R22?: A Design ApproachDocument26 pagesAmmonia or R22?: A Design ApproachSail Vessel J&K Kat100% (1)

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGFrom EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNo ratings yet

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- Ac t680 CompletoDocument124 pagesAc t680 Completojamca100% (2)

- 3066testing & AdjustingDocument129 pages3066testing & AdjustingjamcaNo ratings yet

- C27 Generator Set Electrical System: Dwb1-UpDocument2 pagesC27 Generator Set Electrical System: Dwb1-UpjamcaNo ratings yet

- Maintenance Manual Fan Blade ClearanceDocument1 pageMaintenance Manual Fan Blade ClearancejamcaNo ratings yet

- Best Approach: Compound AngleDocument8 pagesBest Approach: Compound AngleAbhiyanshu KumarNo ratings yet

- Elementary Surveying Problem Set 2 q1Document2 pagesElementary Surveying Problem Set 2 q1soontobengineer50% (2)

- Numerical ModelDocument61 pagesNumerical ModelAlbert AguileraNo ratings yet

- 06 DoniaDocument12 pages06 DoniaOmar ZazaNo ratings yet

- Chapter - Four Soil Permeability and SeepageDocument19 pagesChapter - Four Soil Permeability and SeepageBefkadu KurtaileNo ratings yet

- Calculus 1: CONTINUITYDocument56 pagesCalculus 1: CONTINUITYMa Lorraine PerezNo ratings yet

- IFoA Directory of Actuarial Employers 2016-17-14102016Document22 pagesIFoA Directory of Actuarial Employers 2016-17-14102016Mian BialNo ratings yet

- 144S... - PCB Series: Signal Conditioned Precision Pressure TransducersDocument4 pages144S... - PCB Series: Signal Conditioned Precision Pressure TransducersAnish KumarNo ratings yet

- IS4242 W3 Regression AnalysesDocument67 pagesIS4242 W3 Regression Analyseswongdeshun4No ratings yet

- Histograms - 2Document6 pagesHistograms - 2Sonia HalepotaNo ratings yet

- A Practical Total Synthesis of CocaineDocument13 pagesA Practical Total Synthesis of CocaineRodrigo Fernanda100% (4)

- Linux NFS and Automounter Administration (Craig Hunt Linux Library)Document0 pagesLinux NFS and Automounter Administration (Craig Hunt Linux Library)Bryan BowmanNo ratings yet

- Geared Motors Power Distribution: V V V VDocument2 pagesGeared Motors Power Distribution: V V V VShamim Ahsan ParvezNo ratings yet

- Origin and Structure of The EarthDocument8 pagesOrigin and Structure of The EarthRobin Suarez ViladoNo ratings yet

- PLX7100A Digital Mobile C-Arm X-Ray Machine: 1. Technical SpecificationDocument3 pagesPLX7100A Digital Mobile C-Arm X-Ray Machine: 1. Technical SpecificationAbdalhakeem AlturkyNo ratings yet

- DIO 1000 v1.1 - EN Op ManualDocument25 pagesDIO 1000 v1.1 - EN Op ManualMiguel Ángel Pérez FuentesNo ratings yet

- ECE ExperimentDocument13 pagesECE Experimentasm98090% (1)

- Triosonate in F (TWV 42-F7)Document17 pagesTriosonate in F (TWV 42-F7)EDMILSON BRUNO DO NASCIMENTONo ratings yet

- IncarnationDocument3 pagesIncarnationViviana PueblaNo ratings yet

- 5.3.2 To Sketch Graphs of Trigonometric Functions (Part 2) - SPM Additional MathematicsDocument3 pages5.3.2 To Sketch Graphs of Trigonometric Functions (Part 2) - SPM Additional MathematicsLuke SuouNo ratings yet

- Elecon GearboxDocument19 pagesElecon GearboxShirley Farrace100% (3)

- G3412 - 450 KW Performance DataDocument3 pagesG3412 - 450 KW Performance DataJacob De CasillasNo ratings yet

- Commissioning PFDC DriveDocument45 pagesCommissioning PFDC DriveFonoaudióloga Gisele RezendeNo ratings yet

- HST TrainingDocument11 pagesHST TrainingRamesh BabuNo ratings yet

- ASCE 7 ASD Basic Load CombosDocument1 pageASCE 7 ASD Basic Load CombosAamirShabbirNo ratings yet

- Optical Properties of Gem Substances Educational Objective: This Exercise, Unit 7 in The Above Syllabus, Will Introduce Students To Skills andDocument19 pagesOptical Properties of Gem Substances Educational Objective: This Exercise, Unit 7 in The Above Syllabus, Will Introduce Students To Skills andCarl SoriaNo ratings yet

- Put Call ParityDocument37 pagesPut Call ParityVaidyanathan Ravichandran100% (1)

- Low Temperature Plastics - EnsingerDocument4 pagesLow Temperature Plastics - EnsingerAnonymous r3MoX2ZMTNo ratings yet

- Creative Computing v06 n12 1980 DecemberDocument232 pagesCreative Computing v06 n12 1980 Decemberdarkstar314No ratings yet

- Refining Corrosion Technologist NACE-RCT-001: NACE Cathodic Protection Technician (CP 2) Written ExamDocument16 pagesRefining Corrosion Technologist NACE-RCT-001: NACE Cathodic Protection Technician (CP 2) Written Examshoaib1985100% (1)