Professional Documents

Culture Documents

Ict3 PL0211

Ict3 PL0211

Uploaded by

Rms VicOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ict3 PL0211

Ict3 PL0211

Uploaded by

Rms VicCopyright:

Available Formats

Industrial Control Technology ICT3

Key Features:

Completely self contained

Representation of an automated

assembly system

Performs: Sorting, Assembly, Checking

and Rejection or Acceptance

Two types of conveyor systems

Industrial grade sensors with visible

indicators

Various types of sensors including Infra-

Red, Inductive, Capacitive and Fibre

Optic

Inputs and Outputs 24v dc

Fault insertion switches

The Industrial Control Technology unit (ICT3) is a representation of an industrial assembly system that allows the study

of control methods used in product assembly and inspection in a manufacturing process. Various industrial sensors and

the methods, in which they can be used, are studied. The Sensors and actuators are used to sort components, assemble

them and test for correct assembly followed by acceptance or rejection. The unit can be controlled from a PLC using the

24v dc I/O interface.

The unit assembles two components a plastic ring and an aluminium peg. A chain conveyor processes the components

through the sort area; the plastic rings and aluminium pegs proceed down a ring and peg chute and are then assembled

on the belt conveyor. At the assembly check area components are inspected for correct assembly and when the

components reach the final area, if correctly assembled they proceed to the acceptance area, faulty assemblies are

rejected into a reject bin. Correct programing of the controller (PLC or PC) must be achieved to ensure scrap

components are not sent to the final assembly area.

Once the program has been written and the system is working correctly, various faults can be applied using the fault

insertions switches, providing diagnostic solving issues. LED’s on the sensors provide a visual indication of the

operational status of the sensors. The sort and reject solenoids are fitted with sensors to monitor the operation of the

solenoids and to ensure the operation has been correctly performed.

Curriculum Coverage

Introduction The ICT3 electronics

Principles of operation Sensors

The sort area Photoelectric sensor terminology

The assembly chute Photoelectric sensors

The sensing area Optical fibre sensors

The reject area Capacitive sensors

Getting started Inductive proximity sensors

Interactive software The ICT3 sensors

Using an interface card Switched faults

Using a PLC

Running the ICT3 using the software

Labworks

Sorting routine Metal peg detection/rejection

Closed loop solenoid control Component acceptance and rejection

Queue counting Component queue handling

Operation timing Complete system control

Plastic ring detection/rejection Start / Stop switches

© Bytronic Ltd ICT3-PL0211

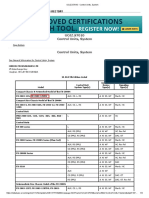

Specification

Inputs 5 x 24V d.c.

Outputs 11 x 24V d.c.

Chain conveyor 24V d.c. Motor with gearbox and slipping clutch

Belt conveyor 24V d.c. Motor

Sensors 3 x Infrared sensors

4 x Inductive Sensors

1 x Capacitive Sensor

1 x Fibre Optic Sensor

Solenoids 1 x 24V d.c. rotary solenoid

2 x 24V d.c. linear solenoid

Switched Faults Six switchable faults

Control 1 x Start and Stop switch in enclosure

1 x Emergency Stop Switch

Connection 1 x 15 way D type connector 24v dc Outputs

1 x 15 way D type connector 24v dc Inputs

2 x 4mm power terminals

2.1mm power jack socket

Power supply requirements 24V d.c. @ 2.5A

Required

A suitable PC with minimum; Pentium processor, 1GB RAM, 20GB HDD, CDROM Drive, and Windows XP or above

Ordering Information

Model Number: ICT3

Consists of: 1 x Industrial control technology unit

1 x 24V d.c power supply unit

8 x Standard plastic rings

8 x Standard pegs

1 x Manual

1 x Software CD

Weights and Dimensions

Un-Packed Packed

Approximate Dimensions (mm) 800L x 460W x 350H Approximate Dimensions (mm) 870L x 540W x 470H

Approximate Weights 16Kg Approximate Weights 18Kg

Bytronic Ltd., reserves the right to make product improvements at any time and without notice and is not responsible for

typographical errors.

Bytronic Limited

124 Anglesey Court, Towers Business Park,

Rugeley, Staffordshire, WS15 1UL.

United Kingdom

Tel; +44(0)8456 123 155 Fax; +44(0)8456 123 156

Email: sales@bytronic.net Website: www.bytronic.net

© Bytronic Ltd ICT3-PL0211

You might also like

- Tomihawk Tools CatalogueDocument60 pagesTomihawk Tools CatalogueRosília DomingosNo ratings yet

- Schneider Price List 2019Document68 pagesSchneider Price List 2019Jacob Varghese83% (6)

- Partes Voluson 730 Expert BT05 ServiceDocument2 pagesPartes Voluson 730 Expert BT05 ServiceHectorOCNo ratings yet

- Aa094.101.05 - Conveyor Belt With Brush DC Motor Dunker Drive CanDocument8 pagesAa094.101.05 - Conveyor Belt With Brush DC Motor Dunker Drive CanplacintaruNo ratings yet

- Sitras Pro enDocument8 pagesSitras Pro enરામ પ્રતાપNo ratings yet

- Schneider Electric Switch Socket 2020Document76 pagesSchneider Electric Switch Socket 2020Kevin MaldeNo ratings yet

- Oilon BURNERS Spare Part CatalogueDocument129 pagesOilon BURNERS Spare Part Cataloguenguyenvanhai1903198192% (12)

- IntelliVibeV3 DSCDocument9 pagesIntelliVibeV3 DSCadnangulgula08No ratings yet

- Overspeed DetectionDocument67 pagesOverspeed Detection20-403 TejashwiniNo ratings yet

- Control System: An Overview.: Presented By: M. Khoirul Effendi St. Msc. (Eng.)Document24 pagesControl System: An Overview.: Presented By: M. Khoirul Effendi St. Msc. (Eng.)Way You EsNo ratings yet

- PLC Based Inspection, Packaging and Storing of MaterialsDocument5 pagesPLC Based Inspection, Packaging and Storing of MaterialsAlauddin khanNo ratings yet

- Intelligent Instrument: Smart SensorDocument21 pagesIntelligent Instrument: Smart SensorAbrhamNo ratings yet

- Mechatronics Automation CH 3Document45 pagesMechatronics Automation CH 3Zeyad AymanNo ratings yet

- Home Security SystemDocument88 pagesHome Security Systemmallanna4blogs0% (1)

- 4CAE000145 REQ650 Technical Summary A4Document2 pages4CAE000145 REQ650 Technical Summary A4Lawrence ChibvuriNo ratings yet

- Manual Optris CTratioDocument47 pagesManual Optris CTratioa.rzeolivaresNo ratings yet

- 4CAE000146 - REL650 - Technical SummaryDocument2 pages4CAE000146 - REL650 - Technical SummaryPrashant SoniNo ratings yet

- Schneider - Final Distribution, WD & Light Control Pricelist 2021Document80 pagesSchneider - Final Distribution, WD & Light Control Pricelist 2021Sahili SalveNo ratings yet

- Klea 220 PDocument5 pagesKlea 220 Psaqib ghouriNo ratings yet

- Ace9000 STP PLC enDocument2 pagesAce9000 STP PLC enmartinNo ratings yet

- PROFINET OverviewSession v1.1Document25 pagesPROFINET OverviewSession v1.1Nilesh GopnarayanNo ratings yet

- PMT Hps Ep03 320 400 v1 c300Document10 pagesPMT Hps Ep03 320 400 v1 c300gabriel augusto arteaga loaizaNo ratings yet

- SCM1 Data Sheet 0522MDocument2 pagesSCM1 Data Sheet 0522Mkeperluan.kantorNo ratings yet

- Ds-En 2502352 Iki-50 1FR2Document9 pagesDs-En 2502352 Iki-50 1FR2saulNo ratings yet

- Preliminary: DescriptionDocument29 pagesPreliminary: DescriptionNegrea CristianNo ratings yet

- Cheap Parking Assist System Using 8051 Family: November 2016Document5 pagesCheap Parking Assist System Using 8051 Family: November 2016Alwan 20No ratings yet

- Component Spec TRIMAX 43C Detector 02162020 (AK0540)Document5 pagesComponent Spec TRIMAX 43C Detector 02162020 (AK0540)RamaNurullarifahNo ratings yet

- DRV 5056Document32 pagesDRV 5056Ahmad AzharNo ratings yet

- Arc Guard System TVOC-2 CatalogueDocument16 pagesArc Guard System TVOC-2 CatalogueEdison EstrellaNo ratings yet

- EE314 Lab 1 FinalDocument19 pagesEE314 Lab 1 FinalCarlos BabuNo ratings yet

- 4CAE000142 REB650 Technical Summary A4Document2 pages4CAE000142 REB650 Technical Summary A4Lawrence ChibvuriNo ratings yet

- Datasheet MICS3-CBUZ40IZ1P01 1094472 enDocument8 pagesDatasheet MICS3-CBUZ40IZ1P01 1094472 enRoberto VieiraNo ratings yet

- 8000P Detection Portal: Metal Weapons, Bomb Components and ContrabandDocument2 pages8000P Detection Portal: Metal Weapons, Bomb Components and ContrabandAli AbidiNo ratings yet

- Product Information Testcontrol Ii For Servo-Hydraulic ApplicationsDocument2 pagesProduct Information Testcontrol Ii For Servo-Hydraulic ApplicationsБахтовар ХолоковNo ratings yet

- Mechatronics, Codes, Logic GatesDocument22 pagesMechatronics, Codes, Logic GatesAfolabi peterNo ratings yet

- The Universal Relay Test Set and Commissioning ToolDocument12 pagesThe Universal Relay Test Set and Commissioning ToolBANOUH LYESNo ratings yet

- CMC 356 Brochure ENUDocument12 pagesCMC 356 Brochure ENUAlaa Zora - OnlineNo ratings yet

- The Universal Relay Test Set and Commissioning ToolDocument12 pagesThe Universal Relay Test Set and Commissioning ToolKhurram ShahzadNo ratings yet

- Pengantar Elektronika Terapan: Ir. Suryani Alifah, MT, PHDDocument55 pagesPengantar Elektronika Terapan: Ir. Suryani Alifah, MT, PHDATEM SemarangNo ratings yet

- Coniq Monitor Iiot Edge System For Coniq CloudDocument3 pagesConiq Monitor Iiot Edge System For Coniq CloudprithwirajroyNo ratings yet

- The Universal Relay Test Set and Commissioning ToolDocument12 pagesThe Universal Relay Test Set and Commissioning ToolPanu Mark IINo ratings yet

- MCB 25.01.2022Document84 pagesMCB 25.01.2022Neetu RaiNo ratings yet

- Solid State SensorsDocument39 pagesSolid State SensorsRona Mae Raza RecaldeNo ratings yet

- Internet of Things (Iot) : Instructor: Fahad MajeedDocument47 pagesInternet of Things (Iot) : Instructor: Fahad MajeedRobina Noor BhattiNo ratings yet

- BPT PL0111Document2 pagesBPT PL0111Rms VicNo ratings yet

- Elements of Mechatronics: V. ThulasikanthDocument46 pagesElements of Mechatronics: V. ThulasikanthPrashanth JagadeeshNo ratings yet

- Hyundai Himap BcsDocument22 pagesHyundai Himap BcsLim Fung ChienNo ratings yet

- Acrylonitrile 200 C3H3NDocument1 pageAcrylonitrile 200 C3H3NAbdul Hakeem MohammedNo ratings yet

- Vbonline-Pro-Fact-Sheet - Gea31855Document3 pagesVbonline-Pro-Fact-Sheet - Gea31855Javier AriasNo ratings yet

- CMC 356 Brochure ENUDocument12 pagesCMC 356 Brochure ENUAchira DasanayakeNo ratings yet

- Datasheet ToxiRAE20Pro20PID DS-1063-07 EMEA-EN LRDocument2 pagesDatasheet ToxiRAE20Pro20PID DS-1063-07 EMEA-EN LRSatish KumarNo ratings yet

- PIRMEC PresentationDocument41 pagesPIRMEC PresentationmanuieeeNo ratings yet

- Substation Automation Systems - Architecture and FunctionsDocument56 pagesSubstation Automation Systems - Architecture and Functionsjmarcelo_pitNo ratings yet

- Leak Alert 73 Data SheetDocument4 pagesLeak Alert 73 Data SheetAndhika PramanaNo ratings yet

- Feeder Protection Relay: With New Functions!Document2 pagesFeeder Protection Relay: With New Functions!Bata ZivanovicNo ratings yet

- ProComp 2 Service Manual SM7008P-01Document22 pagesProComp 2 Service Manual SM7008P-01cobramcNo ratings yet

- 6013840a en FDS 3271 PT VIBSCANNER 2 - DsDocument3 pages6013840a en FDS 3271 PT VIBSCANNER 2 - DsMassamba SarréNo ratings yet

- 9 30783 62576 en AdminDocument2 pages9 30783 62576 en AdminAlek Freire DíazNo ratings yet

- International Journal of Computational Engineering Research (IJCER)Document4 pagesInternational Journal of Computational Engineering Research (IJCER)International Journal of computational Engineering research (IJCER)No ratings yet

- Schneider MCB Price List 2023.Document84 pagesSchneider MCB Price List 2023.NazrulNo ratings yet

- Choosing The Right Industrial Digital I/O Module For Your Digital Output SensorDocument7 pagesChoosing The Right Industrial Digital I/O Module For Your Digital Output SensoracgaitanNo ratings yet

- Practical Data Acquisition for Instrumentation and Control SystemsFrom EverandPractical Data Acquisition for Instrumentation and Control SystemsNo ratings yet

- Multisensor Instrumentation 6σ Design: Defined Accuracy Computer-Integrated Measurement SystemsFrom EverandMultisensor Instrumentation 6σ Design: Defined Accuracy Computer-Integrated Measurement SystemsNo ratings yet

- FX 2003 12nds FacpccDocument4 pagesFX 2003 12nds FacpccProjects aissolNo ratings yet

- Module-5 NotesDocument10 pagesModule-5 NotesRamiksha ShettyNo ratings yet

- Brochure Control Upgrades Shafer en 84314Document4 pagesBrochure Control Upgrades Shafer en 84314josecordova2014No ratings yet

- Fire Equipment - Master List CatalougeDocument32 pagesFire Equipment - Master List CatalougesaeedNo ratings yet

- Bus Broc Bus Eng 1263 4Document1 pageBus Broc Bus Eng 1263 4vijender07No ratings yet

- ATA 29-Hydraulic PowerDocument71 pagesATA 29-Hydraulic PowerChristian LewisNo ratings yet

- Manuals 1098 Egr 1098h Egr Pressure Reducing Regulators Instruction Manual Fisher en en 5969474Document44 pagesManuals 1098 Egr 1098h Egr Pressure Reducing Regulators Instruction Manual Fisher en en 5969474TitoNo ratings yet

- DS51 N DS52Document2 pagesDS51 N DS52Kelvin NgNo ratings yet

- GS GSR GCR UserManual App H GSM Modem V01Document1 pageGS GSR GCR UserManual App H GSM Modem V01John123No ratings yet

- Windows-1256 DC UPS SystemDocument2 pagesWindows-1256 DC UPS SystemwaseemNo ratings yet

- 01-Multi Loose Tube CableDocument1 page01-Multi Loose Tube CableChairul Anam PurbaNo ratings yet

- Manual Wedge Action Grips - 2716-01X-02X and 2736-01XDocument3 pagesManual Wedge Action Grips - 2716-01X-02X and 2736-01XLALO MNo ratings yet

- Service Manual: ACP-12CH35GEKDocument51 pagesService Manual: ACP-12CH35GEKVelimir SlavkovicNo ratings yet

- Photovoltaic Test CapabilitiesDocument4 pagesPhotovoltaic Test Capabilitiesluciano_gularteNo ratings yet

- Construction Safety ManualDocument16 pagesConstruction Safety ManualEd Pawliw100% (1)

- Catalogue 52 KV v13Document18 pagesCatalogue 52 KV v13ZzzdddNo ratings yet

- Trimble R12 - TECHNICAL SPECIFICATIONSDocument2 pagesTrimble R12 - TECHNICAL SPECIFICATIONSmasalpujiNo ratings yet

- CBCS Scheme: Fluid Power Systems (Model QP)Document2 pagesCBCS Scheme: Fluid Power Systems (Model QP)Swaroop SomannaNo ratings yet

- Velvia 50 DatasheetDocument8 pagesVelvia 50 DatasheetKino Tel LokNo ratings yet

- Excavator Service Manual: 6724480 (11-95) Printed in U.S.A. Melroe Company 1995Document13 pagesExcavator Service Manual: 6724480 (11-95) Printed in U.S.A. Melroe Company 1995Fabrizio SarubbiNo ratings yet

- Kone Unidrive: Service ManualDocument56 pagesKone Unidrive: Service Manualprasad100% (1)

- Ground Floor Lighting Layout Second Floor Lighting Layout: Electrical LegendDocument1 pageGround Floor Lighting Layout Second Floor Lighting Layout: Electrical LegendJordan Cabuso Guevarra UapNo ratings yet

- ADC3010 AF 484 Series RegulatorDocument3 pagesADC3010 AF 484 Series RegulatormiguesobeNo ratings yet

- 2015 Itoh Denki Catalog For WebDocument33 pages2015 Itoh Denki Catalog For WebDan ZlateNo ratings yet

- HV-MX100: Simple ManualDocument28 pagesHV-MX100: Simple ManualSimon PapukyanNo ratings yet

- TTA-TWE 7 A 20 TR PDFDocument85 pagesTTA-TWE 7 A 20 TR PDFAnonymous P8TIw3qYvNo ratings yet

- Contact Expansions: PNOZ s7.1Document10 pagesContact Expansions: PNOZ s7.1hector areNo ratings yet