Professional Documents

Culture Documents

Finlay J1175 Hybrid Jaw Crusher

Finlay J1175 Hybrid Jaw Crusher

Uploaded by

BEJOY JOHNOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Finlay J1175 Hybrid Jaw Crusher

Finlay J1175 Hybrid Jaw Crusher

Uploaded by

BEJOY JOHNCopyright:

Available Formats

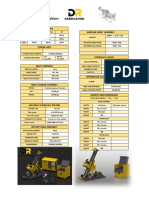

J-1175

JAW C R U S H E R

STRONG HERITAGE, STRONG FUTURE

J-1175

JAW C R U S H E R

1. HOPPER/FEEDER 3. JAW CRUSHER

Hopper capacity: 9m³ (11.7yd³) Terex JW42 Chamber single toggle jaw crusher Inlet width:

Feed height VGF: 3.98m (12’ 11”) 1070mm (42”)

Feed width at rear VGF: 2.67m (8’ 9”) Inlet gap: 760mm (30”)

Hydraulically folding sides and rear Under jaw clearance: 460mm nominal

Full hydraulic closed side setting adjust

2. BY-PASS CONVEYOR (OPTIONAL)

4. MAGNET (OPTIONAL)

Belt Width: 650mm (26”)

Belt Width: 750mm (30”)

Working Angle: 22°

Drive: Hydraulic

Hydraulically folds for transport

Standard Discharge Height: 2.1m (7’)

Stockpile capacity: 13.8m3 (18yd3) @ 40° 5. MAIN CONVEYOR

Belt Width: 1m (40”)

Discharge Height: 3.6m (11’ 10”) with standard conveyor

Stockpile capacity: 69.4m3 (90.8yd3) @ 40°

7

YEAR

DATA

SUBSCRIP TION

TM

T-LINK TELEMATICS

T-Link telematics hardware and software along with free seven

The Finlay® J-1175 hybrid mobile jaw crusher offers TRANSPORT DIMENSIONS year data subscription are fitted and installed as standard.

operators the flexibility to power the plant either by mains 14.5m (47’ 8”)

electric connection or the onboard genset powerpack

configuration.

5. 4. 3. 2. 1.

Either power option presents operators with significant

power, servicing and maintenance cost savings in direct

comparison to a diesel/hydraulic powered plant.

2.9m (9’ 6” )

The plant incorporates the robust Terex® JW42 high

performance electrically driven single toggle jaw

chamber and a heavy duty VGF feeder to give optimum

3.5m (11’ 6”)

production in quarrying, mining, demolition and recycling

applications.

Additional benefits include, rapid set up time, ease of

maintenance, high reduction ratio, high output capacity WORKING DIMENSIONS

and advanced electronic control system. 15.7m (51’ 8”)

FEATURES:

The plant’s electrically driven power systems provide

significant cost advantages and efficiencies.

Superior performance in dusty applications and in high

6.2m (20’ 4”)

altitude environments.

Automatic variable speed VGF ensures continuous choke

3.95m (12’ 1”)

feeding of the crushing chamber for optimal productivity.

High powered electric drive ensures precise chamber

controls and reverse functionality for clearing blockages

and assisting in demolition and recycling applications.

MACHINE WEIGHT: * 54,300kg (119,711lbs)

(VGF, without by-pass conveyor and magnet options)

The material in this document is for information only and is subject to change without notice.

Finlay® assumes no liability resulting from errors or omissions in this document, or from the use of the information contained herein.

Due to continual product development we reserve the right to change specifications without notice. Product performance figures given in this brochure are for guidance purposes only, this

information does not constitute an expressed or implied warranty or guarantee, but shows test examples. These results will vary depending on application. Photographs are for illustrative

purposes only; some or all of the machines in the illustrations may be fitted with optional extras. Please check with your Dealer for details on optional extras.

Published and Printed in 2021

www.terex.com/finlay E: sales@terexfinlay.com T: +44 28 82 418 700

You might also like

- Powerscreen Conveyor BrochureDocument5 pagesPowerscreen Conveyor BrochureDaniel BianchiniNo ratings yet

- Automated Power Catwalk: "Helping Our Customers Achieve Superior Results"Document6 pagesAutomated Power Catwalk: "Helping Our Customers Achieve Superior Results"Pedro RiveraNo ratings yet

- R8505 KVTR100Document88 pagesR8505 KVTR100Rinda_RaynaNo ratings yet

- Hyundai R55 7 Specifikationer PDFDocument8 pagesHyundai R55 7 Specifikationer PDFPatricia CrespoNo ratings yet

- Contactor - Motor Starters - Motor Controls - Overload Relay - Motor (PDFDrive)Document100 pagesContactor - Motor Starters - Motor Controls - Overload Relay - Motor (PDFDrive)HavandinhNo ratings yet

- Hydraulic Tank Jack Equipment Brochure FinalDocument13 pagesHydraulic Tank Jack Equipment Brochure FinalAris MunandarNo ratings yet

- Main Crane CC 2800-1 Main Crane 80t C-054-14 Tailing Crane SL6000 Tailing Crane 43.2t C-054-14Document2 pagesMain Crane CC 2800-1 Main Crane 80t C-054-14 Tailing Crane SL6000 Tailing Crane 43.2t C-054-14Bangun DjiwandonoNo ratings yet

- Super-Capacitor Based UpsDocument15 pagesSuper-Capacitor Based Upsakashlogic100% (1)

- Sandvik DX780: Surface Top Hammer DrillsDocument3 pagesSandvik DX780: Surface Top Hammer DrillsJesusFloresRodriguez100% (1)

- Process Flow & Equipment Description - Ayo Biomass Project #2 (Updated Dec 17)Document1 pageProcess Flow & Equipment Description - Ayo Biomass Project #2 (Updated Dec 17)Nguyên Võ TriệuNo ratings yet

- Impact Crushers: I-110 I-110RS I-130 I-130RSDocument12 pagesImpact Crushers: I-110 I-110RS I-130 I-130RSGabriel InfanteNo ratings yet

- Tadano Rough Terrain Crane 20TDocument12 pagesTadano Rough Terrain Crane 20TShinta Ayuningtyas100% (1)

- Ata 71-80: Power Plant ATA 71: 1.features of PW1100G-JM Engine AreDocument7 pagesAta 71-80: Power Plant ATA 71: 1.features of PW1100G-JM Engine ArePhạm Hà TiếnNo ratings yet

- ELTEK Rectifier Systems Installation GuidelinesDocument11 pagesELTEK Rectifier Systems Installation GuidelinesKatsaras Stelios100% (2)

- Cone Crushers: C-1540 C-1540RS C-1550Document8 pagesCone Crushers: C-1540 C-1540RS C-1550brajesh123No ratings yet

- Panel Type (Dm1-A) 24Kv Switchgear Sm6: Scale: NTSDocument18 pagesPanel Type (Dm1-A) 24Kv Switchgear Sm6: Scale: NTSAris Habbil100% (1)

- Melcs ElectronicsDocument3 pagesMelcs ElectronicsAlex Hermogeno100% (1)

- ANT A794517R0 1470 DatasheetDocument2 pagesANT A794517R0 1470 DatasheetPunky HeroNo ratings yet

- IV-0794-20 CROSS OVER Pin-Box 05807HDocument1 pageIV-0794-20 CROSS OVER Pin-Box 05807Hivan dario benavides bonillaNo ratings yet

- LG Reciprocating Catalog PDFDocument41 pagesLG Reciprocating Catalog PDFIordan Dan Ffn78% (9)

- DX800 2specs PDFDocument3 pagesDX800 2specs PDFMartin AguilarNo ratings yet

- MB Manual Ga-G41mt-S2pt e PDFDocument40 pagesMB Manual Ga-G41mt-S2pt e PDFLeonel AtaramaNo ratings yet

- Sandvik DX700: ApplicationDocument3 pagesSandvik DX700: ApplicationAcar Hakan BayramoğluNo ratings yet

- Finlay J1160 Jaw CrusherDocument3 pagesFinlay J1160 Jaw CrusherAndreasNo ratings yet

- Finlay J960 Jaw CrusherDocument3 pagesFinlay J960 Jaw CrusherAndreasNo ratings yet

- Finlay 694 Inclined ScreenDocument3 pagesFinlay 694 Inclined Screenrobert.korb36No ratings yet

- Finlay 984 Horizontal ScreenerDocument3 pagesFinlay 984 Horizontal Screenercollins051070No ratings yet

- Terex Finlay 863 BrochureDocument4 pagesTerex Finlay 863 BrochureVivekanandh00333 VivekNo ratings yet

- h6203 Horizontal Screen BrochureDocument1 pageh6203 Horizontal Screen BrochureHolger JessaNo ratings yet

- 15 Ton Galion 150Document6 pages15 Ton Galion 150Antonio Junior100% (1)

- MR 6Document1 pageMR 6Omar AymanNo ratings yet

- Striker SQR2062 20x6 Mobile Scalping ScreenDocument2 pagesStriker SQR2062 20x6 Mobile Scalping ScreenBenjamin MurphyNo ratings yet

- Techspec QJ240 PDFDocument2 pagesTechspec QJ240 PDFNazeeh Abdulrhman AlbokaryNo ratings yet

- Unic (1) 706Document10 pagesUnic (1) 706Howard HoacNo ratings yet

- Techspec QJ340Document2 pagesTechspec QJ340Antonio SoaresNo ratings yet

- Powerscreen Screening Brochure 2015 enDocument21 pagesPowerscreen Screening Brochure 2015 ensindy garzonNo ratings yet

- Premiertrak 750: Output Potential Crusher HopperDocument1 pagePremiertrak 750: Output Potential Crusher HopperChris LundstromNo ratings yet

- Striker SQ1653 16x5 DD ScreenDocument2 pagesStriker SQ1653 16x5 DD ScreenBenjamin MurphyNo ratings yet

- Powerscreen Premiertrak 400 R400 Brochure JAW CRUSHERDocument1 pagePowerscreen Premiertrak 400 R400 Brochure JAW CRUSHERFatema KhatunNo ratings yet

- Terex Finlay 984 Horizontal Screen PDFDocument4 pagesTerex Finlay 984 Horizontal Screen PDFeaglego00No ratings yet

- FN Scar - H PR & FN Scar - H TPR: Technical DataDocument1 pageFN Scar - H PR & FN Scar - H TPR: Technical DataengvafonsoNo ratings yet

- DX800LC-7 Crawler Excavator - Doosan Infracore NADocument3 pagesDX800LC-7 Crawler Excavator - Doosan Infracore NAdeepakgkdNo ratings yet

- Geotrek ConveyorDocument2 pagesGeotrek ConveyorRAUL PEREZ NEGREIROSNo ratings yet

- Urw 706Document6 pagesUrw 706schembriryanNo ratings yet

- Powerscreen Metrotrak Brochure EN 2018Document1 pagePowerscreen Metrotrak Brochure EN 2018Nelson Andrade VelasquezNo ratings yet

- FT Sandvik-DX700Document3 pagesFT Sandvik-DX700Misti FuriosoNo ratings yet

- Striker CM500 1350mm Mobile Cone CrusherDocument2 pagesStriker CM500 1350mm Mobile Cone CrusherBenjamin MurphyNo ratings yet

- 73 - B5e 2019 02 26Document12 pages73 - B5e 2019 02 26aykbNo ratings yet

- ST80TF StackerDocument2 pagesST80TF StackerJosé Bayonas MartínezNo ratings yet

- Columbusjack/Regent: Tripod Aircraft Recovery SystemDocument2 pagesColumbusjack/Regent: Tripod Aircraft Recovery SystemGenaire LimitedNo ratings yet

- 770 Trommel Tracked: SpecificationDocument4 pages770 Trommel Tracked: SpecificationVishwdeep VaidNo ratings yet

- Geotrek Conveyor SPLT1049ENPR 01Document2 pagesGeotrek Conveyor SPLT1049ENPR 01JrbritoNo ratings yet

- DR900 U Specifications: Depth Rating Wireline Hoist AssemblyDocument1 pageDR900 U Specifications: Depth Rating Wireline Hoist AssemblyJhonattan GonzalezNo ratings yet

- General Boom PumpDocument2 pagesGeneral Boom PumpJonathan Guzmán MendozaNo ratings yet

- Galion 150FDocument6 pagesGalion 150FLuis avitia ortegaNo ratings yet

- GT205 Multi-Frequency: Track-Mounted ScreenDocument2 pagesGT205 Multi-Frequency: Track-Mounted Screenosvaldo arcos0% (1)

- Hydraulic Excavator: Backhoe DimensionsDocument1 pageHydraulic Excavator: Backhoe DimensionsEko DianNo ratings yet

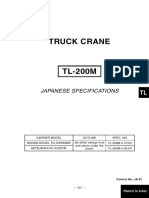

- Fully Hydraulic Truck Crane: 【 Specification】Document8 pagesFully Hydraulic Truck Crane: 【 Specification】fuzailNo ratings yet

- Dynapac CA4000 DCO Dynapac CA4000 DCO: Single Drum Vibratory Rollers Single Drum Vibratory RollersDocument2 pagesDynapac CA4000 DCO Dynapac CA4000 DCO: Single Drum Vibratory Rollers Single Drum Vibratory Rollersabdelrhmangbr86No ratings yet

- J50 Feature Sheet May 2020Document2 pagesJ50 Feature Sheet May 2020victor porrasNo ratings yet

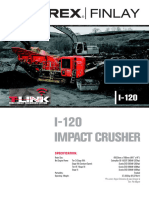

- Technical Specification Impact Crusher I 120Document8 pagesTechnical Specification Impact Crusher I 120Eric EricssonNo ratings yet

- Reference For TdanoDocument11 pagesReference For TdanoPrinces Ann MarcosNo ratings yet

- Slide-Pac and Slide-Stac Conveyors: / Superior IndustriesDocument2 pagesSlide-Pac and Slide-Stac Conveyors: / Superior IndustriesRAUL PEREZ NEGREIROSNo ratings yet

- CBC 30 en 905 753 2Document8 pagesCBC 30 en 905 753 2rigaz6366No ratings yet

- Gruas TC 40Document2 pagesGruas TC 40Raul Alberto AlvarezNo ratings yet

- 920E Excavator: Tough World. Tough EquipmentDocument2 pages920E Excavator: Tough World. Tough EquipmentNur DiansyahNo ratings yet

- Trnasportador TELEBELT MXTB130MXTB600Document2 pagesTrnasportador TELEBELT MXTB130MXTB600yony choqueñaNo ratings yet

- FSO Gagak Rimang Tower Yoke: Banyu Urip Field, IndonesiaDocument1 pageFSO Gagak Rimang Tower Yoke: Banyu Urip Field, Indonesiarieza_fNo ratings yet

- 2010 Prius Maintenance Schedule (Canadian, Based On Owner's Manual Supplement)Document1 page2010 Prius Maintenance Schedule (Canadian, Based On Owner's Manual Supplement)Raihan GrimuflihinNo ratings yet

- Copeland Scroll Compressors Bom Overview Technical Information en GB 4848778Document22 pagesCopeland Scroll Compressors Bom Overview Technical Information en GB 4848778hozaifaalturaikyNo ratings yet

- Lincoln 180HD Users PDFDocument96 pagesLincoln 180HD Users PDFratpacNo ratings yet

- Arduino Webserver Ethernet ENC28J60 With A TemperaDocument3 pagesArduino Webserver Ethernet ENC28J60 With A Temperaosadeamos8684No ratings yet

- Solar Energy: Raveendhra Dogga, M.K. Pathak TDocument17 pagesSolar Energy: Raveendhra Dogga, M.K. Pathak TPablo Omar Luz PedemonteNo ratings yet

- SV03 Product SpecificationsDocument2 pagesSV03 Product SpecificationsMatiasNo ratings yet

- Terasaki Manual Thermal Magnetic TripDocument3 pagesTerasaki Manual Thermal Magnetic TripTosikur RahmanNo ratings yet

- Microcontroller Based Electronic Voting Machine: 1. ObjectiveDocument4 pagesMicrocontroller Based Electronic Voting Machine: 1. ObjectivesagrvNo ratings yet

- Arduino Micro QuadcopterDocument29 pagesArduino Micro QuadcopterdefriNo ratings yet

- Webarticle Blue Switch enDocument5 pagesWebarticle Blue Switch envijayNo ratings yet

- Tre 1130 K Amazonas PDFDocument108 pagesTre 1130 K Amazonas PDFpedro cNo ratings yet

- Installation, Operation & Maintenance ADDENDUM: BULLETIN No. PS-IOM-HYP-0203-HDocument16 pagesInstallation, Operation & Maintenance ADDENDUM: BULLETIN No. PS-IOM-HYP-0203-HAlexis SánchezNo ratings yet

- Ve Series, Ms-02-308 r1Document6 pagesVe Series, Ms-02-308 r1herysyam1980No ratings yet

- Aarambh Machines Catalog Paper CupDocument3 pagesAarambh Machines Catalog Paper CupAtul PatekarNo ratings yet

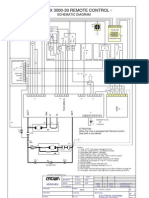

- Diagramas SX3000Document8 pagesDiagramas SX3000Angela ZMNo ratings yet

- Csa12cdi RDocument2 pagesCsa12cdi RWin FloresNo ratings yet

- Transient Response of An RC Circuit: Experiment No: 4Document8 pagesTransient Response of An RC Circuit: Experiment No: 4Haziq MatNo ratings yet

- Catalogo AlmaniDocument28 pagesCatalogo AlmaniCristian BravoNo ratings yet

- TPC8103Document8 pagesTPC8103dreyes3773No ratings yet

- Fundamentals of Turbo TOCDocument1 pageFundamentals of Turbo TOCMohamed Sayed Abdel GaffarNo ratings yet