Professional Documents

Culture Documents

Finlay J1160 Jaw Crusher

Uploaded by

AndreasOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Finlay J1160 Jaw Crusher

Uploaded by

AndreasCopyright:

Available Formats

J-1160

JAW CRUSHER

STRONG HERITAGE, STRONG FUTURE

J-1160

JAW CRUSHER

1. HOPPER/FEEDER 4. UNDERCARRIAGE

Hopper capacity: 5m³ (6.5yd³) Shoe Width: 400mm (16”)

Feed height with standard hopper: 3.4m (11’ 2”) Dual speed tracking with ‘soft start’

Feed height with standard hopper and extensions: 3.7m (12’ 1”) Gradeability: 30°

Vibrating grizzly feeder (VGF)

VGF Speed range: variable, 450-850 rpm 5. MAGNET (OPTIONAL)

Hopper extensions hydraulic folding and hydraulic locking

Belt Width: 750mm (30”)

Drive: Hydraulic

2. BY-PASS CONVEYOR

Belt Width: 650mm (26”) 6. MAIN CONVEYOR

Working Angle: 22°

Belt Width: 900mm (36”)

Hydraulically folds for transport

Working Angle: 25°

Standard Discharge Height: 2.1m (6’ 10”)

Discharge Height: 3.5m (11’ 5”)

Stockpile capacity: 12m3 (15.7yds3) @ 40°

Impact bars and wear resistant liners at feed point

Standard Stockpile capacity: 60m³ (78yd³) @40°

3. JAW CRUSHER

Terex chamber single toggle jaw crusher TM

7

YEAR

DATA

SUBSCRIP TION

Inlet width: 1000mm (40”)

T-LINK TELEMATICS

Inlet gape: 600mm (24”)

T-Link telematics hardware and software along with free seven

Under jaw clearance: 540mm nominal

The Finlay® J-1160 primary mobile jaw crusher was TRANSPORT DIMENSIONS year data subscription are fitted and installed as standard.

designed with the customer and operator in mind. The Drive arrangement: Hydrostatic with full reverse crush capability

15.7m (51’ 6”)

new model features increased under jaw clearance and Maximum Closed Side Settings (CSS): 145mm (5 45/64”)

all round preventative maintenance and serviceability Minimum Closed Side Settings (CSS): 40mm (1 1/2”) Demolition

access. and Recycling applications. 50mm (1 31/32”) quarry application

Reverse action for clearing blockages

The heart beat of the machine is the renowned and

aggressive Terex 1000 x 600mm (40” x 24”) jaw crusher Full hydraulic closed side setting adjust

with a proven pedigree in recycling, demolition and

6. 5. 4. 3. 2. 1.

aggregate production applications. The hydrostatic drive 2.6m (8’ 6”)

gives the operator the flexibility of variable crushing

speed and the ability to run the chamber in reverse in

3.4m (11’ 2”)

certain applications.

Designed to maximize fuel efficiency and deliver one of

the lowest cost per ton in the market place the machine

is the ideal solution for small to medium sized operators.

WORKING DIMENSIONS

15.5m (50’ 10”)

FEATURES:

The robust high performance hydrostatic driven single

toggle jaw chamber provides high capacity with large

reduction ratio’s.

Automatic variable speed VGF ensures continuous choke

feeding of the crushing chamber for optimal productivity.

4.6m (15’ 1”)

High powered hydrostatic drive ensures precise chamber

controls and reverse functionality for clearing blockages

and assisting in demolition and recycling applications.

3.9m (12’ 9”)

Fully hydraulic adjustable closed side setting minimises

downtime and offers quick adjustment.

MACHINE WEIGHT: * 35,350kg (77,930lbs)

* with twin pole magnet, dirt conveyor

and hopper extensions

The material in this document is for information only and is subject to change without notice.

Finlay® assumes no liability resulting from errors or omissions in this document, or from the use of the information contained herein.

Due to continual product development we reserve the right to change specifications without notice. Product performance figures given in this brochure are for guidance purposes only, this

information does not constitute an expressed or implied warranty or guarantee, but shows test examples. These results will vary depending on application. Photographs are for illustrative

purposes only; some or all of the machines in the illustrations may be fitted with optional extras. Please check with your Dealer for details on optional extras.

Published and Printed in 2022

www.terex.com/finlay E: sales@terexfinlay.com T: +44 28 82 418 700

You might also like

- 770 Trommel Tracked: SpecificationDocument4 pages770 Trommel Tracked: SpecificationVishwdeep VaidNo ratings yet

- Impact Crushers: I-110 I-110RS I-130 I-130RSDocument12 pagesImpact Crushers: I-110 I-110RS I-130 I-130RSGabriel InfanteNo ratings yet

- GT205 Multi-Frequency: Track-Mounted ScreenDocument2 pagesGT205 Multi-Frequency: Track-Mounted Screenosvaldo arcos0% (1)

- Techspec QJ240 PDFDocument2 pagesTechspec QJ240 PDFNazeeh Abdulrhman AlbokaryNo ratings yet

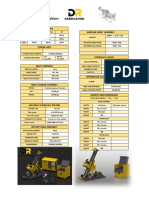

- ONRAM 1000/3 ONRAM 1000/3: Diamond Core Drill Diamond Core DrillDocument4 pagesONRAM 1000/3 ONRAM 1000/3: Diamond Core Drill Diamond Core DrillTomasz TromasNo ratings yet

- Hiab Crane Service ManualDocument16 pagesHiab Crane Service Manualjohan useche33% (3)

- The Impact of Productivity Improvement Approach Using Lean Tools in An Automotive IndustryDocument15 pagesThe Impact of Productivity Improvement Approach Using Lean Tools in An Automotive IndustryNipcela TamayoNo ratings yet

- Division of LabourDocument9 pagesDivision of LabourAPARNANo ratings yet

- Ch01 Problems RevDocument4 pagesCh01 Problems RevHetty Mustika0% (3)

- Solution Manual For Operations and Supply Chain Management 8th Edition by RussellDocument10 pagesSolution Manual For Operations and Supply Chain Management 8th Edition by RussellFirmine TaryanoubaNo ratings yet

- Chapter 5 - Theory of ProductionDocument11 pagesChapter 5 - Theory of ProductionWingmannuuNo ratings yet

- Short-Run Aggregate Supply (SRAS) : Macro Topic 3.3Document2 pagesShort-Run Aggregate Supply (SRAS) : Macro Topic 3.3kawii.fighting10No ratings yet

- Finlay J1175 Hybrid Jaw CrusherDocument3 pagesFinlay J1175 Hybrid Jaw CrusherBEJOY JOHNNo ratings yet

- Finlay 984 Horizontal ScreenerDocument3 pagesFinlay 984 Horizontal Screenercollins051070No ratings yet

- Finlay J960 Jaw CrusherDocument3 pagesFinlay J960 Jaw CrusherAndreasNo ratings yet

- Finlay 694 Inclined ScreenDocument3 pagesFinlay 694 Inclined Screenrobert.korb36No ratings yet

- Terex Finlay 863 BrochureDocument4 pagesTerex Finlay 863 BrochureVivekanandh00333 VivekNo ratings yet

- h6203 Horizontal Screen BrochureDocument1 pageh6203 Horizontal Screen BrochureHolger JessaNo ratings yet

- Striker SQ1653 16x5 DD ScreenDocument2 pagesStriker SQ1653 16x5 DD ScreenBenjamin MurphyNo ratings yet

- Striker SQR2062 20x6 Mobile Scalping ScreenDocument2 pagesStriker SQR2062 20x6 Mobile Scalping ScreenBenjamin MurphyNo ratings yet

- 15 Ton Galion 150Document6 pages15 Ton Galion 150Antonio Junior100% (1)

- Terex Finlay 984 Horizontal Screen PDFDocument4 pagesTerex Finlay 984 Horizontal Screen PDFeaglego00No ratings yet

- S190 Feature Sheet Feb 2022 DigitalDocument2 pagesS190 Feature Sheet Feb 2022 Digitalvictor porrasNo ratings yet

- D36x50DRII SpecSheet 201604Document2 pagesD36x50DRII SpecSheet 201604IBS Soluciones CivilesNo ratings yet

- Striker CM500 1350mm Mobile Cone CrusherDocument2 pagesStriker CM500 1350mm Mobile Cone CrusherBenjamin MurphyNo ratings yet

- Urw 706Document6 pagesUrw 706schembriryanNo ratings yet

- Unic (1) 706Document10 pagesUnic (1) 706Howard HoacNo ratings yet

- Powerscreen Trakpactor 320 Brochure EN2018Document1 pagePowerscreen Trakpactor 320 Brochure EN2018DCNo ratings yet

- Powerscreen Screening Brochure 2015 enDocument21 pagesPowerscreen Screening Brochure 2015 ensindy garzonNo ratings yet

- Trnasportador TELEBELT MXTB130MXTB600Document2 pagesTrnasportador TELEBELT MXTB130MXTB600yony choqueñaNo ratings yet

- Gruas TC 40Document2 pagesGruas TC 40Raul Alberto AlvarezNo ratings yet

- Fully Hydraulic Truck Crane: 【 Specification】Document8 pagesFully Hydraulic Truck Crane: 【 Specification】fuzailNo ratings yet

- Technical Specification Impact Crusher I 120Document8 pagesTechnical Specification Impact Crusher I 120Eric EricssonNo ratings yet

- Cone Crushers: C-1540 C-1540RS C-1550Document8 pagesCone Crushers: C-1540 C-1540RS C-1550brajesh123No ratings yet

- Galion 150FDocument6 pagesGalion 150FLuis avitia ortegaNo ratings yet

- Sandvik CM1211 Mobile Jaw BrochureDocument2 pagesSandvik CM1211 Mobile Jaw BrochureBenjamin MurphyNo ratings yet

- Powerscreen Crushing Brochure 2017 enDocument25 pagesPowerscreen Crushing Brochure 2017 enSivavishalNo ratings yet

- DR900 U Specifications: Depth Rating Wireline Hoist AssemblyDocument1 pageDR900 U Specifications: Depth Rating Wireline Hoist AssemblyJhonattan GonzalezNo ratings yet

- Powerscreen Premiertrak 400 R400 Brochure JAW CRUSHERDocument1 pagePowerscreen Premiertrak 400 R400 Brochure JAW CRUSHERFatema KhatunNo ratings yet

- Tender Lift 2000Document1 pageTender Lift 2000Beltazor HellboyNo ratings yet

- Powerscreen Conveyor BrochureDocument5 pagesPowerscreen Conveyor BrochureDaniel BianchiniNo ratings yet

- Automated Power Catwalk: "Helping Our Customers Achieve Superior Results"Document6 pagesAutomated Power Catwalk: "Helping Our Customers Achieve Superior Results"Pedro RiveraNo ratings yet

- Powerscreen Metrotrak Brochure EN 2018Document1 pagePowerscreen Metrotrak Brochure EN 2018Nelson Andrade VelasquezNo ratings yet

- Mud Cat™ MFD - Multi-Function Dredge: General ComplianceDocument2 pagesMud Cat™ MFD - Multi-Function Dredge: General ComplianceSekson JunsukplukNo ratings yet

- ST80TF StackerDocument2 pagesST80TF StackerJosé Bayonas MartínezNo ratings yet

- J50 Feature Sheet May 2020Document2 pagesJ50 Feature Sheet May 2020victor porrasNo ratings yet

- MR 6Document1 pageMR 6Omar AymanNo ratings yet

- TADANO 80ton GR-800EX - Specification & Load Chart PDFDocument13 pagesTADANO 80ton GR-800EX - Specification & Load Chart PDFBruce Li0% (1)

- D130x150 S-Machine CatalogueDocument2 pagesD130x150 S-Machine CatalogueRa IN100% (1)

- FN Scar - H PR & FN Scar - H TPR: Technical DataDocument1 pageFN Scar - H PR & FN Scar - H TPR: Technical DataengvafonsoNo ratings yet

- IR ICM LifDocument1 pageIR ICM LifSRINIVASA REDDYNo ratings yet

- Terex Finlay 683 (English) PDFDocument4 pagesTerex Finlay 683 (English) PDFTophet0% (1)

- Hydrostatic TractorDocument4 pagesHydrostatic Tractornidia aguilarNo ratings yet

- GustavDocument2 pagesGustavRamani KevinNo ratings yet

- Unic URW 547Document2 pagesUnic URW 547Foromaquinas100% (1)

- Powerscreen Warrior-1400X-and-1400XEDocument1 pagePowerscreen Warrior-1400X-and-1400XEАнтон ЛазаровNo ratings yet

- CBC 30 en 905 753 2Document8 pagesCBC 30 en 905 753 2rigaz6366No ratings yet

- Hydraulic Excavator: Backhoe DimensionsDocument1 pageHydraulic Excavator: Backhoe DimensionsEko DianNo ratings yet

- DX800LC-7 Crawler Excavator - Doosan Infracore NADocument3 pagesDX800LC-7 Crawler Excavator - Doosan Infracore NAdeepakgkdNo ratings yet

- D220x300 Spec Sheet 201507Document2 pagesD220x300 Spec Sheet 201507Sendy IslamiNo ratings yet

- Atf400g-6 B GDocument5 pagesAtf400g-6 B GEder Rodriguez GonzalezNo ratings yet

- Terex Finlay I-110RS Impact Crusher PDFDocument4 pagesTerex Finlay I-110RS Impact Crusher PDFeaglego00No ratings yet

- Belt BroDocument8 pagesBelt BrojagandgnNo ratings yet

- Bluewhale I H1277 UDW D90 5 Outline Specification R1Document5 pagesBluewhale I H1277 UDW D90 5 Outline Specification R1RayodcNo ratings yet

- Anaconda Sr410 - Machine Specs - Rev 9Document1 pageAnaconda Sr410 - Machine Specs - Rev 9gugiNo ratings yet

- Warrior 1400x Xe Scalping Screen BrochureDocument1 pageWarrior 1400x Xe Scalping Screen BrochureChris IrelandNo ratings yet

- AT Screening Technology 2023Document68 pagesAT Screening Technology 2023AndreasNo ratings yet

- Minerals 11 01429Document23 pagesMinerals 11 01429AndreasNo ratings yet

- 230418-Crusher Catalouge-Zhengzhou VanguardDocument44 pages230418-Crusher Catalouge-Zhengzhou VanguardAndreasNo ratings yet

- AT ScreeningTechnology 2022 ArchivDocument36 pagesAT ScreeningTechnology 2022 ArchivAndreasNo ratings yet

- Omega J1065T BrochureDocument2 pagesOmega J1065T BrochureAndreasNo ratings yet

- Single and Multifactor Productivity Analysis of Manual and Automatic Machines at Powder Coating Company PT. TKM in BekasiDocument7 pagesSingle and Multifactor Productivity Analysis of Manual and Automatic Machines at Powder Coating Company PT. TKM in BekasiInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- MD Aminul Islam: ManagerDocument2 pagesMD Aminul Islam: ManagerIslam MarufNo ratings yet

- Productivity Report 2023Document90 pagesProductivity Report 2023nikfaisal05No ratings yet

- International TradeDocument4 pagesInternational TradeAaYush BadoniYaNo ratings yet

- Report - The Kolm Triangle in Public EconomicsDocument2 pagesReport - The Kolm Triangle in Public EconomicsGasimovskyNo ratings yet

- Production ManagementDocument12 pagesProduction ManagementSUSAN KIBUINo ratings yet

- Standardization: Standard WorkDocument2 pagesStandardization: Standard WorkMenganoNo ratings yet

- Labor Productivity of Ethiopian Large and Medium Scale Manufacturing SectorDocument7 pagesLabor Productivity of Ethiopian Large and Medium Scale Manufacturing SectorMihaela SburleaNo ratings yet

- Organizational EffectivenessDocument30 pagesOrganizational EffectivenessAmit Anand KumarNo ratings yet

- SourcesDocument2 pagesSourcesMikhael LaurenteNo ratings yet

- Frederick Taylors Scientific ManagementDocument3 pagesFrederick Taylors Scientific ManagementMickey MoraNo ratings yet

- TransportationMethods PDFDocument11 pagesTransportationMethods PDFFullmetal GunneNo ratings yet

- Group 5 (B) Econ3012 AssignmentDocument10 pagesGroup 5 (B) Econ3012 Assignmentmenurmohamed71No ratings yet

- W1 L1 - IntroductionDocument22 pagesW1 L1 - IntroductionAmiko GogitidzeNo ratings yet

- 5 de Thi ThuDocument46 pages5 de Thi ThuNguyen HưngNo ratings yet

- Operation Management SummaryDocument2 pagesOperation Management SummaryJeanny Lyn CuetoNo ratings yet

- Chapter-1 Operations ManagementDocument22 pagesChapter-1 Operations ManagementadityaibiibhNo ratings yet

- Article AIPDocument15 pagesArticle AIPMapapa MbangalaNo ratings yet

- Work Study ReviewerDocument8 pagesWork Study ReviewerLoala SMDNo ratings yet

- VietNam Rice ExportDocument24 pagesVietNam Rice ExportTrang Uyên ĐàoNo ratings yet

- Problem Statements Chapter 1 - ProductivityDocument2 pagesProblem Statements Chapter 1 - ProductivityStone100% (1)

- Theory of Production and CostsDocument127 pagesTheory of Production and Costssamwelpaul1002No ratings yet

- The Economic Development of Latin AmericaDocument338 pagesThe Economic Development of Latin AmericaArquero PeligroNo ratings yet