Professional Documents

Culture Documents

CH 3 Overview of Baking Process

Uploaded by

Solomon Chakweva0 ratings0% found this document useful (0 votes)

35 views31 pagesThe baking process involves three main stages: mixing, baking, and cooling. During mixing, ingredients are distributed evenly and air is incorporated. Baking involves complex chemical reactions as heat transforms the batter or dough, such as melting fats, forming air bubbles, coagulating proteins, and gelatinizing starches. During cooling, the baked good continues to firm up as gases contract, fats resolidify, and starches and proteins bond. Changes during each stage influence texture, rise, flavor, and more. Careful attention to ingredients, methods, and temperatures at each stage is required for baking success.

Original Description:

Original Title

Ch 3 Overview of Baking Process

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe baking process involves three main stages: mixing, baking, and cooling. During mixing, ingredients are distributed evenly and air is incorporated. Baking involves complex chemical reactions as heat transforms the batter or dough, such as melting fats, forming air bubbles, coagulating proteins, and gelatinizing starches. During cooling, the baked good continues to firm up as gases contract, fats resolidify, and starches and proteins bond. Changes during each stage influence texture, rise, flavor, and more. Careful attention to ingredients, methods, and temperatures at each stage is required for baking success.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

35 views31 pagesCH 3 Overview of Baking Process

Uploaded by

Solomon ChakwevaThe baking process involves three main stages: mixing, baking, and cooling. During mixing, ingredients are distributed evenly and air is incorporated. Baking involves complex chemical reactions as heat transforms the batter or dough, such as melting fats, forming air bubbles, coagulating proteins, and gelatinizing starches. During cooling, the baked good continues to firm up as gases contract, fats resolidify, and starches and proteins bond. Changes during each stage influence texture, rise, flavor, and more. Careful attention to ingredients, methods, and temperatures at each stage is required for baking success.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 31

Chapter 3

Overview of the Baking Process

How Baking Works

Words, Phrases, and Concepts

• Structure builder • Batters and

• Toughener doughs

• Tenderizer • Oven spring

• Moistener • Starch granules

• Drier • Starch

• Air bubbles gelatinization

• Foams and • Maillard browning

sponges

• Hydration • Amylase

• Gluten • Retrogradation

Introduction

Three stages in baking process:

I. Mixing

II. Baking

III. Cooling

Introduction

Success in the bakeshop starts with a

properly-balanced formula that contains a

balance of:

• Tougheners and tenderizers.

• Moisteners and driers.

Introduction

Structure builder

– Also called toughener.

– Examples: flour, eggs, cocoa powder,

cornstarch.

• The proteins and starches in flour, eggs, and

cocoa powder are the actual structure builders.

– Holds the volume and shape of baked goods

in place.

– Too much structure results in tough, hard

baked goods.

Introduction

Tenderizer

– Interferes with the formation of structure.

– Examples: sugars and syrups, fats and oils,

leavening agents

– Softens baked goods, making them easier to

bite into.

– Too much tenderizing leads to crumbling or

collapse.

Introduction

Moistener

– Thins out batters and doughs.

– Examples:

• Water (moisture) and ingredients that contain

water, including milk, eggs, cream, and syrups.

• Oil and melted fat.

Introduction

Drier

– Opposite of moistener.

– An ingredient that absorbs moisteners.

Examples: flour, cornstarch, dry milk solids, cocoa

powder.

Stage I: Mixing

• Mixing method is important

– Example: muffins mixed using muffin method

compared with creaming method

• Ingredient temperature is important

– Example: pie pastry dough mixed with cold

vs. warm ingredients

Stage I: Mixing

As batters and doughs are mixed:

• Ingredients are distributed evenly throughout.

• Air bubbles are mixed in and reduced in size.

– Lightens batter/dough.

– Provides for proper leavening and crumb formation.

note: batters/doughs are considered foams

because air bubbles are trapped.

Stage I: Mixing

As batters and doughs are mixed (cont.):

• Large solid particles are worn down, layer by

layer, into smaller ones.

– Allows them to dissolve or to hydrate faster.

• Fats/oils break into small chunks or droplets.

Stage I: Mixing

Role of water in mixing:

• Dissolves small molecules.

– Activates them.

– Examples: sugar crystals, baking powder.

• Hydrates large molecules and particles.

– Hydration: layers of water surround large molecules

(driers), swelling and suspending them.

– Activates them.

– Example: formation of gluten.

Stage I: Mixing

Role of water in mixing (cont.):

• Hydrates and activates yeast.

• Adjusts batter/dough temperature.

Example: bread dough.

• Adjusts batter/dough consistency.

– Batters are high in moisture; thin and pourable.

– Doughs are low in moisture; thick and moldable.

Stage I: Mixing

Many ingredients are significant sources of

water in the bakeshop.

Stage II: Baking

• During baking:

– Heat is slowly conducted from the outside in.

– Heat transforms batter/dough from a foam

that traps air bubbles to a porous sponge that

does not.

• Term sponge is used whether product has a

springy, spongy texture or not.

Stage II: Baking

Crumb, or grain, of baked goods consists

of air cells surrounded by porous cell

walls.

Stage II: Baking

Baking involves at least eleven events.

– Is complex.

– Events occur concurrently and influence each

other.

– Many would never occur at room temperature;

this is, heat is required.

– Several have no upper limit; that is, they

continue for as long as baked good is in oven.

Examples: protein coagulation, starch

gelatinization, evaporation of gases.

Stage II: Baking

1. Fats Melt.

• Most melt between 90º and 130ºF (30º–55ºC).

• Results in:

• Increased volume, or rise: trapped steam and air

expand.

– The later fats melt, the more rise.

• Increased tenderness: melted fats coat structure

builders.

– The sooner fats melt, often the more tenderness.

Example: oil and pie pastry dough.

• Thinned batters and doughs.

Example: high-fat cookie dough and spread.

Stage II: Baking

2. Gases Form and Expand.

• Starts at room temperature; continues until

about 170ºF (75ºC).

• Three most important leavening gases: air,

steam, carbon dioxide.

• Results in:

• Increased volume or rise: expanding gases push

on cell walls.

Example: Oven spring

• Increased tenderness: expanding gases thin cells

walls, making them easier to bite.

Stage II: Baking

3. Microorganisms Die.

• Microorganisms include: yeast, mold, bacteria,

viruses.

• Most die at 135 –140ºF (55–60ºC).

• Depends on microorganism and amount of sugar

or salt.

• Results in:

• Fermentation stopping.

• Safer food, since pathogenic bacteria are killed.

Examples of pathogens: Salmonella bacteria, hepatitis

virus.

Stage II: Baking

4. Sugar Dissolves.

• Heat of oven dissolves sugar that did not

dissolve during mixing.

• Results in:

• Moistening, tenderizing, browning, sweetening.

• That is, sugar now acts like sugar.

Thinned batters and doughs.

Dissolved sugar pulls water from driers.

Note: other solutes that dissolve during baking include

acid salts in baking powder

Stage II: Baking

5. Egg and Gluten Proteins Coagulate.

• Starts at 140 –160ºF (60–70ºC).

• Egg proteins:

• Unfold (denature) and bond, forming a network

of stretched-out clusters of egg proteins.

• Heat dries out and stiffens the proteins.

• Results in formation of rigid structure that sets

the final size and shape of baked goods.

Stage II: Baking

6. Starches Gelatinize.

• Starts at 120 –140ºF (50–60ºC).

• Starch granules, tightly-packed with starch

molecules, swell and soften.

• Results in:

• Thickening of batter/dough.

• Formation of rigid structure that sets the final

size and shape of baked goods.

• Besides heat, water is required.

• Bread dough vs. cookie dough

Stage II: Baking

7. Gases Evaporate.

• Starts at about 160ºF (72ºC).

• Rigid cell walls rupture from pressure of

expanding gases; gases escape.

• Results in:

• Formation of dry, hard (white) crust.

• Weight loss.

• Aroma loss.

Stage II: Baking

8. Caramelization and Maillard Browning

Occur on Crust.

• Begins at 300ºF (150ºC) and above.

• Temperature of crust rises only after water

evaporation slows.

• Caramelization: breakdown of sugars.

• Maillard browning: breakdown of sugars and

proteins together.

• Results in:

• Brown color.

• Baked flavors.

Stage II: Baking

9. Enzymes are Inactivated.

• By about 160 –180ºF (70–80ºC).

• Below this temperature, rising oven temperatures

increase enzyme activity.

• Enzymes are:

• Proteins.

• Biological catalysts; that is, they speed up

chemical reactions.

• Denatured by heat.

• Example: amylase.

Stage II: Baking

10.Changes Occur to Nutrients.

• Examples of nutrients: proteins, fats,

carbohydrates, vitamins, minerals.

• Results in:

• Proteins and starches becoming more

digestible.

• Destruction of certain vitamins (Vitamin C and

thiamin).

Stage II: Baking

11.Pectin Breaks Down.

• Pectin holds fruits together.

• Dissolves when heated.

• Results in softened fruit.

Stage III: Cooling

• Carryover cooking continues until baked

goods reach room temperature.

• Changes occur during cooling and

continue during storage.

– Changes occur even when baked good is

properly wrapped.

• Many changes result in firming of baked

goods as they cool.

– Best to cool products to 100ºF (38ºC) or

below before slicing.

Stage III: Cooling

Eight main changes:

1. Gases contract; weak structure collapses.

• Example: soufflés

2. Fats resolidify.

• Decrease in greasiness, but product could

become hard and waxy.

3. Sugars recrystallize.

• Provides crunchy crust in low-moisture products.

4. Starch molecules bond and solidify.

• Called retrogradation; major cause of staling.

Stage III: Cooling

Eight main changes (cont.):

5. Proteins bond and solidify.

• Contributes to staling.

6. Moisture is redistributed within crumb.

7. Moisture moves from moist crumb to dry

crust.

• Crust loses crispness; can become tough and

rubbery.

8. Flavors evaporate or become trapped by

starches.

• Brief reheating in oven recovers some lost flavor.

You might also like

- Baking Technology: Bread QualityDocument74 pagesBaking Technology: Bread QualityTayachew BerhanNo ratings yet

- Bakery Confectionary 2 STPNon NSQFDocument88 pagesBakery Confectionary 2 STPNon NSQFirshad100% (1)

- Janny MT CA Modules Extend Product Life for Fruits, Vegetables & FlowersDocument2 pagesJanny MT CA Modules Extend Product Life for Fruits, Vegetables & FlowersHeemanshuNo ratings yet

- The Essential Guide To BakingDocument57 pagesThe Essential Guide To BakinghymerchmidtNo ratings yet

- Manufactureof Processed Cheese SpreadfromDocument12 pagesManufactureof Processed Cheese SpreadfromNguyen Minh TrongNo ratings yet

- Module 1Document7 pagesModule 1Che CheNo ratings yet

- SMAW NC I (Franklin Lirazan)Document119 pagesSMAW NC I (Franklin Lirazan)Franklin LirazanNo ratings yet

- The A-Z of Governance For Microsoft Teams: by Jasper Oosterveld MVPDocument33 pagesThe A-Z of Governance For Microsoft Teams: by Jasper Oosterveld MVPAnees FCWNo ratings yet

- Journal of Occupational Safety and Health, June 2017Document52 pagesJournal of Occupational Safety and Health, June 2017Nurul Nabilah100% (1)

- Miller FinalDocument20 pagesMiller FinalNikhil PalNo ratings yet

- BALINTEC C.J.G. Detailed Lesson PlanDocument12 pagesBALINTEC C.J.G. Detailed Lesson PlanErica O. PagurayanNo ratings yet

- Sunshine BakeryDocument48 pagesSunshine Bakeryለህዳሴአችን እንተባበርNo ratings yet

- Sales Spec 11212222 Organic Ginger Juice, Pasteurized - US v5Document1 pageSales Spec 11212222 Organic Ginger Juice, Pasteurized - US v5Germán R ZapsanNo ratings yet

- Fsa Food Allergen Labelling and Information Requirements Technical Guidance 0Document41 pagesFsa Food Allergen Labelling and Information Requirements Technical Guidance 0Jameel SmithNo ratings yet

- Electric Pressure Cooker: EN FR ESDocument28 pagesElectric Pressure Cooker: EN FR ESalexandra130409No ratings yet

- Cereals For Developing Gluten-Free Products PDFDocument36 pagesCereals For Developing Gluten-Free Products PDFMarwa.berberNo ratings yet

- Module 13 Thermal ApplicationDocument15 pagesModule 13 Thermal ApplicationMitchille Getizo100% (1)

- Usage of Fats and Oils in Cooking and BakingDocument5 pagesUsage of Fats and Oils in Cooking and BakingProbaron BaruahNo ratings yet

- Recipe E-BookDocument38 pagesRecipe E-BookTreks BrionesNo ratings yet

- Loring S35-Kestrel WebDocument2 pagesLoring S35-Kestrel WebLeidy Patricia Poloche GutierrezNo ratings yet

- Extraction of Oil by Soxhelt MethodDocument19 pagesExtraction of Oil by Soxhelt MethodIram AnwarNo ratings yet

- VS248 EnglishDocument22 pagesVS248 EnglishАлла ШульпековаNo ratings yet

- Pharmaceutical ExcipientsDocument46 pagesPharmaceutical ExcipientsMasum HossinNo ratings yet

- Unigaz Corporate Presentation (With References)Document36 pagesUnigaz Corporate Presentation (With References)MeraNo ratings yet

- Flour Provides The Recipe FoundationDocument18 pagesFlour Provides The Recipe FoundationElean Joy Reyes-GenabiaNo ratings yet

- Cheese 935 - 42Document1 pageCheese 935 - 42Mohammed ElsenduonyNo ratings yet

- Pride Magazine's Best of The Best IssueDocument56 pagesPride Magazine's Best of The Best IssueWCNC DigitalNo ratings yet

- Presentation in Bread and Pastry ProductionDocument46 pagesPresentation in Bread and Pastry Productionヘルナンデス レイギナ100% (1)

- SITXFSA001 Student Assessment Tasks - Set-2Document23 pagesSITXFSA001 Student Assessment Tasks - Set-2Mukta AktherNo ratings yet

- TOA Cookbook 102921 v10 NoCropMark 1.1-CompressedDocument31 pagesTOA Cookbook 102921 v10 NoCropMark 1.1-CompressedWolfie BunnyNo ratings yet

- Morphy Richards Breadmaker Manual and Recipe GuideDocument28 pagesMorphy Richards Breadmaker Manual and Recipe GuideFlorentina SibiceanuNo ratings yet

- DPR - Frozen Snack FoodDocument27 pagesDPR - Frozen Snack FoodRekha Kuttappan100% (1)

- NirmaDocument90 pagesNirma68Rohan ChopraNo ratings yet

- AMSCO LS Series Medium Steam Sterilizers 630LS Tech DataDocument10 pagesAMSCO LS Series Medium Steam Sterilizers 630LS Tech DataAlemontse JiménezNo ratings yet

- Codex Alimentarius Commission: ALINORM 99/14Document45 pagesCodex Alimentarius Commission: ALINORM 99/14yurinaNo ratings yet

- Mushroom Training ManualDocument47 pagesMushroom Training ManualJonah Reyes100% (1)

- Types of Cocoa Products and Chocolate Varieties Around the WorldDocument8 pagesTypes of Cocoa Products and Chocolate Varieties Around the Worldkks sdmNo ratings yet

- IngredientsDocument14 pagesIngredientsLiezaNo ratings yet

- HALT Fentanyl ActDocument19 pagesHALT Fentanyl ActSpencer BrownNo ratings yet

- Cara Mudah Membuat Fondant IcingDocument3 pagesCara Mudah Membuat Fondant IcingfauzisamsudinNo ratings yet

- Functionality of Palm Oil As A Stabilizer in Peanut ButterDocument8 pagesFunctionality of Palm Oil As A Stabilizer in Peanut ButterCarlos González VargasNo ratings yet

- Grade 10 P.E. 1st QuarterDocument4 pagesGrade 10 P.E. 1st QuarterAlleah Fate CunananNo ratings yet

- IPC Manual of Methods of AnalysisDocument53 pagesIPC Manual of Methods of AnalysisIndria Yustisi NovianiNo ratings yet

- Standard Operating Procedure: Microwave OvensDocument1 pageStandard Operating Procedure: Microwave OvensFairuz Nikmah NadhifahNo ratings yet

- Baking Cake ModulesDocument62 pagesBaking Cake ModulesMarj IdianNo ratings yet

- Influence of Base On Nitro-Aldol (Henry) Reaction Products For Alternative Clandestine PathwaysDocument11 pagesInfluence of Base On Nitro-Aldol (Henry) Reaction Products For Alternative Clandestine PathwaysYana PotemkinNo ratings yet

- Rational OvenDocument36 pagesRational OvenОлег КунгуровNo ratings yet

- Varian, Inc. 2700 Mitchell Drive Walnut CreekDocument9 pagesVarian, Inc. 2700 Mitchell Drive Walnut Creekkstazi100% (1)

- Human Resource Management: Job RotationDocument19 pagesHuman Resource Management: Job RotationPreeti SharmaNo ratings yet

- Lemon Truffle: Cream Cheese 600g Icing Sugar 200g Mascarpone Chees 600g Vanilla Beans 3pes Cream 90mlDocument4 pagesLemon Truffle: Cream Cheese 600g Icing Sugar 200g Mascarpone Chees 600g Vanilla Beans 3pes Cream 90mlwajira bNo ratings yet

- Ift ArtikelDocument30 pagesIft ArtikelfrendyaaNo ratings yet

- MFVH 66356 1 EN 0409 - RotoflowDocument46 pagesMFVH 66356 1 EN 0409 - RotoflowArif Abu FarhanaNo ratings yet

- ACN 402 Final AssignmentDocument15 pagesACN 402 Final AssignmentSAIMA SHARMINNo ratings yet

- System Guide IntegratedDocument367 pagesSystem Guide Integratedfrancisco jaraNo ratings yet

- Bakery Basics: Measuring Ingredients for Baked GoodsDocument50 pagesBakery Basics: Measuring Ingredients for Baked GoodsHoney VillartaNo ratings yet

- Media For FermentationDocument7 pagesMedia For FermentationProtusha RakshitNo ratings yet

- 7 - Baking Process & Ovens FinalDocument31 pages7 - Baking Process & Ovens FinalshahidNo ratings yet

- Advace Baking Report Page 28 31Document17 pagesAdvace Baking Report Page 28 31Aubrey Dacer100% (2)

- Biscuit Manufacturing: Different Types of BiscuitDocument15 pagesBiscuit Manufacturing: Different Types of Biscuit9889187549No ratings yet

- LP5 - RO - TLE HE BPP Grade 9 10 Q1 Edited - FinalizedDocument9 pagesLP5 - RO - TLE HE BPP Grade 9 10 Q1 Edited - Finalizedgemuel imperialNo ratings yet

- Charmaine Solomon's Asian Favorites PDFDocument193 pagesCharmaine Solomon's Asian Favorites PDFLeyla ZeririNo ratings yet

- Food Allergen Management Plan: Employees and TrainingDocument4 pagesFood Allergen Management Plan: Employees and TrainingKharisma NusantaraNo ratings yet

- A Summer Internship Project Genmo LabsDocument46 pagesA Summer Internship Project Genmo Labssaikumar0% (2)

- Effect of Potassium Bisulphite As A Food PreservativeDocument6 pagesEffect of Potassium Bisulphite As A Food PreservativeMuskan Singh100% (1)

- Global Tapas Menu: Hey, Come Along To Explore The Art of Tapas by The Lovefools!Document20 pagesGlobal Tapas Menu: Hey, Come Along To Explore The Art of Tapas by The Lovefools!shubhankar.dNo ratings yet

- Catanduanes Island BuffetDocument3 pagesCatanduanes Island BuffetJustine Ong ChinelNo ratings yet

- 7-Day Paleo Diabetes Meal PlanDocument10 pages7-Day Paleo Diabetes Meal PlanPatrícia VieiraNo ratings yet

- Kellogg's Nutrigrain case analysis focuses on test marketingDocument2 pagesKellogg's Nutrigrain case analysis focuses on test marketingShaina Aragon100% (2)

- Literature Review 1Document3 pagesLiterature Review 1api-509636353No ratings yet

- Project Report 9988Document6 pagesProject Report 9988prasunꔪNo ratings yet

- PE 10 Quarter II - Module 2Document25 pagesPE 10 Quarter II - Module 2Lea Victoria Pronuevo0% (1)

- Full Report Soft Tofu - Group 7Document16 pagesFull Report Soft Tofu - Group 7SwanBella100% (1)

- Ace3 Unit5 TestDocument2 pagesAce3 Unit5 Testnatacha100% (2)

- The 27 Essential Heart Healthy Diet Recipes Free EcookbookDocument40 pagesThe 27 Essential Heart Healthy Diet Recipes Free EcookbookElizabeth ButtonNo ratings yet

- Kefir GrainsDocument10 pagesKefir GrainsJane GaltNo ratings yet

- Banana Bread: IngredientsDocument2 pagesBanana Bread: IngredientsAlyssa Panuelos FloresNo ratings yet

- IAFP FoodSafety2023-abstract-bookDocument360 pagesIAFP FoodSafety2023-abstract-bookangelaNo ratings yet

- Food Safety Kilang HaccpDocument7 pagesFood Safety Kilang HaccpNurul Balqish Abdul WahabNo ratings yet

- De Thi Hoc Sinh Gioi Lop 12 Mon Tieng Anh Nam Hoc 2018 2019Document13 pagesDe Thi Hoc Sinh Gioi Lop 12 Mon Tieng Anh Nam Hoc 2018 2019Bảo Khánh Lê MaiNo ratings yet

- Module 1. (9pp) Basic Concepts in HorticultureDocument8 pagesModule 1. (9pp) Basic Concepts in HorticultureDimasalang Perez100% (3)

- Main Idea and Supporting Details Practice ExercisesDocument5 pagesMain Idea and Supporting Details Practice ExercisesnewmanhdNo ratings yet

- Companion Planting Printable ColourDocument1 pageCompanion Planting Printable Colourlaila camachoNo ratings yet

- ANDOKDocument1 pageANDOKlouie roderosNo ratings yet

- Urban Agriculture in BostonDocument32 pagesUrban Agriculture in BostonKathrynEntnerNo ratings yet

- The Secrets of Long LifeDocument1 pageThe Secrets of Long LifeRoberto SakiyamaNo ratings yet

- SCP Hoppers Menu New Layout Final 20 4 1Document2 pagesSCP Hoppers Menu New Layout Final 20 4 1Samadhi SamararatneNo ratings yet

- The Codex Committee On Food AdditivesDocument159 pagesThe Codex Committee On Food AdditivesOsama MohammedNo ratings yet

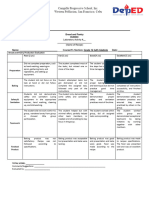

- B P RubricsDocument7 pagesB P RubricsFrederick John CostasNo ratings yet

- Korean Beanpaste FlowerDocument5 pagesKorean Beanpaste FlowerCarrie ChoyNo ratings yet

- Medicinska DijetaDocument5 pagesMedicinska DijetaAna DekicNo ratings yet