Professional Documents

Culture Documents

Night Stand

Uploaded by

Keith WilliamsCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Night Stand

Uploaded by

Keith WilliamsCopyright:

Available Formats

Online Extras

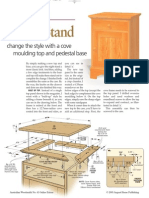

Night Stand

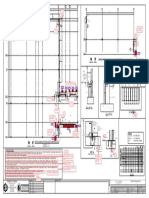

change the style with a cove

molding top and pedestal base

By simply making a new top and into the front and

base, you can give the night stand a sides, as you can

more classic look. And then, adding see in detail ‘a.’

a few edge treatments to the base The new top

and top will make them stand out to panel is the same

complete the change. I finished both size as the origi-

assemblies the same as the case. By nal, but instead

the way, the knobs on the drawer of a crisp cham-

and door are also finished this way. fer, I routed a 1/4" roundover on the add an additional step. First, the

BUILT UP TOP . Instead of a single bottom edges of the top (except the cove frame needs to be screwed to

top panel shown in the magazine, I back edge) to complement the cove the top panel. I drilled oversize

went with a “built-up” style by molding below it. On the top holes and used washers and

adding a frame beneath it, as you edges, simply ease the sharp edges roundhead screws to allow the top

can see in the drawing below. The with some sandpaper. to expand and contract, as illus-

frame is mitered at the front and When it comes time to attach the trated in detail ‘a.’ This assembly

then has a 1/2"-radius cove routed new top to the case, you’ll have to can then be screwed to the case.

20

19

#/4 A

TOP Drill and

countersink from

below for

#8 x 1!/4" Fh

woodscrews

D FRAME

FILLER 3!/2

8#/4

18#/4 15#/4 C

3!/2

12!/2

1

%/8 1 a.

TOP !/4

A

1!/2 #/4

B

COVE FRAME FRONT #8 x 1!/4" Fh

woodscrews B C !/4"

#8 x 1!/4" Rh (3!/2 x 19!/2) #/4 roundover

woodscrews C

with washers COVE

(through cove !/2" cove

FRAME

frame into top) #8 x 1!/4" Rh %/16"-dia. through SIDE

woodscrews with holes with

washers (through case top 1"-dia. x !/4"-deep Case !/4

into cove frame) counterbore top

#8 x 1!/4" FRONT

SECTION

NOTE: Cove frame sides, Rh woodscrews VIEW

cove frame front, and with washers

frame filler are

#/4"-thick hardwood

Woodsmith No. 155 Online Extras © 2004 August Home Publishing

a. Case Drill and countersink

side holes from bottom for

#8 x 1!/4" Fh woodscrews

#8 x 1!/4" Fh

#/8 woodscrew 2

I

Case 17#/8 BASE

!/4 bottom PANEL

!/16 2

#/4 (#/4" plywood)

I 17#/4

!/4"

roundover #8 x 1!/4" Fh

!/4 woodscrews

FRONT #/4

H 17#/4

SECTION

F VIEW

BASE G

F

SIDE BASE

BASE BACK #/4

SIDE

4!/4

b. !/4

G H

H H

#/4 BASE 4!/4

BACK CORNER

Edge of GLUE 18#/8

panel 5

BLOCK

H is flush with

outside #/4

face of back

3 E

F H

BASE I BASE PANEL BASE

SIDE FRONT F

TOP VIEW 18#/4 1 BASE

#/4 SIDE

3

45°

MITERED BASE. The base is pretty straight-

forward, as you can see in the drawing at NOTE: Base sides, front, and back

are #/4"-thick hardwood

right. It consists of a mitered frame hold-

ing a plywood panel that is used to attach shadow line. Second, I cut an arch in the Before gluing the base frame together, I

the base to the case. There are just a few front and sides to lighten up the base. cut a rabbet on the top inside edges of

details on the base that I should mention. The final detail to note is that I wanted each part (except the back) to hold the 3/4"

First, a roundover is routed along the to beef up the frame joints between the plywood panel, as shown in detail ‘b.’

top edge of the front and sides to create a front (E), sides (F) and back (G). So I added After drilling and countersinking some

molded edge. I left a small shoulder, as 3/ "-square hardwood glue blocks to the mounting holes, the base can be glued

4

you can see in detail ‘a’ above, to create a inside of all four of the corner joints. and screwed in place from below. W

Materials, Supplies, & Cutting Diagram

A Top (1) #/4 x 19 - 20 G Base Back (1) #/4 x 4!/4 - 17#/4

B Cove Frame Front (1) #/4 x 3!/2 - 19!/2 H Corner Glue Blocks (4) #/4 x #/4 - 4!/4

C Cove Frame Sides (2) #/4 x 3!/2 - 18#/4 I Base Panel (1) #/4 ply. - 17&/8 x 17#/4

D Frame Filler (1) #/4 x 3!/2 - 12!/2

E Base Front (1) #/4 x 5 - 18#/4 • (10) #8 x 1!/4" Rh Woodscrews w/Washers

F Base Sides (2) #/4 x 5 - 18#/8 • (12) #8 x 1!/4" Fh Woodscrews

#/4" x 6"- 96" Cherry (4.0 Bd. Ft.)

H

A A A A

#/4" x 5"- 96" Cherry (3.4 Bd. Ft.)

C C B D G

#/4" x 6"- 60" Cherry (2.5 Bd. Ft.)

F F E

ALSO NEEDED: One 24" x 24" sheet

of #/4" cherry plywood

Woodsmith No. 155 Online Extras © 2004 August Home Publishing

You might also like

- Cherry ConsoleDocument11 pagesCherry ConsolekathmartinNo ratings yet

- Cordless Tool ShelfDocument1 pageCordless Tool ShelfjuiceNo ratings yet

- ParacordBraceletJig PDFDocument9 pagesParacordBraceletJig PDFAnonymous vRX0OvwHNo ratings yet

- WS #034 PDFDocument24 pagesWS #034 PDFJohnny MoralesNo ratings yet

- Plansnow DownloadDocument4 pagesPlansnow DownloadJimmy Gomez100% (1)

- Dresser PlanDocument11 pagesDresser PlanGsmHelpNo ratings yet

- Country Curio Clock: Project 12231EZDocument7 pagesCountry Curio Clock: Project 12231EZBSulliNo ratings yet

- Plans Now - Woodsmith - Pocket Hole Joinery Basics PDFDocument3 pagesPlans Now - Woodsmith - Pocket Hole Joinery Basics PDFPaweł Jamrożek100% (1)

- ParquetDocument4 pagesParquetFernando FrayreNo ratings yet

- Çalışma Tezgahı PlanıDocument14 pagesÇalışma Tezgahı PlanıÖmür Eryüksel50% (2)

- Pine Cabinet: Project 11142EZDocument5 pagesPine Cabinet: Project 11142EZBSulliNo ratings yet

- WC 54 Aug Sep - 2013Document84 pagesWC 54 Aug Sep - 2013Tim Heis100% (1)

- Shop Drawings: Shaker-Style WorkbenchDocument29 pagesShop Drawings: Shaker-Style WorkbenchamelieNo ratings yet

- Chest of Drawers: Project 11819EZDocument7 pagesChest of Drawers: Project 11819EZBSulli100% (1)

- Pine Desk Organizer: Project 13782EZDocument6 pagesPine Desk Organizer: Project 13782EZBSulli100% (1)

- EAA Chapter 1000 Standardized Work Table Plans: Building InstructionsDocument4 pagesEAA Chapter 1000 Standardized Work Table Plans: Building Instructionsel_generalNo ratings yet

- Record and Tape Cabinet: Project 11185EZDocument8 pagesRecord and Tape Cabinet: Project 11185EZBSulliNo ratings yet

- Portable Sandpaper StorageDocument3 pagesPortable Sandpaper Storagegmand68100% (1)

- WOOD Monthly DownloadDocument9 pagesWOOD Monthly DownloadRoomel UrbinaNo ratings yet

- Desk Plans: Traditional To ContemporaryDocument22 pagesDesk Plans: Traditional To ContemporaryhawunzNo ratings yet

- Broken Arch Mantel Clock Plans: © 2005 by Robert E. Reedy All Rights ReservedDocument25 pagesBroken Arch Mantel Clock Plans: © 2005 by Robert E. Reedy All Rights ReservedLinNo ratings yet

- Shaker Nightstand PlanDocument18 pagesShaker Nightstand PlanJess HendriksmaNo ratings yet

- Recipe Box: Project 15193EZDocument5 pagesRecipe Box: Project 15193EZBSulli100% (1)

- Tilting Mirror Stand - FH96DJADocument7 pagesTilting Mirror Stand - FH96DJAJvlValenzuelaNo ratings yet

- Classic Flag Case: © 2014 August Home Publishing CoDocument11 pagesClassic Flag Case: © 2014 August Home Publishing Cokostas1977No ratings yet

- Wall MirrorDocument4 pagesWall Mirrorrayane ouzmihNo ratings yet

- Wall Hung Magazine and Book Rack: Project 14211EZDocument3 pagesWall Hung Magazine and Book Rack: Project 14211EZBSulliNo ratings yet

- Cove CalculationsDocument1 pageCove CalculationsflerziNo ratings yet

- 5hop Notes n128 PDFDocument57 pages5hop Notes n128 PDFpiedrahecNo ratings yet

- Wall-Hung Telephone Cabinet: Project 11257EZDocument6 pagesWall-Hung Telephone Cabinet: Project 11257EZBSulli100% (1)

- Deluxe Router TableDocument27 pagesDeluxe Router Tableiacob_gilberto6473100% (1)

- Fast FixesDocument3 pagesFast FixesGsmHelpNo ratings yet

- Cortar CirculosDocument7 pagesCortar CirculosarenasrubenNo ratings yet

- Mackintosh Inspiration On California's CoastDocument9 pagesMackintosh Inspiration On California's CoastpanáNo ratings yet

- Materials, Supplies, & Cutting Diagram: Large Craftsman TableDocument1 pageMaterials, Supplies, & Cutting Diagram: Large Craftsman TableDavid TuaineNo ratings yet

- Trestle Coffee TableDocument7 pagesTrestle Coffee Table- yAy3e -No ratings yet

- Wood - Magazine - 259 - Mar 2019Document92 pagesWood - Magazine - 259 - Mar 2019Adam Niddrie100% (1)

- Woodcraft Magazine - April-May 2009 (Malestrom) PDFDocument84 pagesWoodcraft Magazine - April-May 2009 (Malestrom) PDFSammy NgussieNo ratings yet

- WOOD Store: Thank You!Document12 pagesWOOD Store: Thank You!lacroitoruNo ratings yet

- Woodsmith 184 Avoiding Router Table TearoutDocument2 pagesWoodsmith 184 Avoiding Router Table TearoutPaul LauNo ratings yet

- Armario de ParedeDocument4 pagesArmario de ParedetovenoNo ratings yet

- Wood Working Plans 2 PDFDocument9 pagesWood Working Plans 2 PDFNicusor AmihaeseiNo ratings yet

- Woodsmith 135Document36 pagesWoodsmith 135Aditya Rajendran100% (1)

- Modular Planter Bench: Woodworks: Intermediate ProjectDocument7 pagesModular Planter Bench: Woodworks: Intermediate ProjectEucap MdzNo ratings yet

- Woodsmith #250 Aug Sept 2020Document70 pagesWoodsmith #250 Aug Sept 2020reivnaxNo ratings yet

- Good Woodworking December - 2017 PDFDocument92 pagesGood Woodworking December - 2017 PDFAnonymous PcUOts100% (1)

- Classic Two-Piece Library CabinetDocument12 pagesClassic Two-Piece Library CabinetKeith WilliamsNo ratings yet

- Shop Drawings: Modern Power Tool BenchDocument9 pagesShop Drawings: Modern Power Tool Benchn1856390No ratings yet

- Free Heirloom TablesDocument18 pagesFree Heirloom TablesDG100% (1)

- 64 - Hardware Storage CabinetDocument2 pages64 - Hardware Storage CabinetGsmHelpNo ratings yet

- Parsons TableDocument3 pagesParsons Table- yAy3e -100% (1)

- Leg Tapering Jig: Project 14585EZDocument5 pagesLeg Tapering Jig: Project 14585EZBSulliNo ratings yet

- Quick and Easy Router TableDocument5 pagesQuick and Easy Router TableVia CreazionemxNo ratings yet

- Sea ChestDocument2 pagesSea ChestAnninha Sud AlvesNo ratings yet

- Night Stand: Online ExtrasDocument2 pagesNight Stand: Online ExtrasDavid TuaineNo ratings yet

- Modern Plant Stand PlanDocument6 pagesModern Plant Stand PlanJorge NavarroNo ratings yet

- WS22418 Dresser Top ValetDocument8 pagesWS22418 Dresser Top Valetrigono1664No ratings yet

- French Cleat Tool WallDocument6 pagesFrench Cleat Tool WallKeith WilliamsNo ratings yet

- ShopNotes 126Document52 pagesShopNotes 126Keith WilliamsNo ratings yet

- The Complete Small ShopDocument115 pagesThe Complete Small ShopKeith WilliamsNo ratings yet

- Small Shop Solutions With Online ExtrasDocument109 pagesSmall Shop Solutions With Online ExtrasKeith WilliamsNo ratings yet

- Setting Up Shop With Online ExtrasDocument114 pagesSetting Up Shop With Online ExtrasKeith WilliamsNo ratings yet

- ShopNotes 124Document52 pagesShopNotes 124Keith Williams100% (2)

- ShopNotes 117Document52 pagesShopNotes 117Keith WilliamsNo ratings yet

- Rotary Tool Storage CaseDocument6 pagesRotary Tool Storage CaseKeith WilliamsNo ratings yet

- 4-Square Coffee Table WSDocument9 pages4-Square Coffee Table WSKeith WilliamsNo ratings yet

- Classic Two-Piece Library CabinetDocument12 pagesClassic Two-Piece Library CabinetKeith WilliamsNo ratings yet

- Drum Sander StationDocument6 pagesDrum Sander StationKeith WilliamsNo ratings yet

- Cabinetmaker's Tool ChestDocument8 pagesCabinetmaker's Tool ChestKeith WilliamsNo ratings yet

- Hobby BenchDocument14 pagesHobby BenchKeith WilliamsNo ratings yet

- America's Best Home Workshops W 2009Document132 pagesAmerica's Best Home Workshops W 2009Keith Williams100% (1)

- Table Saw Outfeed Table PlansDocument10 pagesTable Saw Outfeed Table PlansKeith WilliamsNo ratings yet

- Plywood Working For EverybodyDocument225 pagesPlywood Working For EverybodyKeith WilliamsNo ratings yet

- Table Saw Crosscut JigDocument3 pagesTable Saw Crosscut JigKeith WilliamsNo ratings yet

- Table Saw Dovetail JigDocument4 pagesTable Saw Dovetail JigKeith Williams100% (1)

- Small Clamp Storage RackDocument2 pagesSmall Clamp Storage RackKeith WilliamsNo ratings yet

- Table Saw Featherboard JigDocument1 pageTable Saw Featherboard JigKeith WilliamsNo ratings yet

- Table Saw Blade Height GaugeDocument1 pageTable Saw Blade Height GaugeKeith WilliamsNo ratings yet

- Plywood Working For EverybodyDocument225 pagesPlywood Working For EverybodyKeith WilliamsNo ratings yet

- GypsyDocument5 pagesGypsyKeith WilliamsNo ratings yet

- Polar BearDocument6 pagesPolar BearKeith WilliamsNo ratings yet

- Crawfish IceboatDocument8 pagesCrawfish IceboatKeith WilliamsNo ratings yet

- SkippyDocument7 pagesSkippyKeith WilliamsNo ratings yet

- DoretteDocument5 pagesDoretteKeith WilliamsNo ratings yet

- PattyDocument6 pagesPattyKeith WilliamsNo ratings yet

- CongaDocument7 pagesCongaKeith WilliamsNo ratings yet

- Column c4 From 3rd FloorDocument1 pageColumn c4 From 3rd Floor1man1bookNo ratings yet

- Daoyin Physical Calisthenics in The Internal Arts by Sifu Bob Robert Downey Lavericia CopelandDocument100 pagesDaoyin Physical Calisthenics in The Internal Arts by Sifu Bob Robert Downey Lavericia CopelandDragonfly HeilungNo ratings yet

- Ra Wah Night Shift - Word Format FiniDocument17 pagesRa Wah Night Shift - Word Format FiniREHOBOTH YAMBO KAHILUNo ratings yet

- NCERT Solutions For Class 12 Maths Chapter 10 Vector AlgebraDocument51 pagesNCERT Solutions For Class 12 Maths Chapter 10 Vector AlgebraKavin .J.S (KingK)No ratings yet

- Phytoremediation Acuatic PlantsDocument120 pagesPhytoremediation Acuatic PlantsFranco Portocarrero Estrada100% (1)

- ELC609F12 Lec0 IntroductionDocument16 pagesELC609F12 Lec0 IntroductionMohammed El-AdawyNo ratings yet

- Double-Outlet Right Ventricle With An An Intact Interventricular Septum and Concurrent Hypoplastic Left Ventricle in A CalfDocument6 pagesDouble-Outlet Right Ventricle With An An Intact Interventricular Septum and Concurrent Hypoplastic Left Ventricle in A CalfYoga RivaldiNo ratings yet

- Paper 2 With Solution MathematicsDocument17 pagesPaper 2 With Solution MathematicsFaiz AhmadNo ratings yet

- XC24M MG DatasheetDocument3 pagesXC24M MG DatasheetAbdulJawad Ibrahim ElmezoghiNo ratings yet

- VAM Must Sumitomo 1209 PDFDocument4 pagesVAM Must Sumitomo 1209 PDFnwohapeterNo ratings yet

- Certified: Steelfab of VirginiaDocument1 pageCertified: Steelfab of VirginiaRamume188No ratings yet

- Science 10 Quarter 2 Module 4Document6 pagesScience 10 Quarter 2 Module 4Jess Anthony Efondo100% (4)

- FORD Falcon XA Repair ManualDocument770 pagesFORD Falcon XA Repair ManualMark Kenzie100% (10)

- CopernikDocument2 pagesCopernikSinister JinNo ratings yet

- Chinese ArchitectureDocument31 pagesChinese Architecturenusantara knowledge100% (2)

- Varaah KavachDocument7 pagesVaraah KavachBalagei Nagarajan100% (1)

- Adminstration of Intramusclar InjectionDocument3 pagesAdminstration of Intramusclar InjectionDenise CastroNo ratings yet

- Beretta 92fs PistolDocument12 pagesBeretta 92fs PistolMustansir Bandukwala67% (3)

- Advanced Steel Structure Concepts: 2 MonthsDocument4 pagesAdvanced Steel Structure Concepts: 2 MonthsAnkit SoniNo ratings yet

- The Explanation of The Fundamentals of Islamic BeliefDocument95 pagesThe Explanation of The Fundamentals of Islamic BeliefbooksofthesalafNo ratings yet

- The World S Finest Ideas in Cooling!: A Division ofDocument4 pagesThe World S Finest Ideas in Cooling!: A Division ofChiragNo ratings yet

- Master Key Utbk Saintek 2022 (Paket 3) Bahasa InggrisDocument5 pagesMaster Key Utbk Saintek 2022 (Paket 3) Bahasa InggrisRina SetiawatiNo ratings yet

- Ieee 802Document3 pagesIeee 802M Zubair AslamNo ratings yet

- 100 Years of Hydrodynamic PDFDocument28 pages100 Years of Hydrodynamic PDFnikodjoleNo ratings yet

- AC350 Specs UsDocument18 pagesAC350 Specs Uskloic1980100% (1)

- Art and Geography: Patterns in The HimalayaDocument30 pagesArt and Geography: Patterns in The HimalayaBen WilliamsNo ratings yet

- Yamaha r6 Yec Kit ManualDocument2 pagesYamaha r6 Yec Kit ManualAlexander0% (1)

- Tank Gauging TankvisionDocument31 pagesTank Gauging Tankvisionkhangduongda3No ratings yet

- Eoi QAMDocument6 pagesEoi QAMPeeyush SachanNo ratings yet

- Draft STATCOM Maintenance Schedule (FINAL)Document36 pagesDraft STATCOM Maintenance Schedule (FINAL)Sukanta Parida100% (2)

- 100 Micro Amigurumi: Crochet patterns and charts for tiny amigurumiFrom Everand100 Micro Amigurumi: Crochet patterns and charts for tiny amigurumiRating: 5 out of 5 stars5/5 (2)

- Crochet with London Kaye: Projects and Ideas to Yarn Bomb Your LifeFrom EverandCrochet with London Kaye: Projects and Ideas to Yarn Bomb Your LifeRating: 5 out of 5 stars5/5 (1)

- Crochet Zodiac Dolls: Stitch the horoscope with astrological amigurumiFrom EverandCrochet Zodiac Dolls: Stitch the horoscope with astrological amigurumiRating: 4 out of 5 stars4/5 (3)

- House Rules: How to Decorate for Every Home, Style, and BudgetFrom EverandHouse Rules: How to Decorate for Every Home, Style, and BudgetNo ratings yet

- The Martha Manual: How to Do (Almost) EverythingFrom EverandThe Martha Manual: How to Do (Almost) EverythingRating: 4 out of 5 stars4/5 (11)

- Crochet Impkins: Over a million possible combinations! Yes, really!From EverandCrochet Impkins: Over a million possible combinations! Yes, really!Rating: 4.5 out of 5 stars4.5/5 (10)

- Dream Sewing Spaces: Design & Organization for Spaces Large & SmallFrom EverandDream Sewing Spaces: Design & Organization for Spaces Large & SmallRating: 4 out of 5 stars4/5 (24)

- Crochet Collage Garden: 100 patterns for crochet flowers, plants and petalsFrom EverandCrochet Collage Garden: 100 patterns for crochet flowers, plants and petalsRating: 5 out of 5 stars5/5 (1)

- The Botanical Hand Lettering Workbook: Draw Whimsical & Decorative Styles & ScriptsFrom EverandThe Botanical Hand Lettering Workbook: Draw Whimsical & Decorative Styles & ScriptsRating: 4.5 out of 5 stars4.5/5 (2)

- Crochet Donut Buddies: 50 easy amigurumi patterns for collectible crochet toysFrom EverandCrochet Donut Buddies: 50 easy amigurumi patterns for collectible crochet toysRating: 4.5 out of 5 stars4.5/5 (7)

- Radical Sewing: Pattern-Free, Sustainable Fashions for All BodiesFrom EverandRadical Sewing: Pattern-Free, Sustainable Fashions for All BodiesNo ratings yet

- Crochet Pattern Books: The Ultimate Complete Guide to Learning How to Crochet FastFrom EverandCrochet Pattern Books: The Ultimate Complete Guide to Learning How to Crochet FastRating: 5 out of 5 stars5/5 (1)

- Crochet Creatures of Myth and Legend: 19 Designs Easy Cute Critters to Legendary BeastsFrom EverandCrochet Creatures of Myth and Legend: 19 Designs Easy Cute Critters to Legendary BeastsRating: 4.5 out of 5 stars4.5/5 (10)

- Modern Granny Stitch Crochet: Make clothes and accessories using the granny stitchFrom EverandModern Granny Stitch Crochet: Make clothes and accessories using the granny stitchRating: 5 out of 5 stars5/5 (1)

- Big Book of Pretty & Playful Appliqué: 150+ Designs, 4 Quilt Projects Cats & Dogs at Play, Gardens in Bloom, Feathered Friends & MoreFrom EverandBig Book of Pretty & Playful Appliqué: 150+ Designs, 4 Quilt Projects Cats & Dogs at Play, Gardens in Bloom, Feathered Friends & MoreRating: 4.5 out of 5 stars4.5/5 (3)

- Kawaii Crochet Garden: 40 super cute amigurumi patterns for plants and moreFrom EverandKawaii Crochet Garden: 40 super cute amigurumi patterns for plants and moreRating: 5 out of 5 stars5/5 (5)

- Amigurumi Cats: Crochet Sweet Kitties the Japanese Way (24 Projects of Cats to Crochet)From EverandAmigurumi Cats: Crochet Sweet Kitties the Japanese Way (24 Projects of Cats to Crochet)No ratings yet

- A Life in Stitches: Knitting My Way Through Love, Loss, and Laughter - Tenth Anniversary EditionFrom EverandA Life in Stitches: Knitting My Way Through Love, Loss, and Laughter - Tenth Anniversary EditionRating: 4.5 out of 5 stars4.5/5 (23)

- Celtic Line Drawing - Simplified InstructionsFrom EverandCeltic Line Drawing - Simplified InstructionsRating: 5 out of 5 stars5/5 (4)

- Knit Soxx for Everyone: 25 Colorful Sock Patterns for the Whole FamilyFrom EverandKnit Soxx for Everyone: 25 Colorful Sock Patterns for the Whole FamilyRating: 4.5 out of 5 stars4.5/5 (2)

- Two Simple Shapes = 26 Crocheted Cardigans, Tops & Sweaters: If you can crochet a square and rectangle, you can make these easy-to-wear designs!From EverandTwo Simple Shapes = 26 Crocheted Cardigans, Tops & Sweaters: If you can crochet a square and rectangle, you can make these easy-to-wear designs!Rating: 3 out of 5 stars3/5 (2)

- Friends: The One with the Crochet: The Official Crochet Pattern BookFrom EverandFriends: The One with the Crochet: The Official Crochet Pattern BookRating: 5 out of 5 stars5/5 (1)

- Crochet Southwest Spirit: Over 20 Bohemian Crochet Patterns Inspired by the American SouthwestFrom EverandCrochet Southwest Spirit: Over 20 Bohemian Crochet Patterns Inspired by the American SouthwestRating: 5 out of 5 stars5/5 (2)

- Timeless Textured Baby Crochet: 20 heirloom crochet patterns for babies and toddlersFrom EverandTimeless Textured Baby Crochet: 20 heirloom crochet patterns for babies and toddlersNo ratings yet

- Crochet Lace: Techniques, Patterns, and ProjectsFrom EverandCrochet Lace: Techniques, Patterns, and ProjectsRating: 3.5 out of 5 stars3.5/5 (3)

- Watercolor: Wild & Free: Paint Cute Animals and Wildlife in 12 Easy LessonsFrom EverandWatercolor: Wild & Free: Paint Cute Animals and Wildlife in 12 Easy LessonsNo ratings yet

- Tunisian Crochet for Beginners: Step-by-step Instructions, plus 5 Patterns!From EverandTunisian Crochet for Beginners: Step-by-step Instructions, plus 5 Patterns!Rating: 5 out of 5 stars5/5 (3)