Professional Documents

Culture Documents

Passivation Titration Instructions

Uploaded by

Manolo CastilloOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Passivation Titration Instructions

Uploaded by

Manolo CastilloCopyright:

Available Formats

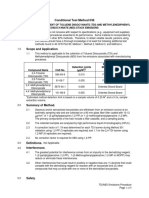

PASSIVATION TITRATION INSTRUCTIONS

1 PURPOSE & APPLICATION 3.3.1.3 Using a pair of green tongs, completely immerse the 125

1.1 The purpose of this instruction is to provide guidance in preparing for ml bottle into the chemical solution to be analyzed until

and performing analytical, wet titrations for the passivation bath. completely full.

1.2 It applies to all personnel that perform titration of the passivation 3.3.1.4 Pour approximately 5 ml of the solution from the bottle

bath. back into the chemical tank.

3.3.1.5 Tightly secure the cap on the 125 ml bottle and wipe the

2 RESPONSIBILITIES outside of the bottle to remove excess chemicals.

3.3.1.6 Immediately label the bottle with the following

2.1 Lab Technician:

information:

2.1.1 Performs weekly solution analysis methods as outlined in

3.3.1.6.1 Date.

this instruction.

3.3.1.6.2 Process identification and contents of the bottle.

2.1.2 Maintains a safe environment for all authorized personnel.

3.3.1.7 Repeat paragraphs 3.1.1 through 3.1.6 for each

2.1.3 Communicates all findings and/or abnormal results

chemical tank to be analyzed.

associated with passivation to the Production Manager.

3.3.2 Titrations for Type VI and VIII

2.1.4 Makes chemical additions recommendations as needed.

3.3.2.1 In the lab pipette a 5 ml sample from the 125 ml bottle.

3.3.2.2 Place the 5 ml sample in a 250 ml beaker and

3 INSTRUCTION thoroughly rinse the pipette out.

3.1 Related Documents 3.3.2.3 Measure a 100 ml sample of DI water and add to the 5

3.1.1 MQ-04-15-00-00 – Laboratory Procedure ml sample in the 250 ml beaker.

3.1.2 MQ-04-19-01-00 – Passivation of 300, 400, and pH Series 3.3.2.4 Place a small spin bar inside of the 250 ml beaker and

Stainless Steel place on the magnetic plate.

3.2 General 3.3.2.5 Turn the magnetic plate to level 2 and allow solution to

3.2.1 Keep the laboratory and its equipment clean of contaminates mix.

that could be detrimental to the process or violate safety procedures. 3.3.2.6 Calibrate the pH meter with a 7.00 and a 4.00 pH buffer.

3.2.2 The processor shall be familiar with all the MSDS’s related to 3.3.2.7 Once the calibration is completed place the pH probe

the chemicals used in this process as well as the processes being into the 250 ml beaker.

tested. 3.3.2.8 Titrate the solution to a 3.5 pH with a 1.0N NaOH

3.2.3 The operator shall be familiar with the emergency actions (Sodium Hydroxide).

specified in the Employee Handbook, MO-02-00-01-00. 3.3.2.9 Record results in computer logbook. The computer will

3.2.4 Process records on solutions and actions taken are retained update SPC data.

for 7 years. 3.3.2.9.1 The computer calculation is ml’s of NaOH used

3.3 Perform chemical analysis per the applicable section of this X 1.68 = oz/gal nitric Acid.

procedure. 3.3.2.9.2 If the solution is out of the SPC control limits

3.3.1 Sample preparation. (UCL, LCL), make the adjustments as required and re-titrate.

3.3.1.1 Obtain a clean 125 ml. bottle for the chemical tank to be 3.3.2.9.3 If the solution is out of specification tolerance

analyzed. (USL, LSL), immediately halt production, notify the PM of the

3.3.1.2 Thoroughly agitate the chemical tank to be analyzed. condition, make the necessary adjustments, then retest the

solution.

Passivation Titration Instructions |1| Date Printed

MQ-04-15-07-00 rev 01 Expires 1 day after printing Oct 17, 2006

3.3.2.9.3.1 Resume production when the solution is

within the SPC control limits.

3.3.2.9.3.2 The PM investigates the condition and

notifies the Quality Director and Plant 2 Operations

Director.

3.3.2.9.3.3 Investigation of products affected will be

performed and action taken per customer requirements.

3.3.2.9.4 Record all adjustments in the appropriate log.

3.3.2.10 Remove the solution from the magnetic stir machine

and pour the solution into the hazardous waste holding tank,

without dumping the stir bar.

3.3.2.11 Rinse the beaker and the stir bar with clean water

and dry off with a clean cotton towel.

4 REVISION HISTORY – Authored by Ray Smith, approved 13 Sep

2002.

4.1 Changed responsibility for notifying the Quality director of out of

tolerance analyses to the Production Manager, changed record retention

to 7 years. Authored by John Topping, approved 2 Dec 2002.

Approvals

2 Dec 2002

Document Custodian Date

2 Dec 2002

Quality Director Date

Passivation Titration Instructions |2| Date Printed

MQ-04-15-07-00 rev 01 Expires 1 day after printing Oct 17, 2006

You might also like

- Media Fill ProtocolDocument33 pagesMedia Fill Protocoltetemaestro83% (6)

- Surface Preparation Specification No. 15: SSPC: The Society For Protective CoatingsDocument6 pagesSurface Preparation Specification No. 15: SSPC: The Society For Protective CoatingsManolo CastilloNo ratings yet

- Unit 2.25 Thiobarbituric Acid Index (TBI) Determination by SpectrosDocument8 pagesUnit 2.25 Thiobarbituric Acid Index (TBI) Determination by SpectrosRiyanNo ratings yet

- D 2574 - 97 Rdi1nzqtukveDocument4 pagesD 2574 - 97 Rdi1nzqtukveGuritno GustiantoNo ratings yet

- Methylnaltrexone Bromide 3.2.P.5 Control of Drug Product 3.2.P.5.2 Analytical ProceduresDocument7 pagesMethylnaltrexone Bromide 3.2.P.5 Control of Drug Product 3.2.P.5.2 Analytical ProceduresSneyder CorredorNo ratings yet

- 6 Coliforms MPNDocument3 pages6 Coliforms MPNVIRAL viralmladNo ratings yet

- Detector: Flame Ionization (FID) - GC Column: 3-m X 2-mm I.D. Glass Column Packed With 10% OV-101Document8 pagesDetector: Flame Ionization (FID) - GC Column: 3-m X 2-mm I.D. Glass Column Packed With 10% OV-101Yesid Orlando Caro RosellonNo ratings yet

- 3.2.1 Anti HIV Testing (ELISA Method)Document5 pages3.2.1 Anti HIV Testing (ELISA Method)BALAJINo ratings yet

- SOP For Water Filteration PlantDocument1 pageSOP For Water Filteration PlantAsad UllahNo ratings yet

- Act-1 SopDocument6 pagesAct-1 SopthomassreisNo ratings yet

- Antimicrobial AssayDocument14 pagesAntimicrobial AssayArvin GerlabanNo ratings yet

- Sn-Qc-Sapp-012 Wadin 250MG Caps.Document7 pagesSn-Qc-Sapp-012 Wadin 250MG Caps.daizhussain004No ratings yet

- CTM 036 TDI EmisionesDocument8 pagesCTM 036 TDI EmisionesNicolas ZeballosNo ratings yet

- Determining Logarithmic Viscosity Number of Poly (Vinyl Chloride) (PVC) in Formulated CompoundsDocument4 pagesDetermining Logarithmic Viscosity Number of Poly (Vinyl Chloride) (PVC) in Formulated CompoundsCheolhyeon ChoNo ratings yet

- SN-QC-SAPP-029 Neamin 500mcg TabletDocument4 pagesSN-QC-SAPP-029 Neamin 500mcg Tabletdaizhussain004No ratings yet

- Mercurous Nitrate Test For Copper and Copper AlloysDocument3 pagesMercurous Nitrate Test For Copper and Copper AlloysLUISALBERTO06011985No ratings yet

- Analysis of Isocyanates Liquid Chromatography: Diode Array/MSDDocument11 pagesAnalysis of Isocyanates Liquid Chromatography: Diode Array/MSDDianthony LuisNo ratings yet

- Method of Test For Non-Volatile Content of Chemical Admixtures, Latex Admixtures and Curing CompoundsDocument3 pagesMethod of Test For Non-Volatile Content of Chemical Admixtures, Latex Admixtures and Curing Compoundsming_zhu10No ratings yet

- D 1766 - 01 - Rde3njyDocument2 pagesD 1766 - 01 - Rde3njyDr. Ahmed Abdel-HakimNo ratings yet

- Rat HbA1c Assay v4Document6 pagesRat HbA1c Assay v4Amos Babu JettiNo ratings yet

- Astm D5355 95Document1 pageAstm D5355 95gmpd.labNo ratings yet

- Standard Operating Procedure Somatec: TITLE: SOP FOR DM Plant SanitizationDocument3 pagesStandard Operating Procedure Somatec: TITLE: SOP FOR DM Plant SanitizationMajed HossainNo ratings yet

- MSC-Circ 798Document10 pagesMSC-Circ 798DujeKnezevicNo ratings yet

- Chemical Engineering AssignmentsDocument43 pagesChemical Engineering AssignmentsMalik DaniyalNo ratings yet

- DOC022.53.80225 10edDocument138 pagesDOC022.53.80225 10edPedro MamaniNo ratings yet

- Lab Report 3, P1-L01, G5Document10 pagesLab Report 3, P1-L01, G5Arham SyamNo ratings yet

- GC Residual Solvents PharmaceuticalsDocument7 pagesGC Residual Solvents PharmaceuticalsReem MohamedNo ratings yet

- Methodology PDFDocument15 pagesMethodology PDFEzwan HanafiahNo ratings yet

- Pierce Micro BCA Protein AssayDocument6 pagesPierce Micro BCA Protein AssayTim CharltonNo ratings yet

- Introduction 3Document11 pagesIntroduction 3cindyn_46No ratings yet

- Acm 003Document5 pagesAcm 003Roan BNo ratings yet

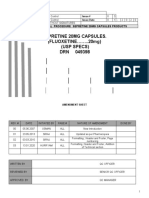

- Sn-Qc-Sapp-014 Xegen 20MG Caps.Document6 pagesSn-Qc-Sapp-014 Xegen 20MG Caps.daizhussain004No ratings yet

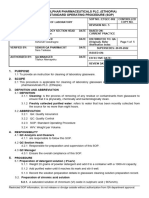

- SN-QC-SAPP-005 Sepretine 20mg CapsDocument6 pagesSN-QC-SAPP-005 Sepretine 20mg Capsdaizhussain004No ratings yet

- AA - SPEC - GRAVITY - SOP - 5730220 - 01 (Eeee)Document7 pagesAA - SPEC - GRAVITY - SOP - 5730220 - 01 (Eeee)Joe LavaNo ratings yet

- ETQCC 002 EditedDocument5 pagesETQCC 002 EditedTilahun AlemayehuNo ratings yet

- SOP For Cleaning and Sterilization of Glass Ware Used in Microbiology Lab.Document3 pagesSOP For Cleaning and Sterilization of Glass Ware Used in Microbiology Lab.Bejoy Karim100% (1)

- FOODCHEM EXP 6 EnzymeDocument10 pagesFOODCHEM EXP 6 EnzymesitinurhanizaNo ratings yet

- Waste Management SopDocument8 pagesWaste Management SopLibérée Rumagihwa100% (1)

- Full Download Book Integration and Optimization of Unit Operations Review of Unit Operations From RD To Production Impacts of Upstream and Downstream Process Decisions PDFDocument41 pagesFull Download Book Integration and Optimization of Unit Operations Review of Unit Operations From RD To Production Impacts of Upstream and Downstream Process Decisions PDFlouise.cowell660100% (16)

- 9023Document8 pages9023Sylab InstrumentsNo ratings yet

- Determining Silicone Volatiles in Silicone Rubber For Transportation ApplicationsDocument3 pagesDetermining Silicone Volatiles in Silicone Rubber For Transportation ApplicationsAMUL VEKARIANo ratings yet

- C837.1207978-1 (Azul de Metileno)Document2 pagesC837.1207978-1 (Azul de Metileno)Victor Manuel50% (2)

- Micro BCA™ Protein Assay Kit: InstructionsDocument6 pagesMicro BCA™ Protein Assay Kit: InstructionsThearith UngNo ratings yet

- In Vitro Test Method Which Determines TheDocument12 pagesIn Vitro Test Method Which Determines TheSiti InayahNo ratings yet

- Practice 7Document3 pagesPractice 7Neha SharmaNo ratings yet

- Lab Report Jar TestDocument10 pagesLab Report Jar TestnainaNo ratings yet

- ACM THA 06 Testing MethodDocument13 pagesACM THA 06 Testing MethodThanh ThảoNo ratings yet

- 3 TPCDocument3 pages3 TPCVIRAL viralmladNo ratings yet

- Biological Control Agents As Alternative TTo FungicidesDocument131 pagesBiological Control Agents As Alternative TTo FungicidesEsquepiola EsquejesNo ratings yet

- 5.3.2.2 Prednisone Standard Solution: Procedure Number: Page 6 of 13 TitleDocument2 pages5.3.2.2 Prednisone Standard Solution: Procedure Number: Page 6 of 13 TitlenutrimakeNo ratings yet

- Sn-Qc-Sapp-001 Fitcid 30MG Caps.Document7 pagesSn-Qc-Sapp-001 Fitcid 30MG Caps.daizhussain004No ratings yet

- MEA-Application Note - HL-1Document13 pagesMEA-Application Note - HL-1xiaochenhuang87No ratings yet

- Sn-Qc-Sapp-006 Shaez 40MG CapsDocument7 pagesSn-Qc-Sapp-006 Shaez 40MG Capsdaizhussain004No ratings yet

- 〈206〉 AluminumDocument3 pages〈206〉 AluminumAvijit HazraNo ratings yet

- Safety 2020-21Document5 pagesSafety 2020-21SKITTLE BEASTNo ratings yet

- Sn-Qc-Sapp-008 Shawbal CapsDocument6 pagesSn-Qc-Sapp-008 Shawbal Capsdaizhussain004No ratings yet

- 1Document4 pages1AIN NUR AISYAH MOHAMAD SUHAILINo ratings yet

- Advanced Dairy Science and TechnologyFrom EverandAdvanced Dairy Science and TechnologyTrevor BritzNo ratings yet

- Sample Preparation Techniques in Analytical ChemistryFrom EverandSample Preparation Techniques in Analytical ChemistrySomenath MitraNo ratings yet

- Reactive Distillation: Status and Future DirectionsFrom EverandReactive Distillation: Status and Future DirectionsKai SundmacherRating: 1 out of 5 stars1/5 (1)

- Rust TestDocument16 pagesRust TestManolo CastilloNo ratings yet

- 7 Things To Know About Flash RustDocument4 pages7 Things To Know About Flash RustManolo CastilloNo ratings yet

- Stainless Steel and CorrosionDocument11 pagesStainless Steel and CorrosionManolo CastilloNo ratings yet

- Stainless Steel 303Document13 pagesStainless Steel 303Manolo CastilloNo ratings yet