Professional Documents

Culture Documents

pwm-900 Clockinginst

Uploaded by

Taller PahrOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

pwm-900 Clockinginst

Uploaded by

Taller PahrCopyright:

Available Formats

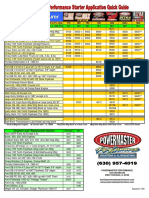

Ph.

630-957-4019

1833 Downs Drive Clocking Instructions

West Chicago, IL 60185

www.powermasterperformance.com Infi-CLOCK Starter

IMPORTANT!

If “clocking” of the starter block is required,

it is critical that the infi-CLOCK ring be tightened correctly. TM

Note: The starter comes pre-clocked for most applications.

Clocking steps:

1. Loosen the two bolts that retain the infi-CLOCK

ring using a T25 TORX bit.

DO NOT USE A HEX KEY.

2. Temporarily mount the starter to the engine.

3. Rotate the starter body to the preferred

position and make a reference mark from the

starter block to the starter body.

4. Remove the starter. Using Blue Loctite® or

equivalent thread lock on

5. Rotate the block into position and tighten the two ring bolts is

the two ring bolts. The bolts must be REQUIRED!

tightened evenly. While holding the ring

parallel to the block, lightly snug each bolt.

Evenly tighten the bolts in an alternating

pattern. Torque to 50 in/lbs. Inspect the ring

again to be certain it is parallel to the block.

6. Reinstall the starter to the engine.

* Ring and block face must

be parallel after clocking is

complete.

See Reverse side for

Shimming Instructions

04/03/2017 900_IS_ClockingInst ©Powermaster Performance

Ph. 630-957-4019

1833 Downs Drive Shimming Instructions

West Chicago, IL 60185 Infi-CLOCK Starter

www.powermasterperformance.com

IMPORTANT!

It is critical that the infi-CLOCK ring be tightened correctl . TM

After the starter has been installed, there should be 1/16” (0.062) mini-

mum between the engine side of the ring gear and the front edge of the

teeth on the starter pinion gear. Check this distance with the ring gear in

at least three different positions. If the distance is too little, a shim can

be installed inside the starter, which will pull the pinion into the starter an

additional 1/16” (0.062). This will result in additional clearance between

the pinion and the ring gear.

1. Mark the starter body to starter block position so it

can be correctly positioned during reassembly. Ring Bolts

(Figure 1)

2. Remove the two bolts that retain the infi-CLOCK ring

using a T25 TORX bit (figure 1).

Using Blue Loctite® or

DO NOT USE A HEX KEY.

equivalent thread lock on

3. Remove the ring and block.

the two ring bolts is

4. Install the shim and reassemble as shown (figure 2) REQUIRED!

5. Rotate the block into position and tighten the two

ring bolts. The bolts must be tightened evenly. While

holding the ring parallel to the block, lightly snug each

bolt (figure 3). Evenly tighten the bolts in an alterna -

ing pattern. Torque to 50 in/lbs. Inspect the ring again

to be certain it is parallel to the block.

6. Reinstall the starter to the engine.

(Figure 2)

*Ring and block face must be *Powermaster recommends no more than one set of

parallel after clocking is com- internal shims be installed in a starter.

plete. (figure 3

04/03/2017 907_IS_InfiCLOCKshim ©Powermaster Performance

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Aw55 51leDocument369 pagesAw55 51leJuanortega92% (37)

- 3.03 3-Speed ToploaderDocument13 pages3.03 3-Speed ToploaderTaller Pahr50% (2)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 6 HP 26Document92 pages6 HP 26Atanas Janchev100% (1)

- Transmission Eccom 1.5Document179 pagesTransmission Eccom 1.5Sabadsag DariusNo ratings yet

- F4a51 PDFDocument82 pagesF4a51 PDFJoão Ezer0% (1)

- Transmissao CVT - Jf010e - Jf011eDocument56 pagesTransmissao CVT - Jf010e - Jf011eautomaticosbrasil100% (1)

- Pcsection prh081Document2 pagesPcsection prh081Taller PahrNo ratings yet

- Ver Paginas 18 y 19Document28 pagesVer Paginas 18 y 19Taller PahrNo ratings yet

- ETERNAL A10V Series 52 53Document49 pagesETERNAL A10V Series 52 53Taller PahrNo ratings yet

- Testeo TransmisionDocument53 pagesTesteo TransmisionTaller Pahr100% (1)

- PLL 1388Document12 pagesPLL 1388Taller PahrNo ratings yet

- CAT 769c Valvula de Control de Transmision 1Document28 pagesCAT 769c Valvula de Control de Transmision 1Taller Pahr100% (1)

- CAT 320 Holgura BaldeDocument3 pagesCAT 320 Holgura BaldeTaller PahrNo ratings yet

- PWM 9604Document1 pagePWM 9604Taller PahrNo ratings yet

- Sem 816d TT Data SheetDocument2 pagesSem 816d TT Data SheetTaller PahrNo ratings yet

- CAT 769 C Especificaciones Transmision 1Document41 pagesCAT 769 C Especificaciones Transmision 1Taller PahrNo ratings yet

- CAT 769c Valvula de Freno de Parking1Document3 pagesCAT 769c Valvula de Freno de Parking1Taller PahrNo ratings yet

- CAT 769c Valvula de Freno de ParkingDocument2 pagesCAT 769c Valvula de Freno de ParkingTaller PahrNo ratings yet

- Inlet Elements With Limitation of Primary Pressure, LS Compensated Ow Control and Solenoid Operated UnloadingDocument4 pagesInlet Elements With Limitation of Primary Pressure, LS Compensated Ow Control and Solenoid Operated UnloadingTaller PahrNo ratings yet

- Eaton YBV Brake Valves: © 2019 Eaton. All Rights ReservedDocument18 pagesEaton YBV Brake Valves: © 2019 Eaton. All Rights ReservedTaller PahrNo ratings yet

- 604 605 610 611 612 InstructionsDocument1 page604 605 610 611 612 InstructionsTaller PahrNo ratings yet

- Starter App Quick Guide 2013Document1 pageStarter App Quick Guide 2013Taller PahrNo ratings yet

- 18 RepDocument146 pages18 RepTaller PahrNo ratings yet

- Technical Information: TMK, TMKW and TMK FL Orbital MotorsDocument28 pagesTechnical Information: TMK, TMKW and TMK FL Orbital MotorsTaller PahrNo ratings yet

- Nhce Hydraulic Excavator E215c EvoDocument4 pagesNhce Hydraulic Excavator E215c EvoTaller PahrNo ratings yet

- Cavidad Hydraforce 9-108-1Document5 pagesCavidad Hydraforce 9-108-1Taller PahrNo ratings yet

- RE18301-91 - Cartridge Valves - NloDocument12 pagesRE18301-91 - Cartridge Valves - NloTaller PahrNo ratings yet

- RE18300-06 TE06 NloDocument4 pagesRE18300-06 TE06 NloTaller PahrNo ratings yet

- Resource Guide: Information On Tool Selection, Grit Selection, Suggested RPM's and MoreDocument6 pagesResource Guide: Information On Tool Selection, Grit Selection, Suggested RPM's and MoreTaller PahrNo ratings yet

- Insert Type, Relief, Direct Acting Poppet Type: Special Cavity, 730-ADocument2 pagesInsert Type, Relief, Direct Acting Poppet Type: Special Cavity, 730-ATaller PahrNo ratings yet

- Power Flow in Transmission - Neutral ZFDocument25 pagesPower Flow in Transmission - Neutral ZFSeshagiri Deenadayalu100% (3)

- Maaggear CpuDocument8 pagesMaaggear Cpuhumayun121No ratings yet

- Differential GearDocument28 pagesDifferential GearFauzan BillyNo ratings yet

- A Review On: Stair Climber Material Handling SystemDocument4 pagesA Review On: Stair Climber Material Handling SystemS. ThivyanNo ratings yet

- BR Cat 300ind Nem Eng r00 0Document608 pagesBR Cat 300ind Nem Eng r00 0Putut Suprihartono100% (1)

- Section 6007 Mechanical Front Drive AxleDocument52 pagesSection 6007 Mechanical Front Drive Axlelungu mihaiNo ratings yet

- BME Assessment 02 QPDocument2 pagesBME Assessment 02 QPSiddharth MohananNo ratings yet

- System of Pulleys AND Gear TrainDocument22 pagesSystem of Pulleys AND Gear TrainMohammad TahaNo ratings yet

- Hyster F007 (H8.00-12.00XM Europe) ForkliftDocument21 pagesHyster F007 (H8.00-12.00XM Europe) ForkliftHector Peña100% (1)

- ExperimentsDocument4 pagesExperimentsRohitGuptaNo ratings yet

- Details of GearsDocument88 pagesDetails of Gearsramchandra rao deshpandeNo ratings yet

- Wind Turbine Nacelle Thermal ManagementDocument18 pagesWind Turbine Nacelle Thermal ManagementAbhijeetNo ratings yet

- C Engine Electrical: To IndexDocument29 pagesC Engine Electrical: To Indexwei fooNo ratings yet

- Epicyclic Gearbox Components Working Principle Advantages Disadvantages and Applications PDFDocument7 pagesEpicyclic Gearbox Components Working Principle Advantages Disadvantages and Applications PDFDarshan UghadeNo ratings yet

- Gear Box Design Project Two: Faculity of Mechanical and Industrial EngineeringDocument131 pagesGear Box Design Project Two: Faculity of Mechanical and Industrial Engineeringnigusu sisayNo ratings yet

- DRIVELINEAXLES Rear Axle - 267 AA (10 12) - Ram Pickup PDFDocument78 pagesDRIVELINEAXLES Rear Axle - 267 AA (10 12) - Ram Pickup PDFcharlesNo ratings yet

- HW19710 Instruções de OperaçãoDocument14 pagesHW19710 Instruções de OperaçãoJuarezGeronimo100% (8)

- Industrial Planetary Gearmotors SEWDocument364 pagesIndustrial Planetary Gearmotors SEWDaniel SmsNo ratings yet

- Automatic TransmissionDocument358 pagesAutomatic TransmissionHassan ZAFFA CISNEROS100% (1)

- UA-Series EN F2005E-3.0 0302Document25 pagesUA-Series EN F2005E-3.0 0302PrimanedyNo ratings yet

- IMO Slew DriveST211-GBDocument61 pagesIMO Slew DriveST211-GBNemanja ProrokNo ratings yet

- Working Principle of Single Clutch PlateDocument17 pagesWorking Principle of Single Clutch PlateThinesh Rau KrishnamurtyNo ratings yet

- Daka Research v. Schedule A - ComplaintDocument160 pagesDaka Research v. Schedule A - ComplaintSarah BursteinNo ratings yet

- Manual Del Estudiante d7r 2pdf PDF FreeDocument106 pagesManual Del Estudiante d7r 2pdf PDF FreehaiderNo ratings yet

- Group 2 Major Component: 1. Main PumpDocument11 pagesGroup 2 Major Component: 1. Main PumpHậu MinhNo ratings yet