Professional Documents

Culture Documents

Asme Sec Viii Div 1 Uw-51

Uploaded by

ALEXIS MORALES0 ratings0% found this document useful (0 votes)

2K views1 pageCopyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

2K views1 pageAsme Sec Viii Div 1 Uw-51

Uploaded by

ALEXIS MORALESCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

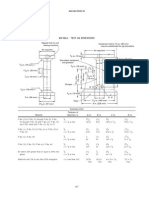

ASME BPVC.VIII.

1-2019 UW-50 – UW-52

(1) For Part UCS materials, the governing thickness where

as defined in UCS-66(a) shall be limited to a maximum

t = the thickness of the weld excluding any allowable re-

governing thickness of 1/2 in. (13 mm) for materials as-

inforcement. For a butt weld joining two members

signed to Curve A, and 1 in. (25 mm) for materials as-

having different thicknesses at the weld, t is the thin-

signed to Curve B, C, or D in Figure UCS-66.

ner of these two thicknesses. If a full penetration

(2) For austenitic chromium–nickel stainless steels

weld includes a fillet weld, the thickness of the throat

304, 304L, 316, 316L, 321, and 347 in Part UHA, the max-

of the fillet shall be included in t.

imum nominal material thickness shall be 3/4 in. (19 mm).

(3) For aluminum, aluminum alloy 3000 series, alu- (3) any group of aligned indications that have an ag-

minum alloy 5000 series, and aluminum alloy 6061-T6 gregate length greater than t in a length of 12t , except

in Part UNF, the maximum nominal material thickness when the distance between the successive imperfections

shall be 1 in. (25 mm). exceeds 6L where L is the length of the longest imperfec-

tion in the group;

ð19Þ UW-51 RADIOGRAPHIC EXAMINATION OF (4) rounded indications in excess of that specified by

WELDED JOINTS the acceptance standards given in Mandatory Appendix 4.

(a) All welded joints to be radiographed shall be exam-

ined in accordance with Section V, Article 2, except as spe- UW-52 SPOT EXAMINATION OF WELDED JOINTS

cified below. NOTE: Spot radiographing of a welded joint is recognized as an effec-

(1) A complete set of radiographic images and exam- tive inspection tool. The spot radiography rules are also considered

ination records, as described in Section V, Article 2, for to be an aid to quality control. Spot radiographs made directly after a

each vessel or vessel part shall be retained by the Manu- welder or an operator has completed a unit of weld proves that the

facturer, as follows: work is or is not being done in accordance with a satisfactory proce-

dure. If the work is unsatisfactory, corrective steps can then be taken

(-a) radiographic images until the Manufacturer’s

to improve the welding in the subsequent units, which unquestion-

Data Report has been signed by the Inspector ably will improve the weld quality.

(-b) examination records as required by this Divi-

Spot radiography in accordance with these rules will not ensure a

sion (10-13)

fabrication product of predetermined quality level throughout. It

(2) Demonstration of acceptable density on radio- must be realized that an accepted vessel under these spot radiogra-

graphic films and the ability to see the prescribed image phy rules may still contain defects which might be disclosed on

quality indicator (IQI) image and the specified hole or further examination. If all radiographically disclosed weld defects

the designated wire of a wire IQI shall be considered sat- must be eliminated from a vessel, then 100% radiography must be

isfactory evidence of compliance with Section V, Article 2. employed.

(3) The requirements of Section V, Article 2, T-274.2, (a) Butt-welded joints that are to be spot radiographed

are to be used only as a guide for film-based radiography. shall be examined locally as provided herein.

(4) As an alternative to the radiographic examination (b) Minimum Extent of Spot Radiographic Examination

requirements above, all welds in which the thinner of the (1) One spot shall be examined on each vessel for

members joined is 1/4 in. (6 mm) thick and greater may be each 50 ft (15 m) increment of weld or fraction thereof

examined using the ultrasonic (UT) method specified by for which a joint efficiency from column (b) of Table

UW-53(b). UW-12 is selected. However, for identical vessels or parts,

(b) Indications revealed by radiography within a weld each with less than 50 ft (15 m) of weld for which a joint

that exceed the following criteria are unacceptable and efficiency from column (b) of Table UW-12 is selected,

therefore are defects. Defects shall be repaired as pro- 50 ft (15 m) increments of weld may be represented by

vided in UW-38, and the repaired area shall be reexam- one spot examination.

ined. In lieu of reexamination by radiography, the (2) For each increment of weld to be examined, a suf-

repaired weld may be ultrasonically examined in accor- ficient number of spot radiographs shall be taken to ex-

dance with Mandatory Appendix 12 at the Manufacturer’s amine the welding of each welder or welding operator.

option. For material thicknesses in excess of 1 in. Under conditions where two or more welders or welding

(25 mm), the concurrence of the user shall be obtained. operators make weld layers in a joint, or on the two sides

This ultrasonic examination shall be noted under Re- of a double‐welded butt joint, one spot may represent the

marks on the Manufacturer’s Data Report Form: work of all welders or welding operators.

(1) any indication characterized as a crack or zone of (3) Each spot examination shall be made as soon as

incomplete fusion or penetration; practicable after completion of the increment of weld to

(2) any other elongated indication on the radiograph be examined. The location of the spot shall be chosen

which has length greater than: by the Inspector after completion of the increment of

(-a) 1/4 in. (6 mm) for t up to 3/4 in. (19 mm) welding to be examined, except that when the Inspector

(-b) 1/3 t for t from 3/4 in. (19 mm) to 2 1/4 in. has been notified in advance and cannot be present or

(57 mm) otherwise make the selection, the Manufacturer may ex-

(-c) 3/4 in. (19 mm) for t over 21/4 in. (57 mm) ercise his own judgment in selecting the spots.

153

--`,``,``,,`,`,,````,`,``,,,`-`-`,,`,,`,`,,`---

Copyright ASME International (BPVC)

Provided by IHS under license with ASME Licensee=Khalda Petroleum/5986215001, User=Amer, Mohamed

No reproduction or networking permitted without license from IHS Not for Resale, 07/02/2019 13:29:04 MDT

You might also like

- Asme Viii - Mandatoryappendix 12 - UtDocument1 pageAsme Viii - Mandatoryappendix 12 - UtDjamelNo ratings yet

- Sa 388Document8 pagesSa 388Widya widyaNo ratings yet

- 7.5.5.2asme Sec Viii Div 2 2017Document3 pages7.5.5.2asme Sec Viii Div 2 2017James100% (2)

- Asme Section II A Sa-435 Sa-435mDocument4 pagesAsme Section II A Sa-435 Sa-435mAnonymous GhPzn1xNo ratings yet

- Asme Sec Viii d1 Ma App 12Document1 pageAsme Sec Viii d1 Ma App 12Gwynnbleid100% (2)

- Ultrasonic Exam RequirementsDocument2 pagesUltrasonic Exam RequirementsAngelTinocoNo ratings yet

- Asme Section II A Sa-299 Sa-299mDocument4 pagesAsme Section II A Sa-299 Sa-299mAnonymous GhPzn1xNo ratings yet

- Iso 20669 2017 en PDFDocument8 pagesIso 20669 2017 en PDFTHIRU.SNo ratings yet

- ASME Section V Article 5 (2019)Document7 pagesASME Section V Article 5 (2019)Baguz SaputraNo ratings yet

- ASME SB-444 (2013) - В-444-06 (R11) - eng.Document4 pagesASME SB-444 (2013) - В-444-06 (R11) - eng.TetianaNo ratings yet

- Automated Ultrasonic Report Sample PHASE ARRAYDocument2 pagesAutomated Ultrasonic Report Sample PHASE ARRAYAzrul Hanif100% (2)

- Ultrasonic Testing of Steel Plates for DiscontinuitiesDocument6 pagesUltrasonic Testing of Steel Plates for DiscontinuitiesDavid EstradaNo ratings yet

- Difference Between ASTM A435 and ASTM A578Document1 pageDifference Between ASTM A435 and ASTM A578Vijay BedakihaleNo ratings yet

- ASME V Art 10 Press PDFDocument25 pagesASME V Art 10 Press PDFWutthinan Petchpeng100% (2)

- ASME SEC V ARTICLE 9 VISUAL EXAMINATION PROCEDURESDocument11 pagesASME SEC V ARTICLE 9 VISUAL EXAMINATION PROCEDURESRamesh R100% (1)

- Standard Practice For Measuring Thickness by Manual Ultrasonic Pulse-Echo Contact MethodDocument7 pagesStandard Practice For Measuring Thickness by Manual Ultrasonic Pulse-Echo Contact MethodRenzo BellotaNo ratings yet

- ASTM E746-07 (2014) Standard Practice For Determining Relative Image Quality Response of Industrial Radiographic Imaging SystemsDocument7 pagesASTM E746-07 (2014) Standard Practice For Determining Relative Image Quality Response of Industrial Radiographic Imaging SystemsnationalfoxNo ratings yet

- Asme Sec I PWHT RequirementDocument6 pagesAsme Sec I PWHT RequirementSajin ChandranNo ratings yet

- Corrosion - Mapping Usign Phased Array - Olympus NDTDocument3 pagesCorrosion - Mapping Usign Phased Array - Olympus NDTpokeboy19No ratings yet

- API 611 ScopeDocument1 pageAPI 611 ScopeLeon Sanchez67% (3)

- VESV1003 - Fabrication of Welded Vessels and Tanks To Be LinedDocument6 pagesVESV1003 - Fabrication of Welded Vessels and Tanks To Be LinedMuhammad Farukh ManzoorNo ratings yet

- E 543 - 04 - Rtu0mw - PDFDocument11 pagesE 543 - 04 - Rtu0mw - PDFUpul Eranda AbeyrathnaNo ratings yet

- Asme b31. 8 Latest EditionDocument2 pagesAsme b31. 8 Latest EditionAhsan AliNo ratings yet

- API 650 Technical Inquiries SummaryDocument28 pagesAPI 650 Technical Inquiries SummaryIgnatios Staboulis0% (1)

- Astm Se-273Document5 pagesAstm Se-273Deyci Yamile Peña SantosNo ratings yet

- Bentley Autopipe v8 CrackDocument3 pagesBentley Autopipe v8 CrackAdi M. Mutawali100% (2)

- Post Weld Heat TreatmentDocument1 pagePost Weld Heat Treatmentthho84No ratings yet

- Cs & Las Impact Req - Asme Sec Viii Div 2Document16 pagesCs & Las Impact Req - Asme Sec Viii Div 2AmitNarayanNitnawareNo ratings yet

- Guided Bend Test Jig Dimension ASME 9Document3 pagesGuided Bend Test Jig Dimension ASME 9esamhamad50% (2)

- Pressure Vessel NDT Inspection BrochureDocument1 pagePressure Vessel NDT Inspection BrochureAhmed DeghicheNo ratings yet

- E243 13 PDFDocument6 pagesE243 13 PDFDaniel Mauricio Prieto ValderramaNo ratings yet

- Uw-51 RT Acceptance CriteriaDocument12 pagesUw-51 RT Acceptance CriteriaSameer RajuNo ratings yet

- Code Case 2235-10Document10 pagesCode Case 2235-10MarleneLopesNo ratings yet

- WPQ WELDER PERFORMANCE QUALIFICATIONDocument2 pagesWPQ WELDER PERFORMANCE QUALIFICATIONalokbdasNo ratings yet

- ASME B16 Welding EndsDocument2 pagesASME B16 Welding Endsf_riseNo ratings yet

- Standard Guide For Evaluating Performance Phased Array UnitDocument20 pagesStandard Guide For Evaluating Performance Phased Array UnitAnonymous m43RBxOVZ2No ratings yet

- Astm E1032-2012Document6 pagesAstm E1032-2012vivicastedoNo ratings yet

- NBIC Part 2 PDFDocument12 pagesNBIC Part 2 PDFjhonjimenez87No ratings yet

- 2 - HydroFORM - Mechanical Setup R2Document17 pages2 - HydroFORM - Mechanical Setup R2carlosNo ratings yet

- Positive Material Identification ProcedureDocument6 pagesPositive Material Identification Procedureomar100% (1)

- PMI Testing - Limitations With XRFDocument3 pagesPMI Testing - Limitations With XRFArun Kumar Kar100% (2)

- DS 324 ManualDocument44 pagesDS 324 ManualAshish Srivastava100% (1)

- ASTM D573 04 - Standard Test Method For Rubber-Deterioration in An Air OvenDocument6 pagesASTM D573 04 - Standard Test Method For Rubber-Deterioration in An Air OvenAndre Spirim100% (1)

- Case 2235-9 2010Document10 pagesCase 2235-9 2010Jimmy Márquez100% (1)

- ASME V Art 5 UTDocument24 pagesASME V Art 5 UTMarcelino Navarrete EvaristoNo ratings yet

- E 215 - 98 R04 - Rtixnq - PDFDocument7 pagesE 215 - 98 R04 - Rtixnq - PDFLeón SuárezNo ratings yet

- SE-797 Measuring Thickness by Manual Ultrasonic Contact MethodDocument9 pagesSE-797 Measuring Thickness by Manual Ultrasonic Contact MethodmaxikowaNo ratings yet

- Ut ProcedureDocument7 pagesUt Procedurearavindan100% (1)

- PAUT Procedure EEISDocument13 pagesPAUT Procedure EEISZakirUllahNo ratings yet

- G8s-5034-02-Bubble Leak TestDocument4 pagesG8s-5034-02-Bubble Leak TestmaheshNo ratings yet

- Visual Examination Requirements and TechniquesDocument3 pagesVisual Examination Requirements and TechniquesfelipefistNo ratings yet

- Article 5 Ultrasonic Examination Methods For MaterialsDocument10 pagesArticle 5 Ultrasonic Examination Methods For Materialsr_ramiresNo ratings yet

- Hydrualic Tube Expansion Vs Metallic Tube ExpansionDocument3 pagesHydrualic Tube Expansion Vs Metallic Tube ExpansionNath BoyapatiNo ratings yet

- Astm e 1032-06Document6 pagesAstm e 1032-06Renato BarretoNo ratings yet

- 16mo3 MıgMagDocument4 pages16mo3 MıgMagKerem İnanNo ratings yet

- Asme Section 8 Div 1 - RTDocument12 pagesAsme Section 8 Div 1 - RTGulfnde Industrial ServiceNo ratings yet

- Case 2235-13 Use of Ultrasonic Examination in Lieu of Radiography Section Section XIIDocument12 pagesCase 2235-13 Use of Ultrasonic Examination in Lieu of Radiography Section Section XII나무No ratings yet

- Asme Sec V A-2-2004 PDFDocument39 pagesAsme Sec V A-2-2004 PDFjaire esparzaNo ratings yet

- RadiographyDocument5 pagesRadiographyAman KumarNo ratings yet

- Electronic Control Module (ECM) : Shutdown SIS Previous ScreenDocument5 pagesElectronic Control Module (ECM) : Shutdown SIS Previous ScreenWladimir AmaguañaNo ratings yet

- An Example of A HypothesisDocument2 pagesAn Example of A HypothesisAjibade TaofikNo ratings yet

- Katalog Single Split Packaged AC 2015-2016 PanasonicDocument32 pagesKatalog Single Split Packaged AC 2015-2016 Panasonicdoris0% (1)

- Predicting Iron Losses in Soft Magnetic Materials With Arbitrary Voltage Supply An Engineering ApproachDocument9 pagesPredicting Iron Losses in Soft Magnetic Materials With Arbitrary Voltage Supply An Engineering Approachmayur isameNo ratings yet

- DPS Nashik Class 12 Science SyllabusDocument18 pagesDPS Nashik Class 12 Science SyllabusSayali Morwal-KumawatNo ratings yet

- Mater BiDocument10 pagesMater BihanjunyieeNo ratings yet

- Water Transport Studies in Stone Masonry With Soil Cement MortarDocument10 pagesWater Transport Studies in Stone Masonry With Soil Cement MortarTJPRC PublicationsNo ratings yet

- CerebrumDocument26 pagesCerebrumsanthiyasandy100% (1)

- SB 10054865 6305Document15 pagesSB 10054865 6305Ralph WamaeNo ratings yet

- BrinjalDocument2 pagesBrinjalGajananNo ratings yet

- Fault Codes: Brake (DSC/DXC (Dynamic Stability Control) - Bosch 8.0 - Tyre Pressure Monitoring)Document5 pagesFault Codes: Brake (DSC/DXC (Dynamic Stability Control) - Bosch 8.0 - Tyre Pressure Monitoring)zacarias NiquiceNo ratings yet

- Subway's Fresh Look: CEO Suzanne Greco Is Taking The Company To A Whole New Level With The Fresh Forward RebrandDocument9 pagesSubway's Fresh Look: CEO Suzanne Greco Is Taking The Company To A Whole New Level With The Fresh Forward RebrandTanvir KhanNo ratings yet

- Rohail Hassan: ObjectiveDocument3 pagesRohail Hassan: ObjectiveNoumanKhanNo ratings yet

- Unit 1 The Multidisciplinary Nature of Environmental StudiesDocument35 pagesUnit 1 The Multidisciplinary Nature of Environmental StudiesNishant GawadNo ratings yet

- Chana Masala Powder RecipeDocument215 pagesChana Masala Powder RecipeTIRUPUR OFFICENo ratings yet

- Tunics Step by StepDocument10 pagesTunics Step by Stepsarahmichelef100% (18)

- Provisional RestorationsDocument9 pagesProvisional RestorationsshivaprasadmNo ratings yet

- EA PSC Substation Earthing Course Leaflet PSC006CL MAR15Document2 pagesEA PSC Substation Earthing Course Leaflet PSC006CL MAR15David RothwellNo ratings yet

- Easytronic Micro II 28 05 2010 08 35 20 Revision 05 Controller 1 PDFDocument10 pagesEasytronic Micro II 28 05 2010 08 35 20 Revision 05 Controller 1 PDFСергей Заика100% (1)

- Joycie 4-7Document2 pagesJoycie 4-7Jay VillasotoNo ratings yet

- Fine ArtsDocument12 pagesFine Artsatul prajapatiNo ratings yet

- Chanda Paints: Bitumen 158 BLACKDocument1 pageChanda Paints: Bitumen 158 BLACKsureshNo ratings yet

- HeavyMetalLimits For Leachability PROP 65 PB and CDDocument3 pagesHeavyMetalLimits For Leachability PROP 65 PB and CDspades24kNo ratings yet

- 1Document36 pages1Abrvalg_1No ratings yet

- Cja YDocument18 pagesCja YC-jay PizarraNo ratings yet

- Learning Activity Sheet In: Computer Systems ServicingDocument12 pagesLearning Activity Sheet In: Computer Systems ServicingCarvalds 0315No ratings yet

- Ch02 World Trade An Overview 1Document32 pagesCh02 World Trade An Overview 1XIKAMNo ratings yet

- Fmea PC ProcessDocument2 pagesFmea PC Processsudeep_singh1No ratings yet

- Saa6d170e-5 HPCR Egr Sen00190-04Document415 pagesSaa6d170e-5 HPCR Egr Sen00190-04Ahmad Mubarok100% (4)

- Men FootwearDocument442 pagesMen FootwearAbhishekNo ratings yet