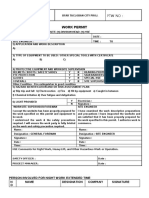

Daily Pre-Start Safety Checklist

Project: Date:

Task Item Yes No N/A Task Item Yes No N/A

TBT completed and documented Chain sling - wear,stretching,c/coded

SAFETY

TALKS

Work permits issued as required/ conditions Wire rope slings (SWL,condition,c/code)

specified are complied with. Flat webbing sling - condition c/code

Safety helmet ( ANSI or CE ) Round sling - condition c/code

Correct eye protection worn chain block,turfors,come-a-long,etc

Safety footwear - serviceable Shackles - stamped,condition,c/code

PPE

Hearing protection - where applicable Storage of rigging gear not in use OK

RIGGING / LIFTING

Gloves - serviceable and being worn Crane pre-start inspection documented

Respiratory protection - where applicable Counter weight swing radius barricaded

Material at site correctly stored Crane located on level and stable ground

HOUSEKEEPPING / WASTE

Material stacked in a stable manner Outrigger extended

Waste Material at site correctly stored/piled up weight distribution pads in good condition and pad

MANAGEMENT

- skip not overfull not attached to the outrigger

Skip / Bin available for waste material in all

Operator trained & certified to operate crane

areas - not too far from the work front

ACI certified and stickered, 3rd party certification for

Separate bins for construction waste /

lifting equipment and with valid registration/ insurance

domestic waste and hazardous waste storage

for the crane

areas

Environmental advised to arrange empty

Certified Banksman/Rigger present

for bins near full , work areas are clean tidy.

With ACI stickers and inspected regulary Personnel not standing under the loads

TRANSPORTATION

No excess materials/tools store at cabin/

WORK @ HEIGHT

Harness and lanyards worn correctly

passenger side, access/ egress way clear

Correct type of fire extinguishers placed Condition of lanyards OK - General

Vehicle registration and insurance available All double lanyards provided

Driver has proper driving license and third pary Anchor points/lifeline inspected and tagged by

training cerficate if required. the competent person.

Welding machine condition OK , Toilet facilities are cleaned regularly and supplied

WELFARE

welding machine earthed and tagged with soap and paper

& CUTTING

WELDING

Gas cylinders are secured & upright Drinking Water Storage kept filled, clean and labeled

Regulators / hoses / handsets condition OK Rest shelters provided and in good condition

Flashback arrestor fitted at both ends Excavation entry logs completed when required.

Welding leads ( condition and position ) Spotter present &used for heavy equipment

EXCAVATION

Prestart inspection completed and logged for

Sufficient safety signage available at site

heavy equipment

MSDS available at site for chemicals in use Operator licensed for heavy equipment

CHEMICALS

Containers labeled clearly Access & egress are proper

No liquid in unidentified containers and no

Protective measures taken (sloping / shoring / benching)

containers with unidentified contents.

PPE provided ( in accordance with MSDS ) Fire extinguisher and first aid kit in good order

No temporary storage of chemicals and fuels Static plant inspected and tagged,(eg.rebar

outside approved area bender,bench saws, generator

GENERAL

Distribution board ( locked / condition OK ) Safe operating instruction posted

ELCB's devices fitted to power sources Operator are trained

Portable electrical equipment tagged / color Perimeter hoarding as designed and traffic signs as

ELECTRICALS

coded in accordance with the procedure. well as signal lights installed as planned

No dead-Man switches/DMS disabled Evidence of smoking in un-authorized area

Ext. leads ( conditions and position OK ) Permit are in place

CONFINED SPACE

Correct type plugs in correct type socket, or

Gas test certificate is available

adaptors used

Generators (conditions and position OK, Workers are trained for the job and provided with all

grounded) the necessary PPE required

SCAFTAG affixed and completed on scaffold Access & egress control in place.

SCAFFOLDING

Base plate fitted and stable Check list to be used as an aid memoir and is not all inclusive to be completed at

Scaffold straight and square start of shift and after lunch break and submitted daily to HSE Supervisors.

Ladder access fitted correctly Other routine inspection using checklist need not to be documented.

Name of certified person clear on tag I have checked my area (enter area here) …………………. and corrected

Signature completed on tag or reported to my Supervisor any unsafe condition.

HSE Officer: Signature:

NOTE :- () = Checked OK , ( x ) = Corrective required Checked by Area Supervisor:

N/A = Not applicable

Date: Signature: