0% found this document useful (0 votes)

124 views10 pagesRebar Cutting & Bending Guide

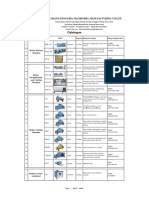

This document is a report submitted by Group 3 of the Civil Engineering department at UET Taxila. It contains summaries of 4 machines:

1. A rebar cutting machine that uses an alloy dull blade, pulleys, gears and an electric motor to grip and slice rebars.

2. A bar bending machine that can bend steel round bars and rebar into various angles using a semi-automatic process.

3. An adjustable column formwork made of steel plates with ribs for constructing concrete columns.

4. A diamond core drill bit used to drill holes in materials like granite to access pipes and drains.

Uploaded by

Hamza JameelCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOCX, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

124 views10 pagesRebar Cutting & Bending Guide

This document is a report submitted by Group 3 of the Civil Engineering department at UET Taxila. It contains summaries of 4 machines:

1. A rebar cutting machine that uses an alloy dull blade, pulleys, gears and an electric motor to grip and slice rebars.

2. A bar bending machine that can bend steel round bars and rebar into various angles using a semi-automatic process.

3. An adjustable column formwork made of steel plates with ribs for constructing concrete columns.

4. A diamond core drill bit used to drill holes in materials like granite to access pipes and drains.

Uploaded by

Hamza JameelCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOCX, PDF, TXT or read online on Scribd

/ 10