Professional Documents

Culture Documents

Cantilever Slab Check

Uploaded by

bsreenu393Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cantilever Slab Check

Uploaded by

bsreenu393Copyright:

Available Formats

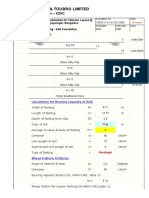

AAES ENGINEERING, INC. Project no.

18-00-020

Prep By MCR Date 10/3/22 Project 359-367 Hamilton Ave Sheet of

Chkd By ERK Date 10/3/22 Subject Slab Design

SLAB DESIGN

MATERIAL INFORMATION:

Concrete fc' = 4000 psi DL + LL

Reinf. Steel fy = 60 ksi

Concrete Weight (gcon) = 150 lb/ft3

Slab short span L = 36 ft

Slab width b = 12 in

Depth of slab D = 11 in

Effective Depth of slab d = 11 - 0.75 -8/(8x2) = 9.750 in (In Short span direction)

Positive Moment :

Maximum factored positive moment Mu = 32789 lb -ft / ft of slab (From Staad, Plate no: 396 L/c : 101)

Mu = 12x32788.8 = 344.92

bd2 12x9.75 2

r = 0.0068 (from chart)

r min = = 0.0018

Use r = 0.0068

Area of steel required Ast = rbd = 0.80 sq.in / ft

Providing steel = # 8 @ 10 "

Area of steel provided = 0.79 x 12 = 0.94 sq.in / ft > Ast required 0.80 sq.in / ft OK

10.0

Use r = 0.0018

Area of steel required Ast = rbd = 0.21 sq.in / ft

Providing steel = # 4 @ 12 "

Area of steel provided = 0.20 x 12 = 0.20 sq.in / ft > Ast required 0.21 sq.in / ft NOT OK

12.0

AAES ENGINEERING, INC. Project no. 18-00-020

Prep By MCR Date 10/3/22 Project ACE, 77-91 Park Ave Paterson Sheet of

Chkd By ERK Date 10/3/22 Subject Slab Design

SLAB DESIGN

MATERIAL INFORMATION:

Concrete fc' = 4000 psi DL + LL

Reinf. Steel fy = 60 ksi

Concrete Weight (gcon) = 150 lb/ft3

Slab short span L = 6 ft

Slab width b = 12 in

Depth of slab D = 11 in

Effective Depth of slab d = 11 - 0.75 -7/(8x2) = 9.813 in (In Short span direction)

Positive Moment :

Maximum factored positive moment Mu = 1256 lb -ft / ft of slab (From Staad, Plate no: 396 L/c : 101)

Mu = 12x1256.4 = 13.05

bd2 12x9.8125 2

r = 0.0002 (from chart)

r min = = 0.0018

Use r = 0.0018 Since it is smaller than R min, multiply this number with 1.33

Area of steel required Ast = rbd = 0.21 sq.in / ft

Providing steel = # 7 @ 10 "

Area of steel provided = 0.60 x 12 = 0.72 sq.in / ft > Ast required 0.21 sq.in / ft OK

10.0

Use r = 0.0018

Area of steel required Ast = rbd = 0.21 sq.in / ft

Providing steel = # 4 @ 12 "

Area of steel provided = 0.20 x 12 = 0.20 sq.in / ft > Ast required 0.21 sq.in / ft NOT OK

12.0

AAES ENGINEERING, INC. Project no. 18-00-020

Prep By MCR Date 10/3/22 Project ACE, 77-91 Park Ave Paterson Sheet of

Chkd By ERK Date 10/3/22 Subject Slab Design

SLAB DESIGN

MATERIAL INFORMATION:

Concrete fc' = 4000 psi DL + LL

Reinf. Steel fy = 60 ksi

Concrete Weight (gcon) = 150 lb/ft3

Slab short span L = 33 ft

Slab width b = 12 in

Depth of slab D = 11 in

Effective Depth of slab d = 11 - 0.75 -8/(8x2) = 9.750 in (In Short span direction)

Positive Moment :

Maximum factored positive moment Mu = 27552 lb -ft / ft of slab (From Staad, Plate no: 396 L/c : 101)

Mu = 12x27551.7 = 289.83

bd2 12x9.75 2

r = 0.0056 (from chart)

r min = = 0.0018

Use r = 0.0056

Area of steel required Ast = rbd = 0.66 sq.in / ft

Providing steel = # 8 @ 10 "

Area of steel provided = 0.79 x 12 = 0.94 sq.in / ft > Ast required 0.66 sq.in / ft OK

10.0

Use r = 0.0018

Area of steel required Ast = rbd = 0.21 sq.in / ft

Providing steel = # 4 @ 12 "

Area of steel provided = 0.20 x 12 = 0.20 sq.in / ft > Ast required 0.21 sq.in / ft NOT OK

12.0

SLAB DESIGN

MATERIAL INFORMATION:

Concrete fc' = 4000 psi DL + LL

Reinf. Steel fy = 60 ksi

Concrete Weight (gcon) = 150 lb/ft3

Slab short span L = 3 ft

Slab width b = 12 in

Depth of slab D = 11 in

Effective Depth of slab d = 11 - 0.75" -0.625/2" = 9.750 in (In Short span direction)

Positive Moment :

Maximum factored positive moment Mu = 33935 lb -ft / ft of slab (From Staad, Plate no: 396 L/c : 101)

Mu = 12x33934.5 = 356.97

bd2 12x9.75 2

r = 0.0071 (from chart)

r min = = 0.0018

Use r = 0.0071

Area of steel required Ast = rbd = 0.83 sq.in / ft

Providing steel = # 8 @ 10 "

Area of steel provided = 0.79 x 12 = 0.94 sq.in / ft > Ast required 0.83 sq.in / ft OK

10.0

Use r = 0.0018

Area of steel required Ast = rbd = 0.21 sq.in / ft

Providing steel = # 4 @ 12 "

Area of steel provided = 0.20 x 12 = 0.20 sq.in / ft > Ast required 0.21 sq.in / ft NOT OK

12.0

AAES ENGINEERING, INC. Project no. #REF!

Prep By ERK Date 10/3/22 Project #REF! Sheet of

Chkd By JE Date 10/3/22 Subject #REF!

SLAB DESIGN

MATERIAL INFORMATION:

Concrete fc' = 4000 psi

Reinf. Steel fy = 60 ksi

Concrete Weight (gcon) = 150 lb/ft3

Slab short span L = 18 ft

Slab width b = 12 in

Depth of slab D = 12 in

Effective Depth of slab d = 12 - 0.75" -0.625/2" = 10.938 in (In Short span direction)

Positive Moment :

Maximum factored Hogging moment Mu = 22000 lb -ft / ft of slab (From Staad)

Mu = 12x22000 = 183.90

bd2 12x10.9375 2

r = 0.0035 (from chart)

r min = = 0.0018

Use r = 0.0035

Area of steel required Ast = rbd = 0.46 sq.in / ft

Providing steel = # 5 @ 8"

Area of steel provided = 0.31 x 12 = 0.46 sq.in / ft > Ast required 0.46 sq.in / ft OK

8.0

AAES ENGINEERING, INC. Project no. #REF!

Prep By MCR Date 10/3/22 Project ACE, 77-91 Park Ave Paterson Sheet of

Chkd By ERK Date 10/3/22 Subject Slab Design

SLAB DESIGN

MATERIAL INFORMATION:

Concrete fc' = 4000 psi DL + LL

Reinf. Steel fy = 60 ksi

Concrete Weight (gcon) = 150 lb/ft3

Slab short span L = 18 ft

Slab width b = 12 in

Depth of slab D = 12 in

Effective Depth of slab d = 12 - 0.75" - 0.625/2" = 10.938 in (In Short span direction)

Positive Moment :

Maximum factored positive moment Mu = 50500 lb -ft / ft of slab (From Staad, Plate no: 16147 L/c : 1002)

Mu = 12x50500 = 422.14

bd2 12 x 10.9375 2

r = 0.0084 (from chart)

r min = = 0.0018

Use r = 0.0084

Area of steel required Ast = rbd = 1.10 sq.in / ft

Providing steel = # 5 @ 4"

Area of steel provided = 0.31 x 12 = 0.92 sq.in / ft > Ast required 1.10 sq.in / ft NOT OK

4.0

Shear check :

Maximum Allowable shear at the face of support, Vu = 93 psi (Max Shear stress at 'd' distance from face of column)

Value of f = 0.75

Permissible Shear , f2 f'c = 0.75 x 2 x 4000 = 95 psi

> 93 OK

Punching Shear Check :

Critical section for two - way shear is located at a distance "d/2" from the face of the axle.

Perimeter around the area bo = 2 x (a+ d)+(b+d) 24

bo = 2 x (14 + 10.9375)+(24+10.9375)

bo = 119.8 " 14

Actual shear developed under the Equipment = = 316391 lb (From Staad , member no 10611)

Permissible Shear , f4 f'c bo d = 0.75 x 4 x 4000 x 119.75x10.9375 = 248511 lb

> 316391 NOT OK

AAES ENGINEERING, INC. Project no. #REF!

Prep By MCR Date 10/3/22 Project ACE, 77-91 Park Ave Paterson Sheet of

Chkd By ERK Date 10/3/22 Subject Slab Design

SLAB DESIGN

MATERIAL INFORMATION:

Concrete fc' = 4000 psi DL + LL

Reinf. Steel fy = 60 ksi

Concrete Weight (gcon) = 150 lb/ft3

Slab short span L = 18 ft

Slab width b = 12 in

Depth of slab D = 12 in

Effective Depth of slab d = 12 - 0.75" - 0.625/2" = 10.938 in (In Short span direction)

Positive Moment :

Maximum factored positive moment Mu = 60000 lb -ft / ft of slab (From Staad, Plate no: 16147 L/c : 1002)

Mu = 12x60000 = 501.55

bd2 12 x 10.9375 2

r = 0.0102 (from chart)

r min = = 0.0018

Use r = 0.0102

Area of steel required Ast = rbd = 1.34 sq.in / ft

Providing steel = # 5 @ 3"

Area of steel provided = 0.31 x 12 = 1.36 sq.in / ft > Ast required 1.34 sq.in / ft OK

2.7

Shear check :

Maximum Allowable shear at the face of support, Vu = 93 psi (Max Shear stress at 'd' distance from face of column)

Value of f = 0.75

Permissible Shear , f2 f'c = 0.75 x 2 x 4000 = 95 psi

> 93 OK

Punching Shear Check :

Critical section for two - way shear is located at a distance "d/2" from the face of the axle.

Perimeter around the area bo = 2 x (a+ d)+(b+d) 24

bo = 2 x (14 + 10.9375)+(24+10.9375)

bo = 119.8 " 14

Actual shear developed under the Equipment = = 316391 lb (From Staad , member no 10611)

Permissible Shear , f4 f'c bo d = 0.75 x 4 x 4000 x 119.75x10.9375 = 248511 lb

> 316391 NOT OK

AAES ENGINEERING, INC. Project no. #REF!

Prep By MCR Date 10/3/22 Project 170 Grant Ave, NJ Sheet of

Chkd By ERK Date 10/3/22 Subject Slab Design

SLAB DESIGN

MATERIAL INFORMATION:

Concrete fc' = 4000 psi DL + LL

Reinf. Steel fy = 60 ksi

Concrete Weight (gcon) = 150 lb/ft3

Slab short span L = 23 ft

Slab width b = 12 in

Depth of slab D = 18 in

Effective Depth of slab d = 18 - 0.75" - 0.6-0.6/2" = 16.350 in (In Short span direction)

Positive Moment :

Maximum factored positive moment Mu = 72000 lb -ft / ft of slab (From Staad, Plate no: 396 L/c : 101)

Mu = 12x72000 = 269.34

bd2 12x16.35 2

r = 0.0052 (from chart)

r min = = 0.0018

Use r = 0.0052

Area of steel required Ast = rbd = 1.02 sq.in / ft

Providing steel = # 7 @ 7"

Area of steel provided = 0.60 x 12 = 1.03 sq.in / ft > Ast required 1.02 sq.in / ft OK

7.0

Shear check :

Maximum Allowable shear at the face of support, Vu = 80 psi (Max Shear stress at 'd' distance from face of column)

Value of f = 0.8

Permissible Shear , f2 f'c = 0.75 x 2 x 4000 = 95 psi

> 86 OK

Punching Shear Check :

Critical section for two - way shear is located at a distance "d/2" from the face of the axle.

Perimeter around the area bo = 2 x (a+ d)+(b+d) 24

bo = 2 x (14 + 16.35)+(24+16.35)

bo = 141.4 " 14

Actual shear developed under the Equipment = = 215000 lb (From Staad , member no 10615)

Permissible Shear , f4 f'c bo d = 0.75 x 4 x 4000 x 141.4x16.35 = 438650 lb

> 215000 OK

AAES ENGINEERING, INC. Project no. 17-16-002

Prep By MCR Date 10/3/22 Project 170 Grant Ave, NJ Sheet of

Chkd By ERK Date 10/3/22 Subject Slab Design

SLAB DESIGN

MATERIAL INFORMATION:

Concrete fc' = 4000 psi DL + LL

Reinf. Steel fy = 60 ksi

Concrete Weight (gcon) = 150 lb/ft3

Slab short span L = 23 ft

Slab width b = 12 in

Depth of slab D = 12 in

Effective Depth of slab d = 12 - 0.75" - 0.44-0.44/2" = 10.590 in (In Short span direction)

Positive Moment :

Maximum factored positive moment Mu = 25200 lb -ft / ft of slab (From Staad)

Mu = 12x25200 = 224.70

bd2 12x10.59 2

r = 0.0043 (from chart)

r min = = 0.0018

Use r = 0.0043

Area of steel required Ast = rbd = 0.55 sq.in / ft

Providing steel = # 7 @ 10 "

Area of steel provided = 0.60 x 12 = 0.72 sq.in / ft > Ast required 0.55 sq.in / ft OK

10.0

Shear check :

Maximum Allowable shear at the face of support, Vu = 93 psi (From Staad,)

Value of f = 0.75

Permissible Shear , f2 f'c = 0.75 x 2 x 4000 = 95 psi

> 93 OK

Punching Shear Check :

Critical section for two - way shear is located at a distance "d/2" from the face of the axle.

Perimeter around the area bo = 2 x (a+ d)+(b+d) 24

bo = 2 x (14 + 10.59)+(24+10.59)

bo = 118.4 " 14

Actual shear developed under the Equipment = 1.6 x 93x12x10.59 = 18910 lb

Permissible Shear , f4 f'c bo d = 0.75 x 4 x 4000 x 118.36x10.59 = 237822 lb

> 18910 OK

AAES ENGINEERING, INC. Project no. #REF!

Prep By MCR Date 10/3/22 Project ACE, 77-91 Park Ave Paterson Sheet of

Chkd By ERK Date 10/3/22 Subject Slab Design

SLAB DESIGN

MATERIAL INFORMATION:

Concrete fc' = 4000 psi DL + LL

Reinf. Steel fy = 60 ksi

Concrete Weight (gcon) = 150 lb/ft3

Slab short span L = 18 ft

Slab width b = 12 in

Depth of slab D = 24 in

Effective Depth of slab d = 24 - 0.75" - F30/8/2" = 22.875 in (In Short span direction)

Positive Moment :

Maximum factored positive moment Mu = 189000 lb -ft / ft of slab (From Staad, Plate no: 16147 L/c : 1002)

Mu = 12x189000 = 361.19

bd2 12 x 22.875 2

r = 0.0071 (from chart) Check

r min = = 0.0018

Use r = 0.0071

Area of steel required Ast = rbd = 1.95 sq.in / ft

Providing steel = # 6 @ 3" 4.4444

Area of steel provided = 0.44 x 12 = 1.96 sq.in / ft > Ast required 1.95 sq.in / ft OK

2.7

Shear check :

Maximum Allowable shear at the face of support, Vu = 93 psi (Max Shear stress at 'd' distance from face of column)

Value of f = 0.75

Permissible Shear , f2 f'c = 0.75 x 2 x 4000 = 95 psi

> 93 OK

Punching Shear Check :

Critical section for two - way shear is located at a distance "d/2" from the face of the axle.

Perimeter around the area bo = 2 x (a+ d)+(b+d) 24

bo = 2 x (14 + 22.875)+(24+22.875)

bo = 167.5 " 14

Actual shear developed under the Equipment = = 316391 lb (From Staad , member no 10611)

Permissible Shear , f4 f'c bo d = 0.75 x 4 x 4000 x 167.5x22.875 = 726988 lb

> 316391 OK

You might also like

- Solutions Manual to accompany Engineering Materials ScienceFrom EverandSolutions Manual to accompany Engineering Materials ScienceRating: 4 out of 5 stars4/5 (1)

- Oneway Slab CheckDocument11 pagesOneway Slab Checkbsreenu393No ratings yet

- Areva T& D India Limited: Design of Circular Sump Input DataDocument2 pagesAreva T& D India Limited: Design of Circular Sump Input DatajatinNo ratings yet

- Design of Rigid Pavement: A) Design Period and Traffic ProjectionDocument2 pagesDesign of Rigid Pavement: A) Design Period and Traffic ProjectionMitali MajumderNo ratings yet

- One Way SlabACIDocument9 pagesOne Way SlabACIshinichi falcoNo ratings yet

- R2-Earthmat - Calculations-MIOA-0.5Sec (00000002)Document13 pagesR2-Earthmat - Calculations-MIOA-0.5Sec (00000002)manishNo ratings yet

- Pipe Support3of 5Document1 pagePipe Support3of 5Anonymous fLgaidVBhzNo ratings yet

- Design 1-Way One End Continuous SlabDocument9 pagesDesign 1-Way One End Continuous SlabRbcabajes ButalonNo ratings yet

- Design Calculations: Clear Water ReservoirDocument2 pagesDesign Calculations: Clear Water ReservoirAnoop KumarNo ratings yet

- Project: Footing Number: Engineer: Date:: Design 3-Pile Cap FootingDocument3 pagesProject: Footing Number: Engineer: Date:: Design 3-Pile Cap FootingMars TinNo ratings yet

- Isolated Footing (R or S)Document19 pagesIsolated Footing (R or S)Shaniha kkNo ratings yet

- Earthmat - Calculations-Noida 10 MeterDocument6 pagesEarthmat - Calculations-Noida 10 MeterAnoop DikshitNo ratings yet

- Grade Slab ACI 150thkDocument7 pagesGrade Slab ACI 150thkraahul_nNo ratings yet

- Zn-Al Tank-175kL Design 12M STAGING - SMTDocument63 pagesZn-Al Tank-175kL Design 12M STAGING - SMTRajendra MittalNo ratings yet

- Portal FrameDocument42 pagesPortal Framesurendra_pangaNo ratings yet

- SBC DesignDocument5 pagesSBC DesignNitesh SinghNo ratings yet

- Stair Flight & Landing - Single 2Document1 pageStair Flight & Landing - Single 2Isaac JosephNo ratings yet

- 14 Isolated FootingDocument2 pages14 Isolated FootingBißék Śílwàl100% (2)

- Title: Slab Design PDI Block-Hetauda Input ParametersDocument13 pagesTitle: Slab Design PDI Block-Hetauda Input ParametersAnimras TamrakarNo ratings yet

- Concrete Planks DesignDocument1 pageConcrete Planks DesignZohaib Sattar NagraNo ratings yet

- Beam DesignDocument54 pagesBeam DesignLagnajit DasNo ratings yet

- Cantilever SlabDocument7 pagesCantilever SlabAamirShabbirNo ratings yet

- 1.0 Diesel Tank SupportsDocument3 pages1.0 Diesel Tank SupportsKushan Dhanushka NanayakkaraNo ratings yet

- Kuantum - Design of Eccentric FootingDocument18 pagesKuantum - Design of Eccentric FootingAamir SuhailNo ratings yet

- Cantilever SlabDocument10 pagesCantilever SlabNiko Ništić100% (1)

- One Way SlabDocument9 pagesOne Way SlabJane RoNo ratings yet

- JTP Consulting Engineers PVT LTDDocument4 pagesJTP Consulting Engineers PVT LTDVasanthakumarNo ratings yet

- Conc Short ColDocument13 pagesConc Short ColEngDbtNo ratings yet

- Earthmat Calculation FOR 132/25Kv Quazigund TSS: Northern RailwayDocument4 pagesEarthmat Calculation FOR 132/25Kv Quazigund TSS: Northern RailwayRaj-Kanishk SharmaNo ratings yet

- RF Reinforcement r1Document63 pagesRF Reinforcement r1VasanthakumarNo ratings yet

- 5 - 2020foundation - 05 - 20!10 - 37 - 07 - PM - 2Document11 pages5 - 2020foundation - 05 - 20!10 - 37 - 07 - PM - 2Tahir FadhilNo ratings yet

- Contiguous PileDocument34 pagesContiguous PileAnonymous USbc7XzsA6No ratings yet

- Flight: Spreadsheets To BS 8110Document6 pagesFlight: Spreadsheets To BS 8110Kem RaiNo ratings yet

- Water Tank Design (Aci 318-05 & 350-01)Document5 pagesWater Tank Design (Aci 318-05 & 350-01)Arman20190% (10)

- Rectangular Beam Design Name of Method: UsdDocument11 pagesRectangular Beam Design Name of Method: UsdSumon RoyNo ratings yet

- RC One Way Slab Design (ACI318)Document2 pagesRC One Way Slab Design (ACI318)Bunkun15100% (1)

- Isolated Footing Design As Per Is 456Document2 pagesIsolated Footing Design As Per Is 456Sanjay Rokka50% (2)

- Circular Foundation Design For PoleDocument2 pagesCircular Foundation Design For PoleJayNo ratings yet

- Two Way Slab LetangDocument11 pagesTwo Way Slab LetangAnonymous DimshdqkNo ratings yet

- Slab DesignDocument1 pageSlab DesignMadhu SudhanNo ratings yet

- Cantilever Slab GFDocument10 pagesCantilever Slab GFahmedhusseinkamelNo ratings yet

- Design Calculation of Rss Building 3VIN 9 554 D1 S1 202 R0 Design of Foundations DataDocument56 pagesDesign Calculation of Rss Building 3VIN 9 554 D1 S1 202 R0 Design of Foundations DataARUNKUMAR KNo ratings yet

- Design of Cantilever Retaining Wall Per Aci318-05Document8 pagesDesign of Cantilever Retaining Wall Per Aci318-05LE ANH TRANNo ratings yet

- Staff Quarter Type-H DBR For Upper Veda WTP 28-12-2023Document25 pagesStaff Quarter Type-H DBR For Upper Veda WTP 28-12-2023PramodNo ratings yet

- Retaining Wall DesignDocument180 pagesRetaining Wall DesignVictor Rudio71% (7)

- Retrofit Design (Manish)Document6 pagesRetrofit Design (Manish)Manish MaharjanNo ratings yet

- 05.08.2009 - Cable Trench SectionsDocument22 pages05.08.2009 - Cable Trench SectionsandyhrNo ratings yet

- WallDocument5 pagesWallSURIYANo ratings yet

- Calculation of Moments and Shear: Input DataDocument3 pagesCalculation of Moments and Shear: Input DataARSENo ratings yet

- Made Date Sheet AR 17-Jul-11 1 Check Date Rev. MKI 17-Jul-11 0 PROJECT TITLE: Minhal Crowne Plaza Location: RiyadhDocument6 pagesMade Date Sheet AR 17-Jul-11 1 Check Date Rev. MKI 17-Jul-11 0 PROJECT TITLE: Minhal Crowne Plaza Location: Riyadhsidiq7No ratings yet

- Stair Case Design: Schematic PlanDocument6 pagesStair Case Design: Schematic Planthanigai veluNo ratings yet

- Design of Thrust Block: G Q in DegreesDocument56 pagesDesign of Thrust Block: G Q in DegreesChandan VatsNo ratings yet

- Staircase RC Council (Long & Midspan)Document4 pagesStaircase RC Council (Long & Midspan)WRay TanNo ratings yet

- Crack & Thermal Checks - Wal & SlabsDocument3 pagesCrack & Thermal Checks - Wal & SlabsMuhammad IshaqNo ratings yet

- Cal Temp Latest 2Document79 pagesCal Temp Latest 2Benedict OgbaghaNo ratings yet

- Grade Slab CSB BuildingDocument7 pagesGrade Slab CSB BuildingersivarajNo ratings yet

- Solution Manual for an Introduction to Equilibrium ThermodynamicsFrom EverandSolution Manual for an Introduction to Equilibrium ThermodynamicsNo ratings yet

- KMPS, Standard Connections Report - 04.17.23 1555Document1 pageKMPS, Standard Connections Report - 04.17.23 1555bsreenu393No ratings yet

- Flat Slab DesignDocument26 pagesFlat Slab Designbsreenu393No ratings yet

- Wall Footing CalculationsDocument12 pagesWall Footing Calculationsbsreenu393No ratings yet

- Eccentric Wall Footing CalculationsDocument11 pagesEccentric Wall Footing Calculationsbsreenu393No ratings yet