Professional Documents

Culture Documents

инстр Кулокран 5

инстр Кулокран 5

Uploaded by

Evgeni Frangov0 ratings0% found this document useful (0 votes)

25 views51 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

25 views51 pagesинстр Кулокран 5

инстр Кулокран 5

Uploaded by

Evgeni FrangovCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 51

4

42

43

44

$y

SAN MARCO}

INTERNATIONAL

CRANE SMH 322 ~ EDITION 02/200 - 3t

12.4. DISASSEMBLING THE TOWER,

Rotate the crane to align the upper and lower sections of the base-freme by the locking pin 10 for

transport. If required, the crane can be disassembled in any position along its arc of slewing and

alignment of upper and lower base-frame can be effected before transporting the machine. In this

way, It Is therefore not possible to employ axles and stabilizers to remove the crane from its wooden

rests,

Effectuate all the checks of the hydraulic devices described in the paragraph 04.6.2.

‘Turn selector switch SA to position 1 and depress UP or DOWN push-buttons to position the load

block one metre below the trolley.

Set selector switch SA1 in position 2 and depress RANGE FAR push-button to move the boom

trolley near the boom-jib articulation in such a position that the trolley sliding block actuates

enabling micro switch 54 (being the micro switch actuated, the trolley is automatically stopped).

ie (contin en the mpage)

- 12. CRANE DISASSEMBLY - 12-9

INTERNATIONAL

48

46

47

Prior to start folding the tower, briefly depress UP or DOWN push-buttons alternatively to make

CRANE SMH 322 ~ EDITION 02/200 - 3t.

sure the two chambers of the’ assembly cylinders are filled wth oll and pressurised (paragraph

04.6.2).

Depress DOWN push-button to start lowering the crane tower.

Proceed with tower lowering, checking that the movement is regular, that the derrick 41. lowers in

the correct position and that cables and tie rods do not entangle. Keep danger zones A B and C

completely free. Frequently inspect readings on the station pressure gauge. Should it read a sudden

pressure increase, stop the movement and check for the cause. Check that tie rod 33 rests on

Wheel 35.

12-10

(continua ont nxt paps)

~ 12, CRANE DISASSEMBLY -

__INTERNATIONAL CRANE SMH 322 ~ EDITION 02/200 - 3t

4.8 The lowering operation must continue without any interruption or reverse movements, as these

‘could exert abnormal stress on the crane structure, As soon as the boom rests onto the tower and

before tie rod 33 slackens, stop the lowering movement. Depress FAR push-button to unfold the jib

of such an angle to the boom so as to allow brace 39 to fold.

4.9 Check that derrick 42 rests on the apposite support in a position so as to allow the following

disassembly operations.

4.10 When required, turn the selector switch SA4 to position 1 and recover the hoisting cable.

____oomitinned om the ment pgs)

- 12. CRANE DISASSEMBLY - 12-11

Sor ror

INTERNAT inet CRANE SMH 322 ~ EDITION 02/200 - 3t

| 4.11 Unfold the jb by acting on FAR push-button. Limit switch FP2 prevents the jib from unfolding

| beyond 2 certain position if there is no ballast on base-frame FP3, position in which the jib =

automatically stopped.

(continived on the nxt page}

12-12 ~ 12. CRANE DISASSEMBLY -

|

|

[SAN MARCO

= CRANE SMH 322 ~ EDITION 02/200 ~ 3t

4.12 Proceed with tower lowering, making sure that brace 39 rotates forward until resting onto the boom

Upper stringer. Check that all movements are carried out correctly, that the cables and tie rods do

not entangle and tie rod 33 rests onto the support roll 34,

AN WARNING! ©

> Failure in unfolding the jib before tie rod 33 is slackened may cause serious damages to the crane

structure.

4.13 When brace 39 rests onto the boom upper stringer, stop the tower lowering movement and then

Gepress the RANGE NEAR push-button to fold the jib completely.

[AA WARNING!

> ___This movement is not controlled by any electrical limit switch therefore, during the folding final

(cwntinoad on the nex page)

~ 12, CRANE DISASSEMBLY - 12-13

INTERNATION

CRANE SMH 322 ~ EDITION 02/200 - 3t

phase, carefully check the reciprocal position of the structural parts to avoid interferences and

damages to frameworks and mechanisms.

44

415

4.16

4a7

Lower the tower. When required, turn selector switch $A1 to position 4 and recover the hoisting

‘cable to prevent the load block from reaching the ground and resting on it.

Check that the lowering movement is carried out regularly, that cables and tie rods are not

entangled or crashed and that the movements of all structural elements are carried out without any

friction. If it not yet done, remove the enclosure around danger zone A.

When the tower is about to rest onto the base-frame, check that tie rod 33 is in middle position, so

that it is not crushed under the tower.

Lower the tower until it rests onto the base-frame with the boom in horizontal position,

‘WARNING!

Failure in inspecting the hydraulic equipment prior to disassembly (see paragraph 04.6.2) may lead

to uncontrolled movements of the metal frame with consequent damages to the structural parts.

To position the trolley on micro switch 5S1 enabling disassembling, always displace it from the

tower towards the tip; by displacing it in the opposite direction, the micro switch will not enable the

procedure next steps.

Feailure in resting the jib onto brace 39 and tie rod 38 will cause an abnormal stress to be exerted

om the tower cylinder during cisassembly, with consequent danger of damaging the structures.

Failure in opening the jib to allow the rotation of brace 39 when the boom is resting on the tower

‘and before tie rod 33 is slackened, may cause serious damages to the structure.

Failure in recovering the hoisting cable when required and resting the load block onto the ground

Could slacken the cable on the drum with consequent possible damages.

Failure in checking the correct positioning of derrick 41 on its apposite support during tower

1244

lowering may cause damages to the frame and cables.

ee

~ 12. CRANE DISASSEMBLY -

SAN MARCO)

TERNATIONAL i CRANE SMH 322 ~ EDITION 02/200 - 3t

> Failure in checking the correct of tie rod 33 when the tower is about to rest onto the base-frame

may cause damages to the tle rod,

> Failure in clearing danger zones A - B - C during crane disassembly may engender risks of crushing

‘and colisions for all exposed persons.

> Disassembling the crane with wind speed higher than 10 km/b will seriously damage the structural

parts.

> Failure in removing the enclosure around danger zone A before the final phase of tower lowering

‘may result in damages to the structural parts.

> If the switches and selector switches are not set to their correct positions in the various disassembly

stages, it will not be possible to carry out the disassembly procedure correcty.

>» The assembly ballast blocks 320/2 and 400/1 must be unloaded from the machine base-

frame only after that all disassembly operations have been completed, with the tower is

on the ground and with the crane resting on its rubberised axles by means of an

auxiliary lifting means and not the derrick. Without the blocks 320/2 and 400/1 on

board, the crane will overturn.

12. CRANE DISASSEMBLY - 12-15

INTERNATIONAL CRANE SMH 322 ~ EDITION 02/200 - 3t

12.5. TRANSPORTATION ARRANGEMENTS

LAX | warsanst me

> The assembly ballast blocks 320/2 and 400/1 must be unloaded from the machine base-

frame only after that all disassembly operations have been completed, with the tower is.

on the ground and with the crane resting on its rubberised axles by means of an

auxiliary lifting means and not the derrick. Without the blocks 320/2 and 400/1 on

board, the crane will overturn.

5.1 For the following operations of axle assembling operation, the cable between load block and trolley

must be 1.04.5 m long; if necessary, lower the load block.

5.2 Fold the rear brace 32 with wheel upwards. Extract the pin n1.540.35 from the hole 44 of the

fixed section and hole 45 of the rotating section, rotate the brace upwards to align holes 45 of the

rotating section with 44. Reinsert pin n.540.35in holes 44 to lock the brace.

7 (continaad onthe next page)

12-16 = 12. CRANE DISASSEMBLY -

INTERNATIONAL CRANE SMH 322 ~ EDITION 02/200 ~ 3t

Remove the two pins 3.32.20 locking sideways the hinge of the jib terminal part to the jib, on the

opposite side as regards to the trolley cable. Remove the pin r3.60.30 locking the central stringer.

Remove the two screws M16x140 locking below the terminal part of the jib to jib. Bend the

terminal part sideways, making It turn around the two pins r3.32.20 of the hinge.

Lock the terminal part of the jib in folded position, inserting the pin r4.60.20 into the holes of the

connecting plates, placed on the lower tracks of the jib and of the terminal part.

Re-assemble the rear axle and secure it to the tower plates by pins n1.60.35.

= a saa =a

Depress UP push-button to lift the rear axle wheels of 20-25 cm from the ground to allow for the

fitting of wooden boards underneath. Depress DOWN pust-button to lower the wheels back onto

the wooden boards and lift stabilizer arms 1 and 2 from theit resting plates.

Release stabilizer arms 1 and 2 by extracting driving pins 1.80.35 out of the operating holes 6;

rotate the two stabilizer arms towards the front of the crane so that pins 11.80.35 can be inserted

into levelling holes 5. Fit two temporary wooden bases under the resting plates of stabilizer screws

Land 2.

© - LEVELLING HOLES

© - OPERATING HOLES

® @ - TRANSPORTING HOLES

eee

{coutinwad on the next page)

= 12. CRANE DISASSEMBLY - 1217

INTERNATIONAL CRANE SMH 322 ~ EDITION 02/200 ~ 3t

5:8 Place two temporary wooden bases and rest plates 11 under stabilizers 1 and 2, depress UP push-

button to lower the stabilizers 1 and 2 until they rest on their corresponding rest plates. Depress UP

Push-button once again to lower the crane on its rear side, thus ling stabilizers 3 and 4 off their

resting plates.

5.9 Remove pins 14.80.35 securing stabilizer arms 3 and 4 from holes 6 and fold the stabilizers back to

their transportation position. Secure them by pins 11.80.35 inserted into holes 7,

5.10 Depress DOWN push-button to lower the crane, when the front axle wheels touch the ground, the

rane rests on both front and rear axles. Axle wheels are still raised above the wooden boards. In

this way stabilizer arms 1 and 2 are raised from their rest plates and can be folded to the

transportation position.

5.11 Secure all stabilizer arms in transportation position by pins r1.80.35 inserted into holes 7. Remove

pins 13 and 14 locking the front axle crawbar,

52 Remove the electrical connections of the crane by disconnecting the cable from the terminals of the

‘main switch situated on the base-frame; disconnect the crane from the mains and from the earthing

network,

5.13 Create @ short descent ramp and tow the crane by a suitable means to lower the rear axle wheels

off the wooden boards they where resting on.

Z (coottuosd on the mex page)

12-18 ~ 12. CRANE DISASSEMBLY -

fy

INTERNATIONAL _

CRANE SMH 322 - EDITION 02/200 - 3t

TOWER SIDE AXLE

11.80.35

11.80.35

{continued om tne mes page)

~ 12. CRANE DISASSEMBLY - 12-19

BA

are)

IITERNATIONAL CRANE SMH 322 - EDITION 02/200 ~ 3t

[A

WARNING!

v

Failure in wearing the prescribed double-lock safety belt to access any structural parts 2 m above

the ground might cause the risk of felling

When folding sideways the terminal part of the jib, there subsists the danger, in case the terminal

part is not properly supported, of uncontrolled movements with consequent risk of crushing or

shearing forall exposed persons

\When folding upward the rear brace with wheel, there subsists the danger, in case the cusp is not

properly supported, of uncontrolled movements with consequent risk of crushing or shearing for all

exposed persons,

Failure in locking the upper section of the base-frame to the lower by pin 10 may lead to the

uncontrolled slewing of the crane lower part, with consequent risks for all the exposed persons

during machine transporting or levelling,

Do not disconnect the earthing system before disconnecting the power supply, to prevent the risk of

electric shocks.

Failure in locking the stabilzer arms with the relevant pins might cause their uncontrolled stewing

during transport, with consequent possible damages to the structures and serious risks for all

exposed persons.

Do not displace the crane without previously removing pins 13 and 24 locking the drawbar. Risk of

seriously damaging the front axle,

Should axles not be securely fixed to the crane, serious accidents might occur during machine

transportation.

WARNING!

‘The assembly ballast blocks 320/2 and 400/1 must be unloaded from the machine base~

frame only after that all disassembly operations have been completed, with the tower is

on the ground and with the crane resting on its rubberised axles by means of an

auxiliary lifting means and not the derrick. Without the blocks 320/2 and 400/1 on

board, the crane will overturn.

12-20

~ 12. CRANE DISASSEMBLY -

2&2

BANE rGrs)

INTERNATIONAL CRANE SMH 322 - EDITION 02/200 - 3t

12.6. TRANSPORTING AND TOWING INSTRUCTIONS

WN

> The assembly ballast blocks 320/2 and 400/1 must be unloaded from the machine base-

frame only after that all disassembly operations have been completed, with the tower is |

‘on the ground and with the crane resting on its rubberised axles by means of an

auxiliary lifting means and not the derrick. Without the blocks 320/2 and 400/1 on

board, the crane will overturn.

> When the first block 320/2 (1000 kg) is removed from the rotating base frame, the crane is

Unbalanced and tends to bend on the side where the other block has been left installed. It's

recommended to do this operation on a plain and solid ground, keeping to a safety distance,

consistent with the operation. The second block 320/2 must be unloaded immediately after the first

‘one, in order to balance the crane. It takes to follow the same prescriptions and procedure for the

unloading of the biocks type 400/1 (1,850 kg).

=

}

~ Sy et |

6.1 Make sure that all movable parts of the crane are securely locked, in ofcer not to crate any problem

during transport. In particular, check that: i

© the upper section of the base-frame is locked to the lower one;

© the

is locked to its fixing support;

othe load biock is locked to the trolley, to avoid damages to the cable; !

© the stabilizer arms and wind braces are properly locked;

othe wheels are locked to the hubs and the axles are locked to the base-frame;

© the drawbar is locked to the front axle,

6.2 Use an auxiliary lifting means to unload the assembly ballast (2 blocks type 320/2 and 2 blocks

type 400/1) from the crane base-frame.

6.3 Fix ropes or tie rods enough not to move during the transport.

64 Carry out any other locking or preparing intervention suitable to protect the safety of the exposed

personnel and the integrity of the crane.

65 To transport, tow or lift the crane strictly following the prescriptions given in paragraph.01,6 and

paragraph 01.7.

(conftinned on the next pags)

~ 12, CRANE DISASSEMBLY - 12-21

12-22

When the crane is parked or stationary, even on a level ground, its wheels must be securely locked

by manual brakes with the purpose to prevent any accidental machine rotation or displacement.

When parking on transit areas, place suitable warning signs, or indicator lights, to warn of the

presence of the parked crane.

When transporting and towing the crane, operate in strict observance of all prescriptions stated in

the present paragraph.

- 12, CRANE DISASSEMBLY -

13. RESIDUALS RISKS

13.1. RESIDUALS RISKS ......:ssesss0e

et tennant de

INTERNATIONAL CRANE SMH 322 ~ EDITION 02/200 - 3t

Ll

13.1. RESIDUALS RISKS

Failure in strcty observing all the instructions given point by point in the present instruction manual

will engender danger situations and consequent residual risks, as pointed out in each paragraph,

which can prejudice the crane integrity and as well as the safety of the operators and all exposed

persons.

‘AN

12

13

14

15

16

17

18

19

WARNING!

Several parts of the disassembled crane (arms, cusps, etc.) and assembled crane (upper level

Of the ballast, etc.) are fitted at @ position higher than 2 m above the ground and their surfaces

are not protected by non-slip paint. There subsists the risk of falling and access is therefore strictly

forbidden,

It is compulsory for all technicians in charge of crane erection and assembly and for operators in

general to wear the personal protective equipment prescribed by current regulations and laws

relating to safety.

Should the crane be operated at wind speeds over 70 km/h, its stability would be compromised

‘along with the integrity of its structural parts. Should the wind reach or exceed a speed of 70 km/h,

stop operating, release the slewing brake (paragraph.09.13) and lift the hook to it uppermost

position,

When hoisting and distributing loads, there subsists the residual risk of loads crashing against

unexpected obstacles met on their aerial path. It is therefore at the operator care and

responsibility to continuously check that the aerial path of the hook is free from obstacles.

Loads incorrectly slung or secured may fall, totally or partially, thus prejucicing the health and

safety of all exposed persons as well as the stability of the crane.

After any assistance intervention or crane erection operations, make sure that no tools and

working equipment are left on the crane’s structural parts. This may cause the residual risk

of tools and equipment falling downward during or after crane assembly, with subsequent danger

for the operators and all exposed persons.

‘If more cranes operating on the same building site should interfere with one other, or should

@ crane interfere with fixed obstacles (buildings, trees, poles, etc.), although limit switches are

installed to stop interference, there subsists the residual risk of crashes,

As far as crane installed in special conditions (e.g. near to transmitters) are concerned, it may

happen that the accumulation of static electricity in the crane metal frame is not discharged

by the grounding system. This means there subsists the risk of electroshock for operators and

exposed persons who, from the ground, may enter in contact with the structural parts of the crane,

the load block, cables or suspended loads. It is at the building site manager responsibilty to warn all

Operators and exposed persons of the above risk, prescribing to wear insulated shoes and gloves

‘and placing an insulating sling between the winch and the hoisted loads,

When operating the crane for long periods at high ambient temperatures, it is possible that the

extemal protections and/or enciosures of the electrical equipment and motors reach rather high

‘temperatures. Do not touch these parts without making sure their temperature is such not to cause

any burns.

The crane is equipped with all necessary devices to prevent the crane elements from overheating,

‘Should any of the combustible equipment (panel board, rubber cables, rubber oll pipes, etc.)

reach elevated temperatures, there subsist the risk of fire; suitable fire extinguishing means

must be kept at hand on the building site.

# ____(cotinaad on the mat pags)

~ 13, RESIDUALS RISKS - 13-1

163

ISAN MARCO}

INTERNATIONAL CRANE SMH 322 ~ EDITION 02/200 - 3t

1.12

1.13

114

14s

1.16

119

1.20

13-2

Under normal operating conditions, there is no risk of vibration, emission of radiation, dust and gas;

however, the crane is not protected against external radiation and is not equipped with laser

devices.

While using the crane, operators must be capable of directly inspecting from their work posts the

entire building site, all loading and unloading points, the aerial path of the load, the signs indicating

allowed load capacities as well as and the danger zone, to make sure that no exposed persons are

Present. Should, due to particular or exceptional conditions, it be impossible to meet even one of

these prescriptions, the operator must immediately call for the assistance of a second operator in

charge of signalling who, with direct visibility of the area not directly controlled, provide

instructions for the manoeuvres with clear and easily understood signals,

Should the operators or the exposed persons be daily exposed to a noise airborne level higher

than 80 dBA, they must wear appropriate ear protective equipment. The operators and all the

exposed persons wearing earplugs or ear protective devices will be thus unable to hear the crane

‘acoustic warnings of load hoisting and passage, 25 well as those signalling that the load and

‘moment thresholds have been exceeded. If ths isthe case, 2 visual flashing indicator light must

be added to the acoustic warning, placed in such a position that all exposed persons who are not

able to hear the auditory warning signal can see it. Connect one or more 48 Volt flashing light to

the terminals provided above the acoustic warning connecting terminals inside the electric cabinet.

Risk of corrosion. The crane non-galvanised elements are protected with a double layer of paint.

Abrasions caused by erection, disassembly or transport operations may damage the layer of paint,

thus exposing surfaces to oxidation. To prevent corrosion from spreading and damaging the frame,

restore the protection with a double layer of paint after each disassembly operation, taking care to

thoroughly clean the surface before applying the paint.

Risks due to frost. A number of holes are driled in the tubular elements of the galvanised

structural parts, in particular on the boom stringers, to allow the cast zinc to flow in and out of the

tubular elements during the galvanisation process. If one of these holes, in the lower part of a

tubular element, is obstructed during crane use, water could collect inside the element and, at low

temperature, ice could be formed with consequent damage to the frame. Each time the crane is

disassembled, check the holes on the lower part of the tubular elements to ensure they are not

obstructed and that rainwater and condensation can drain freely.

If the crane is erected in an area subject to frequent thunderstorms and therefore at elevated risks

of lightening, protect it by means of a suitable lightening protection system.

While there are no limits to the surface of hoisted loads in wind free conditions, an increase in

wind speed with consequent pressure exerted on the hoisted load reduces proportionally the

Surface of the exposed actual load (paragraph. 10.3.1). Should the wind reach the max wind

‘speed of 70 km/h (crane operating limit), the hoisted load surface must be smaller than one square

‘metre. With a wind of 35 km/h, the surface must be smaller than two square metres, and so on,

‘The maximum permitted tolerance for the crane supply voltage is 45% of the rated

value 380 V for the three-phase connection, whether with or without load. Should a generator

supply the power to the crane, make sure the generator is equipped with all the necessary devices

to ensure the prescribed maximum voltage deviations at all crane operating stages.

‘The present use and maintenance instruction manual reflects the state-of-the-art at the time the

Crane is put on the market. The present instruction manual cannot be considered as inadequate only

because manuals for the same type of crane, manufactured at a later date, are updated to take into

‘account any technological progress. The manufacturer secures the right to update its production and

the relevant instruction manuals, but is not obliged to update previous productions and previous

instruction manuals. Therefore any lack in technical updating may be a source of residual risks for

the user, due to the crane obsolescence.

(couttnned on te nas pgs)

~ 13. RESIDUALS RISKS -

nae

|

|

|

|

|

Brrr

1.21

122

123

1.24

125

1.26

BNATIONAL CRANE SMH 322 ~ EDITION 02/200 - 3t

Capacitors arranged inside the variable speed drives have a discharge time of several

‘minutes. Should it be necessary to carry out any maintenance intervention requiring the removal of

the variable speed drive outer protections, wait at least five minutes after the equipment has been

switched off before removing the protections and handling internal components. Acting in disregard

of these instructions may cause the risk of electroshock.

In order to assure a correct functioning in any condition of feeding with inverter for the hoisting

winch, the power of the motor is superabundant as to the max. loads admitted according with lifting

‘speeds, Under the best conditions of feeding, the installed power would allow to lift loads exceeding

the max. loads admitted; in order to avoid risk of breaking or damaging for the hoisting devices and

for the structural parts, it is compulsory to lift loads according with the max. loads admitted

and indicated in the present Manual, and always to keep efficient the speed limiters and

the max. capacity limiter.

Alll lubricants, especially the liquid ones, used in the reduction units or in the hydraulic system,

that come into contact with the skin or eyes or if swallowed are polluting substances that may have

serious consequences. The crane is delivered complete with a technical file containing the safety

data sheets of the lubricants used by the manufecturer.

The hydraulic devices must be used only for assembly and disassembly. Never use the hydrat

assembly devices when the crane has a load hanging to the hook. Danger of great damages

for the hydraulic devices.

The occurrence of atmospheric discharge due to storms may cause overvoltages on the feeding

line of the crane, that may cause damages to the electrical equipments of the machine; when the

weather conditions may foster the forming of lightning, it is necessary to shut down the crane

and to disconnect the feeding line to the crane electric cabinet, opening the disconnecting

switch or disconnecting the plug-socket connections. All the operators and the exposed persons

must immediately get away from the metal frame of the crane.

In accordance with the rules in force, San Marco cranes are verified, for what concems the stability

of the shut-down cranes, as a function of the following max. wind speeds:

HEIGHT OF THE STRUCTURAL PARTS ‘MAX, WIND SPEED.

(0-8 meters “100 km/h -

8-20 meters: 130 km/h

Higher than 20 meters_ 150 km/h

‘Should the weather forecast or the civil defence foresee hurricanes with wind speeds higher than those

listed in the table, the crane must be immediately disassembled.

~ 13. RESIDUALS RISKS - 13:3

14. REPAIRING THE MOST COMMON

FAILURES

14.1. IRREGULARITIES DURING CRANE ASSEMBLY AND DISASSEMBL'

14.2. IRREGULARITIES DUE TO ENVIRONMENTAL FACTORS.

14.3. IRREGULARITIES DURING CRANE EMPLOY

OPERATIONS IN AN EMERGENCY SITUATION

|

|

BSE rGre

INTERNATIONAL — CRANE SMH 322 ~ EDITION 02/200 - 3t

14,1. IRREGULARITIES DURING CRANE ASSEMBLY AND

DISASSEMBLY

The crane does not work.

‘The electric cabinet is equipped with a relay for phase sequence contro! (KSF). The power cables must be

correctly connected with the relevant R S T terminal (yellow led ON).

[Connect R ST in the proper sequence. Ei]

It's impossible to proceed with crane assembly or disassembly. i

ris ‘POSSIBLE CAUSE z z

The boom trolley Is not positioned on the relevant enabing micro Switch arranged near the boom

articulation.

‘Check for correct position of the trolley, whose sliding block must actuate the lever of the enabling micro

switch

It’s impossible to proceed with crane assembly or disassembly

z POSSIBLE CAUSE

“The selector switches inside the electric cabinet are not placed in the position proper for the assembly or

disassembly stage that must be executed.

= INTERVENTION

(Check the correct position of the selector switches. J

TRREGULARTTY,

At pickup stage, or when switching from one speed to another, the absorbed current reaches,

for few instants, higher values than measured while the crane is normally operating and

employed to calculate the rated values.

WARNING?

The indicated operating power vaiues are rated ones. a

ae INTERVENTION z aE

Connection to the main power supply must be equipped with delayed valves (not quick ones) to absorb the

pickup currents,

7X

> The most common faults can be inspected and repaired by skilled technicians from the building site,

| hhaving all the required information to carry out the tasks. Should these technicians be unable to

restore the crane operation, immediately contact the After-Sales Dept. of the manufacturer's

authorised dealer.

~ 14, REPAIRING THE MOST COMMON FAILURES - 141

s

BSG)

CRANE SMH 322 ~ EDITION 02/200 - 3t

INTERNATIONAL

14,2, IRREGULARITIES DUE TO ENVIRONMENTAL FACTORS

The brake of one electric motor (or of more electric motors) remains locked.

ae __ POSSIBLE CAUSE z sae

In presence of humidity, due to periods of rain or in winter, the electric motors brakes may sick to the

frame or the armature overnight or during long periods of inactivity. If this is the case, the traction of the

magnet will not be sufficient to release the brake.

The brake may burn or the motor, running with the brake locked, may be damaged.

Manually release the brake by inserting the tip of a screwdriver, Just once, between the brake and magnet

‘or the brake and its frame to set the device free. is

TRREGULARTTY

At high ambient temperatures the electric motors, when subjected to heavy load conditions, may increase

in temperature so much to trip the motor thermal protections.

Immediately stop operating so that the motor can cool down and reset the protection device.

ss TRREGULARTTY,

At very low or very high temperatures, the oil density of the hydraulic system is significantly

modified.

INTERVENTION.

[titakes to execute a specific adjustment of the valves of the assembly cyinders. Z

| A\ ea sito Sn es

* The most common faults can be inspected and repaired by skiled technicians from the bullding site,

having all the required information to carry out the tasks, Should these technicians be unable to

restore the crane operation, immediately contact the After-Sales Dept. of the manufacturer's

authorised dealer.

14-2 "= 14, REPAIRING THE MOST COMMON FAILURES -

|

CRANE SMH 322 ~ EDITION 02/200 ~ 3t

NTERNATIONAL

14,3. IRREGULARITIES DURING CRANE EMPLOY

“TTRREGULARITY

A movement is not ‘executed after its control.

[tis POSSIBLE CAUSE

Tt may be due to the intervention of a micro-switch or @ position limit switch, its incorrect set-up, or a

movement over-travel beyond its control.

INTERVENTION

Control 2 movement in the opposite direction and check the setting of the position limit switch involved.

‘The motors driving the operating movements of the crane are provided with magneto-thermal protections.

In case of overload, one of these protections may trip, thus stopping the motor and preventing the

execution of the requested movement.

Check inside the eecc cabinet and eventual restore the protecion infeed. ]

‘A movement is not. executed after its control.

Problem of the controling device:

‘© a faulty control board connection; |

© damages to the board connecting cable;

© improper plugging-in;

o_etc.

INTERVENTION.

‘Check all connections of the controlling device.

IRREGULARITY.

“The motor brakes can become jammed. To ascertain jamming, check ifthe brake disc detaches

freely.

‘POSSIBLE CAUSE

Different causes may lead to this irregularity

‘abnormal value of the gap size;

environmental coneitions (frost, humidity, etc.);

burnt-out brake coil;

faulty coil, causing brake malfunctioning after short periods of use. HH

INTERVENTION

If the gap size is abnormal, it must be restored to that specified in the instruction Manual. |

If the coll is bourn-out or faulty, replace the coll. |

LN WARNINGE &

> The most common faults can be inspected and repaired by skilled technicians from the building site,

| having all the required information to carry out the tasks. Should these technicians be unable to

restore the crane operation, immediately contact the After-Sales Dept. of the manufacturer's

‘authorised dealer.

(coxtinwad on he pags)

= 14, REPAIRING THE MOST COMMON FAILURES - 14-3

INTERNATIONAL CRANE SMH 322 - EDITION 02/200 - 3t

14-4 - 14, REPAIRING THE MOST COMMON FAILURES -

ISAN MARCO

INTERNATIONAL __CRANE SMH 322 ~ EDITION 02/200 - 3t

14.4, OPERATIONS IN AN EMERGENCY SITUATION

mn WARNING! ~~

> The following emergency operations can be carried out in case of power failure and in

case of lifted load stopped middle-way due to the power failure.

inet

A) TO LOWER THE LOAD

4.1 Remove the protective case from the hoisting motor brake (paragraph. 09.4);

4.2 Insert a lever between the compression plate and brake lining;

4.3. Operate the lever to move the compression plate away from the brake lining as much as required to

allow motor to rotate;

4.4 Actuate the lever with short jog movements so that the load is lowered slowly.

B) TO ROTATE THE CRANE

4.5 Fully release brake handgrip as when the crane is out-of-service (paragraph 08.13);

4.6 Push the ballast on one side so that the crane is slowly rotated;

4.7 Should the above operation not be possible, dismantle the stewing motor and act directly on the

washer on the gearbox entry side. By turning the washer with a proper tool, the crane is rotated

slowly.

©) IN CASE THE TROLLEY SHOULD STOP DUE TO A FAILURE

4.8 Should the trolley be on the jib (front part of the boom):

lower the load block next to the ground, or at leas to the lowest point allowed;

© inside the electric cabinet, by-pass the enabling micro switch 551;

fold the jib;

© disassemble the crane;

© being the crane disassembled, unfold the jib to place the trolley in correspondence of the micro

switch 581.

4.9 Should the trolley be on the rear part of the boom, or in such a position that it would be

crushed between the tower and the boom during crane disassembly:

© lower the load block next to the ground;

© inside the electric cabinet, by-pass the enabling micro switch 551;

fold the jib;

handling the load block by its handles, displace it sideways as regards to the crane;

7 (contd on thn nes pape)

= 14, REPAIRING THE MOST COMMON FAILURES - 14-5

BAN)

CRANE SMH 322 - EDITION 02/200 ~ 3t

4.10

NATIONAL,

© start tower lowering: the boom, lowering, rests to the tower by mean of the trolley and its

‘supports, preventing pulleys and cable from damaging, because the cable is pulled sideways;

being the tower completely lowered, the boom stands inclined under the effect of the trolley,

but it is stable and allows to repair the motor or the gear unit of the trolley. In such a

Position, it is forbidden to unfold the jib.

Should the trolley cable be broken:

© lower the load block next to the ground;

‘© making the hoisting cable slide, place the trolley in correspondence of the micro switch 5S2;

© fold the jib, by-passing, if needed, the micro switch 5S;

© disassemble the crane.

WARNING! ~~

Only trained, skilled and expert technicians should carry out emergency interventions.

Never, under any circumstances, disassemble the crane with unfolded jib. Whenever

necessary, use a truck crane and platform suitable for lifting up people to carry out the repairs

required to fold the jib prior to crane disassembly.

14-6

= 14, REPAIRING THE MOST COMMON FAILURES -

1

1

|

15.1, STEERING REAR AXLE.

15.2. HEADLIGHT..

15.3, ANEMOMETER..

15.

OPTIONAL

ea

at)

INTERNATIONAL

CRANE SMH 322 ~ EDITION 02/200 - 3t

15.1, STEERING REAR AXLE

1.1 The crane is supplied complete with a steering rear axle, easing crane displacement during its

Positioning on the building site.

1.2 At the crane transporting stage, the hubs rotation is normally locked by pin 2 with the wheels

Parallel to the crane axis and drawbar 2 dismantled, when operating in the above conditions, the

Fear axle operates as a standard fixed axle.

1.3. To employ the steering axle, operate as described: remove lock pin 4, fit angle draw bar 2 and

secure by means of pin 3. The angle draw bar allows operating the crane both on its left and right

side, depending on the installation of the draw bar.

WARNING!

> fet alte above describe operations only withthe rane at stan stil, stopped, and with the front

Wheels locked by wedges.

> Both the front and the rear axle drawbars must be controlled with the crane towed, while itis

displaced. Trying to control the draw bar with fixed crane will couse excessive stress to exerted on

the crane, and will damage the wheels and the mechanisms,

1.4 The mutiple-hole rest plate 4 allows for axle locking in more different oblique postions, so that the

crane can be towed in a direction different from its ais,

(covftd mt na pga)

15-1

~ 15. OPTIONAL -

BASORGrs)

INTERNATIONAL CRANE SMH 322 ~ EDITION 02/200 - 3t

15 In addition, itis possible to control sideward displacement of the crane by turning the rear axle

wheels by 90° to the crane axis. To the purpose, proceed as described:

remove pins 5 coupling the wheel hubs to the drawbar 8;

rotate the wheels in @ perpendicular position to the crane axis so that the holes of plates 6

Perfectly match those of plates 7. To ease rotation, eventually lift the wheels up with a jack;

secure wheels in that position by inserting lock pins into the holes of plates 6 and 7;

by acting on the front axle drawbar, rotate its wheels in perpendicular postion, too;

by Pushing the crane sideward itis now possible to effect short lateral displacing manoeuvres.

Side push must be applied to the lower base-frame; it shall be gradual in order not to prejudice

crane stability.

15-2

(continued on the nant page)

~ 15. OPTIONAL -

on an renee mama er eee —enlhtennninwhahN ARS

SAN MARCO)

CRANE SMH 322 — EDITION 02/200 - 3t

INTERNATIONAL

STEERING REAR AXLE

cseee>

inn

Li|

|

i

~ 15. OPTIONAL - 15-3

|

|

}

}

|

SAN MARCO]

__INTERNATIONAL

24

2.2

23

24

CRANE SMH 322 ~ EDITION 02/200 - 3t %y

15.2, HEADLIGHT :

‘The crane can be supplied complete with an optional lamp for lightening the working area of the

building site. The 500 W floodlight is fitted at the boom foot, inside it.

To supply power at 220 V to the headlight, the crane connection o electric cabinet of the building

site shall be effected by means of a 5-wire cable (R4+S+T+N+PE); by a 4-wire cable, the

connection phases-neutral to obtain 200 V would not be possible,

‘Shouid the healight be successively installed, secure by self-locking nuts and screws the support to

the plate of the terminal board at the jib foot and then connect the headlight supply cable to the

terminals N3 and $10 inside the terminal board through the free cable gland.

To switch the headlight on, close the magnetic switch 1QF2 inside the electric cabinet.

15-4

| WARNING!

‘At the transporting stage, should the crane undergo bumps and oscillations, the headlight bulb could

be damaged.

- 15. OPTIONAL -

&

BETS

__INTERNATIONAL

Ba

32

CRANE SMH 322 ~ EDITION 02/200 ~ 3t

15.3. ANEMOMETER

‘The anemometer is installed inside the boom of the crane, near the connection boom-tower hinge.

‘The paddle receiver is mounted on the upper part, signalation lamps and the siren are in the lower

part

The protected position avoids damages to the structure during the erection and the dismantling of

the crane,

7 \

In the electric cabinet there is the magnetothermic 1QT5, which controls the electrical supply 48 V

33

Of the anemometer. Opening it you close the supply of the anemometer, which is deactivated. If the

‘anemometer is broken, the magnetothermic automatically opens itself, letting the crane working

3.4 When the wind speed attends 50 km/h, in the metal box the alert starts:

flashing orange light;

© Intermittent alarm.

(continnrad om the maxet page)

- 15, OPTIONAL - 15-5

Brrr

INTERNATIONAL CRANE SMH 322 ~ EDITION 02/200 ~ 3t

35 When the wind speed attends 70 km/h, in the metal bx the alert starts:

© fixed red light;

© continuous alarm,

15-6 ~ 15. OPTIONAL -

ITERNATIONAT. CRANE SMH 322 ~ EDITION 02/200 ~ 3t

a z __-PAGEFORNOTES ]

I

|

|

|

|

hey *

|

a

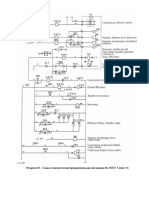

pete (ROS SUHSO1riverter444 C.C.15.44.14443.081.1

xo (SHC) ‘SAN MARCO_INTERNATIONAL

ame ie R.05.02 | OPEP*SHOM HAN POWER CRCUT

oois__21/08/2007

INVA. CEVA,

a

SMH322 [Ra]

a KW

sar

LeU

on x R,05.02 reais

(SPR tor “] SMH307 2

R.05.02 sane. SMH322 [SER]

21/06/2007 nuove ceva

2;2Kw 18 kW

a: ven 1

B wee i

| sl | sf 5} al 3) 8) |

semen) led pale | he be ss bw fw TET

a

os. R,05.02

(PX)

05.02

21/08/2007

‘SMH301 2

SMH322 aE

on R05.02 ; a

ons R05.02 | cyiSortriverter444 C.0.15.44.14443.081.1] _ 803.02

oo SK) WN MARCO. INTERNATIONAL Coo SMH301

ome Fen R.05.02 | S™PPSHEME AN CONTROL CRCUT we ‘SMH322

ele___21/08/2007 NUOVA COVA

3 ease [eee oa

|] =! ee

| jose 2

S03

ma

1

= Time —T =

fe» R062 TeirSortivererees C0.15.44.14443001.]. e502

[S20] I SAN MARCO. INTERNATIONAL Tommaso SMH301 5

8.05.02 [Perominesone “HOISTING CONTROL ORCUT (1 eae neaee SMH322 [Sue]

21/08/2007 ae ceva |

at

SMH30 I triverteraa4 C.

MARCO

‘SMH301

SMH322

Fieatore

INUOWA. CEVA

21/08/2007

orsee decease z cc

| "eggro| tare

4 Sean eee

) + 4

SECC

a OD OKA KAS.

_ [ea

sr by sua seus |y se

|

on on

3 3

oz n R.05.02

jez 2.05.02 _| rivertert44 0.0. 15.44.14443.08;

cao __[SPAC) SAN MARCO INTERNATIONAL ‘SMH301

Noma Fie _.05.02 Desemineriene "TROLLEY CONTROL CRCUT (11 ‘SMH322

| 3 ] q Pa 3 ¢

| Het east |

3 | |

ROS To sumecnraaa costs an 4sacoes | Rosca a

(x0) SAN MARCO_ INTERNATIONAL Tames SMH301 8

R.05.02 eo LEY CONTROL CREUT SMH322— [SEO

21/06/2007

sx

A | ,

, m

mi i “by

Lp _

pen Rosine SMe130 tr ter4 C.C.15.44,14443.081.

O52 Sor ueractes GIS tt et

fs

Nuova. CEVA

21708/2007_|

The indoor radio remote control, is always powered

, connect its control cable coming from

the electric cabinet, to the CN1 female connector.

‘SMH3O 1 triverter444 C.C.15.44.14443.081.1|

‘SAN _MARCO_INTERNATIONAL

fore “(na REMOTE CONTROL PLUG connecToR | _F:0502 |

‘SMH301

‘SMH322

—_s 2] aywaszena- om wpe

= . oe

wy HOLIMS fil] LHD

©. a Pe eee = wu. +] ny waaHonaNy

7 esa

wT sos fins eee

_ muss LENA (cI bo LTH MS TTWNDIS HET

= cae

a. *NaWOW JILVIS.

Dus UT ONNOTS é0 (Goma) RT

cr ast, oO r

1st io. 2

o =. z+ HOLIMS Li dn jo o

a — S #

See) gS Bie 8 Fa] sas

jer °— al (348 HOH ONION iS =

a |? |e 1 lo Zz ays ‘WANOD NILSAOI=ON

2 oe a Inaiow tes fo wel | sanoLunausna-an

is lo wa +

22 ge) eee ee

38 28 eee [a

[3 |" 15k HOLIMS LIA =

E ne 4

oo my

3 aves 37) -

2: foe tom azT0eL Il Se) ataower

5) sacar

fleet et WL) ana outtoan ar

“83 (gE EY pense omas 1 ta

slek | BS ESEG wiovomasis oa seven sdlbyov anno

: Seteeereeeeeeeetrees a

g ts anova nanos

Ee. | FSS a

eas | et g =e

3\30 : Oe Of] tano2 ates onus

ak cy a E48

32 | fo ZI] ive onusion (IIT) aS seine

g | a

5 — ON. ead

8 fost ceaea ie

BSF cust sen ig

= ° a (o TT) vais Wt ounsao air

aaa

a — os

38/23/8"| (oa as nraens wrosnnon — @ = a ‘ms nokHbOd AITIONL

is (o Os “80151534 ONLWIH HOUIMS Lin 1048

(o ee) ws ena 2. =F HOLIMS Lin HLaOs 9b

28 — so

22 Sey + HOLIMS Lin] HLeOs 46

de

gag

z z z

ir one ee

[Descrizione/Description

Costruttore/Maker [Quadro

ran TCH wT OR NTERLOCE

EBRECHER SH ow SHCA [0G

nan ac BRE

TOLLEY GACT BREARER

T ROPENT BREALATH ROLAY

0K UP RELAY re

[p.0ck oan RELA

STNG LOw SPEEORELAY

ER SLA ac

[MDER OF SPL AR lac

EROER OR SAAR ca

FROCR OF SIAR a

SMH301triverter444 C.0.15.44.14443.081.1_ 05.02

‘SAN MARCO_INTERNATIONAL

‘SMH301

21/08/2007 _|

omens CONPOENTS IST

SMH322

NUOVA. CEVA

Peay,

one = Seem

[Nome/item

Costruttore/Maker

[FRoen Sera (as

[FROER 8 Sra a6

factor

[xo RECEVER(GPTOWALT

PENDANT STATION SOC COMECTOR

Toa ETON

BAHN RESTSTORS BOX

ESIETORS FASTENER

21/08/2007

swusOttriverter444. C.C.15.44,14443.081.1| 0802

'SANMARCO_INTERNATIONAL =

DererineHene COMPONENTS UIST @) eee

NUOVA. CEVA

‘SMH301

SMH322,

- 7 z i —= z 5 T z T = ieee

NI ~ CONNECTOR

PUSHBUTTON P

riverterA44 C.C.15.44.14443.081. 7

IN MARCO_ INTERNATIONAL SMH301

CONTROL COMECTORS SMH322 | ROE

NOVA CEVA

7nas oRGOBOW eayDedS BIB EDL epaues

‘ALBS¥S*ONVANOD A GOISA GNVAWOO A,

eS arm 4)

COS

Ses

OSes

r OBS TH 1avis

g aos ES OSs asvus

3 Fe asvsis 2

E aaays Fr assas y

[saws sf

Oe ss

OS =o 1s

o>—_D Ce} mcs

@—= > C

3 > epee es

[aan => a

AlddNS YIMOd uMs

Izv

OW9080V> - T8V

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5819)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Multitel 1Document22 pagesMultitel 1Evgeni FrangovNo ratings yet

- 24 5vdcDocument5 pages24 5vdcEvgeni FrangovNo ratings yet

- Red RazganatiDocument3 pagesRed RazganatiEvgeni FrangovNo ratings yet

- Brrigs StrattionDocument37 pagesBrrigs StrattionEvgeni FrangovNo ratings yet

- BK 1Document4 pagesBK 1Evgeni FrangovNo ratings yet

- ARON VentilDocument22 pagesARON VentilEvgeni FrangovNo ratings yet

- инстр Кулокран 4Document41 pagesинстр Кулокран 4Evgeni FrangovNo ratings yet

- инстр Кулокран 2Document57 pagesинстр Кулокран 2Evgeni FrangovNo ratings yet

- инстр Кулокран 1Document63 pagesинстр Кулокран 1Evgeni FrangovNo ratings yet

- Bod Koz Most 140Document1 pageBod Koz Most 140Evgeni FrangovNo ratings yet

- ОНК - 140 - 02Document21 pagesОНК - 140 - 02Evgeni FrangovNo ratings yet

- Bod Trub 140Document1 pageBod Trub 140Evgeni FrangovNo ratings yet

- Bod 140Document1 pageBod 140Evgeni FrangovNo ratings yet

- мзонDocument18 pagesмзонEvgeni FrangovNo ratings yet

- 2afdea72 - ETLF Operators Manual 2009Document49 pages2afdea72 - ETLF Operators Manual 2009Evgeni FrangovNo ratings yet

- Avtov Multitel PDFDocument18 pagesAvtov Multitel PDFEvgeni FrangovNo ratings yet

- 1 2Document4 pages1 2Evgeni FrangovNo ratings yet

- Asy 31Document33 pagesAsy 31Evgeni FrangovNo ratings yet

- Telecrane Remote ControlsDocument31 pagesTelecrane Remote ControlsEvgeni FrangovNo ratings yet

- MX2 DatasheetDocument16 pagesMX2 DatasheetEvgeni FrangovNo ratings yet

- KC 3575a PDFDocument164 pagesKC 3575a PDFEvgeni Frangov100% (1)