Professional Documents

Culture Documents

Clamp For Line Post Insulator

Uploaded by

TAEWARAT RAKRUANGOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Clamp For Line Post Insulator

Uploaded by

TAEWARAT RAKRUANGCopyright:

Available Formats

Standard Number: 6941.

15

Seattle City Light Superseding: New

Effective Date: February 23, 2018

MATERIAL STANDARD Page: 1 of 4

Clamps, Trunnion, Line Post Insulator

1. Scope

This standard covers the requirements for trunnion clamps used with clamp top line post

insulators.

Trunnion clamps consist of a body, a keeper (a metal piece that sandwiches the

conductor to the body of the clamp), fastening hardware, and an anti-static spring.

This standard applies to the following Seattle City Light (SCL) stock numbers:

Conductor

Stock No. Metal Range (in)

695182 Ductile Iron 0.25 – 0.56

695183 " 0.50 – 1.06

695192 Aluminum 0.25 – 0.56

695193 " 0.50 – 1.06

695196 " 0.99 – 1.50

695194 " 1.00 – 1.50

695195 " 1.50 – 2.00

2. Application

Trunnion clamps are intended for use on tangent or shallow angle suspension spans with

clamp top horizontal or vertical post insulators.

Aluminum clamps may be used with all aluminum, ACSR, or aluminum alloy conductors.

Ductile iron trunnion clamps are used in copper conductor or ground wire applications.

Aluminum alloy and ductile iron clamps are not interchangeable.

Standards Coordinator Standards Supervisor Unit Director

Quan Wang John Shipek Andrew Strong

Standard Number: 6941.15

Seattle City Light Superseding: New

MATERIAL STANDARD Effective Date: February 23, 2018

Clamps, Trunnion, Line Post Insulator Page: 2 of 4

3. Industry Standards

Trunnion clamps shall meet the applicable requirements of the following industry standards:

ANSI/NEMA C29.7-2015; American National Standard for Wet-Process Porcelain

Insulators—High-Voltage Line-Post Type

ASTM A47 / A47M-99(2009); Standard Specification for Ferritic Malleable Iron Castings

ASTM A153 / A153M-05; Standard Specification for Zinc Coating (Hot Dip) on Iron and

Steel Hardware

4. Requirements

Aluminum trunnion clamps and keepers shall be made of 356 T6 cast aluminum alloy or

high-strength, heat-treated wrought aluminum alloy.

Ductile iron trunnion clamps and keepers shall be made of ductile iron in accordance to

ASTM A47. Iron clamps and keepers shall be galvanized in accordance with ASTM A153.

Trunnion clamps and keepers shall:

▪ Be designed to meet the ultimate strengths shown in Table 4.

▪ Comply with the dimensions and configurations shown in Table 4 and Figures 4a,

4b or 4c.

▪ Have smooth surfaces and all edges rounded to prevent formation of a corona or

damage to the conductor.

▪ Be provided with a stainless steel anti-static spring installed in one of the trunnions.

▪ Be compatible with insulators meeting the applicable requirements of

ANSI/NEMA C29.7.

▪ Have an ultimate strength of 2800 lb.

Fastening hardware shall consist of a 1/2" hex cap screw with a split lock washer.

Fastening hardware shall be galvanized steel coated in accordance with ASTM A153, or

stainless steel.

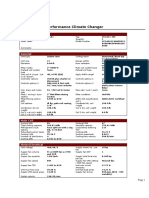

Table 4. Trunnion Clamp Attributes

Dimensions, Nominal Maximum

Length Width Take-Off Angle

Clamp Conductor Diameter (in) (in) (in) (degrees)

Stock No. Metal Min. Max A B C

695182 Iron 0.25 0.56 5-1/8 3-7/8 15

695183 " 0.50 1.06 5-1/2 3-7/8 15

695192 Aluminum 0.25 0.56 5-1/4 3-7/8 20

695193 " 0.50 1.06 5-1/4 3-7/8 20

695196 " 0.99 1.50 7 3-7/8 20

695194 " 1.00 1.50 5-1/4 3-7/8 20

695195 " 1.50 2.00 6-1/2 3-7/8 20

Standard Number: 6941.15

Seattle City Light Superseding: New

MATERIAL STANDARD Effective Date: February 23, 2018

Clamps, Trunnion, Line Post Insulator Page: 3 of 4

Figure 4a. Single Bolt Trunnion Clamp, Hot Line Operable

Figure 4b. Two Bolt Trunnion Clamp

Figure 4c. Two Bolt Trunnion Clamp with Wide Keeper

Standard Number: 6941.15

Seattle City Light Superseding: New

MATERIAL STANDARD Effective Date: February 23, 2018

Clamps, Trunnion, Line Post Insulator Page: 4 of 4

5. Marking

Each clamp shall be permanently and legibly marked in raised or stamped letters.

Marking shall include but not be limited to the following information:

▪ Manufacturer name or symbol

▪ Manufacturer part number

▪ Clamp ultimate strength

6. Packaging

Product shall be packaged to prevent damage during shipping, handling, and storage.

Standard package quantity shall not exceed 25 per box.

Standard package weight shall not exceed 50 pounds.

Individual packages shall be legibly marked with:

▪ Manufacturer name

▪ Manufacturer catalog number

▪ Product description

▪ SCL stock number

7. Issuance

Stock Unit: EA

8. Approved Manufacturers

Single Bolt (Figure 4a) Two Bolt (Figures 4b and 4c)

Hubbell Power Systems – MacLean Power

Stock No. Columbia Mfg. Lindsey Anderson Systems

695182 ALPS-57-SE 1101-RIV 270650-3001-ARIV LPS-57-F

695183 – – 270651-3001-ARIV LPS-118-F

695192 – 1100-RIV TSC-57-ARIV ACTS-057-SL1

695193 – 1104-RIV TSC-106-ARIV ACTS-118-SL1

695196 ALPS-150-SE – – –

695194 – 1108-RIV TSC-150-ARIV ACTS-150-SL1

695195 ALPS-200-SE 1128-RIV TSC-200-ARIV ACTS-200-SL1

9. Sources

www.hubbellpowersystems.com

www.macleanpower.com

SCL Material Standard 6901.40; “Insulator, Vertical Line Post, Porcelain, Clamp Top, for

Distribution Systems”

SCL Material Standard 6901.60; “Insulator, Horizontal Line Post, Porcelain, Clamp Top,

for Distribution Systems”

SCL Material Standard 6951.5 (canceled); “Clamps, Trunnion, Line Post Insulator”

Wang, Quan; SCL Standards Engineer and originator of 6941.15

(quan.wang@seattle.gov)

You might also like

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- ASTM A641 A641M 2003 Standard Specification For Zinc Coated Galvanized Carbon Steel Wire 26 PDFDocument5 pagesASTM A641 A641M 2003 Standard Specification For Zinc Coated Galvanized Carbon Steel Wire 26 PDFRober Moises Chumbe SoveroNo ratings yet

- Parallel Groove Clamp For Earth WireDocument10 pagesParallel Groove Clamp For Earth WireMohamed AhmiedNo ratings yet

- Astm A928Document6 pagesAstm A928iuiuiooiuNo ratings yet

- AMENDMENT 2 (500 KV) (Rev2, Apr2016)Document7 pagesAMENDMENT 2 (500 KV) (Rev2, Apr2016)Jed SrisuthumNo ratings yet

- Aluminium and Its Alloys Used in Electrical EngineeringDocument7 pagesAluminium and Its Alloys Used in Electrical EngineeringTigrilloNo ratings yet

- Cutting Edge BrochureDocument2 pagesCutting Edge BrochureKen SmithNo ratings yet

- Technical Specification Rabbit ACSR ConductorDocument5 pagesTechnical Specification Rabbit ACSR ConductorRiyasKadappayilNo ratings yet

- Vol2 TL-S11-19 3626Document133 pagesVol2 TL-S11-19 3626cantigiNo ratings yet

- ACSR Rail ZTTDocument6 pagesACSR Rail ZTTAntony Cesar Caballero IbarraNo ratings yet

- B 211 - 02 - Qjixms0wmgDocument10 pagesB 211 - 02 - Qjixms0wmgmercab15No ratings yet

- Stud Bolt Specification 3Document7 pagesStud Bolt Specification 3santoshblonkarNo ratings yet

- A648Document4 pagesA648Hanibale Nuril HakimNo ratings yet

- Eti Ohe 11 5 89Document12 pagesEti Ohe 11 5 89Abhishek PandeyNo ratings yet

- Material Specs - LugsDocument15 pagesMaterial Specs - LugsVijay RaghavanNo ratings yet

- Brochure Flujo Magnetico FoxboroDocument4 pagesBrochure Flujo Magnetico FoxboroJuan Carlos Calderón UribeNo ratings yet

- ALLOY 6082: Understanding Extruded Aluminum AlloysDocument0 pagesALLOY 6082: Understanding Extruded Aluminum Alloysetamil87No ratings yet

- B 211m - 02 - Qjixmu0tmdiDocument10 pagesB 211m - 02 - Qjixmu0tmdimercab15No ratings yet

- RIBE - B01 - Overhead Line FittingsDocument165 pagesRIBE - B01 - Overhead Line FittingsSofyan Andika YusufNo ratings yet

- Martin Zhu: Technical SpecificationDocument5 pagesMartin Zhu: Technical SpecificationalfredoNo ratings yet

- Sp0-160041-A-Acsr-Mz 400-51 PDFDocument3 pagesSp0-160041-A-Acsr-Mz 400-51 PDFDuy TiếnNo ratings yet

- Sp0-160041-A-Acsr-Mz 400-51 PDFDocument3 pagesSp0-160041-A-Acsr-Mz 400-51 PDFDuy TiếnNo ratings yet

- C 955 - 03Document4 pagesC 955 - 03Tarek FennicheNo ratings yet

- A12 Appendix 12 Technical ScheduleDocument79 pagesA12 Appendix 12 Technical Scheduleanon_31581079No ratings yet

- A 401 - A401m - 98 Qtqwms05oa - PDFDocument4 pagesA 401 - A401m - 98 Qtqwms05oa - PDFTiến Lượng NguyễnNo ratings yet

- Carraro India LTD Steel Mill Standard Rev 08Document7 pagesCarraro India LTD Steel Mill Standard Rev 08SUNDARNo ratings yet

- Metco 470AW 10-632Document8 pagesMetco 470AW 10-632JSH100No ratings yet

- Oes 25aDocument6 pagesOes 25aBOBNo ratings yet

- L1-CHE-SPE-059 Hard-Drawn Copper Solid Dropper Wire 21.15mm 2Document6 pagesL1-CHE-SPE-059 Hard-Drawn Copper Solid Dropper Wire 21.15mm 2CK TangNo ratings yet

- TS PHIIR Part4Document104 pagesTS PHIIR Part4purechemcabledeptNo ratings yet

- Chapter - E12: Requirements of Auxiliary Items Aluminium Tubular ConductorDocument10 pagesChapter - E12: Requirements of Auxiliary Items Aluminium Tubular ConductorvenkateshbitraNo ratings yet

- Astm 510Document7 pagesAstm 510Arnold Bohorquez Acevedo100% (1)

- Load-Bearing (Transverse and Axial) Steel Studs, Runners (Tracks), and Bracing or Bridging For Screw Application of Gypsum Panel Products and Metal Plaster BasesDocument4 pagesLoad-Bearing (Transverse and Axial) Steel Studs, Runners (Tracks), and Bracing or Bridging For Screw Application of Gypsum Panel Products and Metal Plaster BasesJesús Luis Arce GuillermoNo ratings yet

- Liquidtight Broch DEC06Document8 pagesLiquidtight Broch DEC06Anonymous OnzJpzNo ratings yet

- Acsr SpecsDocument1 pageAcsr SpecsPanda NoirNo ratings yet

- S-LOK Tube FittingsDocument58 pagesS-LOK Tube FittingsCesar YalanNo ratings yet

- SS 316 & SS316LDocument3 pagesSS 316 & SS316LVijayakumar AtthuluriNo ratings yet

- Knowledge Tit-Bits On Transformer Electrical Steels-Part 2Document13 pagesKnowledge Tit-Bits On Transformer Electrical Steels-Part 2salemg82No ratings yet

- GCA CatalogDocument32 pagesGCA CatalogMohamed GallouNo ratings yet

- Electric-Resistance-Welded Carbon and Alloy Steel Mechanical TubingDocument20 pagesElectric-Resistance-Welded Carbon and Alloy Steel Mechanical TubingMohamad ShafeyNo ratings yet

- A667Document6 pagesA667IjabiNo ratings yet

- 6061 Vs 6063Document9 pages6061 Vs 6063SrRonNo ratings yet

- 1 Scope: 1.1 Normative ReferencesDocument8 pages1 Scope: 1.1 Normative ReferencesYenny300000No ratings yet

- Material Standard: 21 KV Heavy Duty Distribution Class, Polymer, Metal-Oxide Surge ArrestersDocument3 pagesMaterial Standard: 21 KV Heavy Duty Distribution Class, Polymer, Metal-Oxide Surge ArrestersShahriar AhmedNo ratings yet

- G&W - Outdoor Termination KitDocument4 pagesG&W - Outdoor Termination Kitchock channel 19No ratings yet

- C 955 - 01 Qzk1ns1sruqDocument6 pagesC 955 - 01 Qzk1ns1sruqHumberto GutierrezNo ratings yet

- Norma A568Document29 pagesNorma A568andersonarizaeNo ratings yet

- ACSR Cataloge, IEC, Charoong Thai Wire & CableDocument2 pagesACSR Cataloge, IEC, Charoong Thai Wire & Cablemaungsoekhin100% (1)

- L1-CHE-SPE-058 Bare Flexible Annealed Copper Jumper Wire 37 - 7 - 0.70 100mm 2Document7 pagesL1-CHE-SPE-058 Bare Flexible Annealed Copper Jumper Wire 37 - 7 - 0.70 100mm 2CK TangNo ratings yet

- Brass 260Document1 pageBrass 260ccocos7182No ratings yet

- ICBO Evaluation Service, IncDocument7 pagesICBO Evaluation Service, InczarafshinNo ratings yet

- Metallic-Coated Steel Marcelled Tension Wire For Use With Chain Link FenceDocument3 pagesMetallic-Coated Steel Marcelled Tension Wire For Use With Chain Link FenceJosé Ramón GutierrezNo ratings yet

- Technical Specification: Aluminum Conductors, Aluminum Clad Steel Reinforced (ACSR/AS-Drake (795MCM) )Document5 pagesTechnical Specification: Aluminum Conductors, Aluminum Clad Steel Reinforced (ACSR/AS-Drake (795MCM) )alfredoNo ratings yet

- C 954 Â " 98 QZK1NC1SRUQDocument4 pagesC 954 Â " 98 QZK1NC1SRUQSebastián RodríguezNo ratings yet

- Arc Welding ElectrodesDocument6 pagesArc Welding ElectrodeswaleedyossefNo ratings yet

- 33kv Techni8cal Specification Edited FormatDocument16 pages33kv Techni8cal Specification Edited Formatvikas kumarNo ratings yet

- A1018Document5 pagesA1018Aleksei AvilaNo ratings yet

- ASTM A325: ScopeDocument2 pagesASTM A325: ScopetylerstearnsNo ratings yet

- Thickness GaugeDocument1 pageThickness GaugeTAEWARAT RAKRUANGNo ratings yet

- Provincial Electricity AuthorityDocument19 pagesProvincial Electricity AuthorityTAEWARAT RAKRUANGNo ratings yet

- EH - Force Gauge - 2015Document1 pageEH - Force Gauge - 2015TAEWARAT RAKRUANGNo ratings yet

- Safety Data Sheet: Penetrox A-13 Oxide Inhibiting Compound Product NameDocument8 pagesSafety Data Sheet: Penetrox A-13 Oxide Inhibiting Compound Product NameTAEWARAT RAKRUANGNo ratings yet

- NZI 2016 A5 Full Range CatalogueDocument108 pagesNZI 2016 A5 Full Range CatalogueTAEWARAT RAKRUANGNo ratings yet

- Astm A123-17Document9 pagesAstm A123-17TAEWARAT RAKRUANG0% (1)

- Astm D 4388 - 02Document3 pagesAstm D 4388 - 02TAEWARAT RAKRUANGNo ratings yet

- ASTM D 4325-13 Standard Test Methods For Nonmetallic Semi-Conducting and Electrically Insulating Rubber TapesDocument7 pagesASTM D 4325-13 Standard Test Methods For Nonmetallic Semi-Conducting and Electrically Insulating Rubber TapesTAEWARAT RAKRUANGNo ratings yet

- ASTM D 4388-13 Standard Specification For Nonmetallic Semi-Conducting and Electrically Insulating Rubber TapesDocument3 pagesASTM D 4388-13 Standard Specification For Nonmetallic Semi-Conducting and Electrically Insulating Rubber TapesTAEWARAT RAKRUANGNo ratings yet

- Kumwell Grounding and Lightning Protection-12Document1 pageKumwell Grounding and Lightning Protection-12TAEWARAT RAKRUANGNo ratings yet

- AL Terminal Lug SD..073935-01Document24 pagesAL Terminal Lug SD..073935-01TAEWARAT RAKRUANGNo ratings yet

- BS 6089 - 2010 - Assessment of Insitu Compressive TestDocument40 pagesBS 6089 - 2010 - Assessment of Insitu Compressive TestMike Chan100% (2)

- ECE Formula SheetDocument7 pagesECE Formula SheetMahendra ReddyNo ratings yet

- 2011-006 Tangram People (All Ages) PDFDocument28 pages2011-006 Tangram People (All Ages) PDFKhalil BarhoumiNo ratings yet

- DEH-1250MPG DEH-1250MP: Owner's Manual Manual de Instrucciones Manual Do ProprietárioDocument80 pagesDEH-1250MPG DEH-1250MP: Owner's Manual Manual de Instrucciones Manual Do ProprietárioMoezz Asif Research Associate-Faculty of Avionics EngineeringNo ratings yet

- ColsonCatalogR27!11!11 15Document124 pagesColsonCatalogR27!11!11 15Roberto SolorzanoNo ratings yet

- Api-650 Storage Tank Design Calculations - DamasGate WikiDocument3 pagesApi-650 Storage Tank Design Calculations - DamasGate Wikipowder18No ratings yet

- Design Calculation of Gantry GirderDocument7 pagesDesign Calculation of Gantry GirderKushal ChhetriNo ratings yet

- First Quarter Examination in PracticalDocument2 pagesFirst Quarter Examination in PracticalMark Anthony B. AquinoNo ratings yet

- AS 3 Mid-Year TestDocument2 pagesAS 3 Mid-Year TestМар'яна НагорнюкNo ratings yet

- Essay On Education in IndiaDocument6 pagesEssay On Education in IndiaSümît DãsNo ratings yet

- CLI Basics: Laboratory ExerciseDocument5 pagesCLI Basics: Laboratory ExerciseJhalen Shaq CarrascoNo ratings yet

- Article Review FormDocument2 pagesArticle Review FormdinarsyifaNo ratings yet

- Visualization BenchmarkingDocument15 pagesVisualization BenchmarkingRanjith S100% (1)

- Offer and Acceptance:: Lapse of An OfferDocument12 pagesOffer and Acceptance:: Lapse of An OfferPriya AroraNo ratings yet

- Calculus: Early Transcendental Functions 7th Edition by Ron Larson, Bruce H. Edwards Test Bank and Solution ManualDocument8 pagesCalculus: Early Transcendental Functions 7th Edition by Ron Larson, Bruce H. Edwards Test Bank and Solution ManualMiguel Tejeda0% (1)

- Kali Kaula A Manual of Tantric Magick HardbackDocument3 pagesKali Kaula A Manual of Tantric Magick Hardbackalintuta20% (1)

- اسئلة الهيئة السعودية- تمريضDocument39 pagesاسئلة الهيئة السعودية- تمريضlolo trabNo ratings yet

- Module Bar PTX1.6 PDFDocument8 pagesModule Bar PTX1.6 PDFkumelachewbirre22No ratings yet

- Program Istp17Document17 pagesProgram Istp17pverma4622No ratings yet

- Behavioural Issues Associated With Long Duration Expedition Missions - NASADocument116 pagesBehavioural Issues Associated With Long Duration Expedition Missions - NASAJp VillalonNo ratings yet

- Architecture Books To ReadDocument3 pagesArchitecture Books To ReadChirag HablaniNo ratings yet

- Aubrey Jaffer: Scheme Implementation Version 5f1Document149 pagesAubrey Jaffer: Scheme Implementation Version 5f1kevinmcguireNo ratings yet

- Induction Motor NotesDocument20 pagesInduction Motor NotesMani SaiNo ratings yet

- ASTM D422 GranulometríaDocument8 pagesASTM D422 GranulometríaDiego Castillo JaramilloNo ratings yet

- Shashika Boteju Mathematics Grade 9Document12 pagesShashika Boteju Mathematics Grade 9Dilruk GallageNo ratings yet

- Silentknight FACP Farenhyt IFP-1000 PDFDocument220 pagesSilentknight FACP Farenhyt IFP-1000 PDFwendy vegaNo ratings yet

- Chem IADocument9 pagesChem IAVita Bayu PutriNo ratings yet

- Dividido Trane 30 TonsDocument23 pagesDividido Trane 30 TonsairemexNo ratings yet

- 4th Year - Sample Online TestDocument6 pages4th Year - Sample Online TestMacarenaNo ratings yet

- Web 24 - Teti Madiadipoera - Treatment and Management of Rhinitis AllergyDocument38 pagesWeb 24 - Teti Madiadipoera - Treatment and Management of Rhinitis AllergyEdzhar HasiholanNo ratings yet