Professional Documents

Culture Documents

2020 06 03 Foreva Resin Epx TFC1000 en V2

Uploaded by

pabloCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2020 06 03 Foreva Resin Epx TFC1000 en V2

Uploaded by

pabloCopyright:

Available Formats

• Solvent-free epoxy resin

EpxTFC 1000 •

•

Two-component

Moisture-tolerant

• High strength

• High modulus

• Weather resistant

SOLUTIONS FOREVA® TFC1100: Epoxy based adhesive and saturation resin for Foreva® TFC1100 composite strengthening system

Foreva® Epx TFC1000 is an epoxy based resin to Physical properties Mix

be used with Foreva TFC1100 structural Density at 73°F (23°C) 1,07 g/ml

strengthening systems.

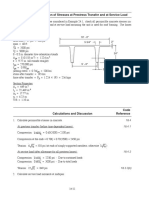

Tensile properties Nominal values

Dry Lay-Up: the resin is specifically designed to Ultimate strength at 7 days 48 MPa

field saturate heavy and dense carbon fibre fabrics Elongation at break at 7 days 3%

and provide a high bond with the substrate being Elastic modulus at 7 days 2300 MPa

reinforced. It can be applied in vertical and

overhead applications. Compression properties Nominal values

Ultimate strength at 7 days 63 MPa

Elastic modulus at 7 days 1000 MPa

Advantages

• Excellent adhesion to concrete. Adhesion properties Min. values

• High impregnation of heavy fabrics Dry prepared concrete at 28 d 2,5 MPa

• Fully compatible with the carbon fibre fabric Wet prepared concrete at 28d 2,0 MPa

Foreva® TFC1100.

• Interior and exterior applications.

• Horizontal, vertical and overhead applications. How to apply

• Concrete and steel substrates. Conditions of application

• Substrate temperature: Min 41°F (5°C).

• Mix temperature: Max 95°F (35°C)

Characteristics

• Relative humidity: Max 90%

• Colour • Substrate temperature shall exceed dew point of

> Part Resin: white gel. at least 3°F (3°C)

> Part Hardener: colourless to yellow liquid/gel.

> Mix: white liquid/gel. Mixing

• Mix entire unit, do not batch.

• Packaging • Pour contents of part Hardener to part Resin.

> Part Resin: 3,6 kg. • Mix thoroughly for 2 - 3 minutes with low speed

> Part Hardener: 1,3 kg. drill (approx. 300 rpm) and mixing paddle until

uniformly blended.

• Mixing ratio • Carefully scrape the sides and bottom of the

> 100/35 by weight. container while mixing.

• Keep the paddle below the surface of the material

• Practical working time to avoid entrapping air.

> 1h40 at 73°F (23°C).

> The practical working time of the mix depends Limitations

on the bucket size and the ambient • Do not thin with solvents.

temperature. • Do not apply on in areas of freezing and thawing.

• Colour may alter due to UV exposure.

• Complete hardening • Take specific measures for temperatures ≤ 41°F

> Approx. 2 days at 73°F (23°C). (5°C) and for temperature of substrate ≥ 95°F

(35°C).

• Hardness Shore D at 23°C

> ~81 at 1d.

> ~84 at 2d.

> ~84 at 7d.

EpxTFC 1000

Safety – Parts Resin & Hardener

Risks

• Harmful if swallowed.

• Causes severe skin burns and eye damage.

• May cause an allergic skin reaction.

• Toxic to aquatic life with long lasting effects.

Precautions

• Make certain the most current versions of SDS

are being used.

• Use impervious gloves, eye protection, protective

clothing.

• Use with adequate ventilation

• Dispose of contents/container to hazardous or

special waste collection point, in accordance with

applicable regulation.

First Aid

• In case of eye contact, flush thoroughly with

water for at least 15 minutes.

• In case of skin contact, wash affected areas with

soap and water.

• If inhaled: remove person to fresh air and keep

comfortable for breathing.

• If swallowed: rinse mouth. Do not induce

vomiting.

• If irritation or discomfort persists, seek medical

attention.

Storage conditions

• Shelf life: 2 years in original non open container.

• Store dry at 41° to 95°F (5°C to 35°C) away from

direct sunlight, flame, or other hazards.

Packaging

• Kit of 4,9 kg

• Part Hardener: 3,6 kg in steel bucket

• Part Resin: 1,3 kg in steel bucket

Transportation

The resin and hardener can be transported at

temperatures of between 14°F (-10°C) and 120°F

(+ 50°C) without any change in their properties. The

duration of transport in extreme conditions

must limited to one month.

Foreva Epx TFC1000 EN

Foreva® solutions

V2 03/06/2020

Extending lifespan of structures

www.freyssinet.com

You might also like

- Epimastic 4100Document2 pagesEpimastic 4100Moin AltafNo ratings yet

- CCI Radome Whitepaper 190813Document9 pagesCCI Radome Whitepaper 190813bardaris100% (1)

- LevitationDocument4 pagesLevitationJorge CordeiroNo ratings yet

- Fatigue Crack Propagation in Steels of Various Yield StrengthsDocument7 pagesFatigue Crack Propagation in Steels of Various Yield StrengthsRodrigo Marin100% (1)

- Malla Electrosoldada (US) PDFDocument2 pagesMalla Electrosoldada (US) PDFCarlos Eduardo RodriguezNo ratings yet

- DRY UNIT WEIGHT - WATER CONTENT RELATIONSHIPDocument17 pagesDRY UNIT WEIGHT - WATER CONTENT RELATIONSHIPmikeNo ratings yet

- Chem ECRDocument214 pagesChem ECRHay100% (1)

- LimitsDocument6 pagesLimitsDan GrayNo ratings yet

- The Order of Battle in The Roman Army - Evidence From Marching CampsDocument15 pagesThe Order of Battle in The Roman Army - Evidence From Marching CampsMariusz MyjakNo ratings yet

- SAP2000 Analysis Report for RACKS EATON 1.SDB StructureDocument17 pagesSAP2000 Analysis Report for RACKS EATON 1.SDB StructureSicea IngenieriaNo ratings yet

- 4D 6560BGDocument1 page4D 6560BGMustafaMahdiNo ratings yet

- Corrosion Basics Expalained in DepthDocument1 pageCorrosion Basics Expalained in DepthAli Asghar100% (1)

- Nanocharacterisation, 2007, p.319 PDFDocument319 pagesNanocharacterisation, 2007, p.319 PDFArunmaalaNo ratings yet

- 2020 06 15 Foreva Composite TFC1100 Eurocode en V2Document2 pages2020 06 15 Foreva Composite TFC1100 Eurocode en V2pabloNo ratings yet

- 2100i VACTOR - FinalDocument8 pages2100i VACTOR - FinalOthoniel Castilla0% (1)

- Asphalt Drum MixersDocument22 pagesAsphalt Drum MixersautocadNo ratings yet

- Reglamento de Construccion en BeliceDocument18 pagesReglamento de Construccion en BeliceLuis NoveloNo ratings yet

- HSS structural steel shapes and properties guideDocument2 pagesHSS structural steel shapes and properties guiderafaelNo ratings yet

- Steel FiberDocument1 pageSteel FiberMustafaMahdiNo ratings yet

- Center of Mass and Rigidity EtabsDocument2 pagesCenter of Mass and Rigidity EtabsBejil Shrestha100% (1)

- MISAPOR THB Daemmbeton 2014-8 ENDocument10 pagesMISAPOR THB Daemmbeton 2014-8 ENsmootherboyNo ratings yet

- Geotech2 Assign1Document10 pagesGeotech2 Assign1Michael Racelis50% (2)

- Teodolito Con Distanciometro South NT-023Document2 pagesTeodolito Con Distanciometro South NT-023JoséLuis100% (1)

- DESPIECE SACABOCADO HIDRAULICO 1-2 - 4.pdf 3 PDFDocument10 pagesDESPIECE SACABOCADO HIDRAULICO 1-2 - 4.pdf 3 PDFAlan FloresNo ratings yet

- Tinius Olsen SL0300EN02 300SLDocument2 pagesTinius Olsen SL0300EN02 300SLMarcelo SánchezNo ratings yet

- Liqua-Blaster 100 Series BrochureDocument4 pagesLiqua-Blaster 100 Series BrochurejleonosNo ratings yet

- MC 5.303 Bases de Rodadura GranularDocument3 pagesMC 5.303 Bases de Rodadura GranularMichael MuñozNo ratings yet

- STP ShaliKote-T-32Document2 pagesSTP ShaliKote-T-32Rana MahatoNo ratings yet

- Airsep Corporation Psa Oxygen Generator Models As-A - As-P: Instruction ManualDocument192 pagesAirsep Corporation Psa Oxygen Generator Models As-A - As-P: Instruction ManualTEMESGENNo ratings yet

- Manta de HormigonDocument8 pagesManta de HormigonJuan Carlos RojasNo ratings yet

- RF Tendon DesignDocument66 pagesRF Tendon DesignJoaquin Galeano AlvarezNo ratings yet

- GTS Civil Safety RequerimentsDocument14 pagesGTS Civil Safety RequerimentsMarco Antonio Roa Garces100% (1)

- Optcut GuiaDocument5 pagesOptcut GuiaMariana VegaNo ratings yet

- GW Geoweb GW30v6 SummaryDocument1 pageGW Geoweb GW30v6 SummaryChowdhury PriodeepNo ratings yet

- Tanque STA RITEDocument3 pagesTanque STA RITECharlie Martinez100% (1)

- Kelly 1999Document6 pagesKelly 1999karenNo ratings yet

- Renderoc LAXtra PlusDocument2 pagesRenderoc LAXtra PlusVenkata Raju Kalidindi100% (1)

- 4 - 4 Diseño de Zapatas ClaseDocument5 pages4 - 4 Diseño de Zapatas ClaseNicolas NuñezNo ratings yet

- Example 24.2-Investigation of Stresses at Prestress Transfer and at Service LoadDocument3 pagesExample 24.2-Investigation of Stresses at Prestress Transfer and at Service LoadMario Antonio Gomez CruzNo ratings yet

- Nitoproof 600PF: Hydrocarbon Free, Liquid Applied Elastomeric One Coat Waterproofing Membrane UsesDocument2 pagesNitoproof 600PF: Hydrocarbon Free, Liquid Applied Elastomeric One Coat Waterproofing Membrane UsesKishore Nayak kNo ratings yet

- Six Zone Fire Alarm SystemDocument2 pagesSix Zone Fire Alarm SystemPablo Jesús Huapaya ChumpitazNo ratings yet

- Floor Patch Fast CureDocument2 pagesFloor Patch Fast CureStevenFerrelNo ratings yet

- Tekafiks Multi Use Super enDocument2 pagesTekafiks Multi Use Super enEzeval GráficaNo ratings yet

- Epilux 82: Product DescriptionDocument2 pagesEpilux 82: Product DescriptionMoin AltafNo ratings yet

- Vibrox TDS enDocument2 pagesVibrox TDS enankarthik11No ratings yet

- Tds Fevitite SuperfastDocument3 pagesTds Fevitite SuperfastNageshri KarhadeNo ratings yet

- E MULTIFILL EPOXY THIXO 12Document4 pagesE MULTIFILL EPOXY THIXO 12Dimitrija GalapchevNo ratings yet

- Devcon flexane-high-performance-putty_15330Document2 pagesDevcon flexane-high-performance-putty_15330Yajaira ValdezNo ratings yet

- Epilux 155Document2 pagesEpilux 155Allana100% (1)

- Durapol Coating For Amines EtcDocument2 pagesDurapol Coating For Amines EtckermadaxNo ratings yet

- High Build Epoxy Coating for Steel and ConcreteDocument2 pagesHigh Build Epoxy Coating for Steel and ConcreteTejinder KumarNo ratings yet

- Corrocoat EP1Document2 pagesCorrocoat EP1stelioskoNo ratings yet

- 4 to 1 Epoxy Resin Technical Data SheetDocument1 page4 to 1 Epoxy Resin Technical Data SheetAnonymous XzqXVMjNo ratings yet

- Weber Euroflor DesignDocument3 pagesWeber Euroflor DesignMaya Trad wehbeNo ratings yet

- Devran 201: Cat. # 201B0245/201C0300Document2 pagesDevran 201: Cat. # 201B0245/201C0300Mohamed NouzerNo ratings yet

- Epilux 8: Product DescriptionDocument2 pagesEpilux 8: Product DescriptionMoin AltafNo ratings yet

- Apcotherm Epn 200Document2 pagesApcotherm Epn 200Moin AltafNo ratings yet

- High Strength Epoxy Floor CoatingDocument3 pagesHigh Strength Epoxy Floor CoatingAhmad BougeisNo ratings yet

- Apcodur Ehb 500-VocDocument2 pagesApcodur Ehb 500-VocMoin AltafNo ratings yet

- Wearing CompoundDocument2 pagesWearing CompoundJuan GuillermoNo ratings yet

- Datasheet Epidermix 344Document2 pagesDatasheet Epidermix 344Vicky MunienNo ratings yet

- Nitrile High Performance Plastic Adhesives: Technical Data March, 2015Document4 pagesNitrile High Performance Plastic Adhesives: Technical Data March, 2015Naveed MalikNo ratings yet

- Sika HibondDocument3 pagesSika Hibondrajkamal4500No ratings yet

- CarbolineDocument18 pagesCarbolineimaduddinshaNo ratings yet

- Thermaline 450 EP PDSDocument3 pagesThermaline 450 EP PDSdgambhavaNo ratings yet

- Fiche - Prod - TFC - UD - 75 - 350-ACI - en - V04 Version TempDocument2 pagesFiche - Prod - TFC - UD - 75 - 350-ACI - en - V04 Version TempDifa LiuNo ratings yet

- Jazeera Epo-Mortar SL5000Document3 pagesJazeera Epo-Mortar SL5000Ahmad BougeisNo ratings yet

- Flexane HP PuttyDocument2 pagesFlexane HP PuttyDivyanshu GuptaNo ratings yet

- LANKO 732 concrete repair mortarDocument2 pagesLANKO 732 concrete repair mortarjet toledoNo ratings yet

- Exponential Shadow Maps: BstractDocument7 pagesExponential Shadow Maps: BstractTed De LeonNo ratings yet

- PVT Analysis: Compiled By: SACHIN NAMBIAR Contact No: 9067111274Document14 pagesPVT Analysis: Compiled By: SACHIN NAMBIAR Contact No: 9067111274ronak pandyaNo ratings yet

- Assignments FinDocument5 pagesAssignments FinGCVishnuKumarNo ratings yet

- Piping Thickness Calculation (ASME B31.3)Document8 pagesPiping Thickness Calculation (ASME B31.3)got youfour onlinesomNo ratings yet

- CIE A Level Chemistry: Relative Isotopic MassDocument28 pagesCIE A Level Chemistry: Relative Isotopic MassSabina SabaNo ratings yet

- Design of Steel StructuresDocument16 pagesDesign of Steel StructureszenitsuNo ratings yet

- Rock Failure Criteria and Strength TestsDocument23 pagesRock Failure Criteria and Strength TestsAlex Fuentes MontesinosNo ratings yet

- Lecture 1aDocument23 pagesLecture 1aSaritaNo ratings yet

- Why Slabs Curl - Part1Document6 pagesWhy Slabs Curl - Part1Tim LinNo ratings yet

- Equation of State Development and UseDocument12 pagesEquation of State Development and UseBilal AbdullahNo ratings yet

- 2018 Semester One Assignment 1 Page 1 of 2Document2 pages2018 Semester One Assignment 1 Page 1 of 2robbie_delavega7000No ratings yet

- متطلبات تخصص الصيانة الكهروميكانيكة العامةDocument68 pagesمتطلبات تخصص الصيانة الكهروميكانيكة العامةibraheemNo ratings yet

- MA3264CHAP1Document59 pagesMA3264CHAP1Nancy QNo ratings yet

- Matrices and Matrix OperationsDocument12 pagesMatrices and Matrix OperationsAzhar SuharjiantoNo ratings yet

- Unknown - Numerical Meth Engineering - 2019 - Qinami - Variational EigenerosionDocument22 pagesUnknown - Numerical Meth Engineering - 2019 - Qinami - Variational EigenerosionHeber Jorge ValenzuelaNo ratings yet

- Topik6 MA2271 - SPDLDocument45 pagesTopik6 MA2271 - SPDLFauzia SavitriNo ratings yet

- Introduction To Basic ConceptsDocument19 pagesIntroduction To Basic ConceptsM Hussnain JavedNo ratings yet

- Summary of Surface Finish ParametersDocument3 pagesSummary of Surface Finish ParametersVarun KumarNo ratings yet

- Photo Study Guide Part 1Document4 pagesPhoto Study Guide Part 1dandresslerNo ratings yet

- GS 142 4 PDFDocument23 pagesGS 142 4 PDFjast111No ratings yet